Walking type pushing construction method for large component and application

A large-scale component, jacking construction technology, applied in the direction of erecting/assembling bridges, bridges, buildings, etc., can solve problems such as unsafe, low production efficiency, prone to leapfrog construction, etc., to improve service life and reduce jacking The effect of reducing the number of frequent take-offs and landings and safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the specific embodiments in the accompanying drawings.

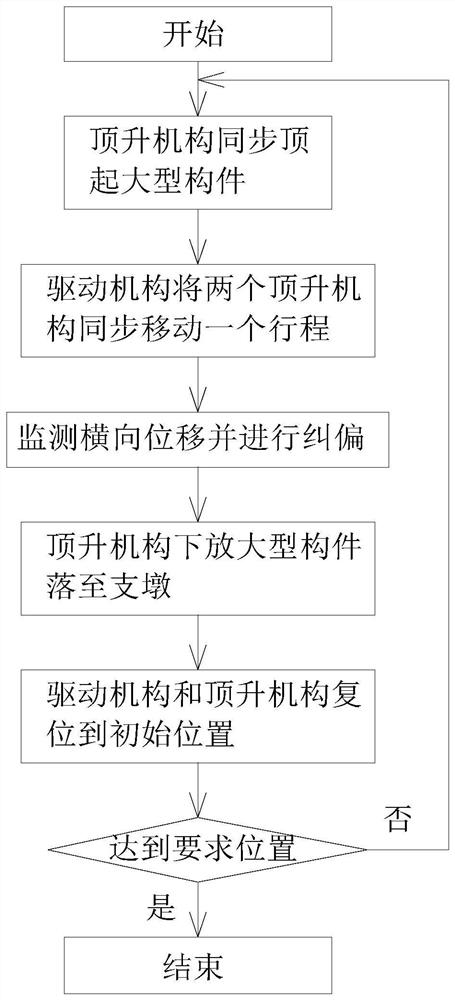

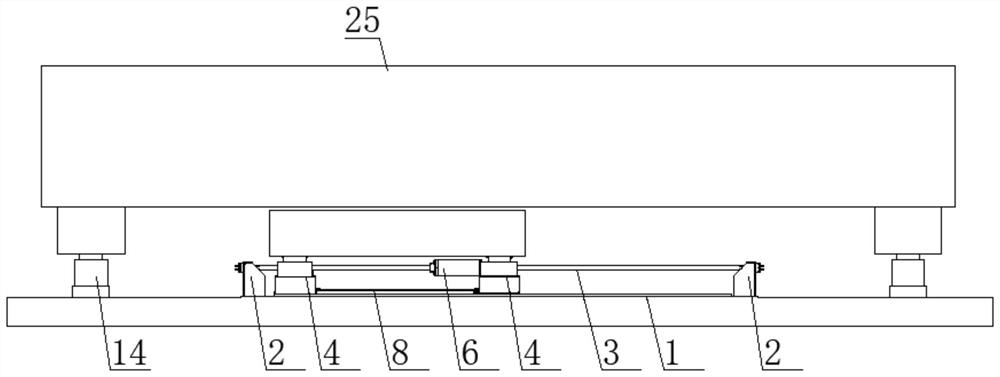

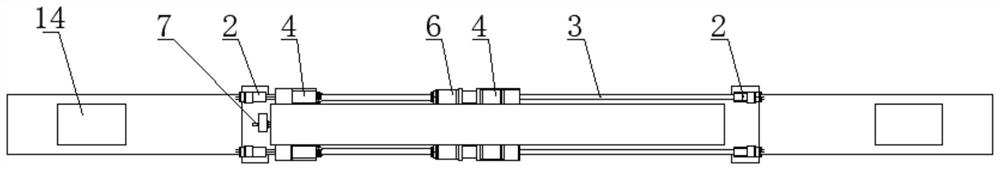

[0040] refer to Figure 1-24 , a walking-type pushing construction method for large-scale components, synchronously jacking up large-scale components through single or multiple sliding mechanisms 4 arranged at longitudinal intervals or transverse intervals or connected; The track 1 moves continuously, and the stroke is only limited by the longitudinal dimension of the construction platform plane slideway. Preferably, the sliding mechanism 4 moves continuously along the slideway 1 for a distance of more than 1 meter synchronously. The length of the slideway 1 is determined according to the beam shape of the large component. , the size of the pier body, the length of the slideway girder, and the construction requirements. For example, the truss girder component of the main bridge of a project has a length of 26 meters. is 32 meters, while the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com