Patents

Literature

91 results about "High temperature electronics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Niobium sodium potassium antimonate-potassium sodium bismuth zirconate leadless piezoelectric ceramic with high piezoelectric constant and preparation method thereof

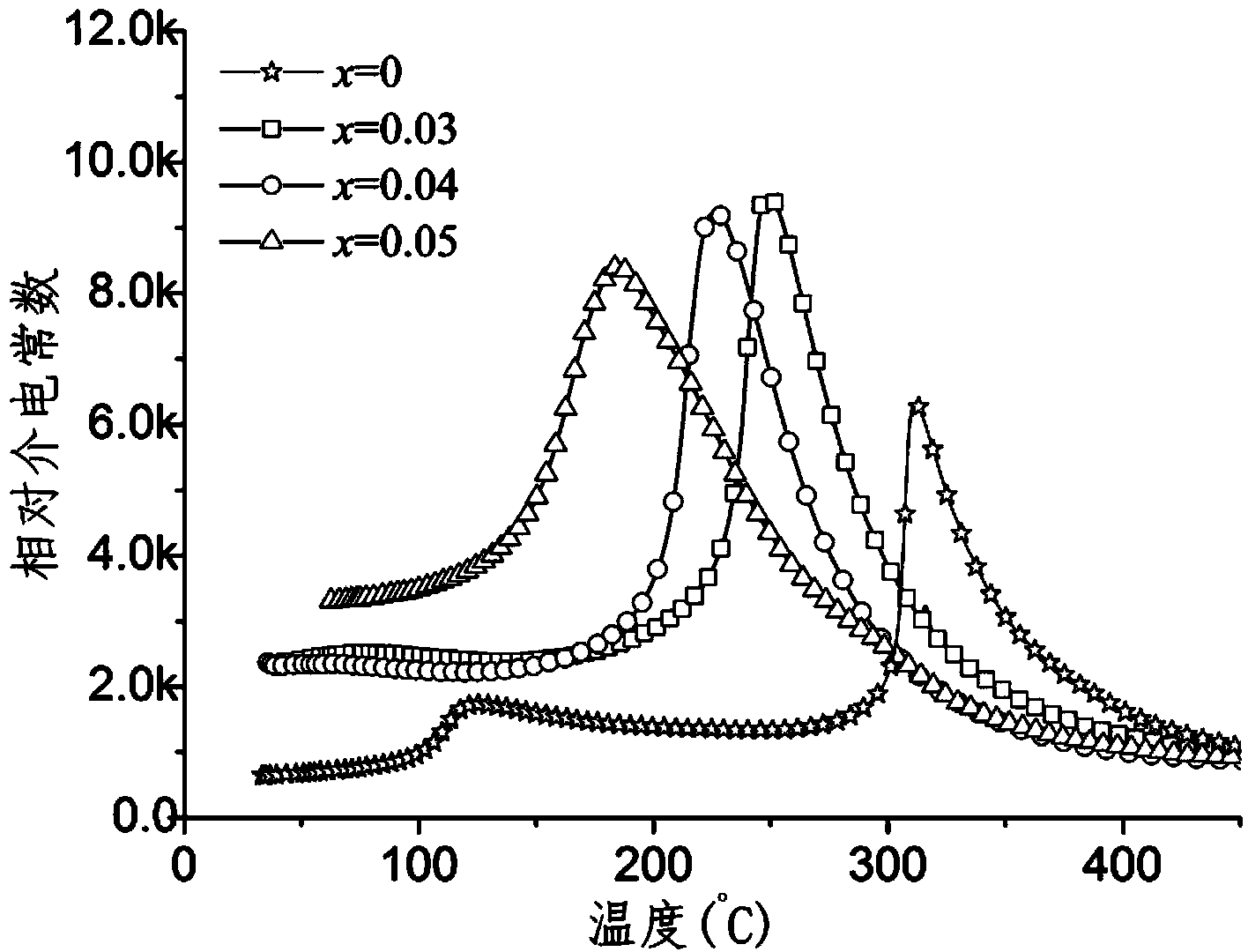

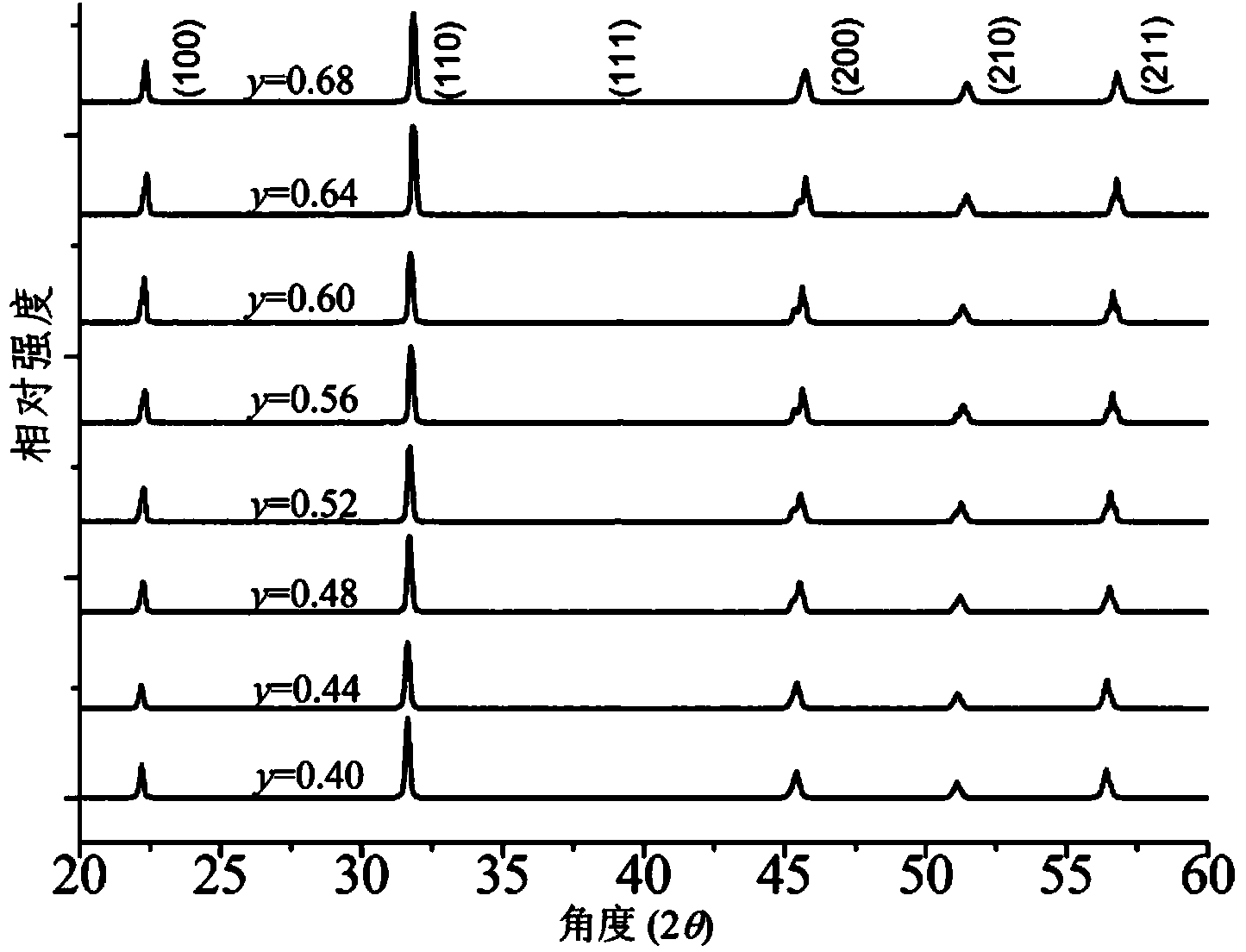

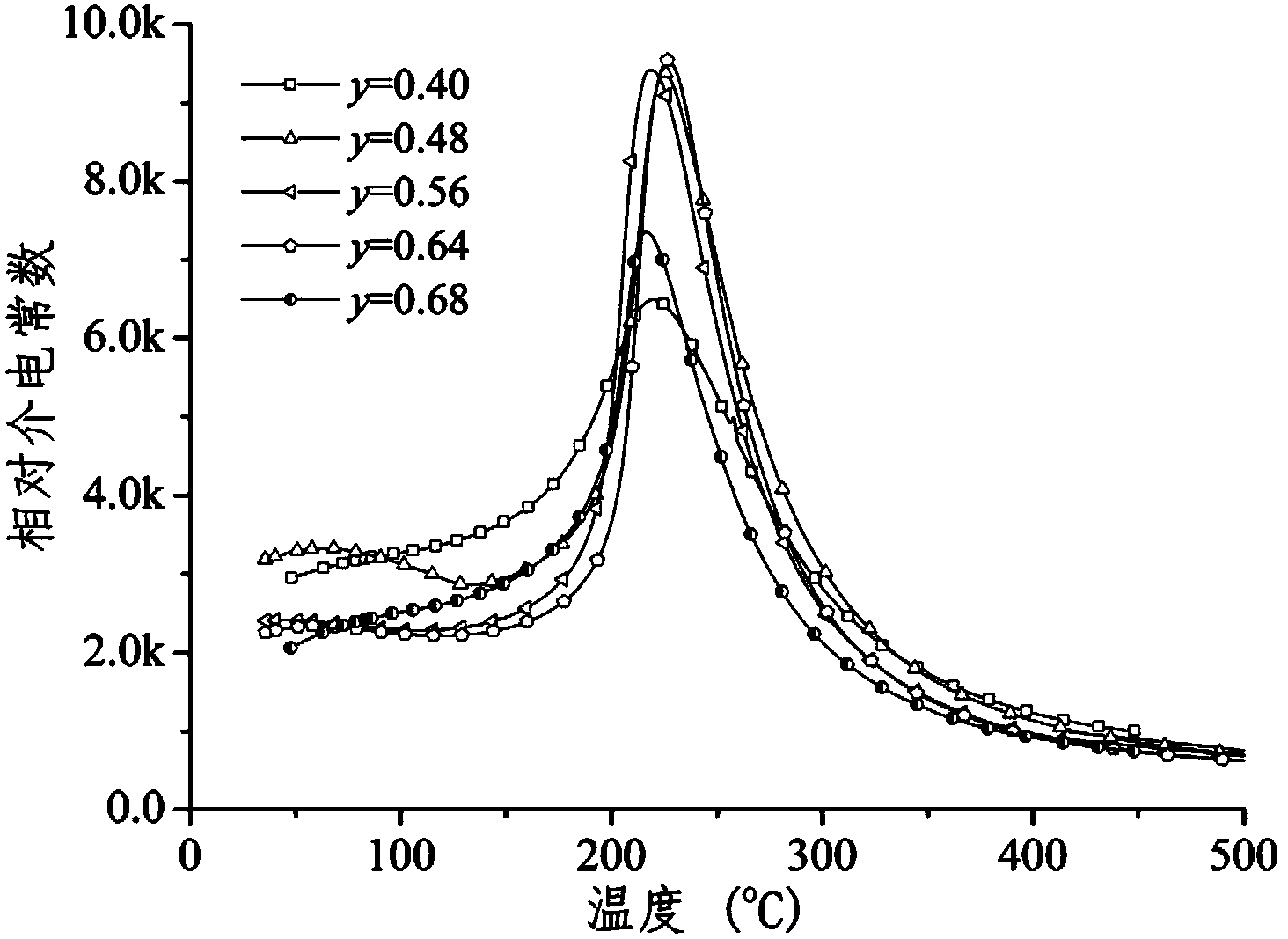

The invention relates to niobium sodium potassium antimonate-potassium sodium bismuth zirconate leadless piezoelectric ceramic with a high piezoelectric constant and a preparation method thereof, which belong to the field of environmental coordinative piezoelectric ceramic of perovskite structures. The leadless piezoelectric ceramic with a general formula of (1-x) (K1-yNay) (Nb1-zSbz) O3 + xBi0.5 (Na1-uKu) 0.5ZrO3 is prepared by a traditional solid state sintering method, wherein in the formula, x is not smaller than 0 while not larger than 0.05, y is not smaller than 0.40 while not larger than 0.68, z is not smaller than 0.02 while not larger than 0.06, and u is not smaller than 0 while not larger than 1; the d33 of the leadless piezoelectric ceramic disclosed by the invention can be as high as 470 pC / N, kp can reach 47%, and Tc is as high as 313 DEG C. Devices prepared by the ceramic can work under high temperatures, so that the ceramic has a practical application value in high-temperature electronic equipment; since the ceramic contains no expensive tantalum element, the price of the used raw materials is low, so that the cost is saved.

Owner:SICHUAN UNIV

Zn (zinc) based high-temperature lead-free soft solder and preparation method for same

InactiveCN102554491AGood wetting and spreadingHigh tensile strengthWelding/cutting media/materialsSoldering mediaManganeseCerium

The invention belongs to the technical field of soldering such as electronic package, assembly and the like of soldering fluxes, and particularly discloses Zn (zinc) based high-temperature lead-free soft solder and a preparation method for the same. In weight percent, components of the Zn based high-temperature lead-free soft solder include 2-30% of aluminum, 1-20% of tin, 0.1-8% of copper, 0.01-3.0% of titanium, 0.1-1.0% manganese and / or 0.1-1.0% of lanthanum-cerium rare earth and the balance zinc. The melting point of the Zn based high-temperature lead-free soft solder ranges from 250 DEG C to 450 DEG C, and the Zn based high-temperature lead-free soft solder has the advantages of fine wetting spreadability and high in tensile strength. The mechanical property of the Zn based high-temperature lead-free soft solder is superior to corresponding high-lead solder, the spreadability of the Zn based high-temperature lead-free soft solder meets the use requirement of soldering, and the Zn based high-temperature lead-free soft solder can replace the high-lead solder widely applied at present and meets the requirements of soldering such as high-temperature electronic package, assembly and the like.

Owner:HENAN UNIV OF SCI & TECH

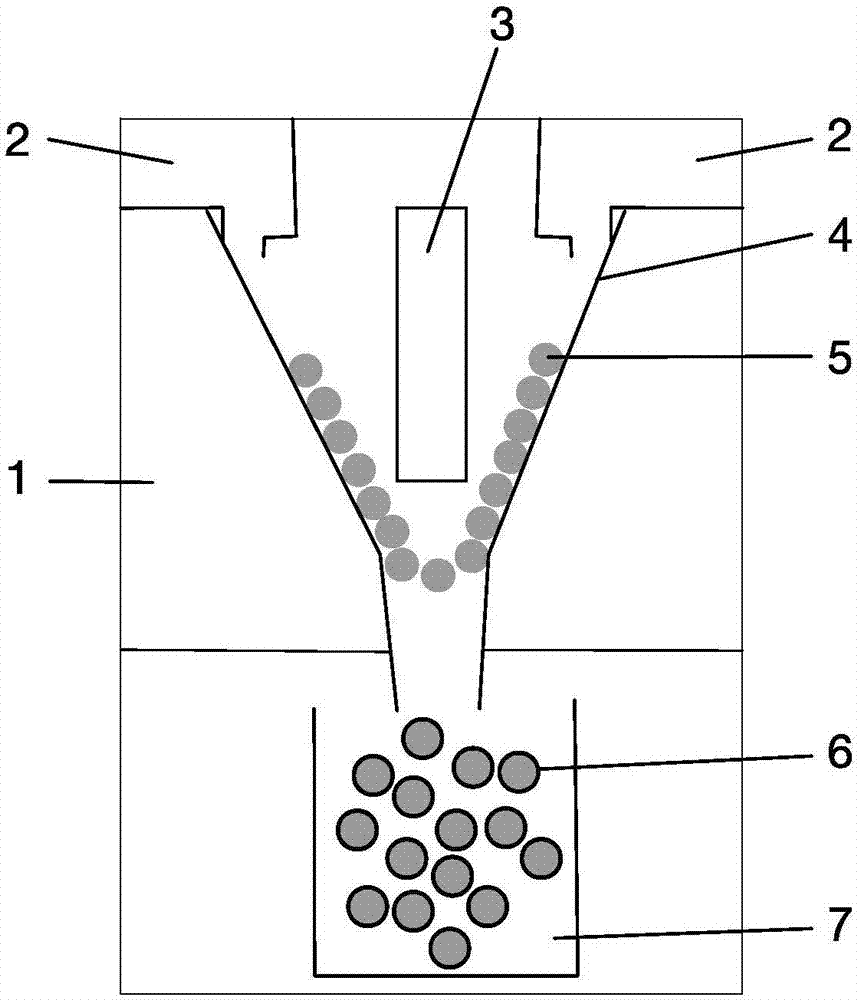

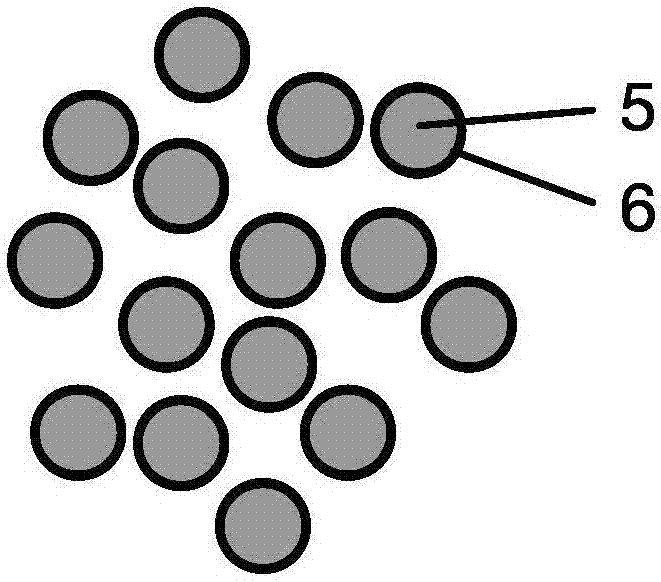

Composite nano silver paste and rapid sintering packaging method

InactiveCN107833651ALow costSmall volume shrinkageMaterial nanotechnologyTransportation and packagingHigh temperature electronicsElectron

