Automatic submerged arc welding method for pearlitic heat-resistant steel composite board

A technology for pearlitic heat-resistant steel and submerged arc automatic welding, which is applied to welding equipment, arc welding equipment, welding/welding/cutting items, etc., and can solve the problems of fast weld cooling, weld strength drop, and fast welding speed, etc. problems, to achieve the effect of reducing welding stress, reducing welding consumable filling, and ensuring welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A material is 15CrMoR+S30408, the specification is Φ2800×(80+4) pearlitic heat-resistant steel composite stainless steel plate automatic welding welding method is as follows:

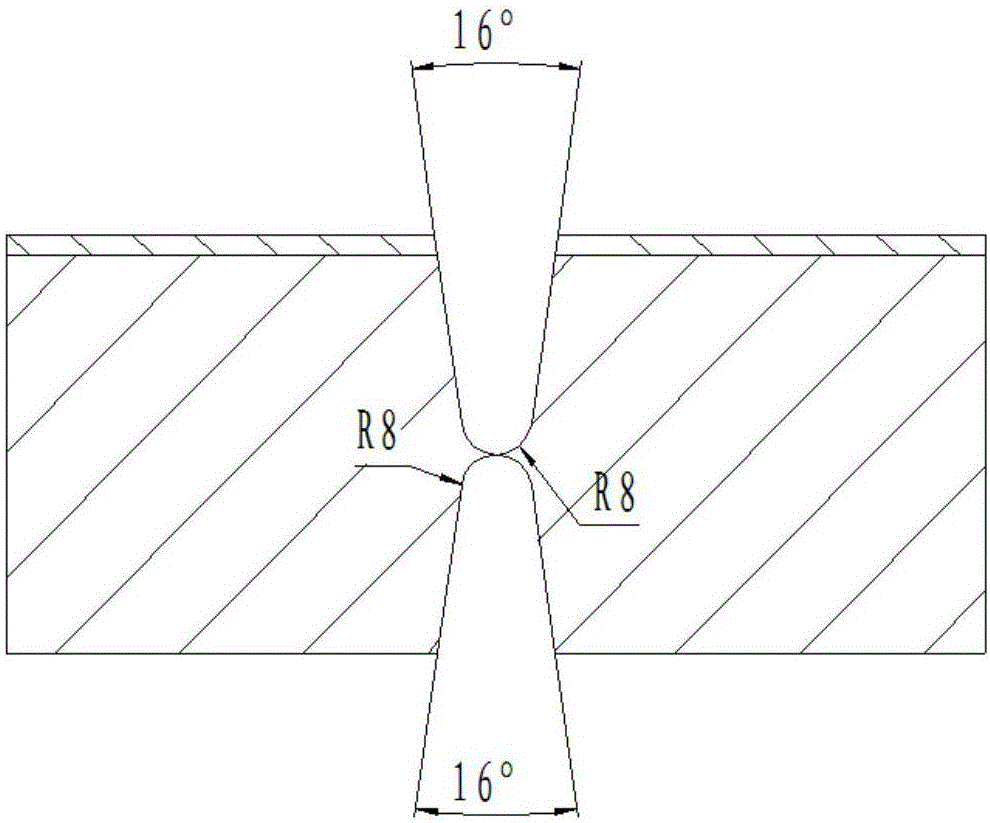

[0044] 1. The double U-shaped groove is adopted. First, the inner groove is processed by mechanical processing method. The angle of the groove is 8° on one side, the groove depth is 50mm, and the root R8 has a smooth transition. The processing form is as follows figure 1 shown.

[0045] 2. Clean up the oil, rust and other impurities within 150mm of the weld groove and both sides of the groove; after cleaning, preheat the weld groove and 200mm of both sides of the groove, and the preheating temperature is 150 ~ 200 ℃ .

