Adjustable Y-type furnace wall grasping nail structure

An adjustable furnace wall technology, applied in the direction of combustion method, combustion chamber, outer cover/lining, etc., can solve the problems of lower work efficiency, different thickness of refractory materials, heavier design, production workload, etc., to improve work efficiency, good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

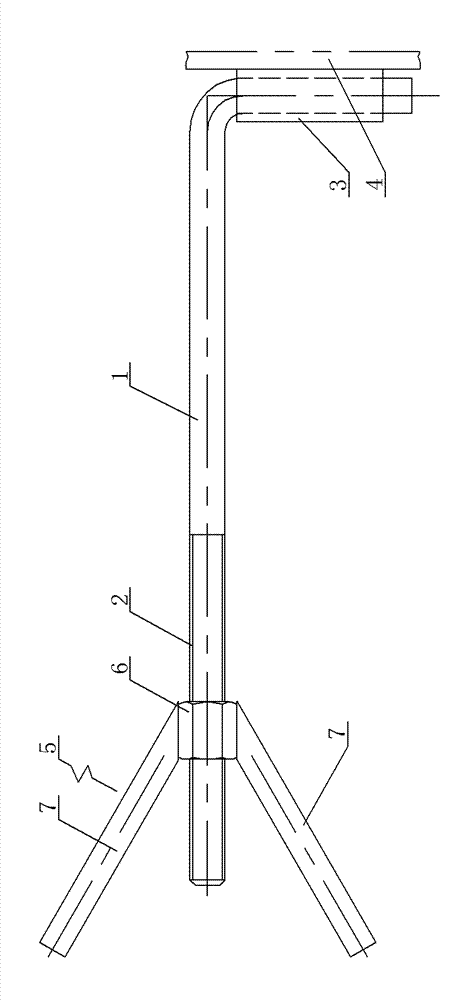

[0011] Specific embodiment one, see figure 1 : it includes a V-shaped head structure 5 and an L-shaped moment arm structure 1, the connection position of the V-shaped head structure 5 is specifically a nut structure 6, and the outer walls on both sides of the nut structure 6 are respectively welded and connected to metal rods 7, The metal rods 7 on both sides are combined to form a V-shaped structure and are located in the same plane. The nut structure 6 is screwed to the external thread structure 2, and the metal rod 7 is a round steel structure.

specific Embodiment 2

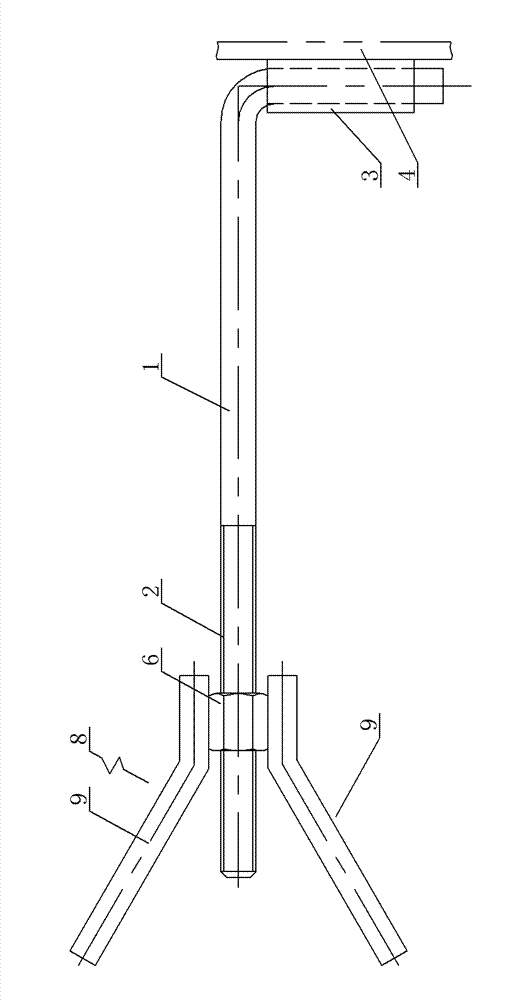

[0012] Specific embodiment two, see figure 2 : It includes a Y-shaped head structure 8, the metal rods on both sides are respectively bent to form symmetrical bent metal rods 9, the bent metal rods 9 are round steel structures, and the mutually parallel parts 10 of the bent metal rods 9 on both sides are The nut structure 6 is welded between them, and the bent metal rods 9 on both sides are welded to form a Y-shaped structure and are located in the same plane; the nut structure 6 is threaded to the external thread structure 3, and the bent metal rods 9 is a round steel structure.

[0013] The nut structures in the specific embodiment 1 and the specific embodiment 2 are all standard nuts. The grab nails are combined with ordinary steel components, which avoids the problems of air holes, shrinkage cavities and slag inclusions that may occur in castings; and the grab nails are welded by round steel and standard nuts, which is easy to manufacture.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com