The invention provides a composite nano silver paste preparation method and a rapid sintering packaging method. The preparation method comprises steps that S1, cleaning treatment and centrifugation ofmicron silver sheets are carried out; S2, nano silver particles and an organic solvent are mixed into the micron silver sheets acquired in S1, and the ultrasonic process and stirring are carried out;and S3, an organic carrier and the surfactant are added to the mixed solution acquired in S2, and the ultrasonic process and stirring are carried out to acquire the composite nano silver paste. The packaging method comprises steps that S1, the silver paste is coated through dispensing or screen printing; S2, a chip coated with the composite nano silver paste and a substrate are aligned and stacked; and S3, hot press welding or ultrasonic hot press welding is utilized for sintering to complete interconnection. The method is advantaged in that rapid sintering and packaging of the composite nanosilver paste are realized, material cost is reduced, the preparation process is environmental friendly, the packaging process and the equipment are simplified, production efficiency is improved, energy saving and emission reduction are facilitated, volume contraction caused by continuous sintering in the service process of a nano silver paste sintering body can be reduced, service life and reliability of a packaging device are improved, and the method is suitable for high reliability low temperature packaging interconnection of high temperature electronic devices in the electronic packaging field.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL +1

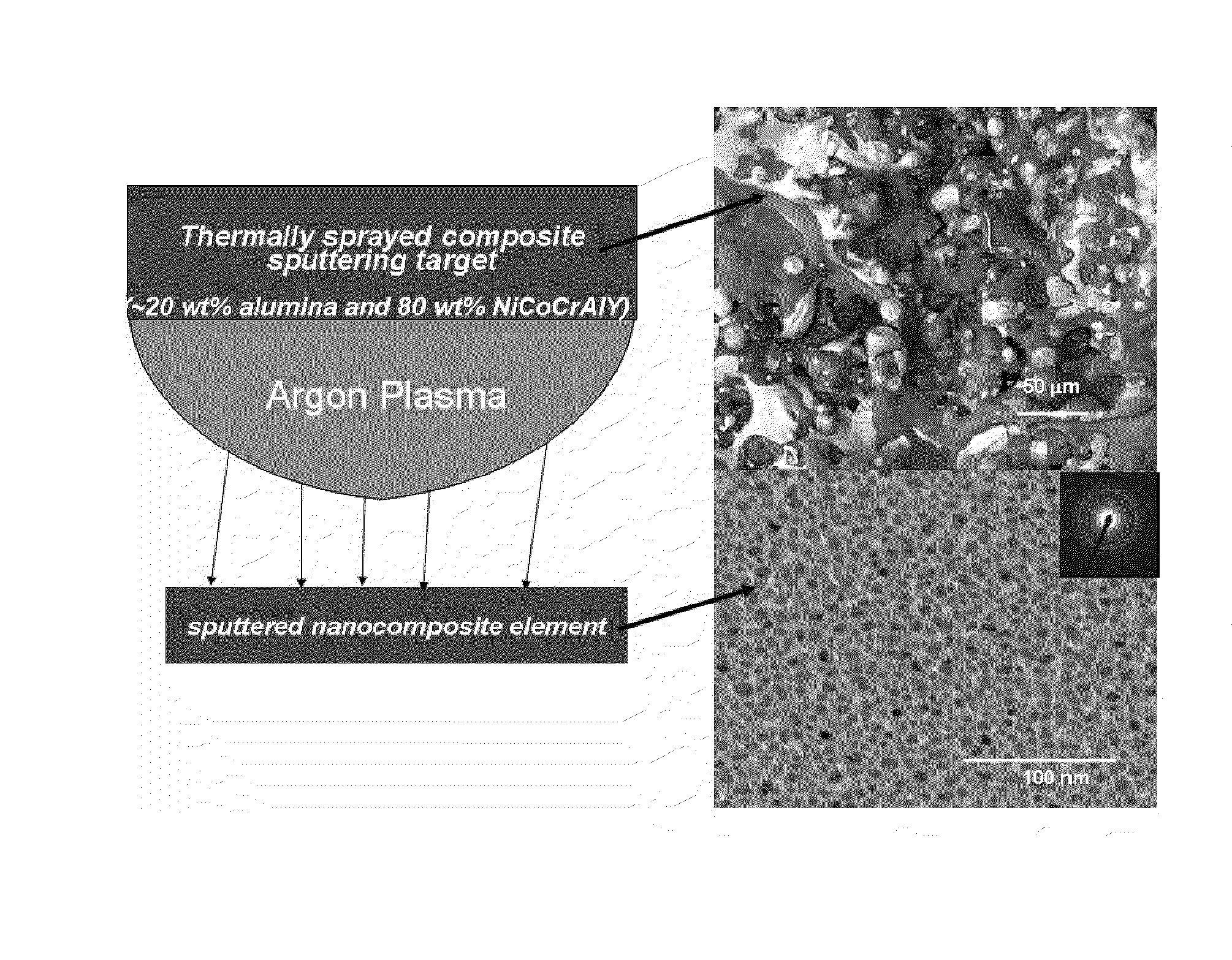

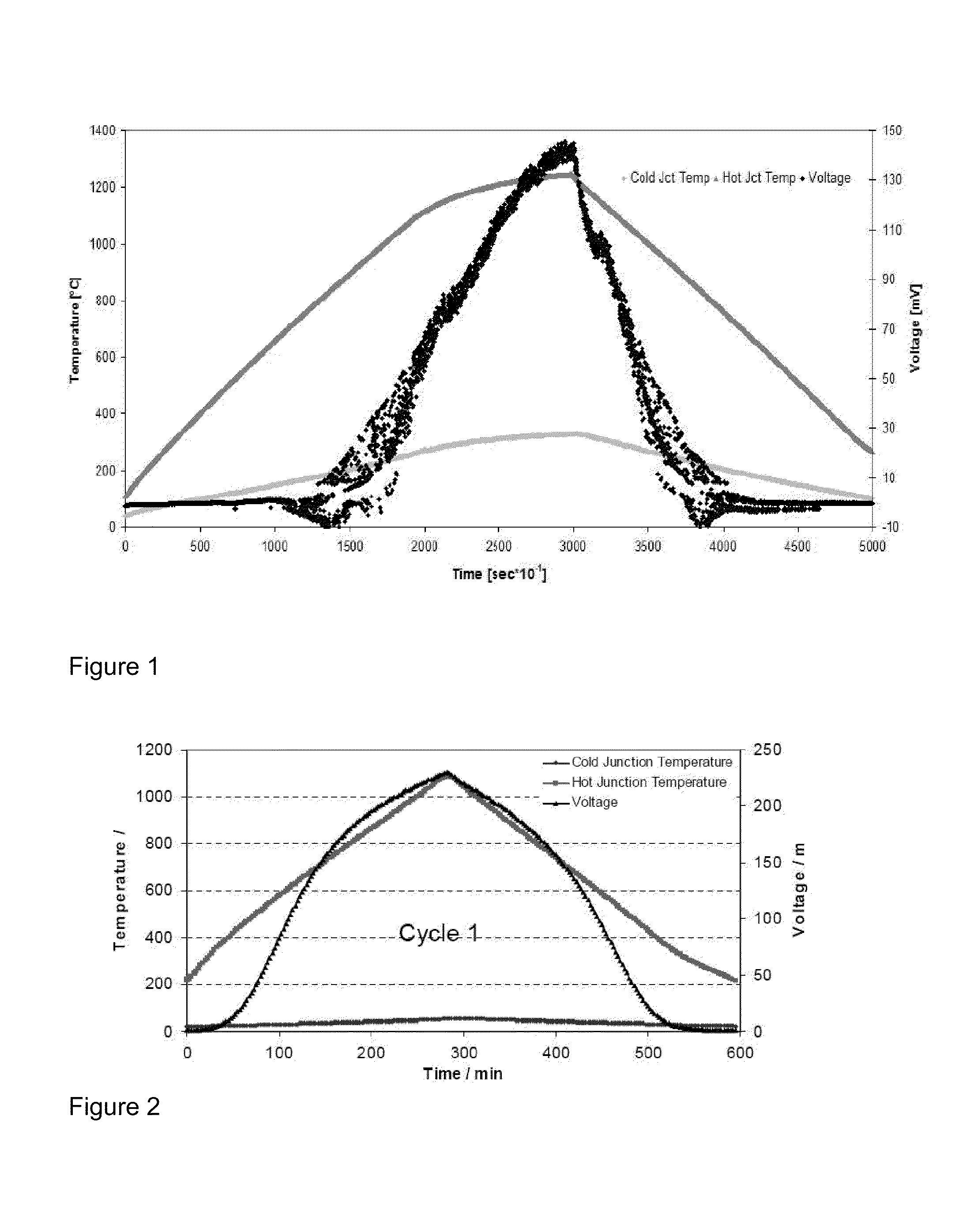

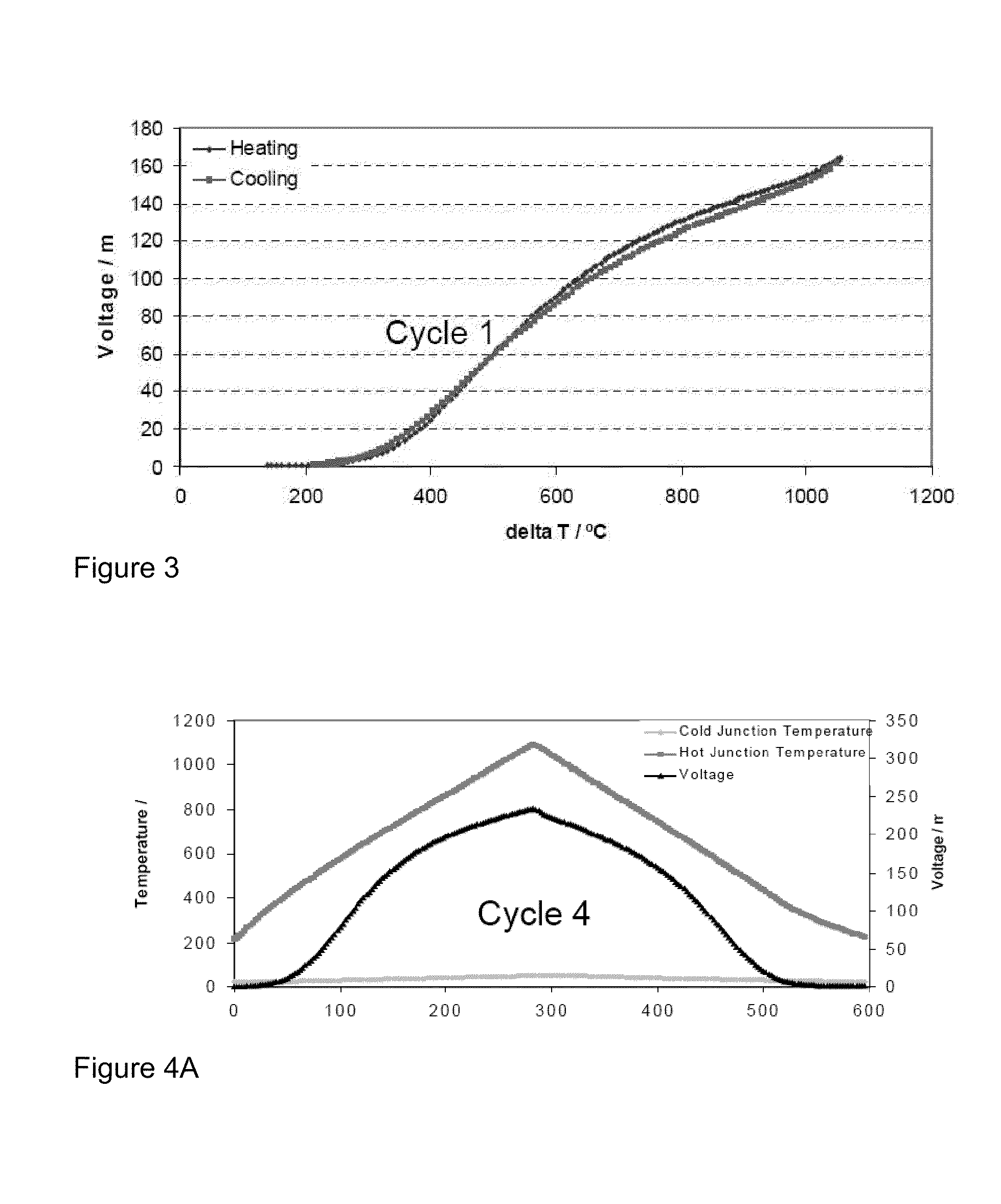

Nano-composites for thermal barrier coatings and thermo-electric energy generators

InactiveUS20090290614A1High voltage outputLow thermal conductivityNanotechLiquid surface applicatorsTurbine bladeHigh temperature electronics

A nano-composite material having a high electrical conductivity and a high Seebeck coefficient and low thermal conductivity. The nano-composite material is capable of withstanding high temperatures and harsh conditions. These properties make it suitable for use as both a thermal barrier coating for turbine blades and vanes and a thermoelectric generator to power high temperature electronics, high temperature wireless transmitters, and high temperature sensors. Unique to these applications is that the thermal barrier coatings can act as a temperature sensor and / or a source of power for other sensors or high temperature electronics and wireless transmitters.

