Carbides-free bainite wear resistant steel plate and production process thereof

A technology of wear-resistant steel plate and production process, which is applied in the direction of temperature control, etc., can solve the problems of complex process, low product strength and toughness, etc., and achieve the effect of ensuring high toughness, good toughness and reducing crack rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

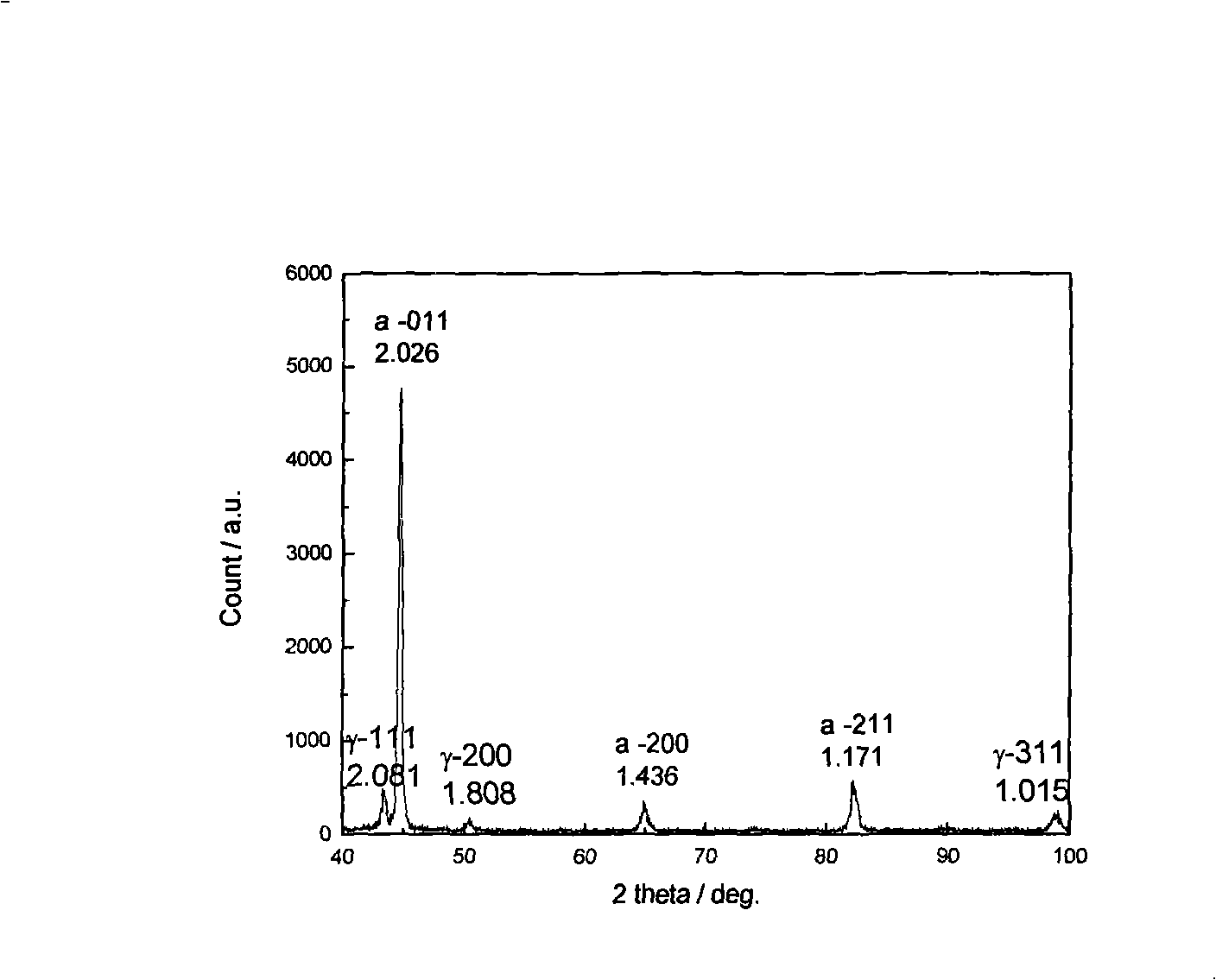

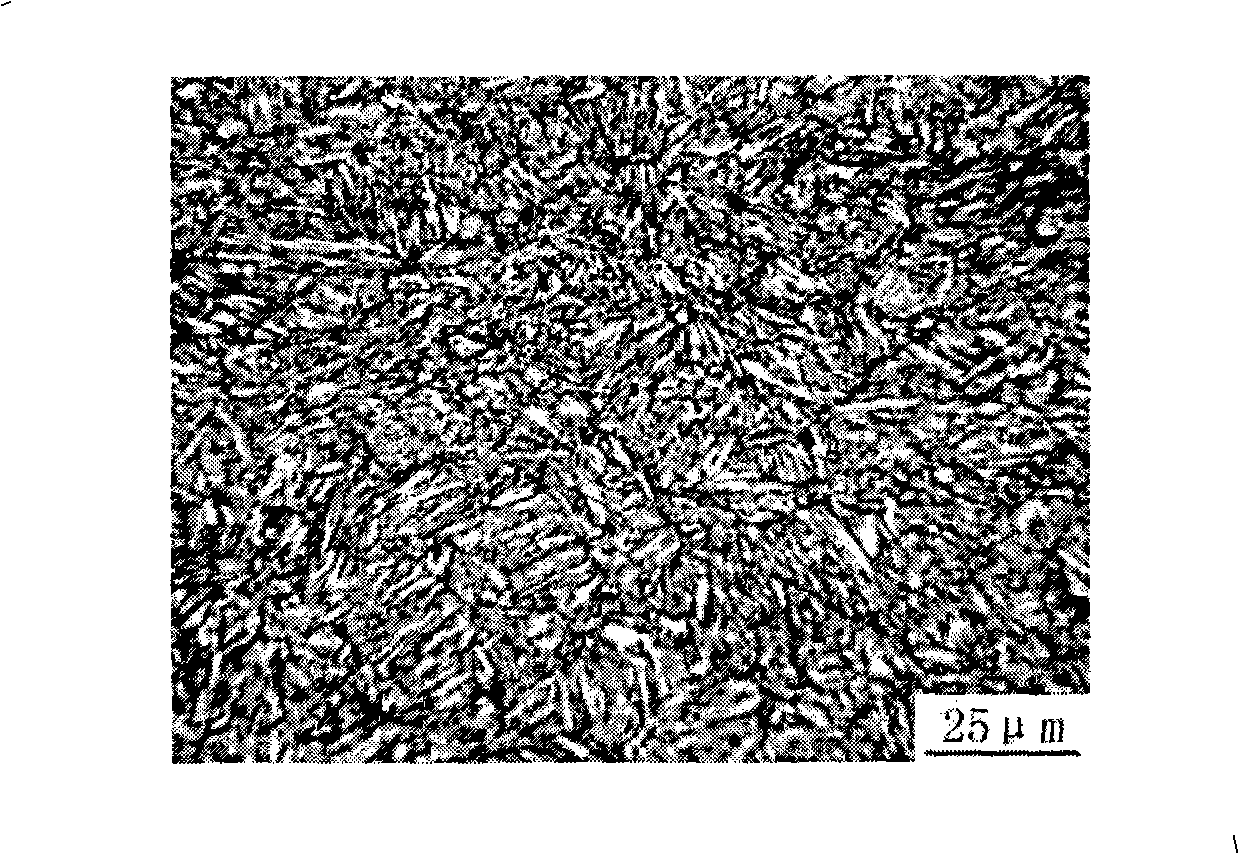

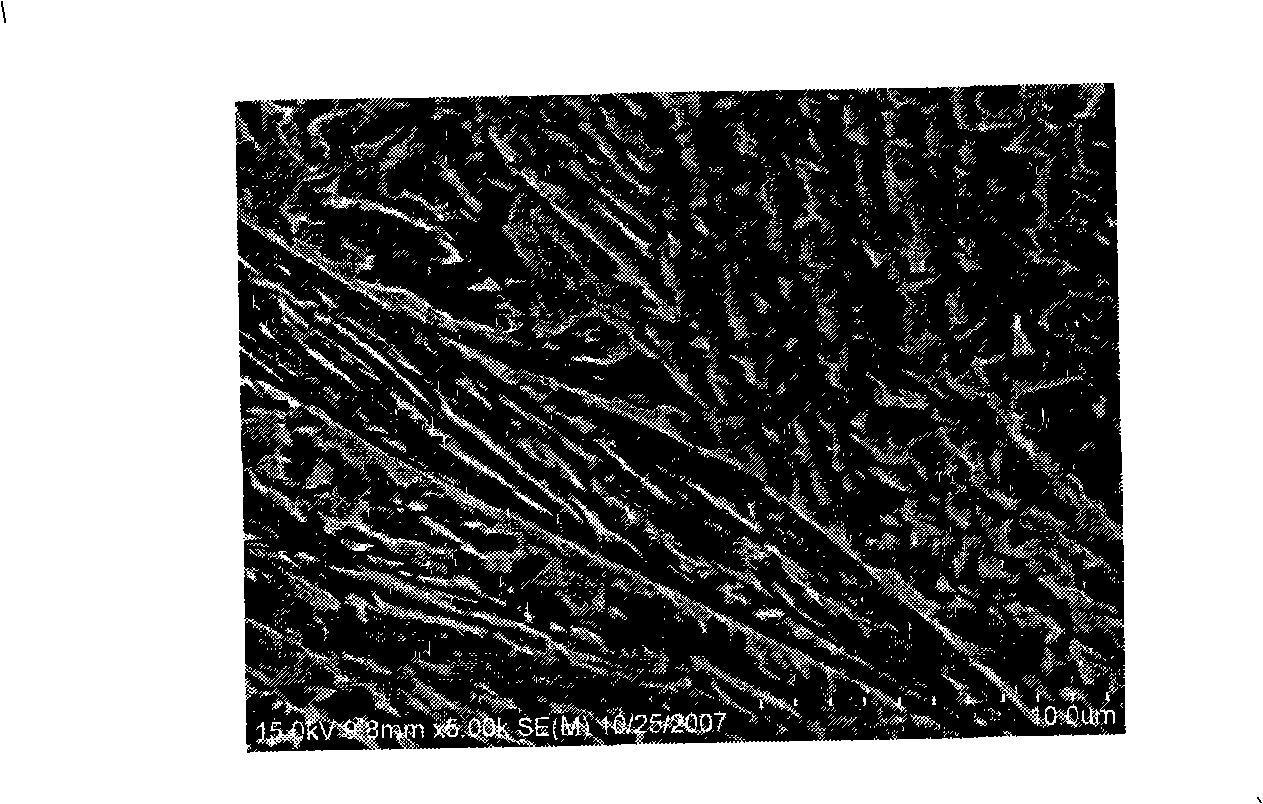

Image

Examples

Embodiment 1

[0027] The composition weight percent of the carbide-free bainite wear-resistant steel plate in this embodiment is: C: 0.15%, Mn: 1.50%, P: 0%, S: 0.006%, Si: 1.30%, Al: 0.60%, Cr : 0.60%, Mo: 0.25%, Nb: 0.010%, Fe: balance.

[0028] The production process of the above carbide-free bainite wear-resistant steel plate is carried out according to the following procedures:

[0029] (1) The continuous casting slab is sent to the heating furnace and heated to 1200°C, and the temperature of the furnace is controlled at 1200±10°C.