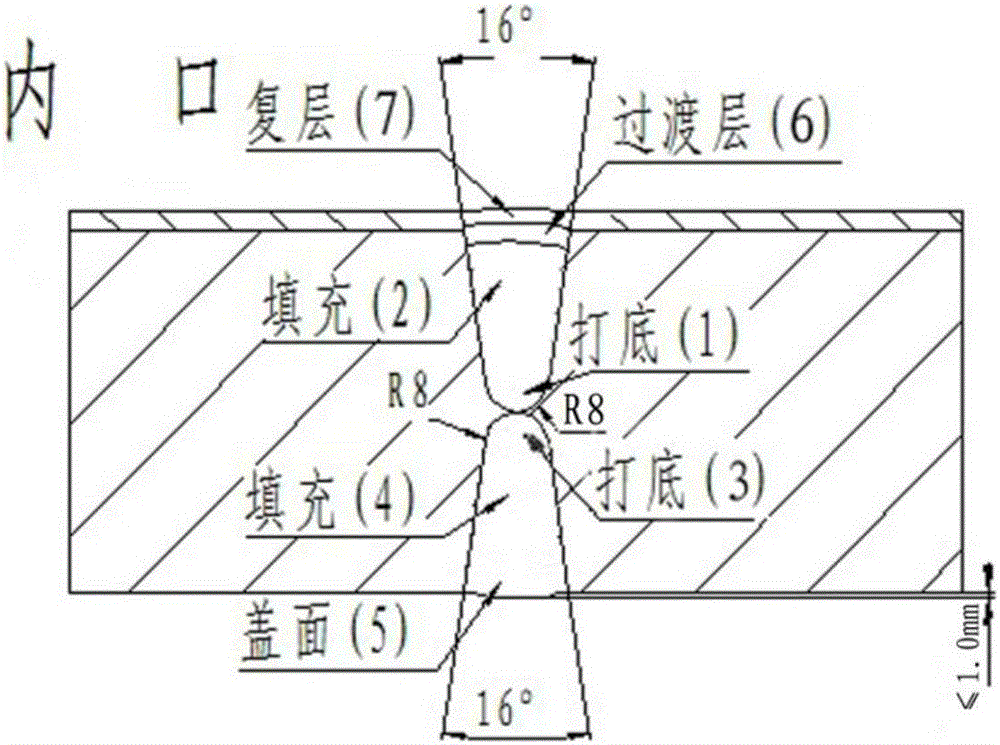

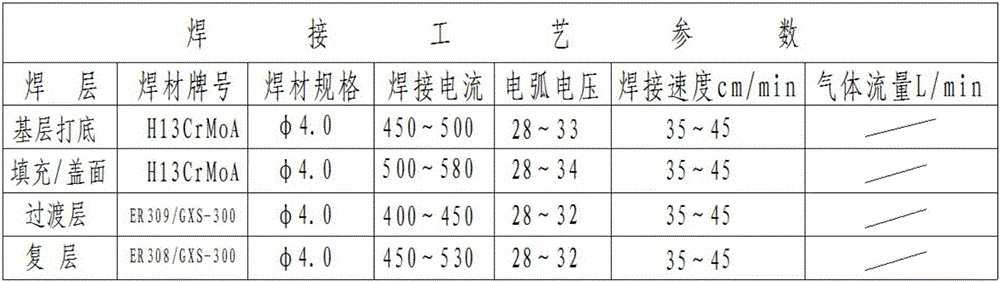

[0046] 3. Weld the inner base layer, and perform the base layer priming (1) and the base layer filling (2) in sequence. Please refer to Table 1 for welding parameters, and see the joint form. figure 2 .

[0047] Further, the welding of the base layer is 1.5 mm lower than the b...

Embodiment 2

[0059] One material is 12Cr2Mo1+S30403 and the specification is Φ2000×(60+5) pearlitic heat-resistant steel clad stainless steel plate welding:

[0060] 1. The double U-shaped groove is adopted, and the inner groove is processed by mechanical processing method. The single edge angle of the groove is 8°, the groove depth is 40mm, and the root R8 has a smooth transition. The processing form is as follows figure 1 shown.

[0061] 2. Clean the weld groove and impurities such as oil and rust within 150mm on both sides of the groove; after cleaning, preheat the weld groove and 200mm on both sides of the groove, and the preheating temperature is 200 ~ 250 ℃ .

[0062] 3. Weld the inner base layer, and perform the base layer priming (1) and the base layer filling (2) in sequence. Please refer to Table 2 for welding parameters and joint forms. figure 2 ;

[0063] Further, the welding of the base layer is 2.5 mm lower than the boundary line between the cladding layer and the base la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com