Owner:BOARD OF GOVERNORS FOR HIGHER EDUCATION STATE OF RHODE ISLAND & PROVIDENCE PLANTATIONS +1

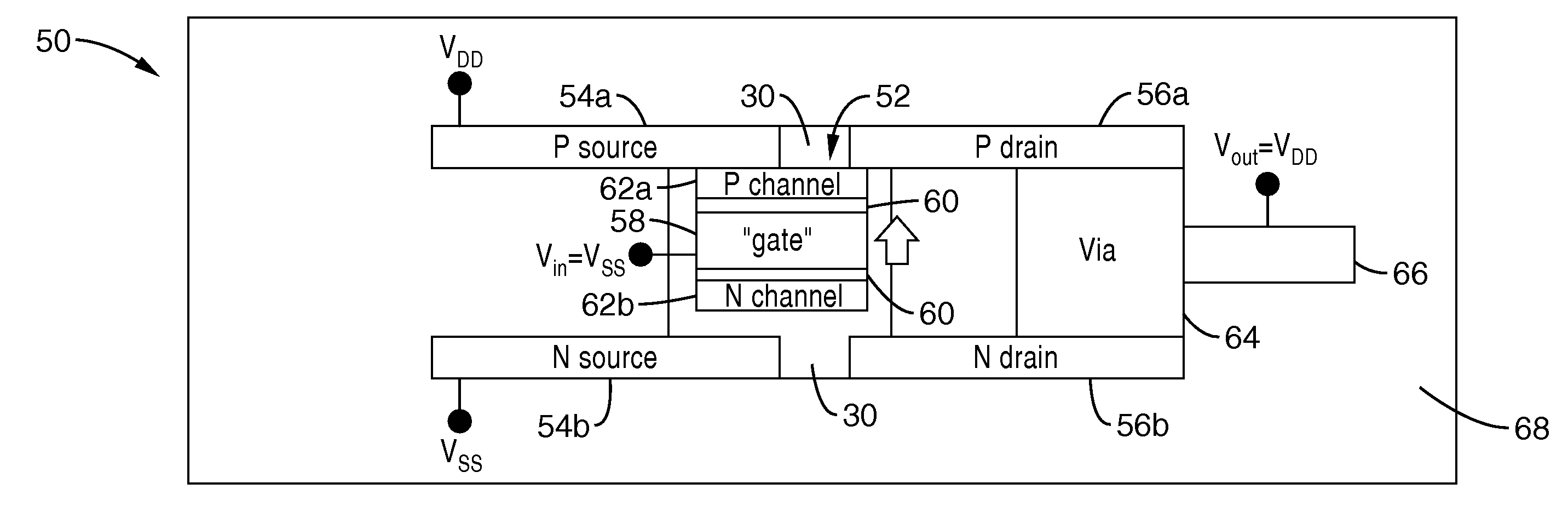

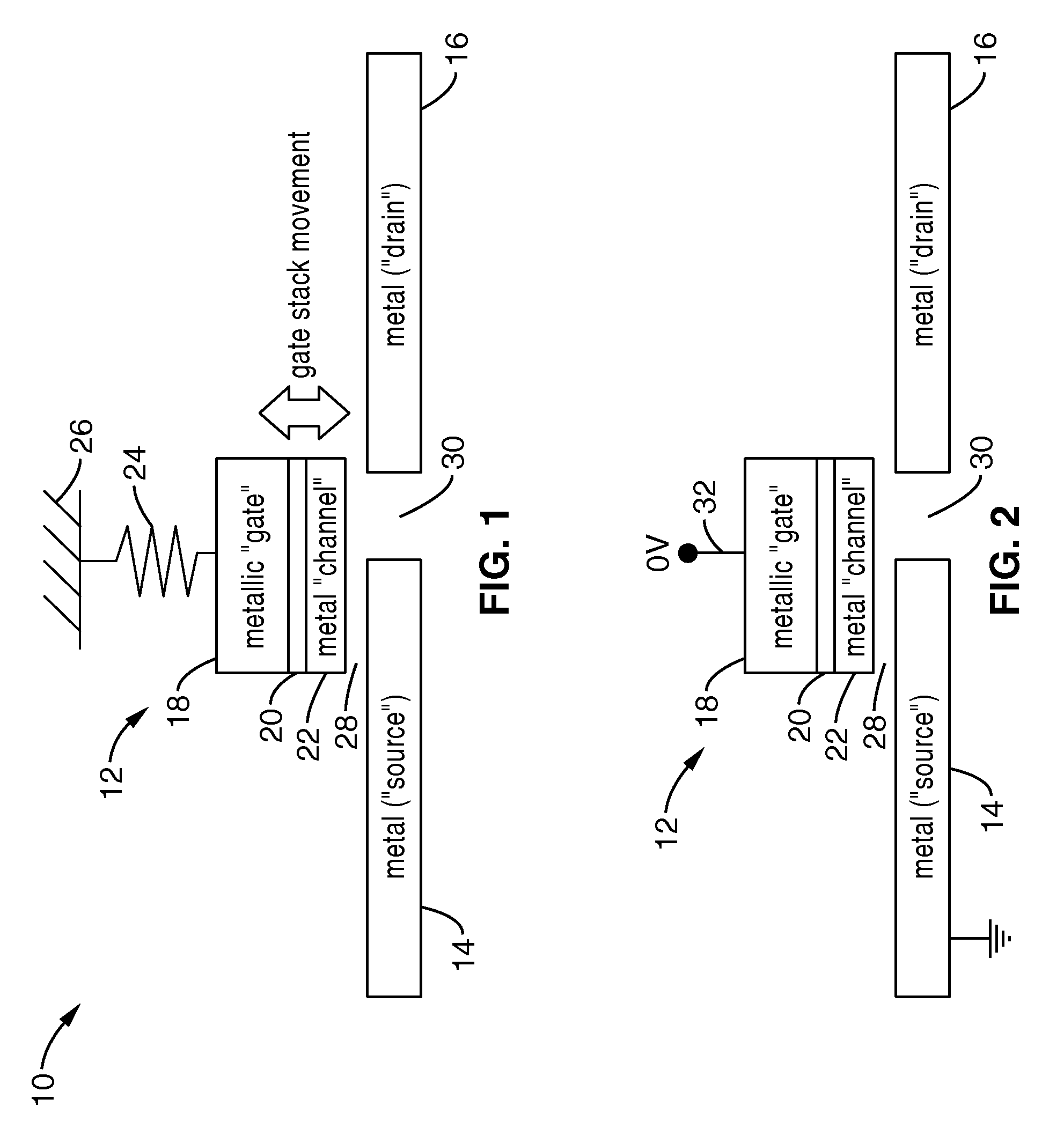

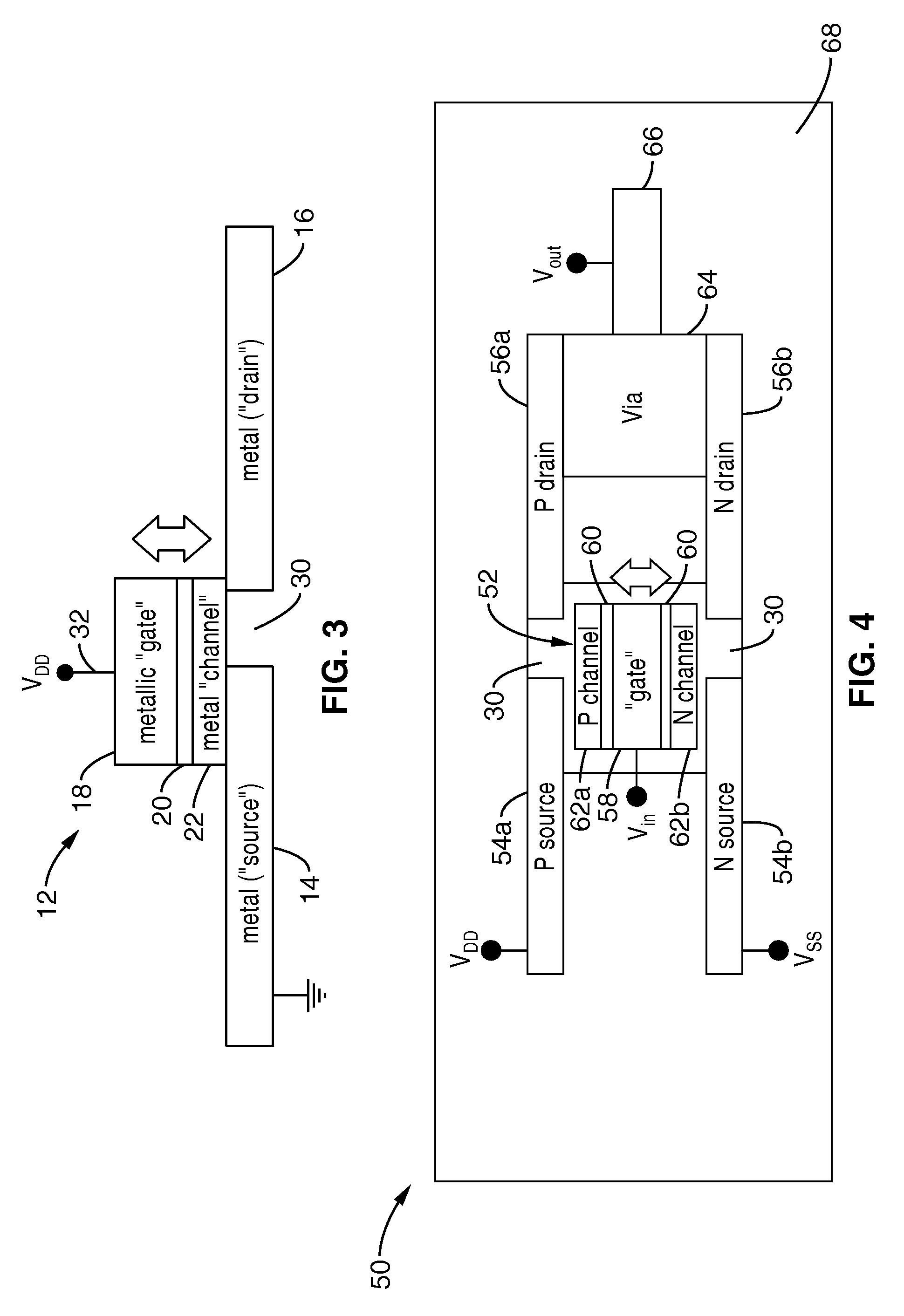

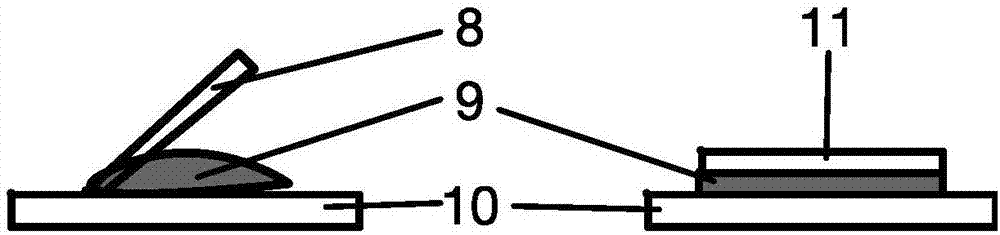

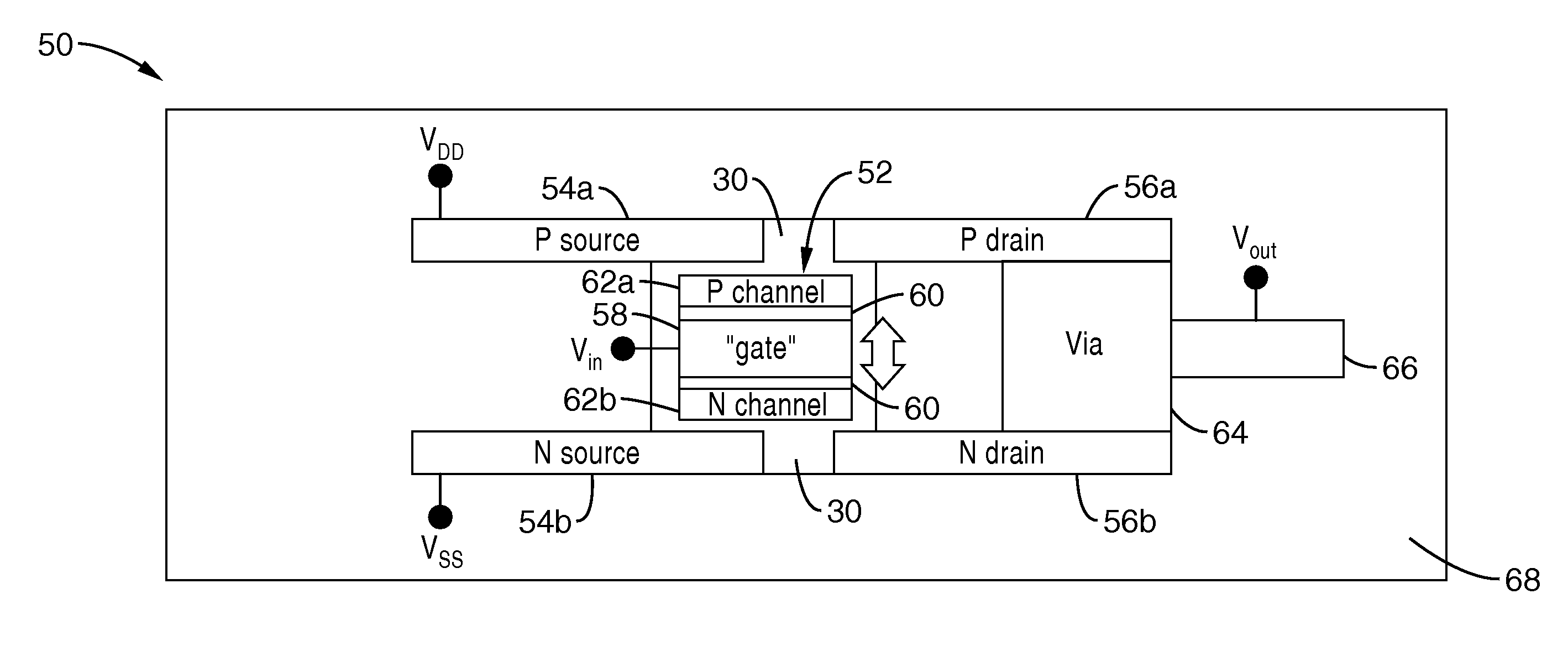

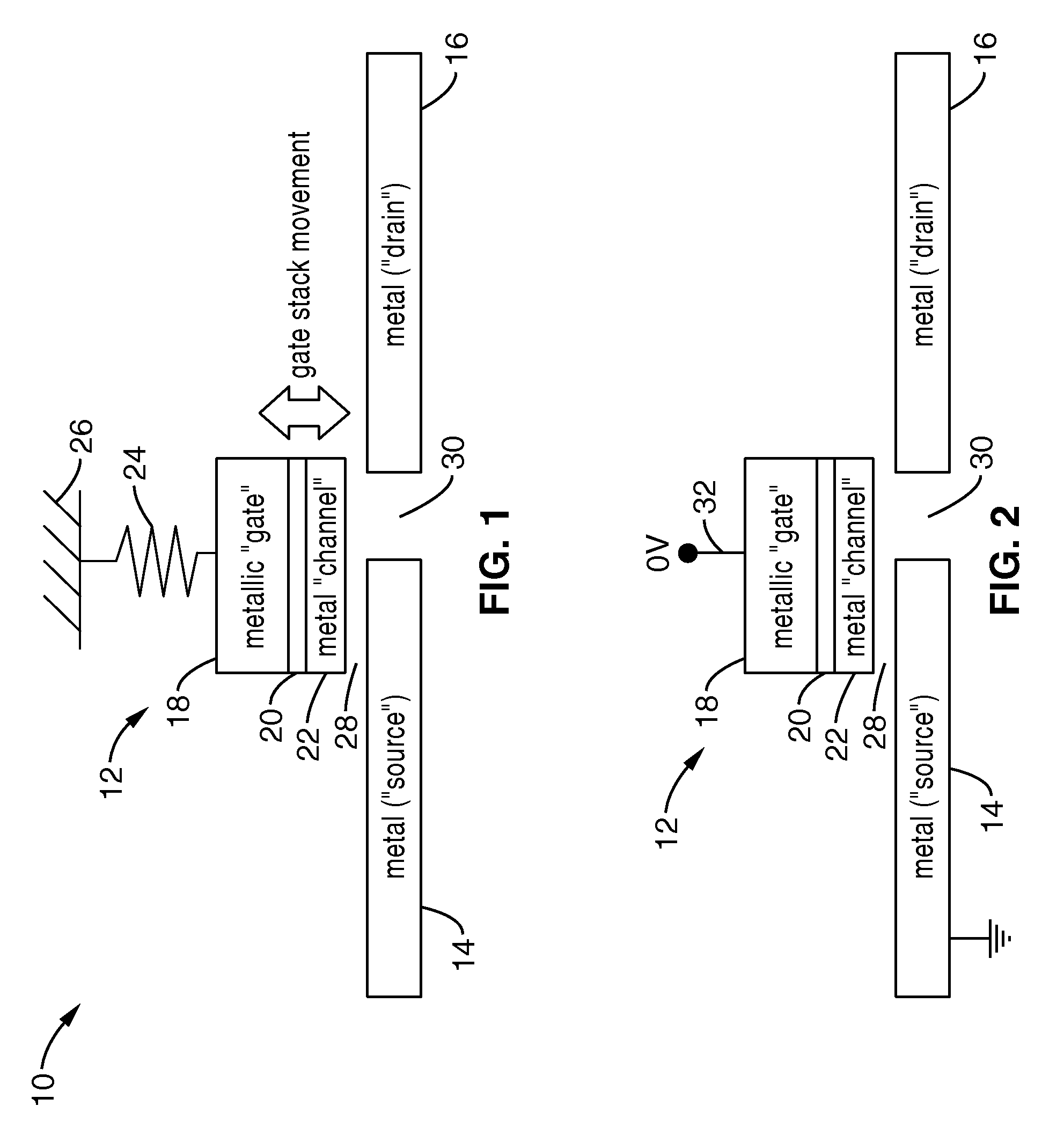

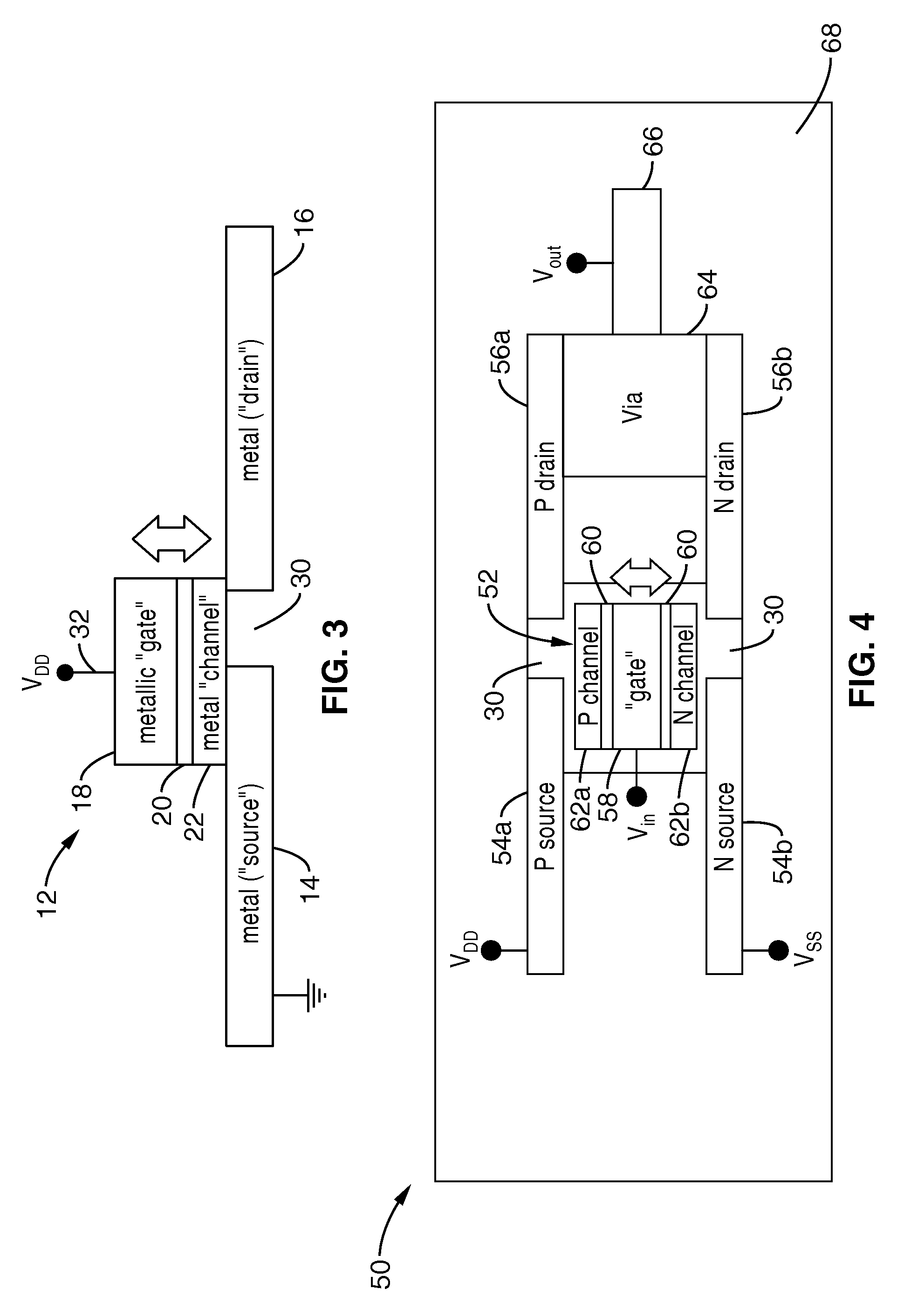

Metal-insulator-metal (MIM) switching devices

ActiveUS20090128221A1Excellent on-state conductanceWide operating temperature rangeTransistorCircuit-breaking switches for excess currentsMetal-insulator-metalHigh temperature electronics

A gated nano-electro-mechanical (NEM) switch employing metal-insulator-metal (MIM) technology and related devices and methods which can facilitate implementation of low-power, radiation-hardened, high-temperature electronic devices and circuits. In one example embodiment a gate electrode is configured as a cantilever beam whose free end is coupled to a MIM stack. The stack moves into bridging contact across a source and drain region when the applied gate voltage generates a sufficient electrostatic force to overcome the mechanical biasing of the cantilever beam. A second set of contacts can be added on the cantilever beam to form a complementary switching structure, or to a separate cantilever beam. The switching can be configured as non-volatile in response to stiction forces. NEM circuits provide a number of advantages within a variety of circuit types, including but not limited to: logic, memory, sleep circuits, pass circuits, and so forth.

