Push plate type side loading and unloading sanitation vehicle

A technology of side loading and unloading and sanitation vehicles, which is applied in the direction of transportation, packaging, garbage storage, etc., can solve the problems of strong impact on garbage cans, shorten the service life of garbage cans, and cumbersome lifting operations of garbage cans, etc., and achieve high garbage dumping efficiency , increase the aesthetics, reduce the welding amount and the effect of the possibility of welding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

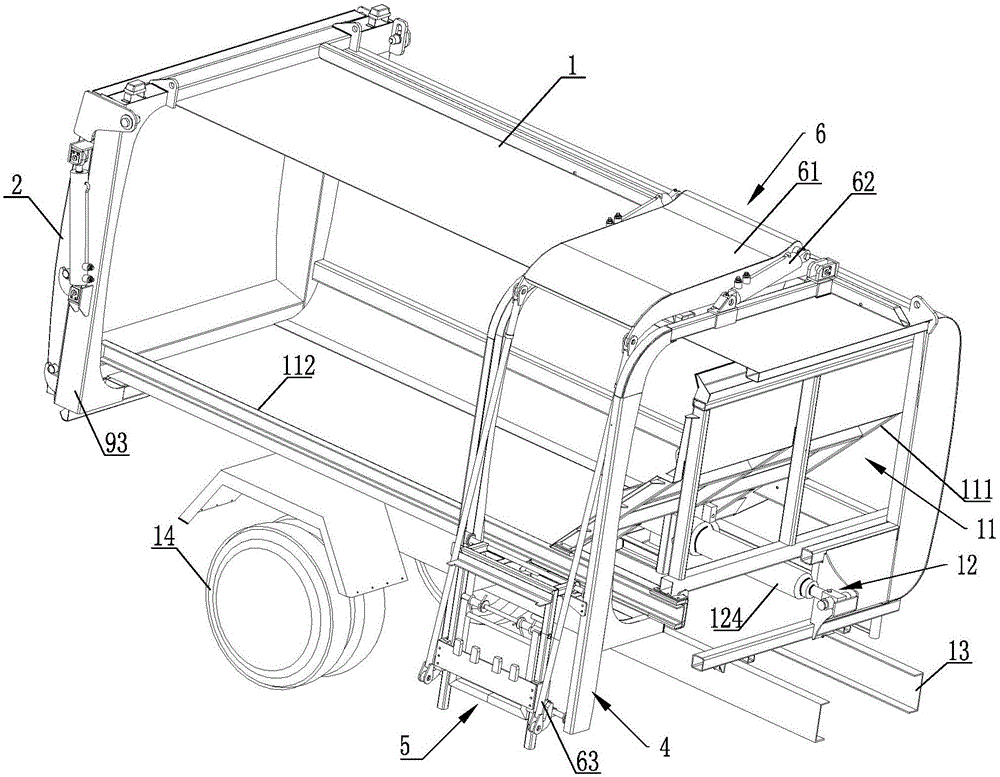

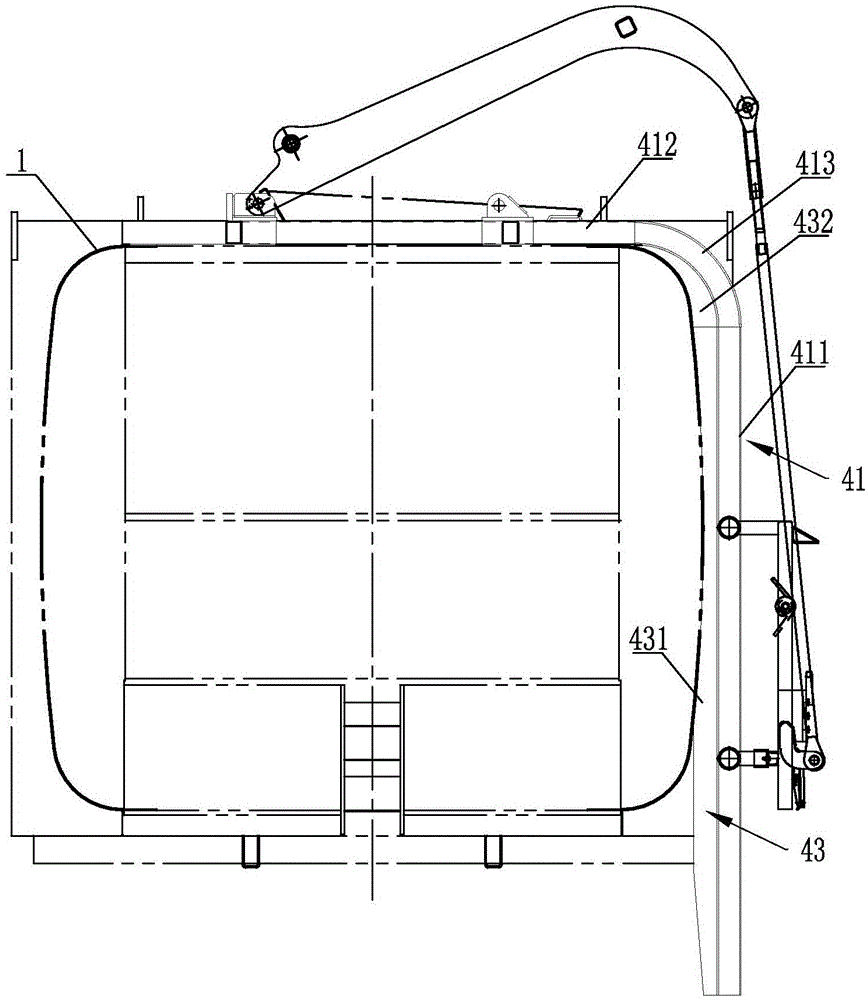

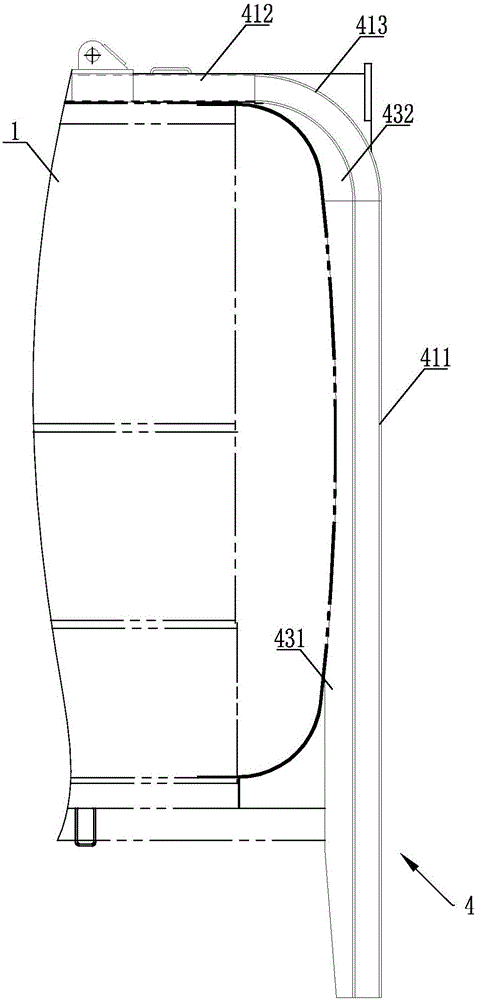

[0041] like figure 1 As shown in the figure, the push plate type side loading and unloading sanitation vehicle includes a box body 1 mounted on the vehicle body 13 and provided with a rear box opening. The top end of the box body 1 is provided with a garbage dump, and the rear end of the box body 1 A box body rear baffle 2 is hinged at the box mouth end, a trash can lifting guide device 4 is fixedly installed on the side wall of the box body 1, and a bucket lifting device 6 is arranged on the top of the box body 1. The barrel lifting device 6 A bucket hanging device 5 is connected, and the bucket hanging device 5 is rolled and arranged in the trash can lifting guide device 4; a garbage pushing device 11 is slidably installed in the box body 1, and the garbage pushing device 11 is connected with an extension to The push control device 12 on the outside of the box body 1 is installed on the body 13 of the garbage truck, the bottom end of the body 13 is installed with wheels 14, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com