[0030] (2) Send the heated continuous casting slab to the hot rolling production line for controlled rolling and controlled cold rolling. Two-stage rolling is adopted, the final rolling temperature in the finishing rolling stage is controlled at 880°C, and the pass strain in the finishing rolling stage is controlled >1, control the cooling rate ≥5°C / s, and control the final cooling temperature at 580°C.

[0031] (3) After rolling, the rolled steel plate ...

Embodiment 2

[0033] The composition weight percent of the carbide-free bainite wear-resistant steel plate of this embodiment is: C: 0.25%, Mn: 2.00%, P: 0.015%, S: 0%, Si: 2.00%, Al: 0.20%, Cr : 1.00%, Mo: 0.50%, Nb: 0.035%, Fe: balance.

[0034] The production process of the above carbide-free bainite wear-resistant steel plate is carried out according to the following procedures:

[0035] (1) The continuous casting slab is sent to the heating furnace and heated to 1250°C, and the temperature of the furnace is controlled at 1200±10°C.

[0036] (2) Send the heated continuous casting slab to the hot rolling production line for controlled rolling and controlled cold rolling. Two-stage rolling is adopted. The final rolling temperature in the finishing rolling stage is controlled at 870°C, and the pass strain in the finishing rolling stage is controlled. >1, control the cooling rate ≥10°C / s, control the final cooling temperature at 630°C, and straighten. (3) After rolling, the rolled steel p...

Embodiment 3

[0038]The composition weight percent of the carbide-free bainite wear-resistant steel plate in this embodiment is: C: 0.20%, Mn: 1.6%, P: 0.01%, S: 0.004%, Si: 1.50%, Al: 0.40%, Cr: 0.80%, Mo: 0.30%, Nb: 0.020%, Fe: balance.

[0039] The production process of the above carbide-free bainite wear-resistant steel plate is carried out according to the following procedures:

[0040] (1) The continuous casting slab is sent to the heating furnace and heated to 1250°C, and the temperature of the furnace is controlled at 1200±10°C.

[0041] (2) Send the heated continuous casting slab to the hot rolling production line for controlled rolling and controlled cold rolling. Two-stage rolling is adopted, the final rolling temperature in the finishing rolling stage is controlled at 860°C, and the pass strain in the finishing rolling stage is controlled >1, control the cooling rate ≥5°C / s, control the final cooling temperature at 590°C, and straighten.

[0042] (3) After rolling, the rolled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com