Owner:RGT UNIV OF CALIFORNIA

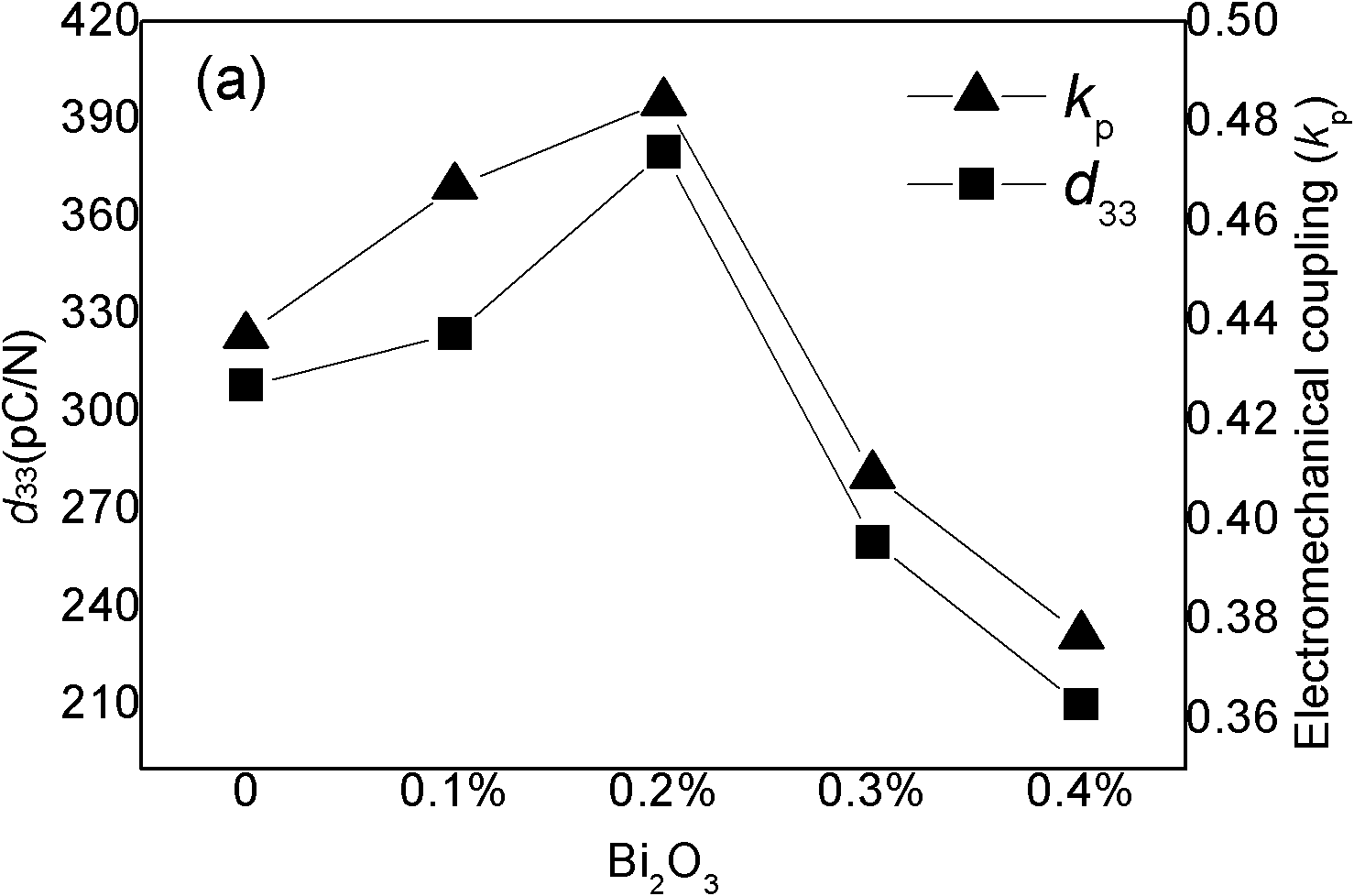

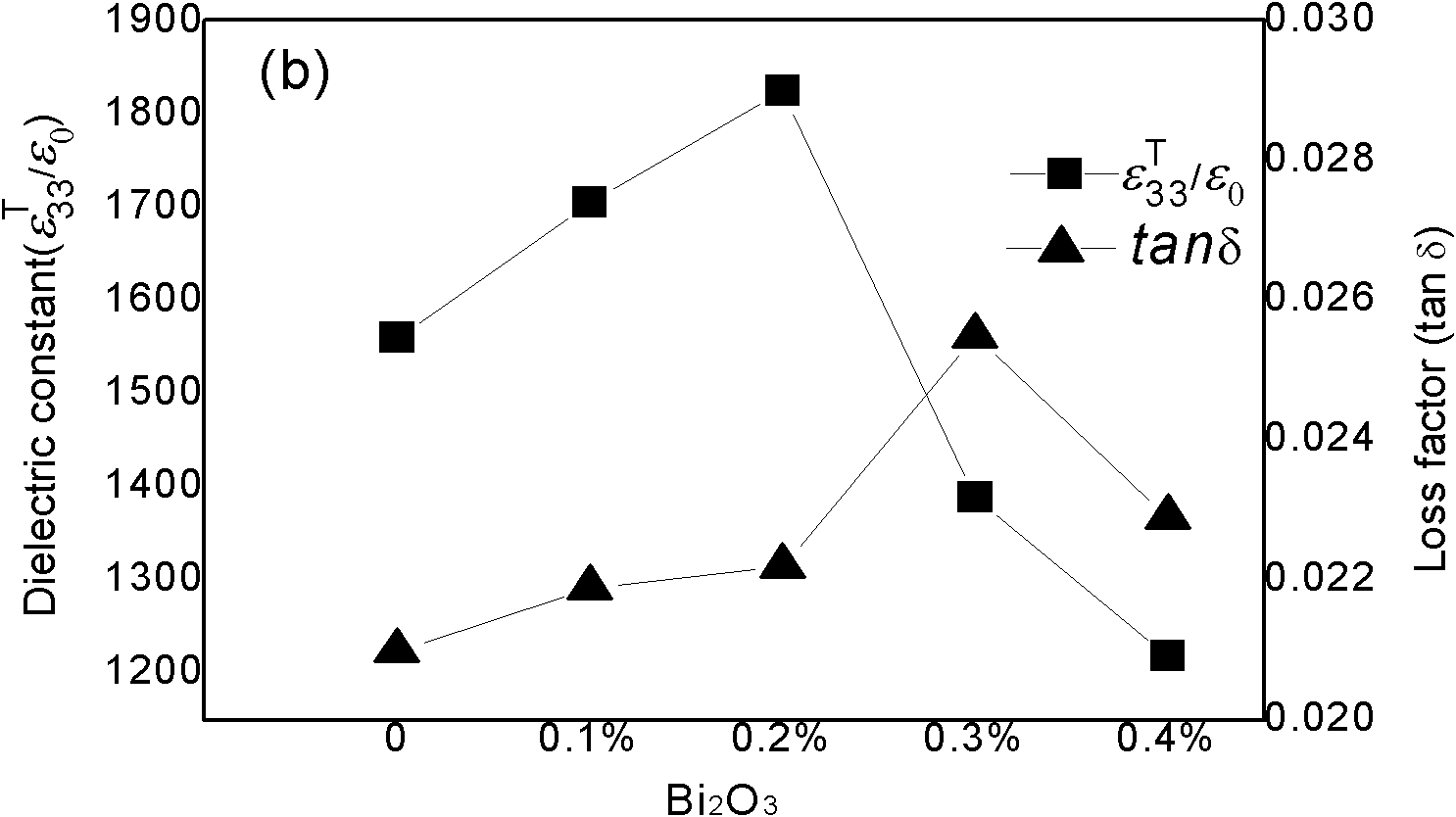

Bismuth scandate-lead titanate high-temperature piezoelectric ceramic material and preparation method thereof

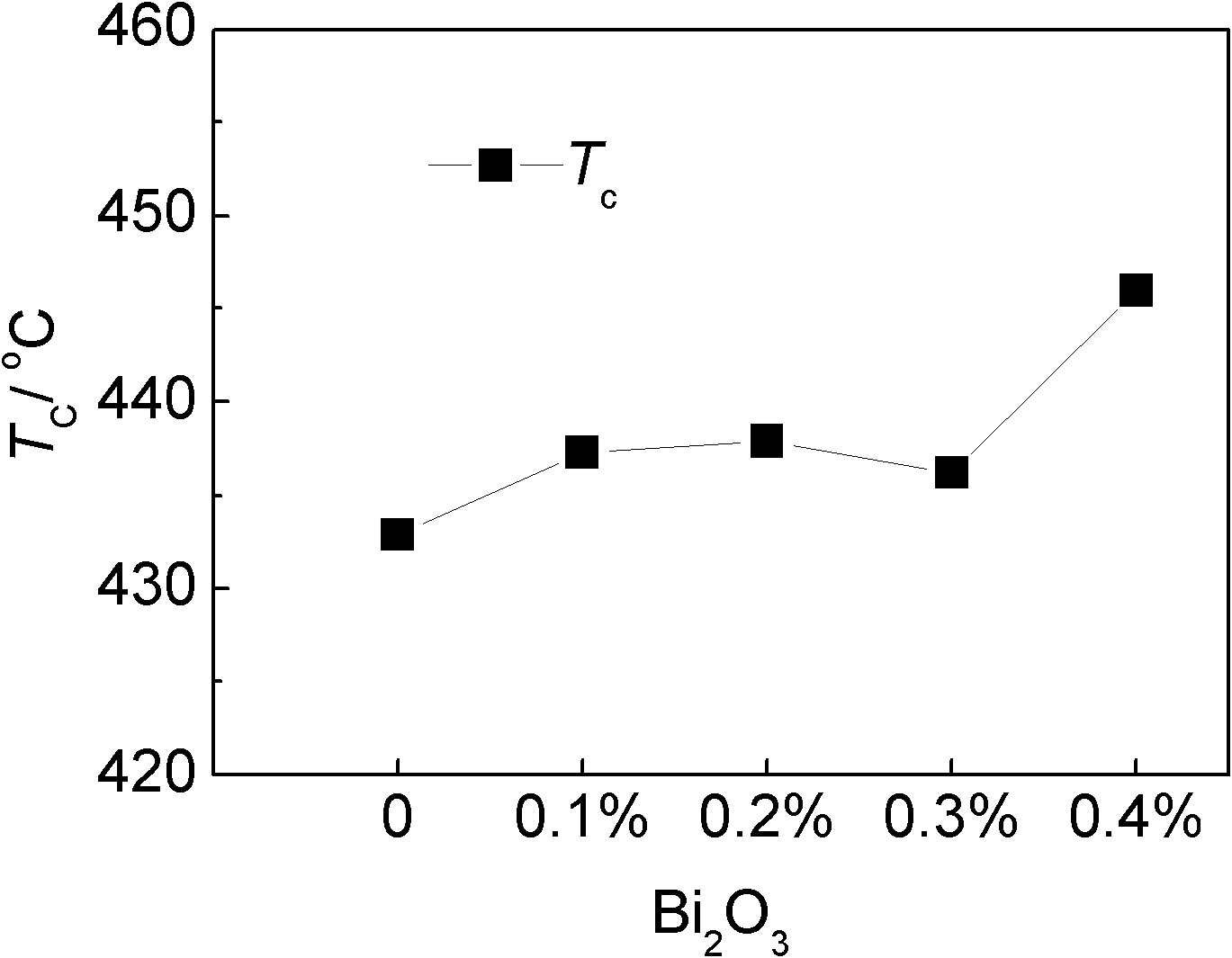

InactiveCN102180665AStoichiometric ratio is accurateLower sintering temperatureCeramic sinteringCurie temperature

The invention discloses a bismuth scandate-lead titanate high-temperature piezoelectric ceramic material. The bismuth scandate-lead titanate high-temperature piezoelectric ceramic material comprises a matrix with the chemical formula of xBiScO3-(1-x)PbTiO3 and bismuth trioxide (Bi2O3) in an amount which is less than 0.4 percent of the total weight of the matrix. The bismuth scandate-lead titanate high-temperature piezoelectric ceramic material is prepared by adding excess Bi2O3 into raw materials of Sc2O3, Bi2O3, Pb3O4 and TiO2 in the metering ratio according to the chemical formula of xBiScO3-(1-x)PbTiO3, wherein x is 0.35 to 0.38; and the using amount of the excess Bi2O3 is 0.1 to 0.4 percent of the total weight of the raw materials of Sc2O3, Bi2O3, Pb3O4 and TiO2 in the metering ratio according to the chemical formula of xBiScO3-(1-x)PbTiO3. The bismuth scandate-lead titanate high-temperature piezoelectric ceramic material solves the problems that ceramic sintering temperature is increased and piezoelectric and dielectric properties are reduced due to deviation of a stoichiometric ratio caused by bismuth volatilization in the sintering process of BSPT ceramic, and has high Curie temperature, excellent piezoelectric property and an actual application value in high-temperature electronic equipment. The invention also discloses a preparation method for the bismuth scandate-lead titanate high-temperature piezoelectric ceramic material. In the preparation method, the piezoelectric ceramic material is prepared by synthesizing and sintering at lower temperature, so production cost is reduced, process steps are simplified, and the material has actual application value.

Owner:MORNSUN GUANGZHOU SCI & TECH +1

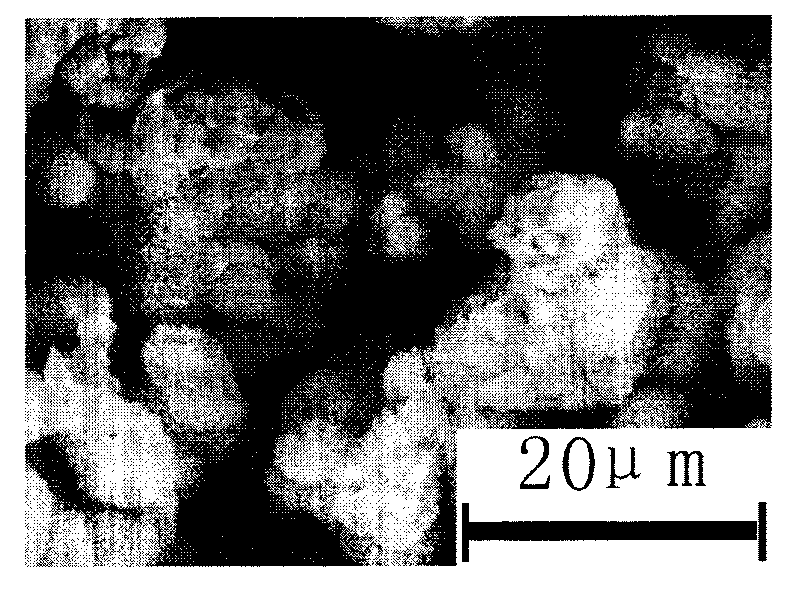

Preparation method of silicon dioxide/silver core-shell composite powder for high temperature electronic paste

ActiveCN103231072AGood dispersionUniform sizeConductive layers on insulating-supportsLiquid/solution decomposition chemical coatingDispersityHydrogen Nitrate

The invention provides a preparation method of silicon dioxide / silver core-shell composite powder for high temperature electronic paste and belongs to the technical field of electronic paste. The preparation method includes: manufacturing silicon dioxide nano-particles firstly, adding a hydrogen nitrate solution to adjust pH value, adding a stannous chloride solution after centrifugal cleaning, adding silicon dioxide microspheres in a silver ammonia solution to be soaked under the condition of ultrasound and then performing centrifugal separation, and enabling a layer of silver nano-particles to be generated on the surfaces of the silicon dioxide microspheres; adding silver nitrate and a dispersing agent under the condition of stirring, and then adding ascorbic acid to obtain silver-plated silicon dioxide composite powder; and removing reaction residues by using a deionized water centrifugal sedimentation and ultrasonic dispersion cycle cleaning mode to obtained the silicon dioxide / silver core-shell composite powder. The preparation method of the silicon dioxide / silver core-shell composite powder for the high temperature electronic paste is simple to operate and low in cost, and particles obtained by the preparation method are remarkable in core-shell structure, even in particle size, high in solid content, ordered in height, good in dispersity and have various application prospects in the aspects of biological sterilization, chemistry, optical materials, electronic paste and the like.

