Super high-rise core tube internal and external hanging tower crane support beam structure and construction method thereof

A construction method and core tube technology, which are applied in cranes and other directions to achieve the effects of reducing construction impact, saving construction period and reducing hoisting times.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

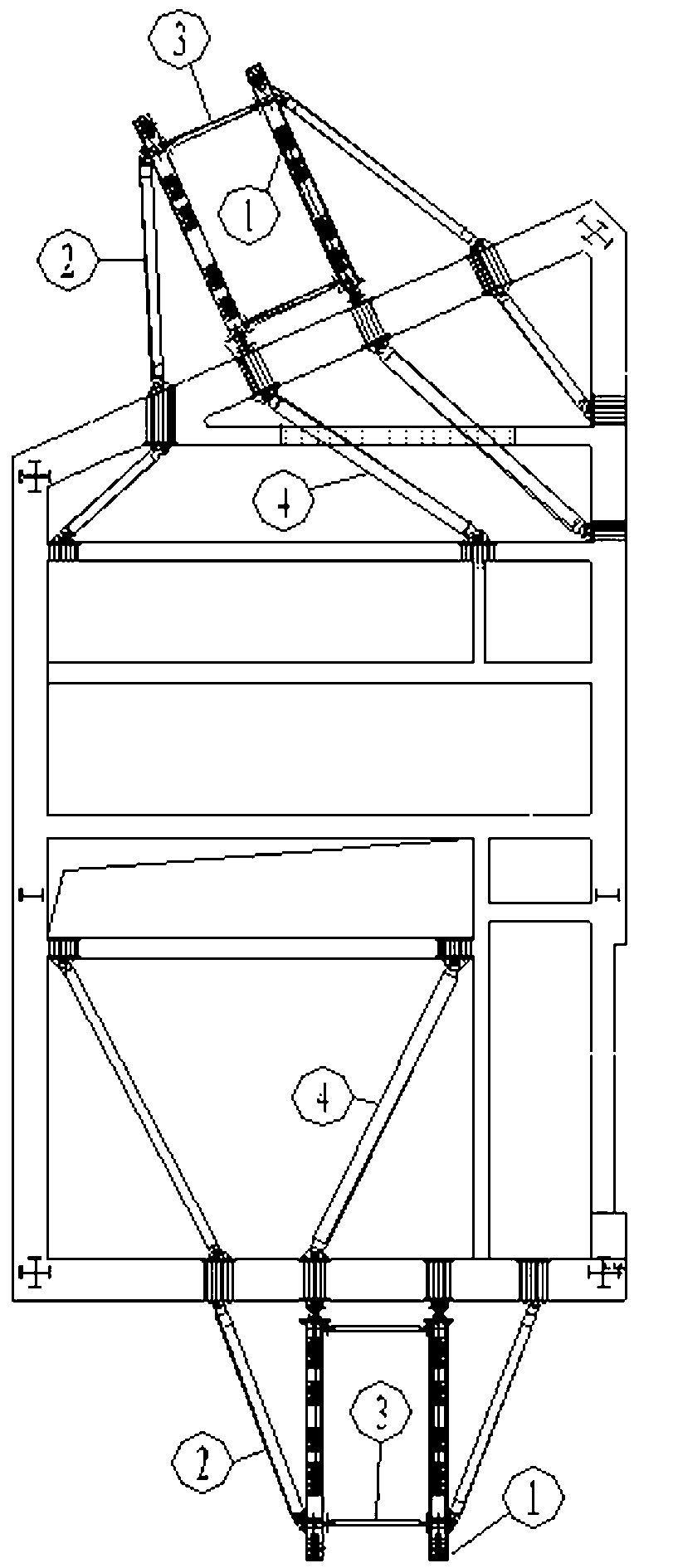

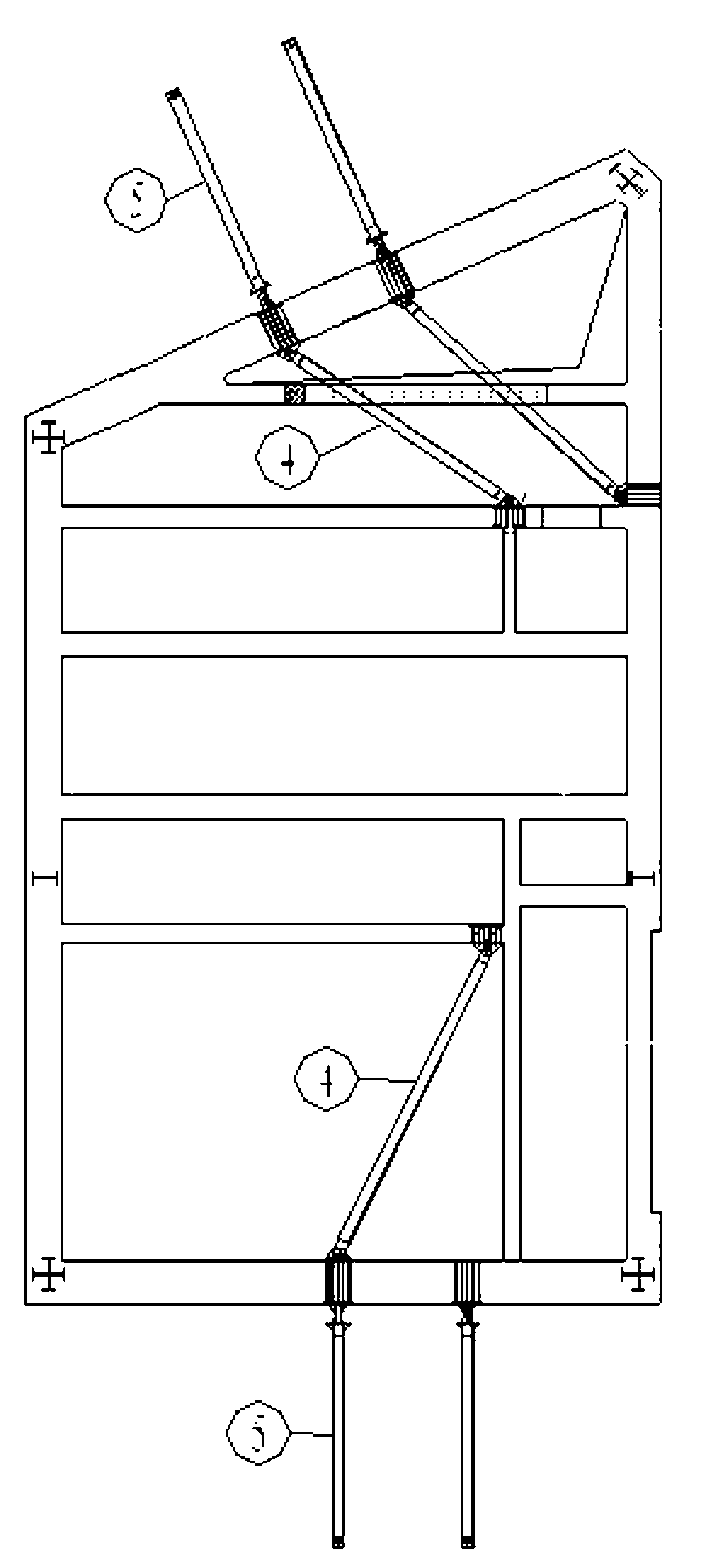

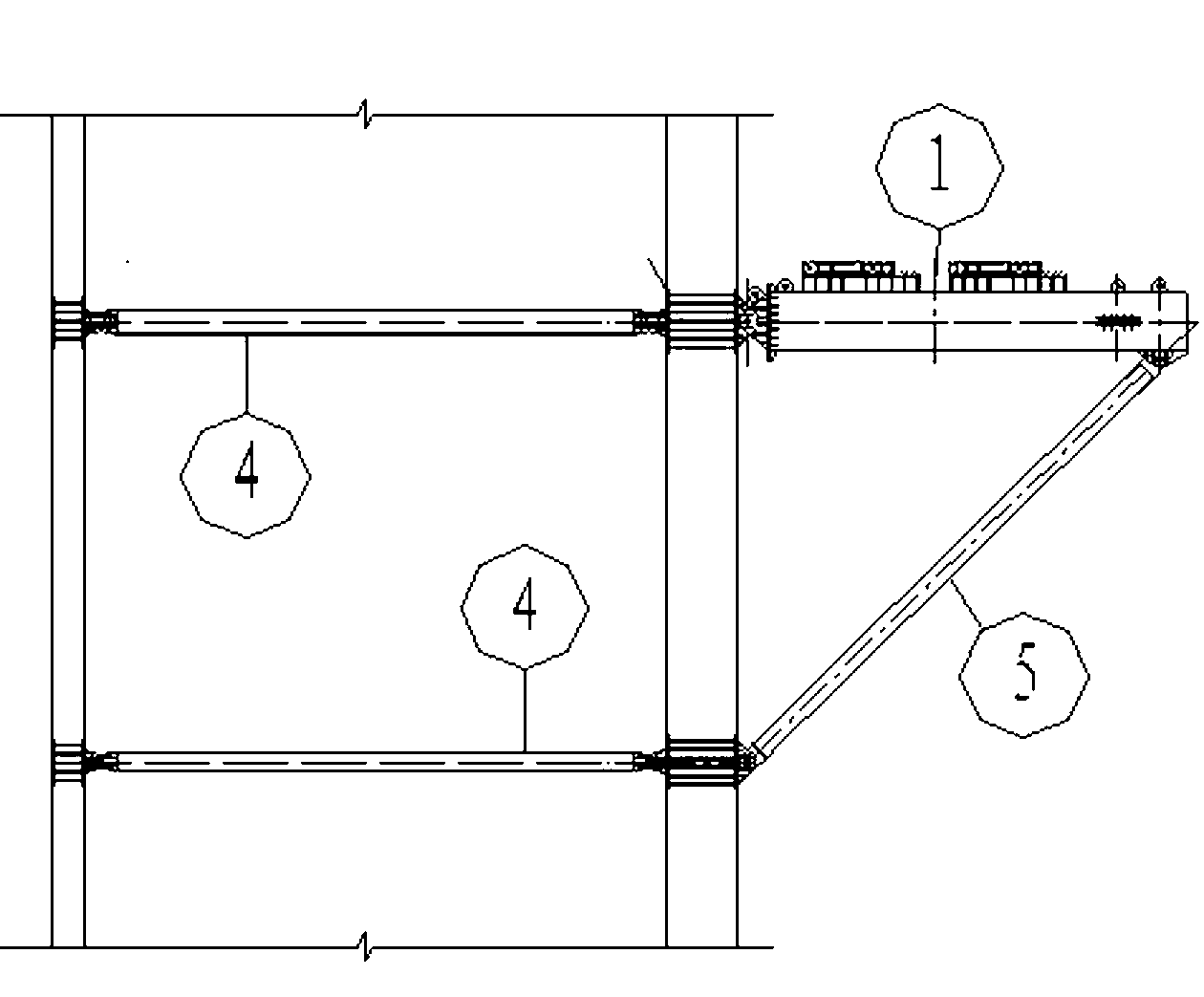

[0041] Such as Figure 1 ~ Figure 3 Shown: super-high-rise core tube hanging tower crane supporting beam structure, including horizontal tower crane supporting main girder 1, diagonal brace 5, horizontal tie rod 2, horizontal connecting rod 3, and reinforcement support 4 inside the core tube, and two parallel horizontal tower cranes are set The supporting main beam has a box-shaped cross-section. The root of each main beam is connected to the embedded part of the core tube through the main beam lug plate. One end of the horizontal tie rod is connected obliquely to the core tube, and the other end is connected to the horizontal end of the corresponding main beam. The two main beams are connected by horizontal connecting rods to form the main frame support system. In the core tube Set the reinforcement support, and the setting position corresponds to the root position of the main beam and the diagonal brace.

[0042] Such as Figure 4 ~ Figure 11 As shown, the construction met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com