Floating track bed precast slab and construction method for precast slab assembled floating track bed

A technology of floating track bed and construction method, applied in the directions of roads, tracks, ballast layers, etc., can solve the problems of unfavorable track structure and train operation, increase construction preparation work, waste manpower and time, etc., to save splicing time, splicing Convenience and improve the effect of construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

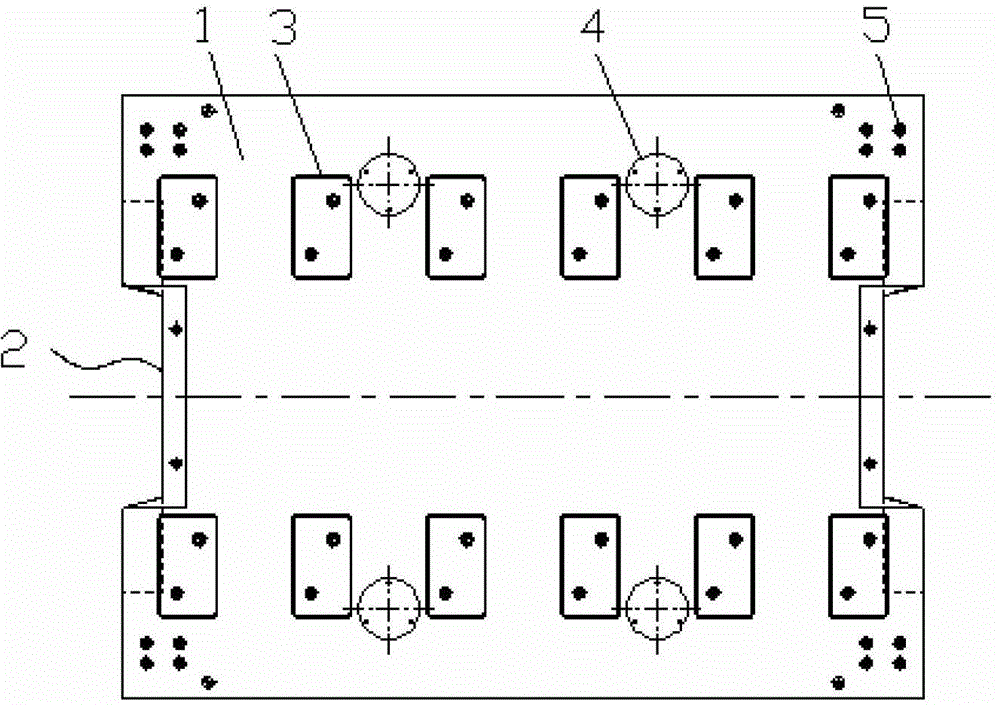

[0051] Such as figure 1 As shown, the prefabricated slab of the floating ballast bed of the present invention includes: a prefabricated slab body 1 in the shape of a cuboid, with groove structures 2 respectively provided at both ends; two rows of rail platforms 3 arranged on the upper surface of the prefabricated slab body 1; A plurality of outer sleeve devices 4 for placing the inner sleeve of the vibration isolator, which are set corresponding to the rail platform 3; sleeve sets arranged at the corners of both sides of the prefabricated panel body 1, each sleeve set consists of multiple sleeves Tube 5 is composed. In addition, on the main body 1 of the prefabricated board, there are confluence terminals located outside the bushing group, and the rail platform 3, the outer sleeve 4, the bushing 5 and the converging terminals are all poured into the main body 1 of the prefabricated board and form a As a whole, the outer sleeve device and the inner sleeve of the vibration isol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com