Owner:昆明高聚科技有限公司

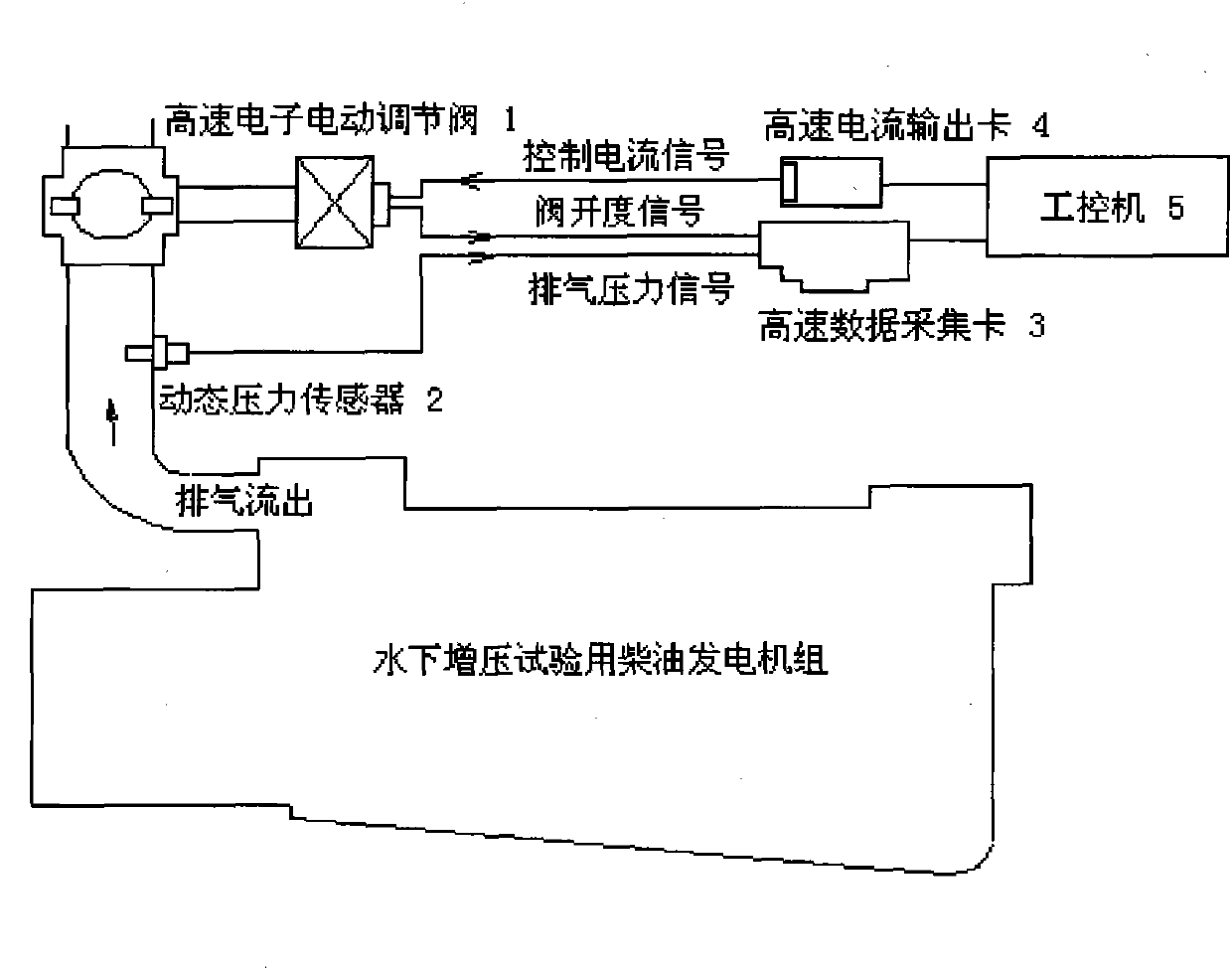

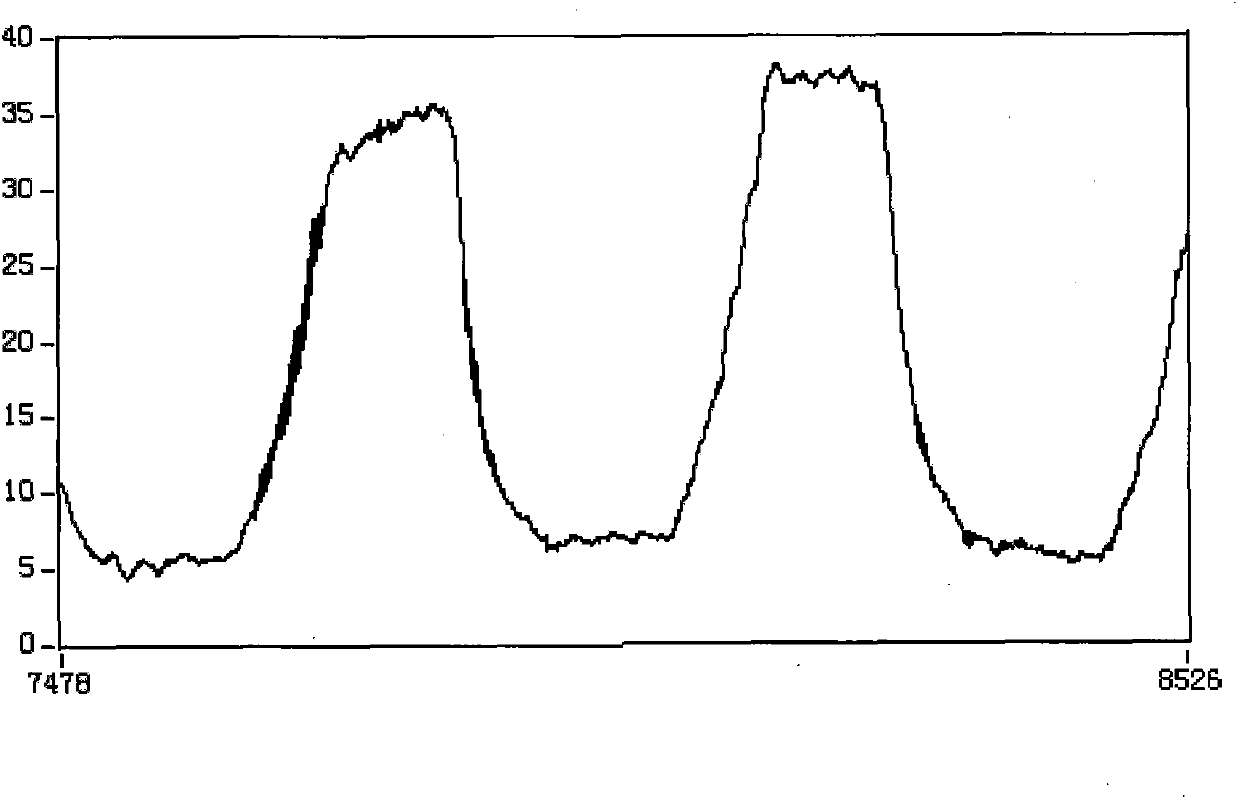

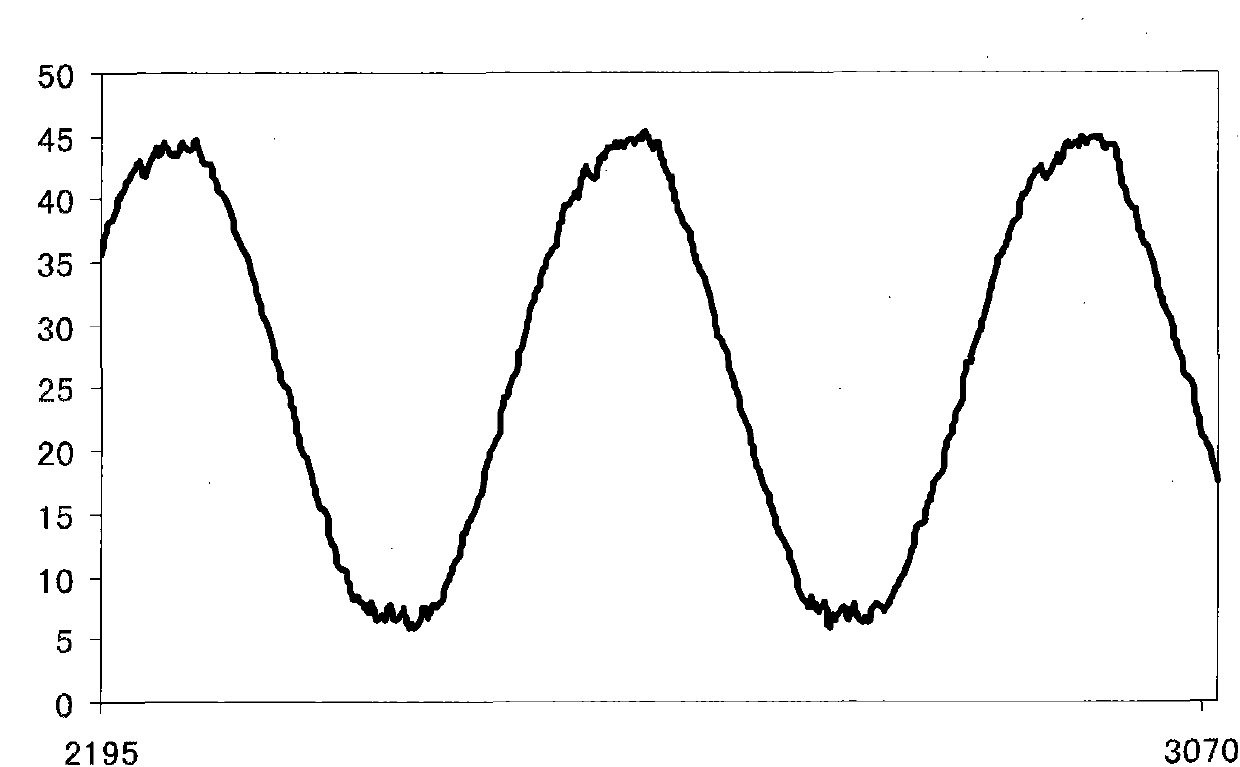

Exhaust back pressure wave adjustment device for supercharged diesel engine

ActiveCN102087168AAchieve the desired effectMeet the needs of performance testingInternal-combustion engine testingA wave amplitudeSea waves

The invention discloses an exhaust back pressure wave adjustment device for a supercharged diesel engine. A high-temperature electronic and electric adjustment valve receives control current of a high-speed current output card, controls the upstream exhaust pressure through the magnitude of the opening of a valve body and feeds back the opening signal of the valve body to a high-speed data acquisition card; a dynamic pressure sensor converts the exhaust pressure signal into a current signal; the high-speed data acquisition card acquires an exhaust pressure wave, the opening value of the high-temperature electronic and electric adjustment valve and the feedback numerical value of the control current; the high-speed current output card discretizes the curve of the control current signal and outputs the discretized curve of the control current signal to a signal input end of the high-temperature electronic and electric adjustment valve; and an industrial personal computer is used for acquiring and processing signals, sending control signals, and generating, displaying, comparing and storing data curves. The device can simulate the dynamic exhaust back pressure wave which is generated by motion of sea waves and applied to a diesel engine working underground in an air pipe state, and the wave form, the wave amplitude and frequency can be adjusted.

Owner:NO 711 RES INST CHINA SHIPPING HEAVY IND GRP

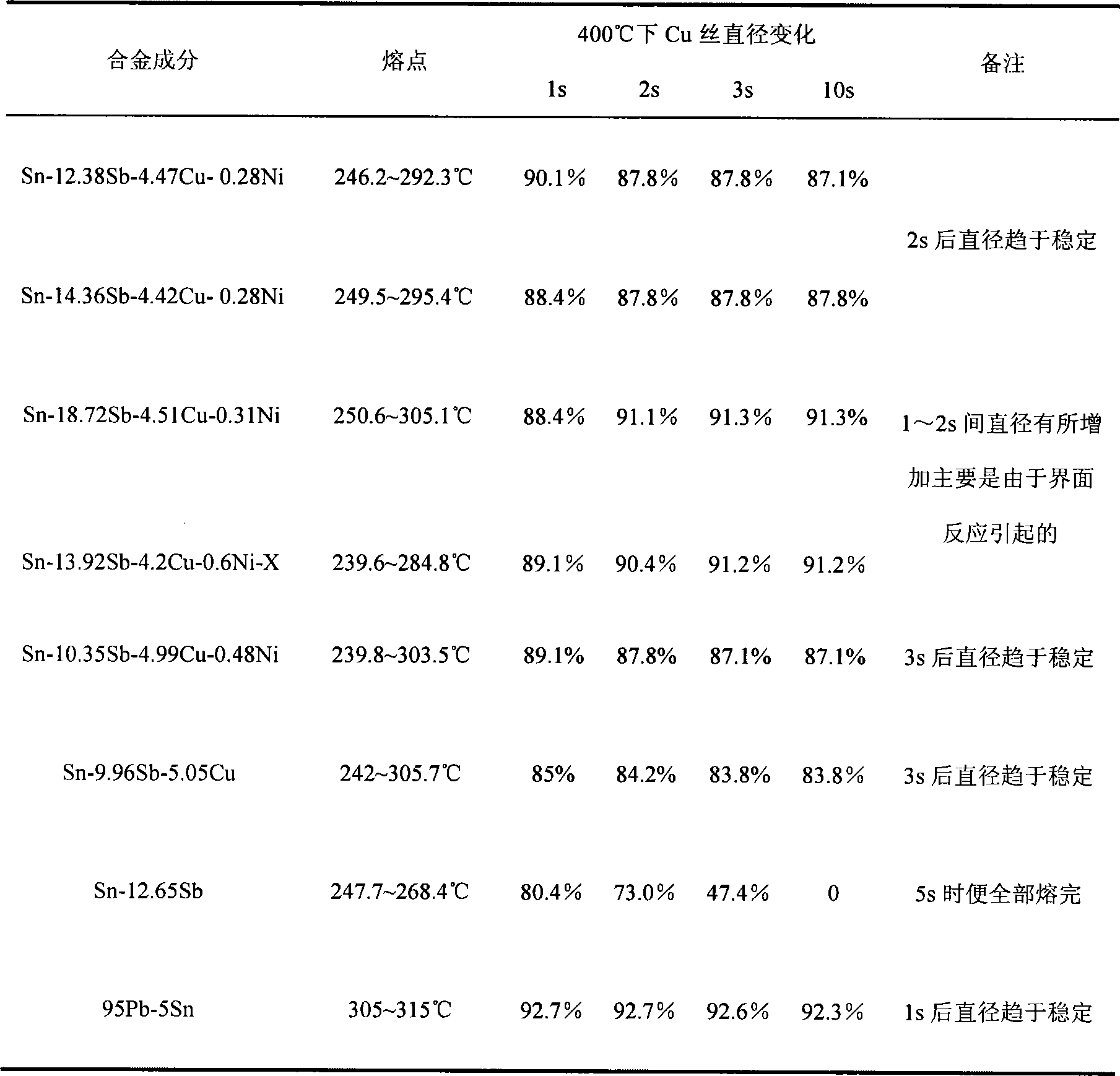

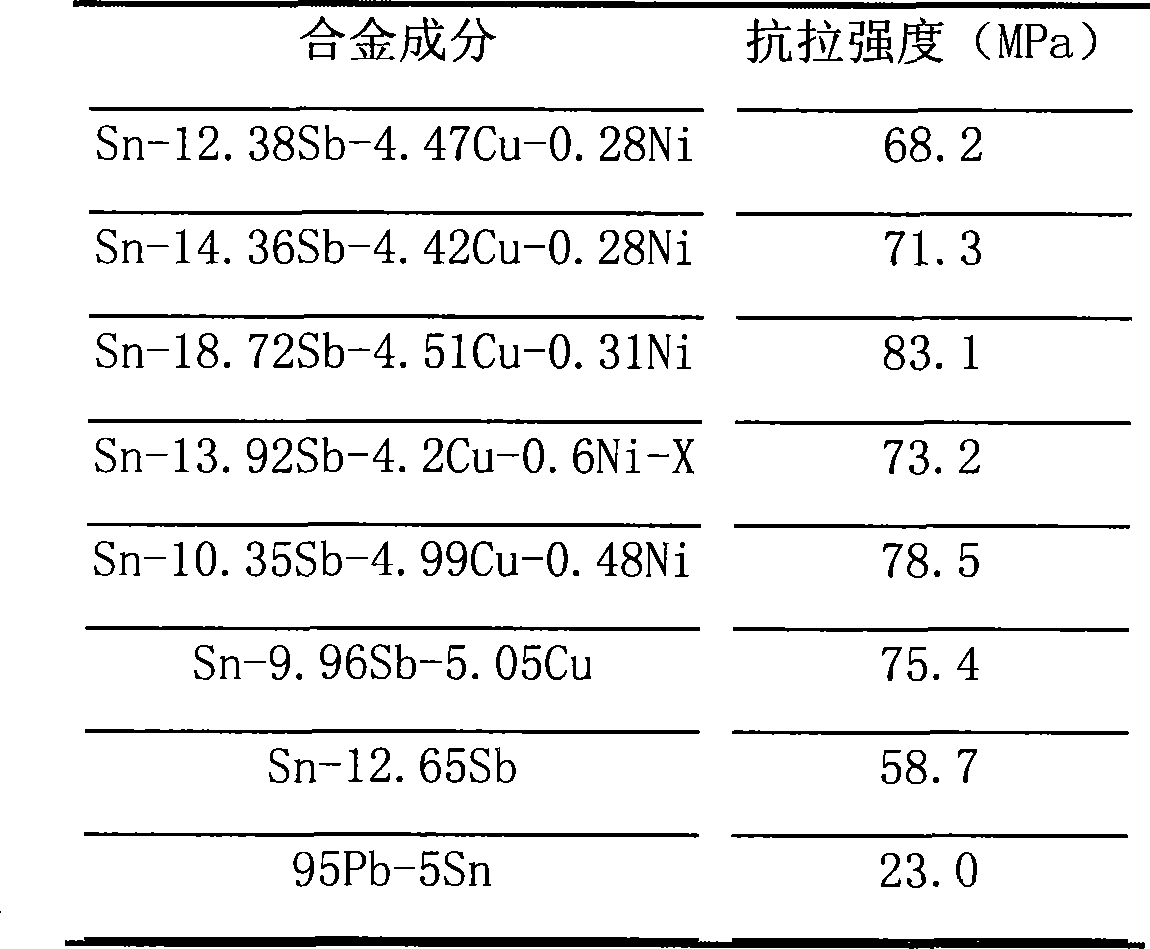

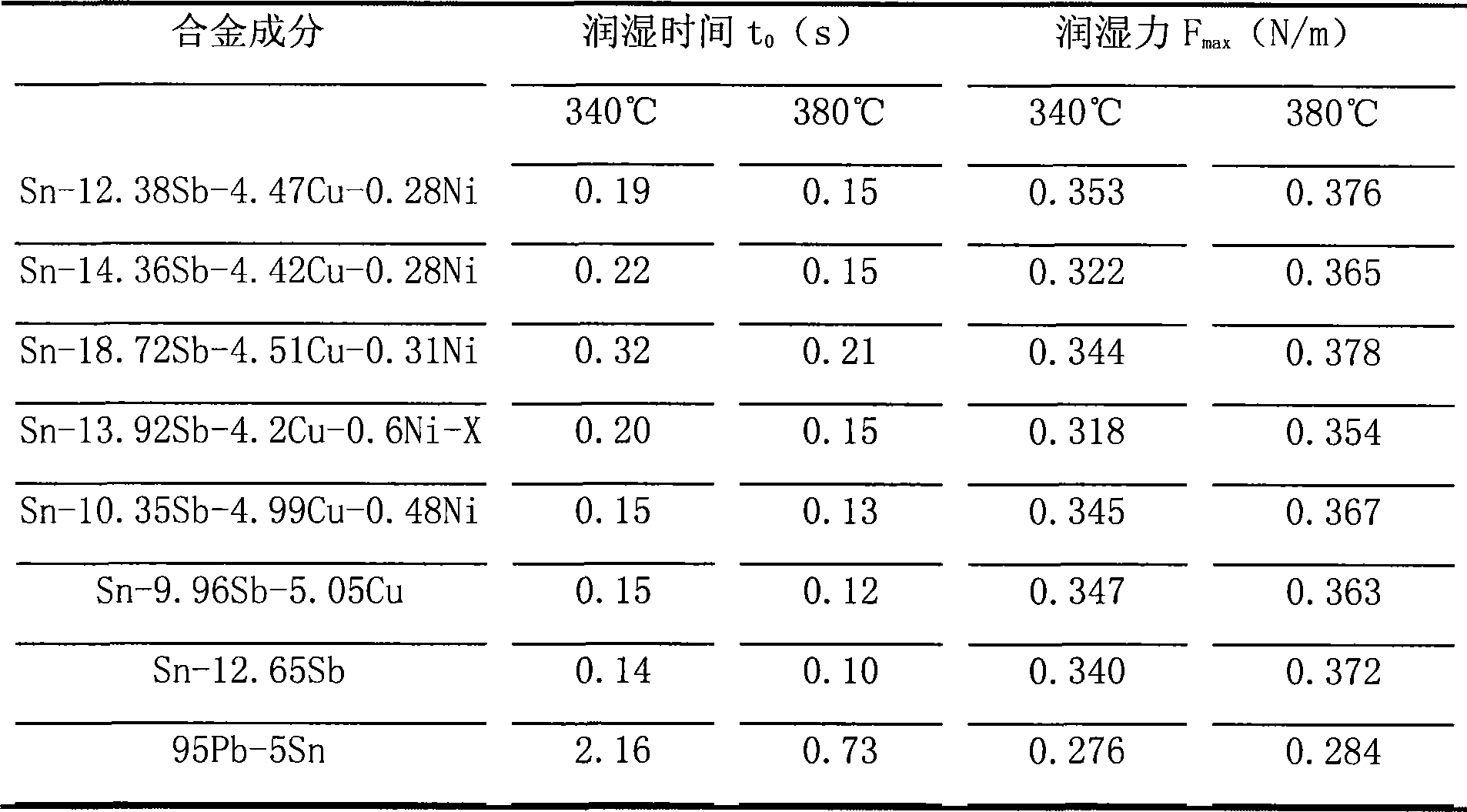

Leadless high-temperature electronic solder and preparation

InactiveCN101239425AHigh melting temperatureImprove antioxidant capacityWelding/cutting media/materialsSoldering mediaRare earthHigh temperature electronics

A leadless hyperthermia electronic solder and preparing method thereof are disclosed. The solder is composed of alloy elements according to flowing percentage by weight: 10-224546014f Sb, 1-84550160f Cu, 0.01-224446740f Ni, 0-0.012f X, residue percent of Sn; wherein X represents zero species, one species or composition of optimal several species of Ga, P and mixed rare earth; the fusion point of the solder is between 240 DEG C to 320 DEG C, the tensile strength is 58-84MPa; the preparing method of the solder is: thermal insulating the prepared each alloy element at a temperature ranging from 850 DEG C to 900 DEG C for 1-2 hours by using a vacuum melting furnace or an antivacuum smelting furnace to melt them sufficiently, and mixing them sufficiently before discharged from the furnace, pouring, solidifying to obtain the solder; the solder is made into at least one of solder master alloy, solder block, soldered ball, soldering ring, soldering foil, soldering powder or soldering cream; the solder is provided with a higher fusion point to improve the fusion activity of solder, enhanced credibility of device, good antioxidant ability and excellent humectation performance.

