Integrated face frame used for panel television (TV) set and manufacturing method of integrated face frame

A manufacturing method and TV technology, applied to color TV parts, TV system parts, TVs, etc., can solve the problems of heavy welding workload, high extension height, waste of raw materials, etc., to reduce production costs and reduce deformation Easy to control and ensure the quality of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

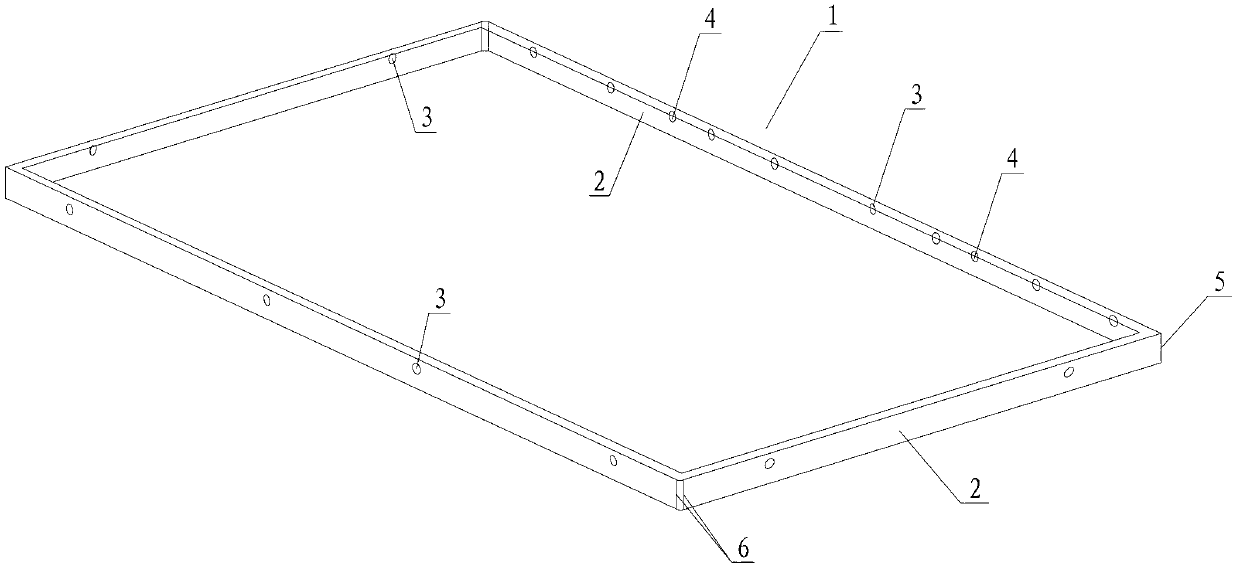

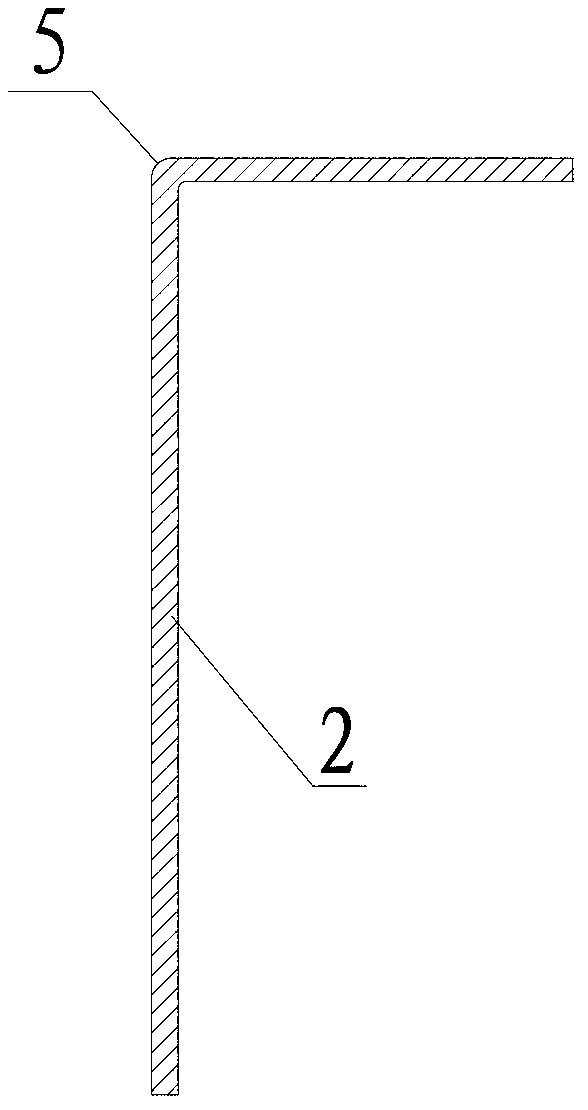

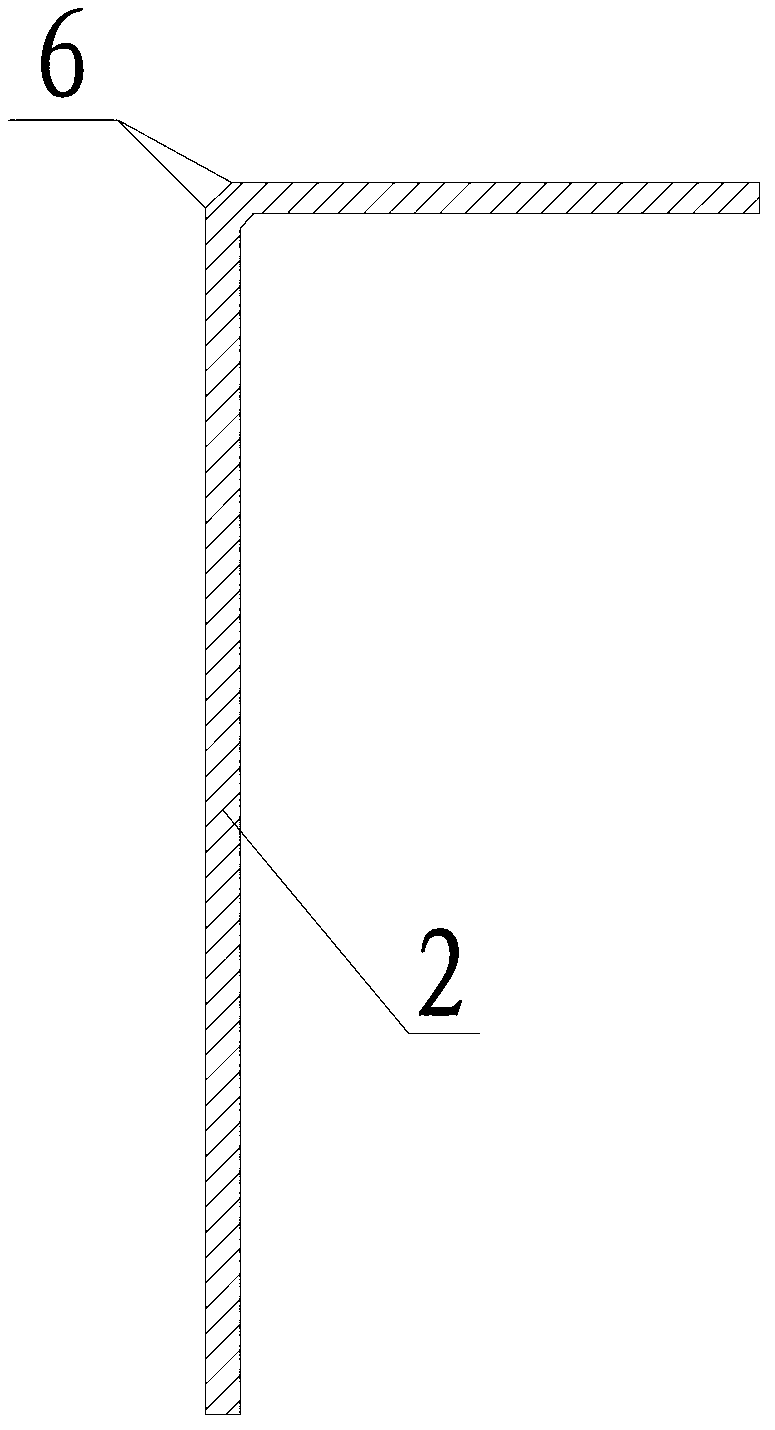

[0024] Such as figure 1 , figure 2 as well as image 3 Shown is an integrated surface frame for flat-panel TVs provided by the present invention, which is simple in structure, less difficult to manufacture, and easy to control deformation, as well as a manufacturing method for the integrated surface frame. The integrated surface frame includes a rectangular surface frame body 1 formed by bending and connecting metal materials. The cross section of each side of the rectangular surface frame body 1 is L-shaped, and each side of the rectangular surface frame body 1 A screen fixing hole 3 and a back cover fixing hole 4 matching the screen connection hole and the back cover connection hole are respectively provided on the side of an L-shaped side 2 . In order to simplify the structure of the L-shaped side 2 constituting the integrated surface frame and to facilitate production, each L-shaped side 2 of the rectangular surface frame body 1 is an integral bending structure, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com