Spiral plate heat exchanger and production method thereof

A technology of spiral plate type and production method, which is applied in the direction of heat exchanger type, indirect heat exchanger, fixed plate duct assembly, etc., can solve the problems of leakage, high labor intensity and large amount of welding at the welding place between the partition plate and the spiral plate. , to achieve the effect of firm and reliable connection, low production cost and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

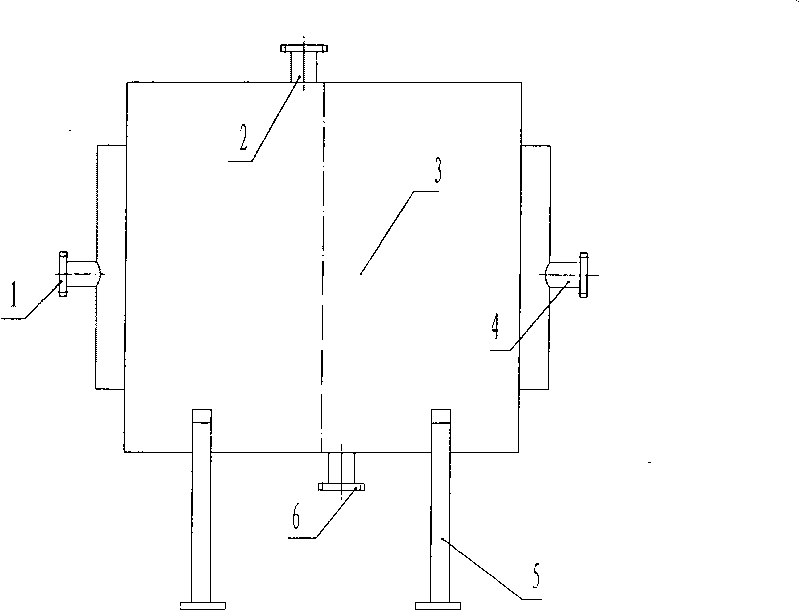

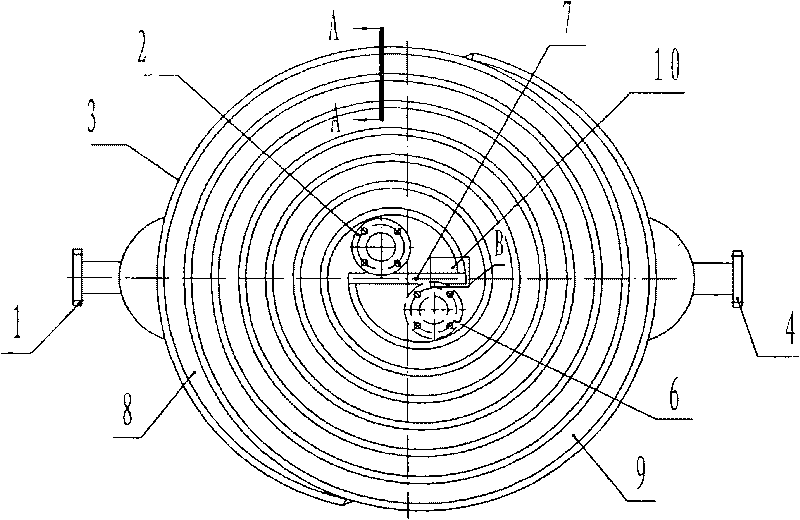

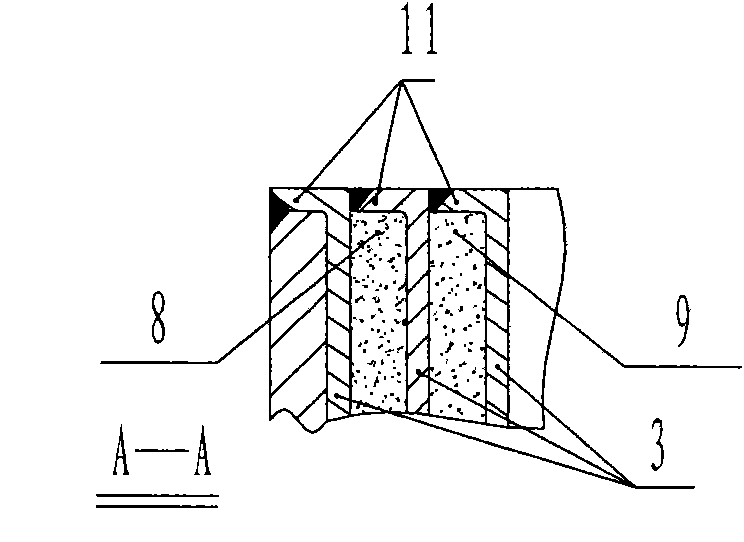

[0010] refer to Figure 1-3 , it includes a helix, the helix is made up of two helical plates 3 (steel plates), forming two uniform spiral passages, i.e. a refrigerant passage 8 and a heat medium passage 9, a partition 7 is arranged in the middle of the helix, and the two sides of the partition are respectively connected to The inner ends of the two spiral plates are welded and sealed to separate the refrigerant channel 8 from the heat medium channel 9. The refrigerant channel has a cold medium inlet 1 and a cold medium outlet 2, and the heat medium channel has a heat medium inlet 6 and a heat medium outlet 4. There is a bracket 5 below the helix, and the upper and lower edges of the two helical plates (steel plates) 3 that make up the helix are bent from the inside to the outside. The end face of the board is welded and sealed.

[0011] refer to Figure 4 , A reinforced sealing angle 10 is added at the angle between the spiral plate and the partition plate, and the reinfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com