Owner:ZHEJIANG METALLURGICAL RES INST

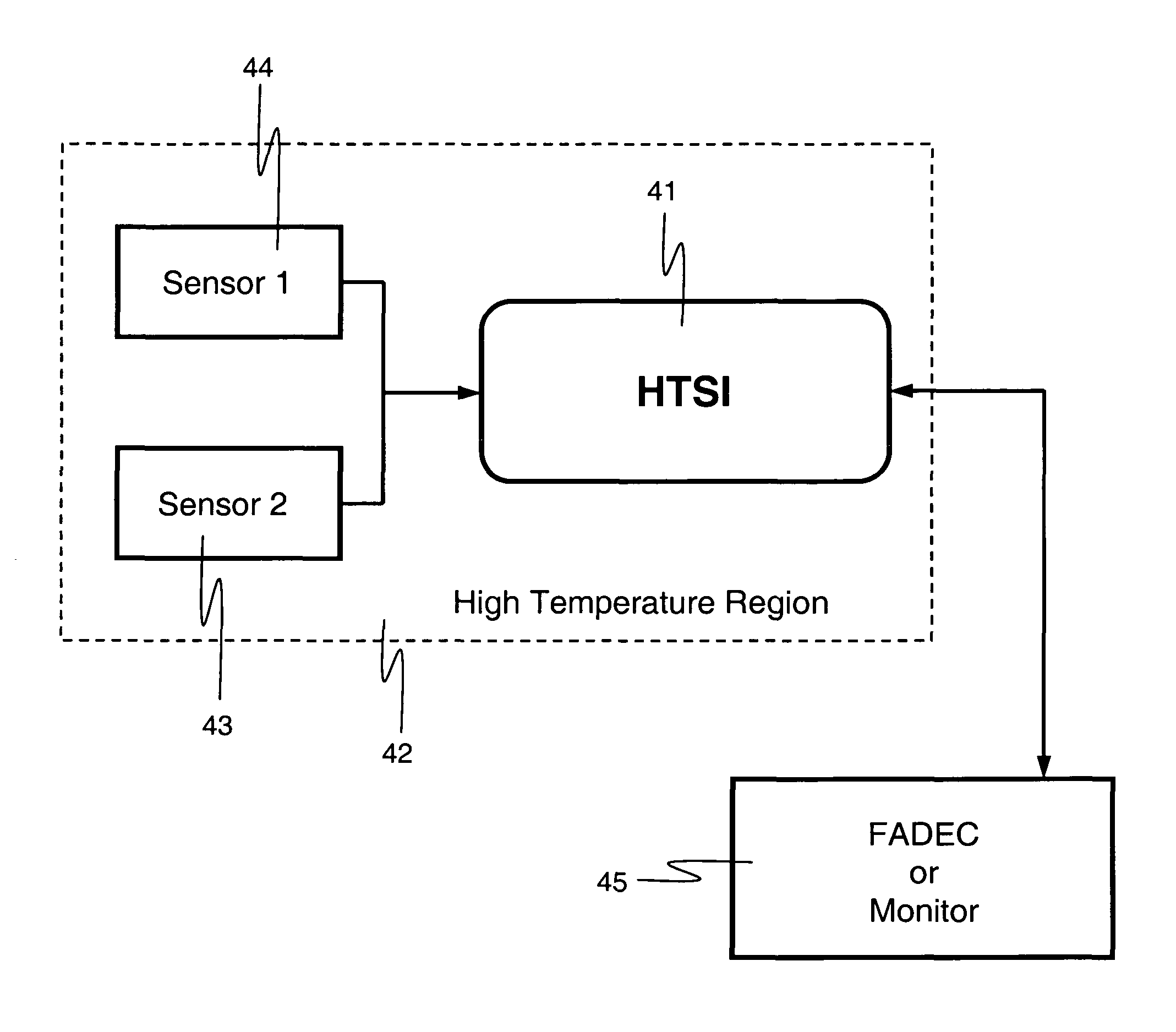

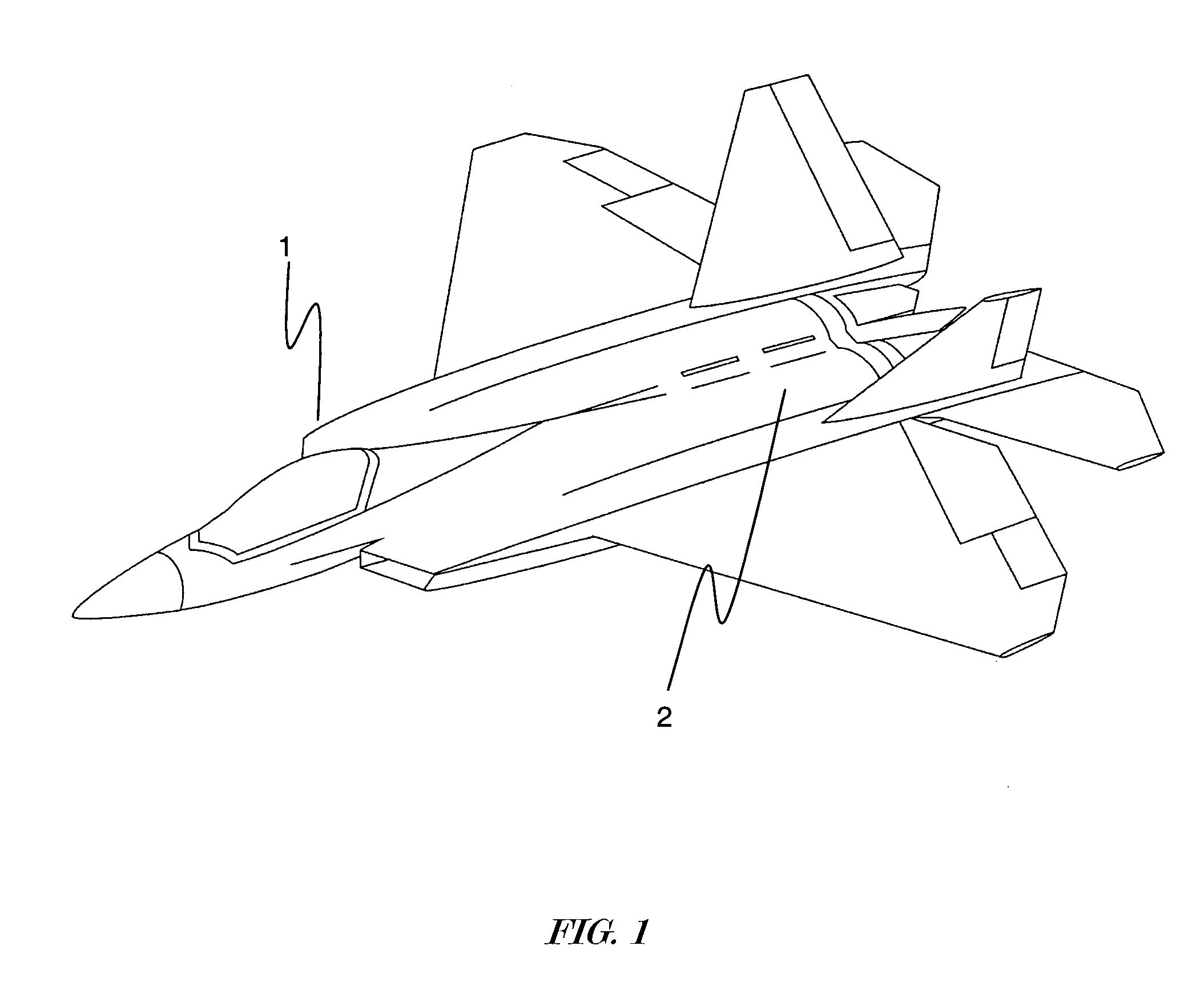

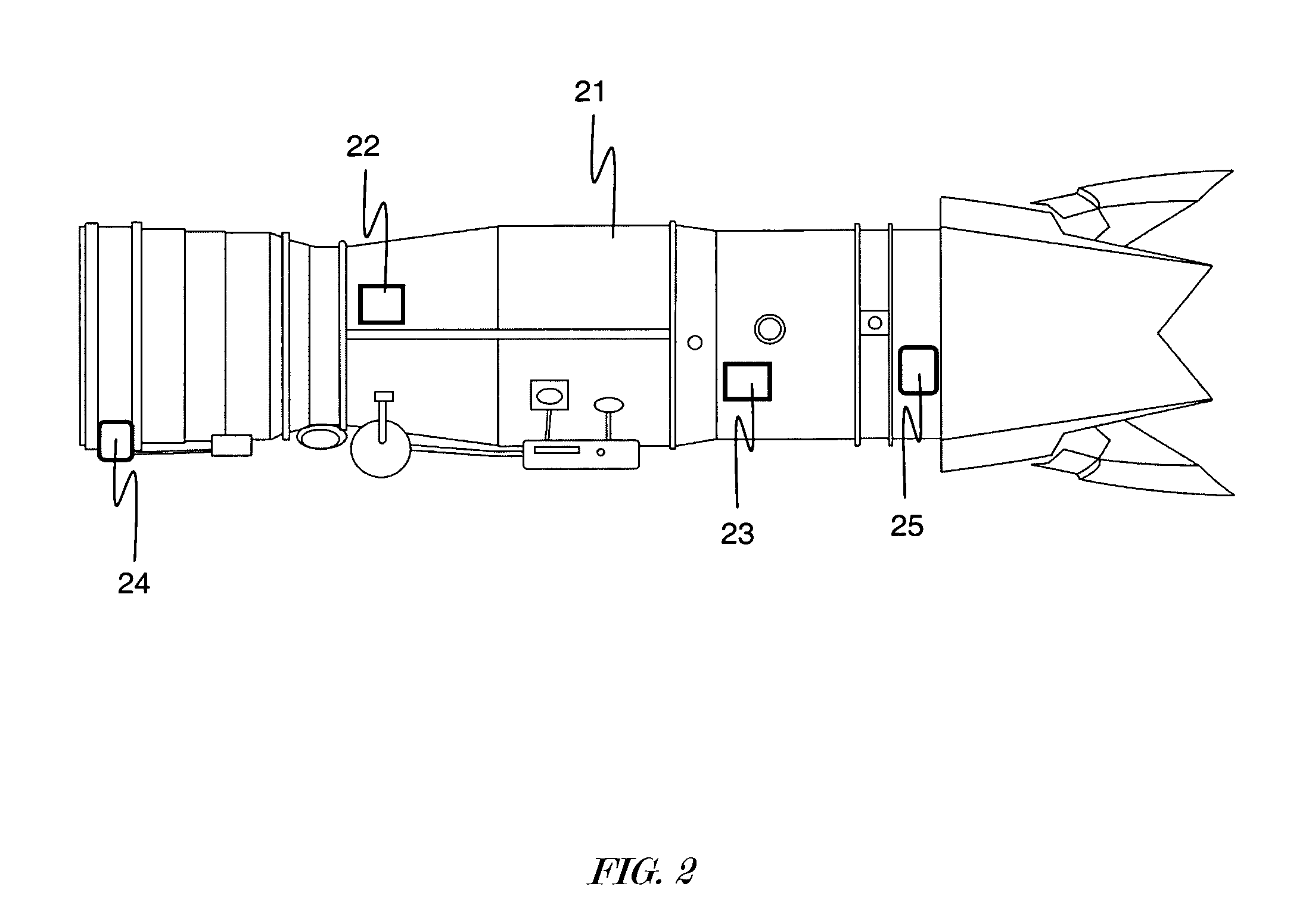

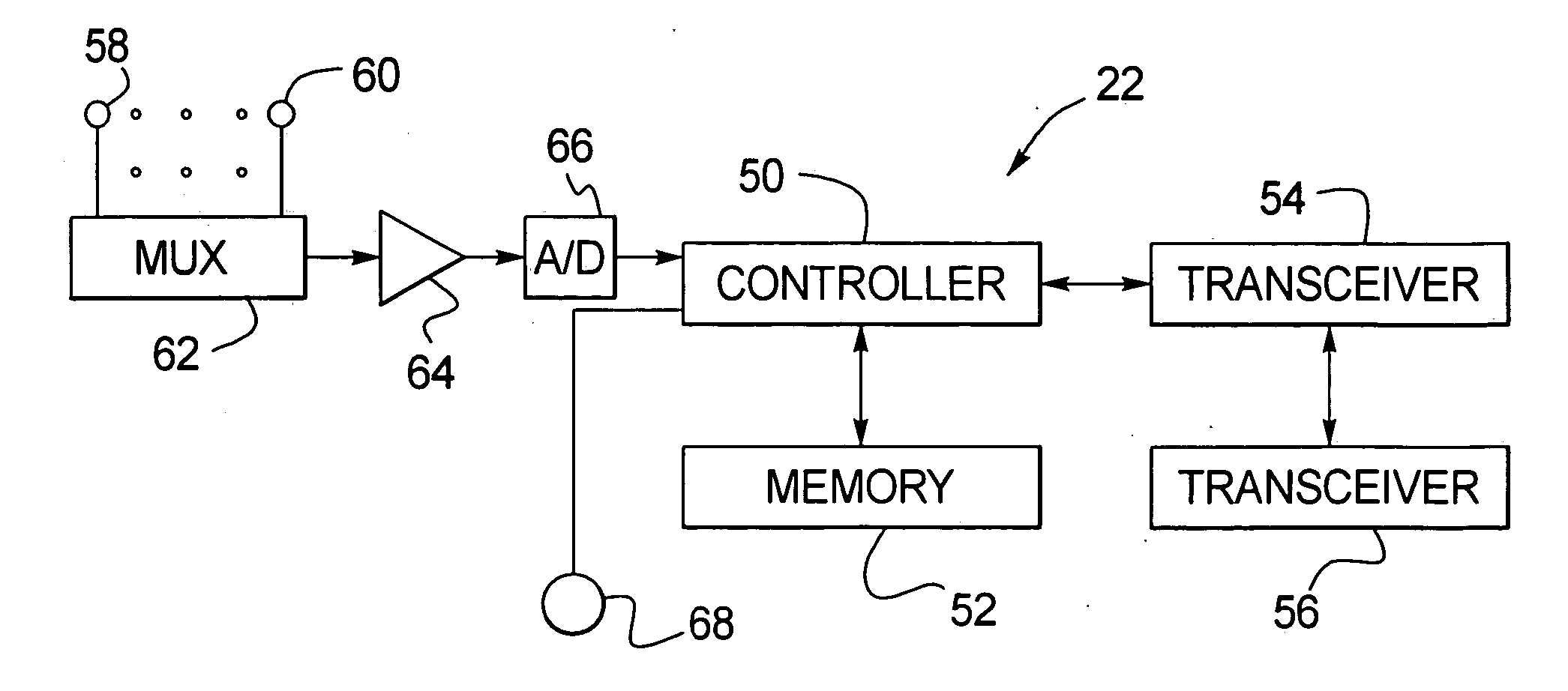

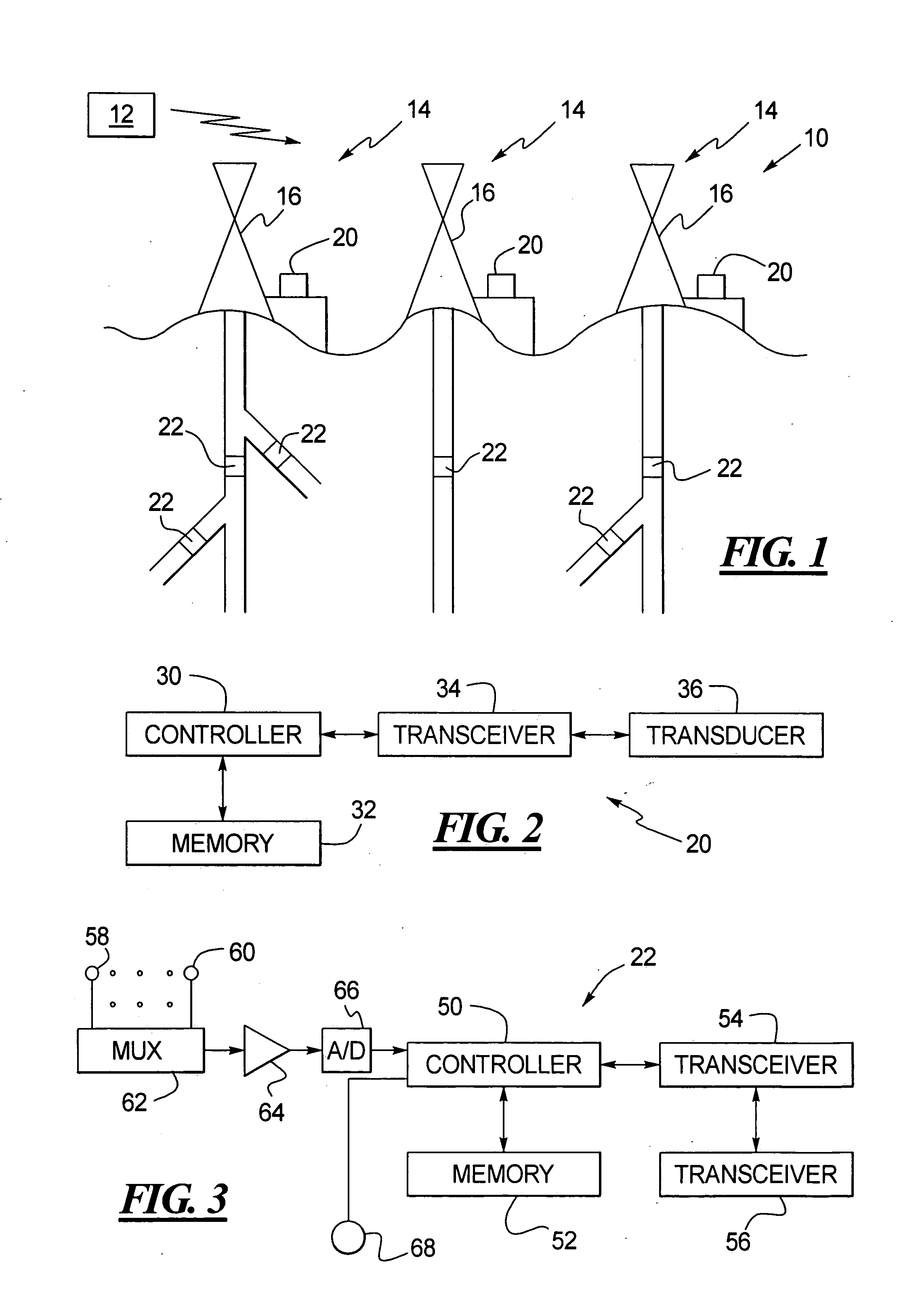

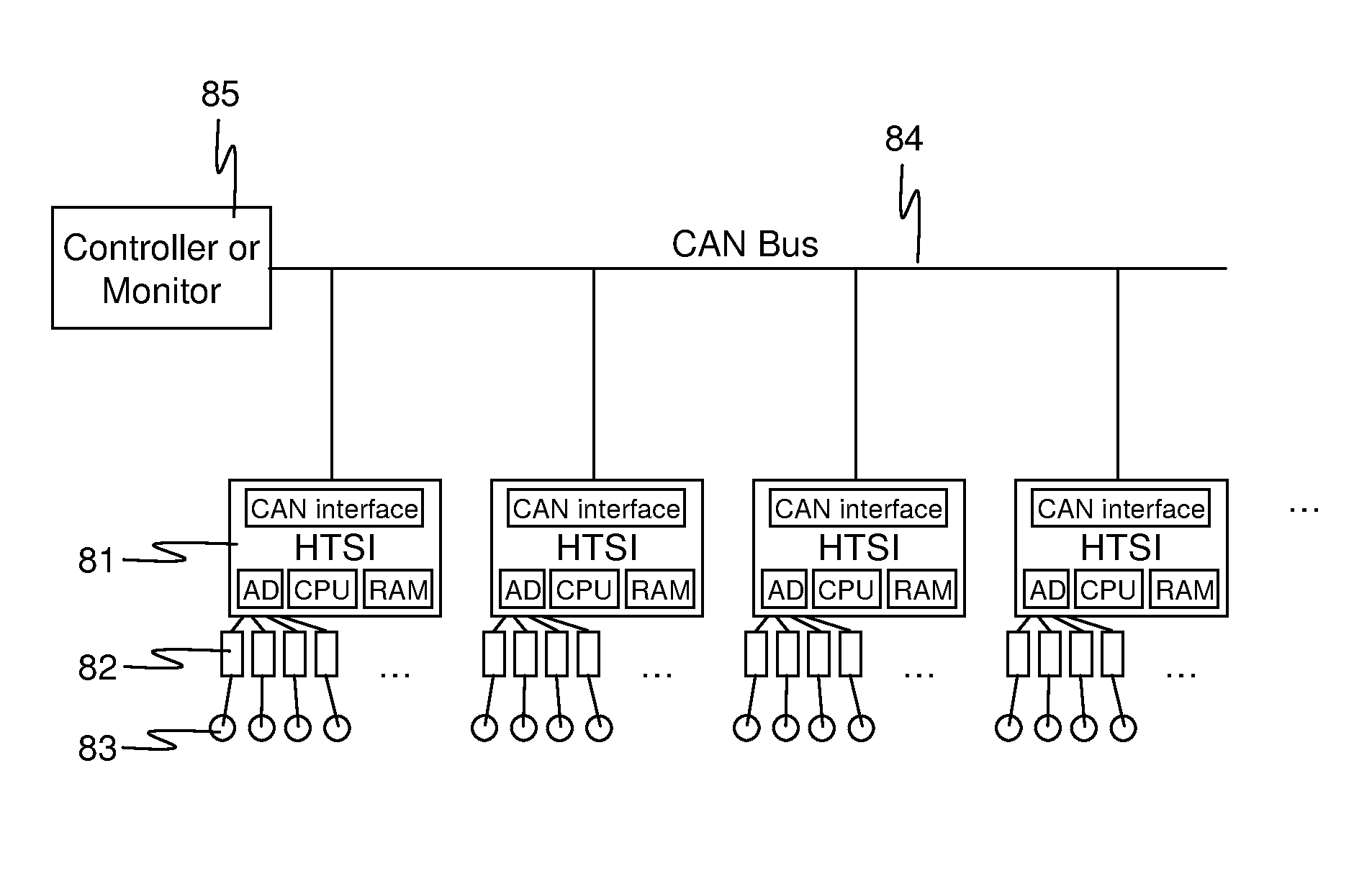

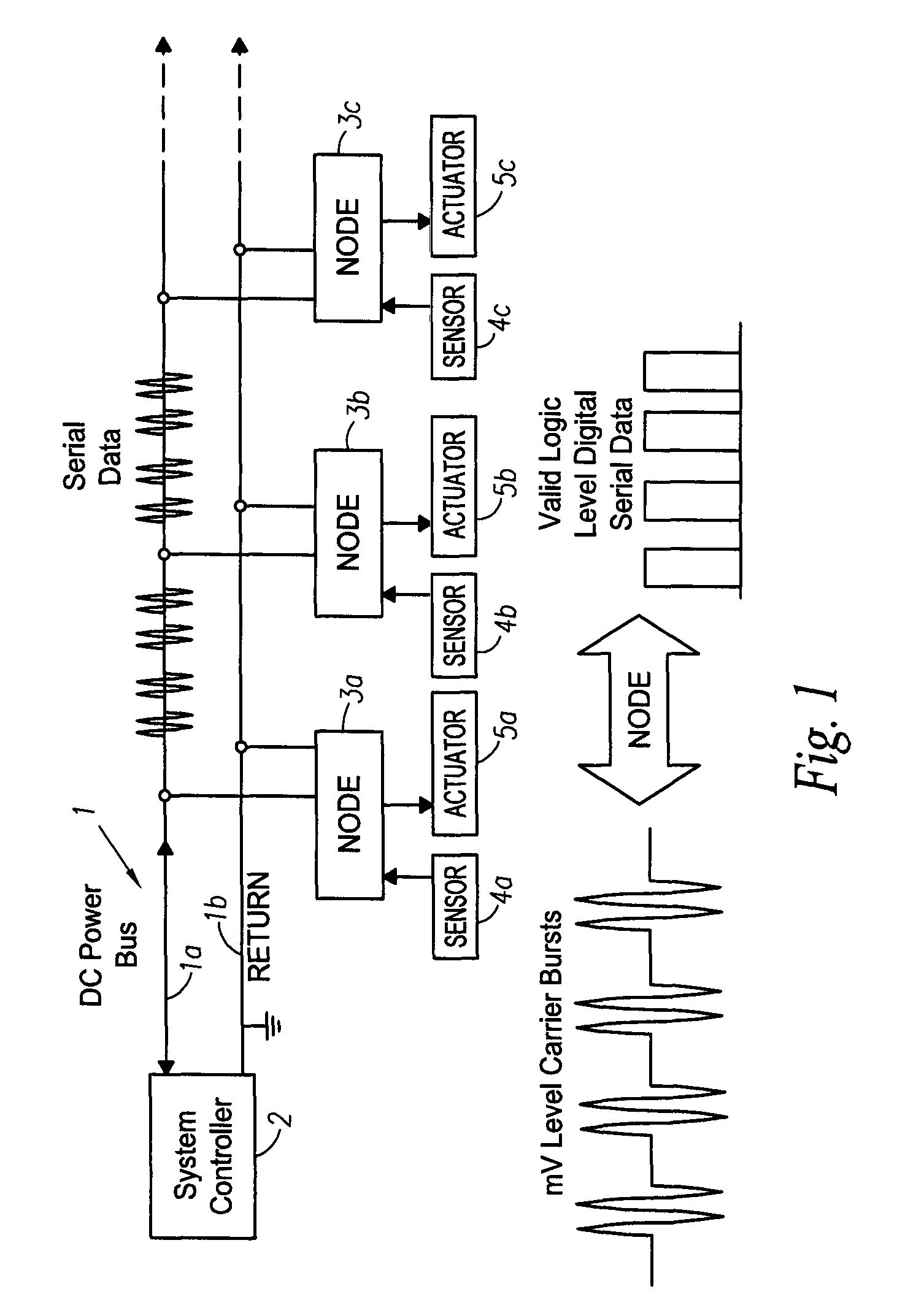

High-temperature sensor interface and network

The present invention is a sensor interface or network of interfaces that utilizes high-temperature electronics to operate at elevated temperatures for applications that include but are not limited to aircraft and automobile engines, vehicle frames, refineries, nuclear and chemical production plants, and in downhole drilling for petroleum and natural gas. The interface or network provide connectors for a variety of sensors with analog and digital outputs, and can in turn provide data to an automated electronic control system or a monitor. Because the sensor interface may be placed in so-called “hot zones” nearer to the sensors being monitored than other systems that use conventional electronics, the sensor interface can increase noise immunity, increase reliability, decrease cost, reduce weight, and increase space.

