Press nail structure of epoxy cast dry-type transformer

A technology of dry-type transformer and epoxy casting, which is applied in the field of transformer manufacturing, and can solve the problems of many machined parts, difficulty in guaranteeing welding quality, and high verticality requirements between nail nuts and clamps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

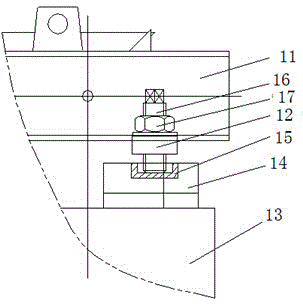

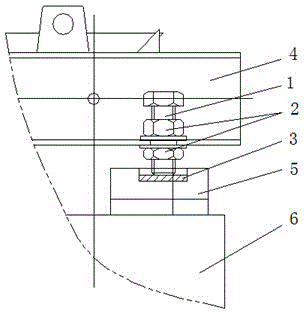

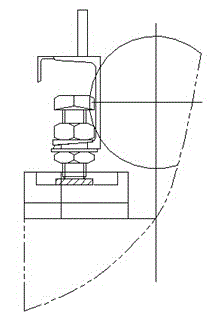

[0013] An epoxy cast dry-type transformer nail structure, see figure 2 and image 3 , the nail structure includes a compression bolt 1, a lock nut 2 and a pressure plate 3, the compression bolt is arranged in the through hole at the bottom of the upper clamp 4 and pressed tightly on the pressure plate 3, and the pressure plate 3 is arranged on the upper pad 5 In the rectangular slotted hole, the pressing plate is a flat steel plate. Two locking nuts 2 are sleeved on the compression bolt 1 and are located on both sides of the through hole at the lower part of the upper clip. The inner diameter of the through hole at the bottom of the upper clamping part is compatible with the compression bolt, and the aperture of the through hole at the lower part of the upper clamping part is slightly larger than that of the compression bolt, so there is no need to weld the clamping screw nut. The pressure nail is replaced by the pressure bolt; the pressure bolt and the lock nut are all sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com