Rapid analysis system for composite material nail loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

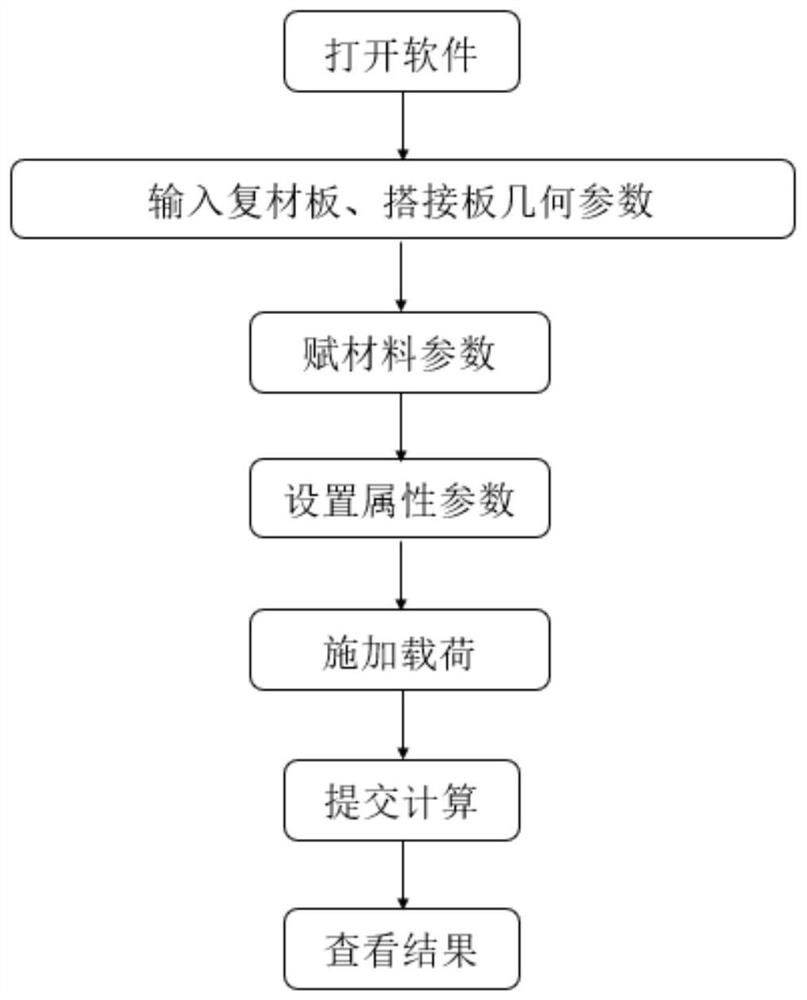

Method used

Image

Examples

Embodiment

[0053] (1) Create a new data file named "110", as attached Image 6 shown;

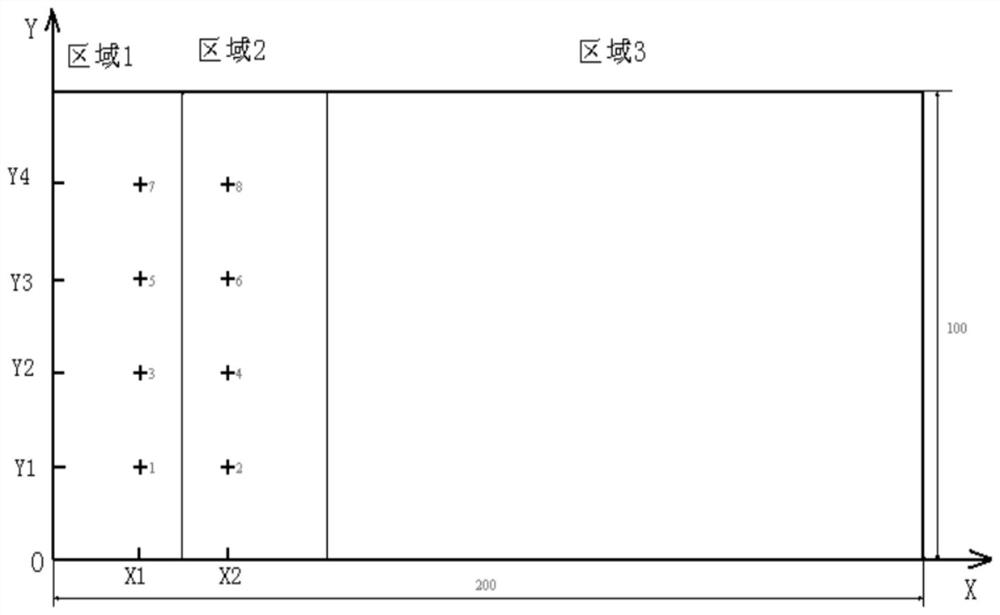

[0054] (2) Input the parameters of the composite material plate. The width and length of each area are attached Figure 7 As shown, set the number of holes and the X and Y coordinates as attached Figure 8 As shown, set the diameter of each hole as attached Figure 9 As shown, the completed composite board is shown in the attached Figure 10 shown;

[0055] (3) Select the lap joint type, and input parameters such as edge distance and end distance of the lap joint plate, as attached Figure 11 shown;

[0056] (4) Establish the material parameters of composite boards, lap joints, screws, etc. The material parameters of composite boards are as attached Figure 12 shown;

[0057] (5) Establish parameters such as composite plate properties, metal plate properties, and beam unit properties in each area. The properties of composite plate units are as follows: Figure 13 shown;

[0058] (6) Assign t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com