Owner:ORBITAL RES

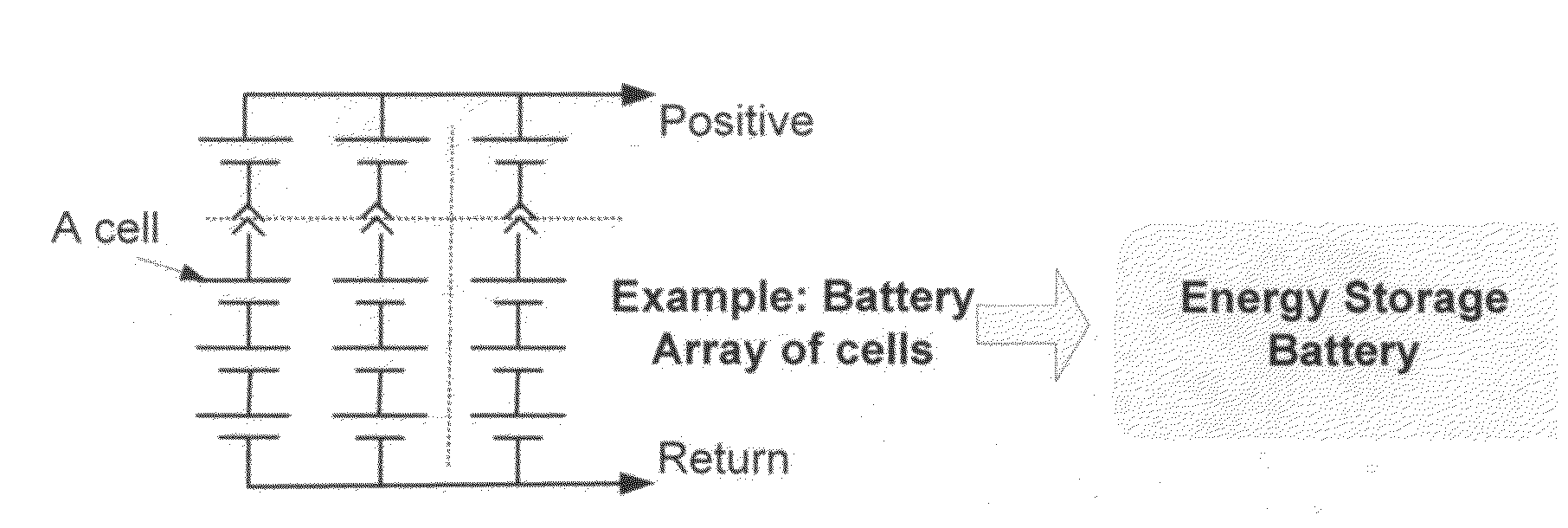

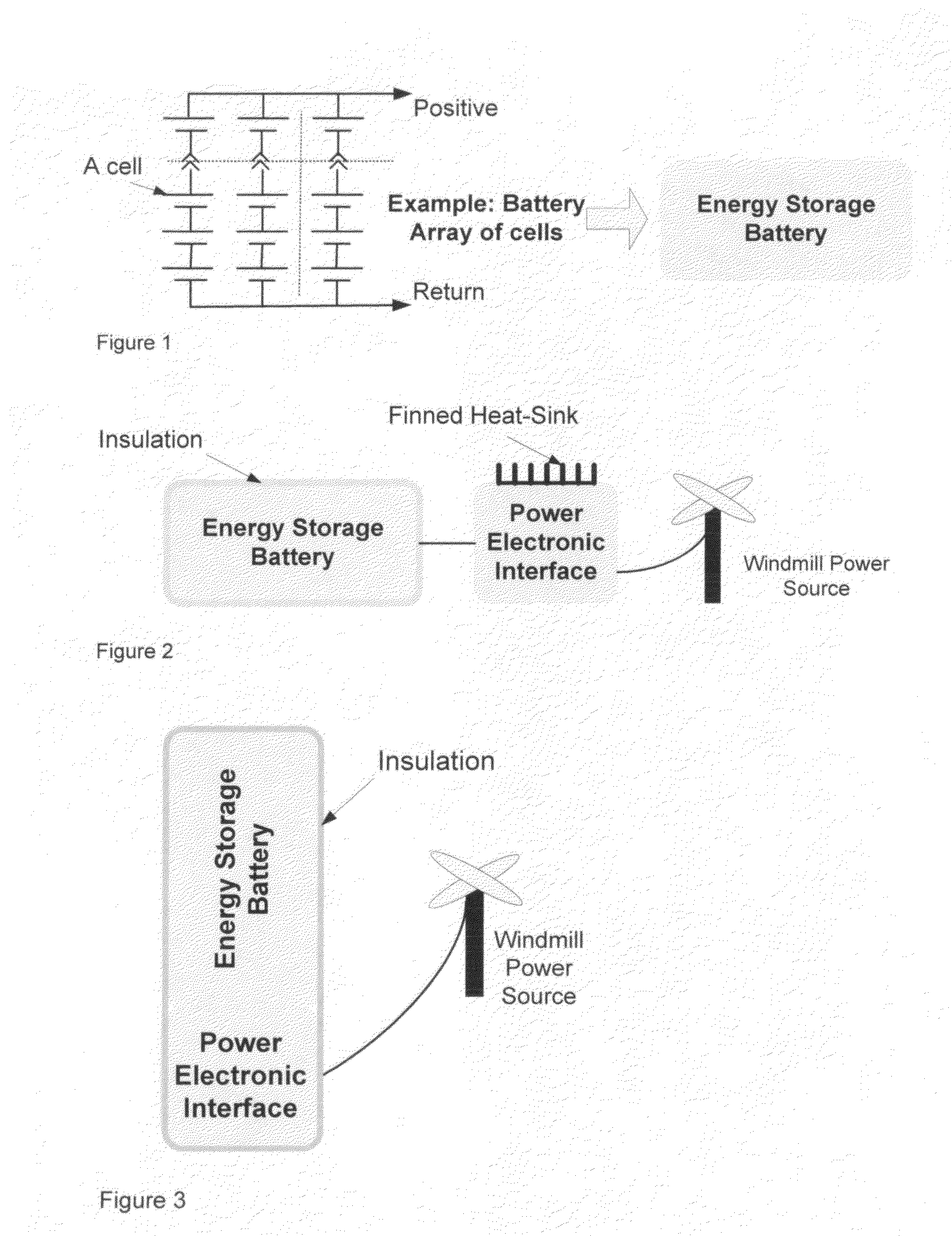

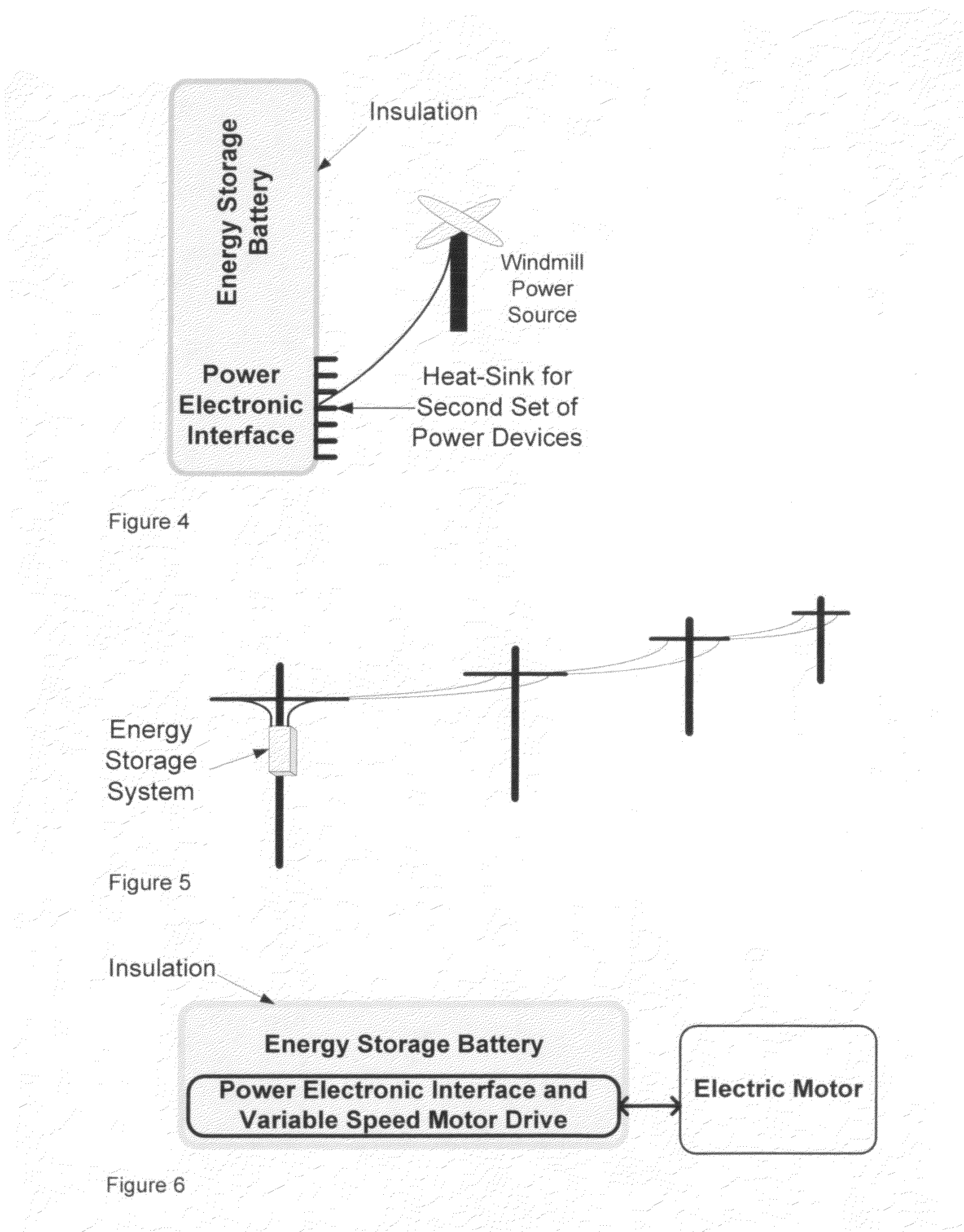

Coupling waste heat into batteries

InactiveUS20100330403A1Improved thermal managementReduce eliminateFinal product manufactureCell temperature controlInternal resistanceGallium nitride

A system for maintaining battery temperatures for energy storage systems using heat created by power electronic device needed to interface the batteries to external power sources or loads is described. Waste heat is a product of internal resistance found in all electronic devices passing current. High-temperature electronics comprised of, silicon-on-insulator, silicon-on-sapphire, silicon-carbide, gallium-nitride or in conjunction with or combination of other wide bandgap semiconductors can used to monitor, charge or discharge the battery array. A thermal system where heat generated by power electronics is used to assist the thermal management of battery energy storage system increases overall system efficiency.

Owner:NORMANN RANDY ALLEN

Well control and monitoring system using high temperature electronics

A remote control center controls and monitors a plurality of wells. A surface control and monitoring system is located at each of the wells, and each of the surface control and monitoring systems is in communication with a remote control center. Also, a down hole monitoring and control system is provided within each of the wells, and each of the down hole monitoring and control systems is in communication with at least one of the surface control and monitoring systems. Each of the down hole monitoring and control systems comprises non-cooled, high temperature electronic equipment that can withstand the high temperature environment within the corresponding well.

Owner:HONEYWELL INT INC

Aluminum nitride porous ceramic and preparation method thereof

InactiveCN101734923AFine grainUniform distribution of poresCeramicwareNitrogen gasHigh temperature electronics

The invention discloses an aluminum nitride porous ceramic and a preparation method thereof. The aluminum nitride porous ceramic comprises the following components by weight percent: 60-72 percent of aluminum oxide, 1-10 percent of sintering assistant, 18-30 percent of carbon black and 1-10 percent of aluminum nitride seed crystal. The preparation method comprises the following steps of: carrying out ball milling mixture on the components with a wetting method to obtain mixed powder; carrying out mould pressing on the components for forming; placing a forming body into an atmosphere furnace, heating the forming body to 1650-1750 DEG C when the nitrogen pressure is higher than one pressure atmosphere and keeping the temperature for 1-4 hours to obtain a sintering body. The aluminum oxide and the carbon black with low cost are used as raw materials to prepare the aluminum nitride porous ceramic with high porosity, therefore, the invention can overcome the defects of the complicated process of preparing the aluminum nitride porous ceramic by using the traditional method and the excessive cost, and can be widely applied in photoelectricity fields of high-temperature electronic devices, microwave integrated circuits, mixed integrated circuits, power electronic modules, laser diodes and the like as well as reinforced phases of metal-based composite materials.

Owner:XI AN JIAOTONG UNIV

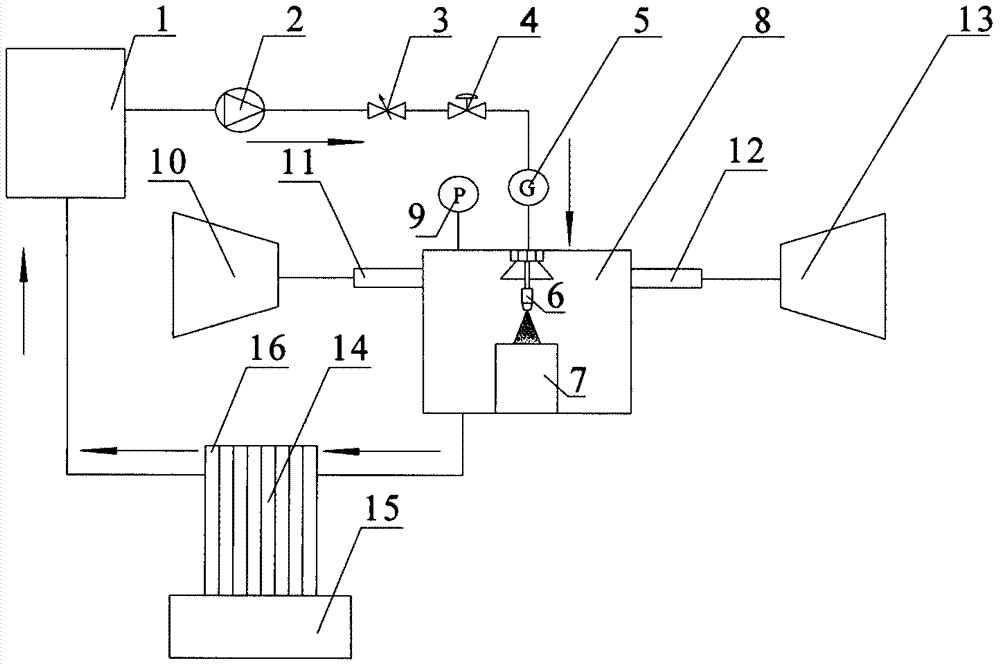

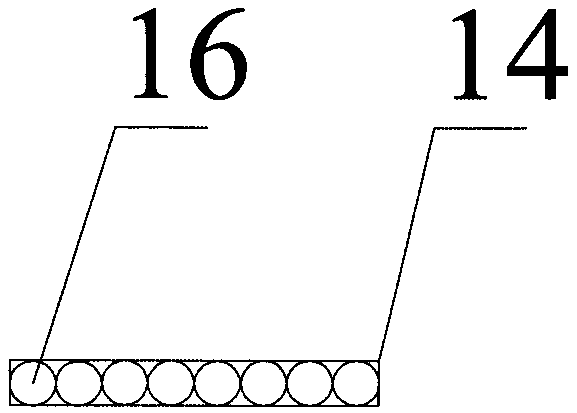

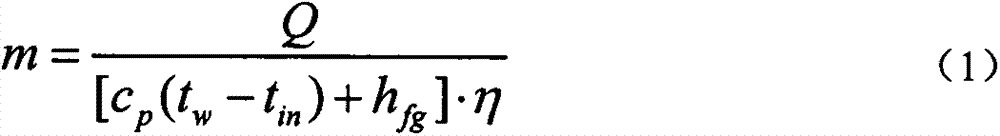

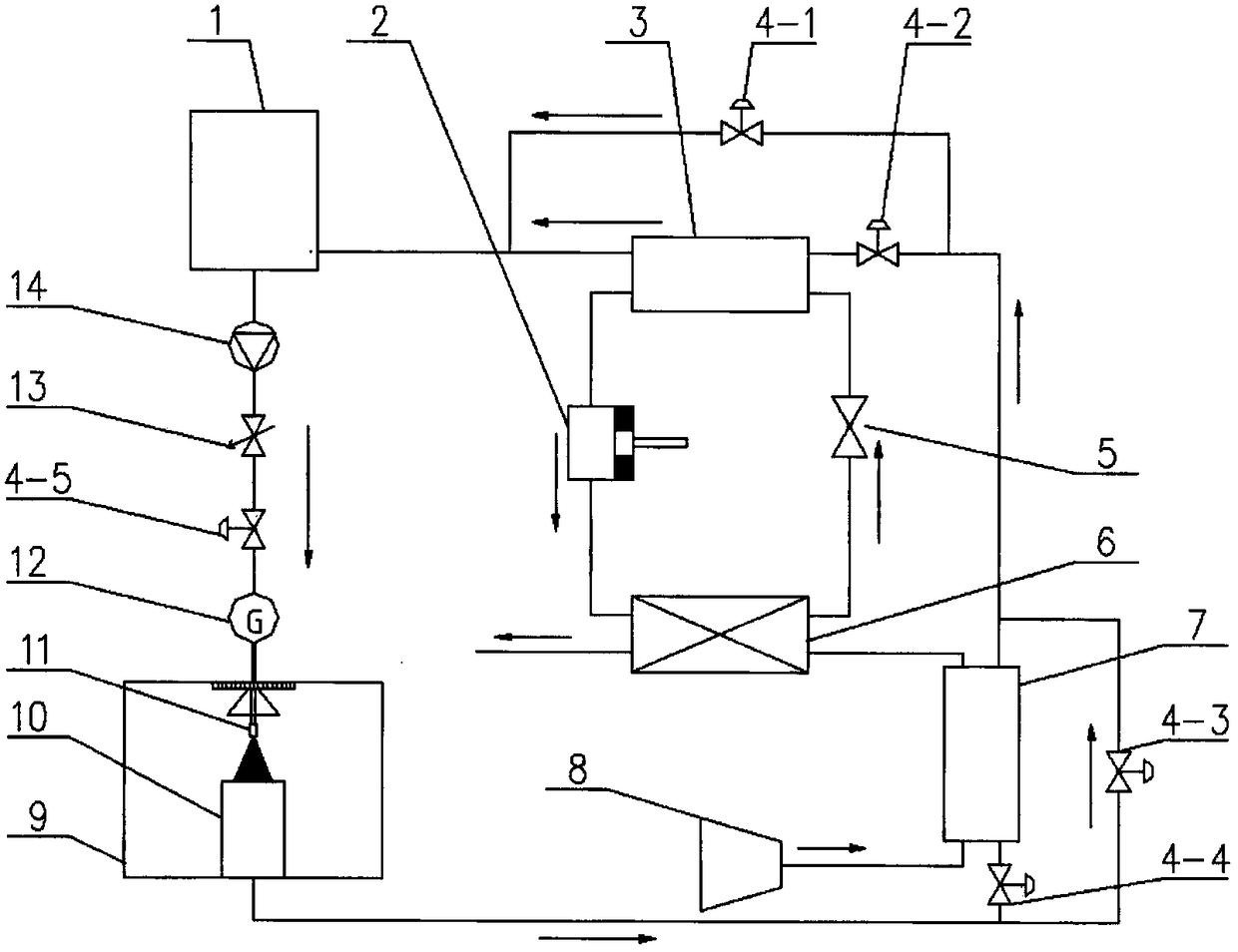

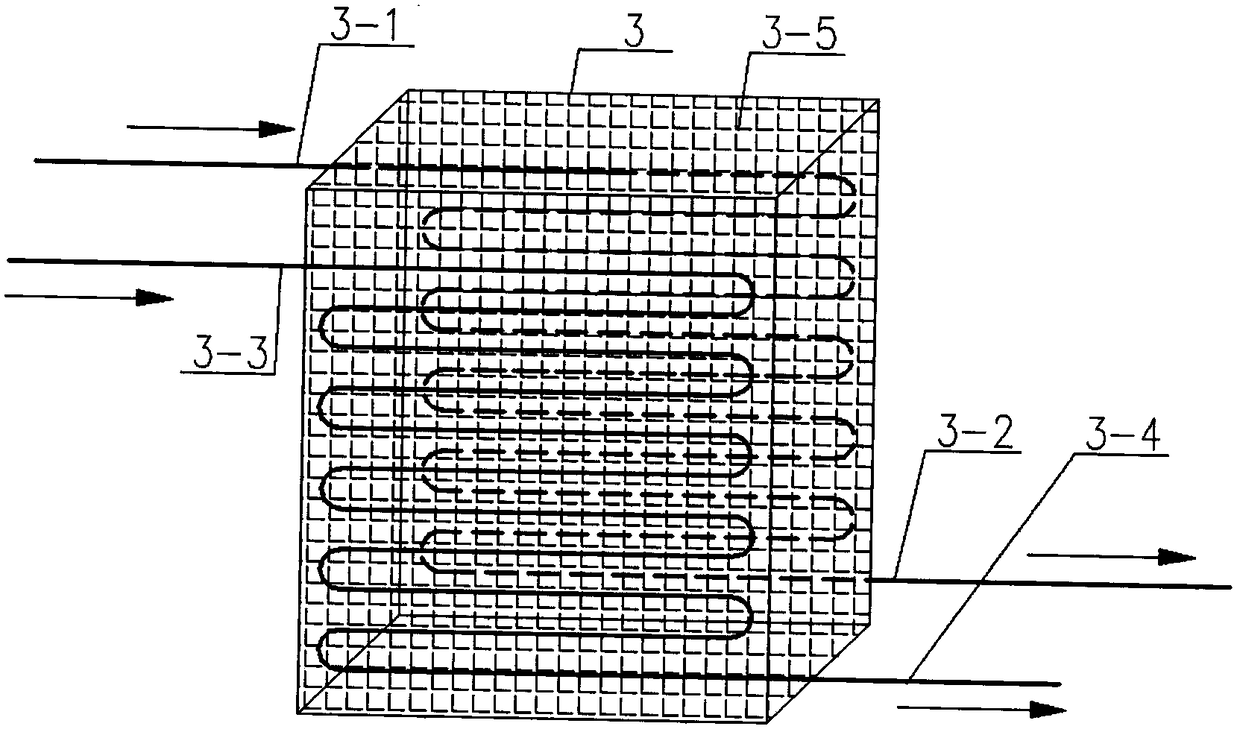

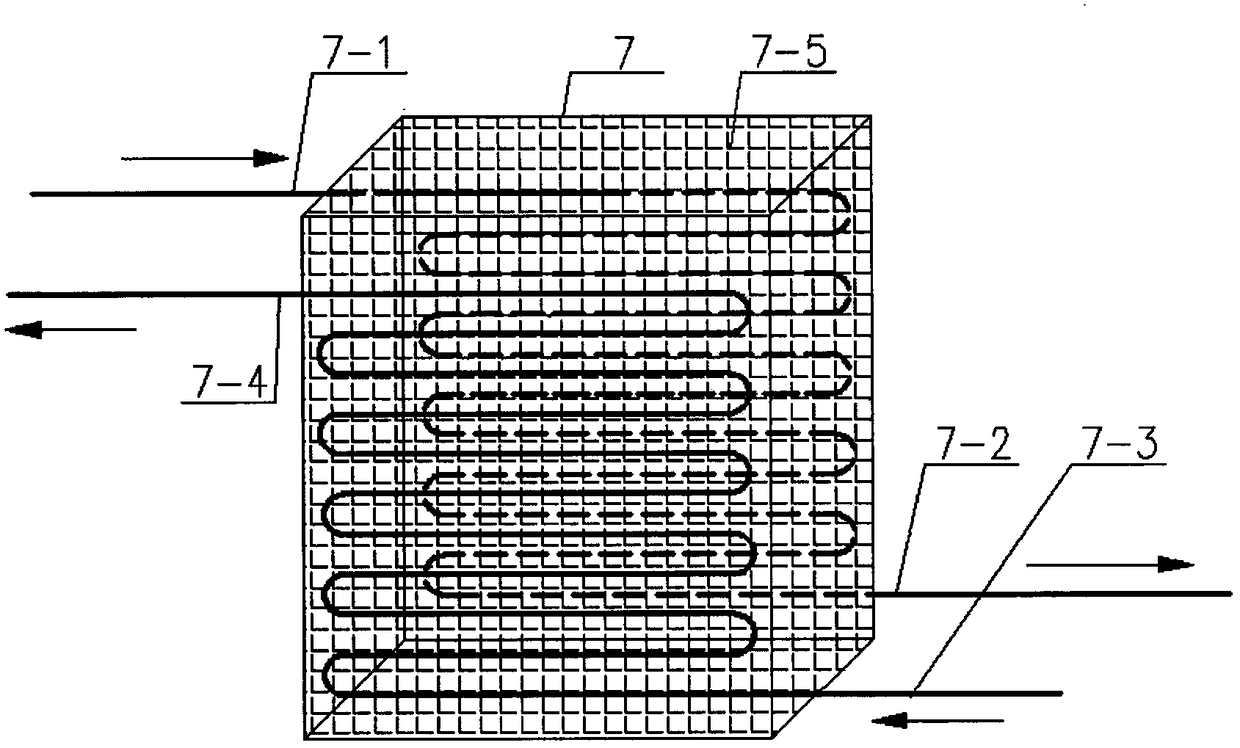

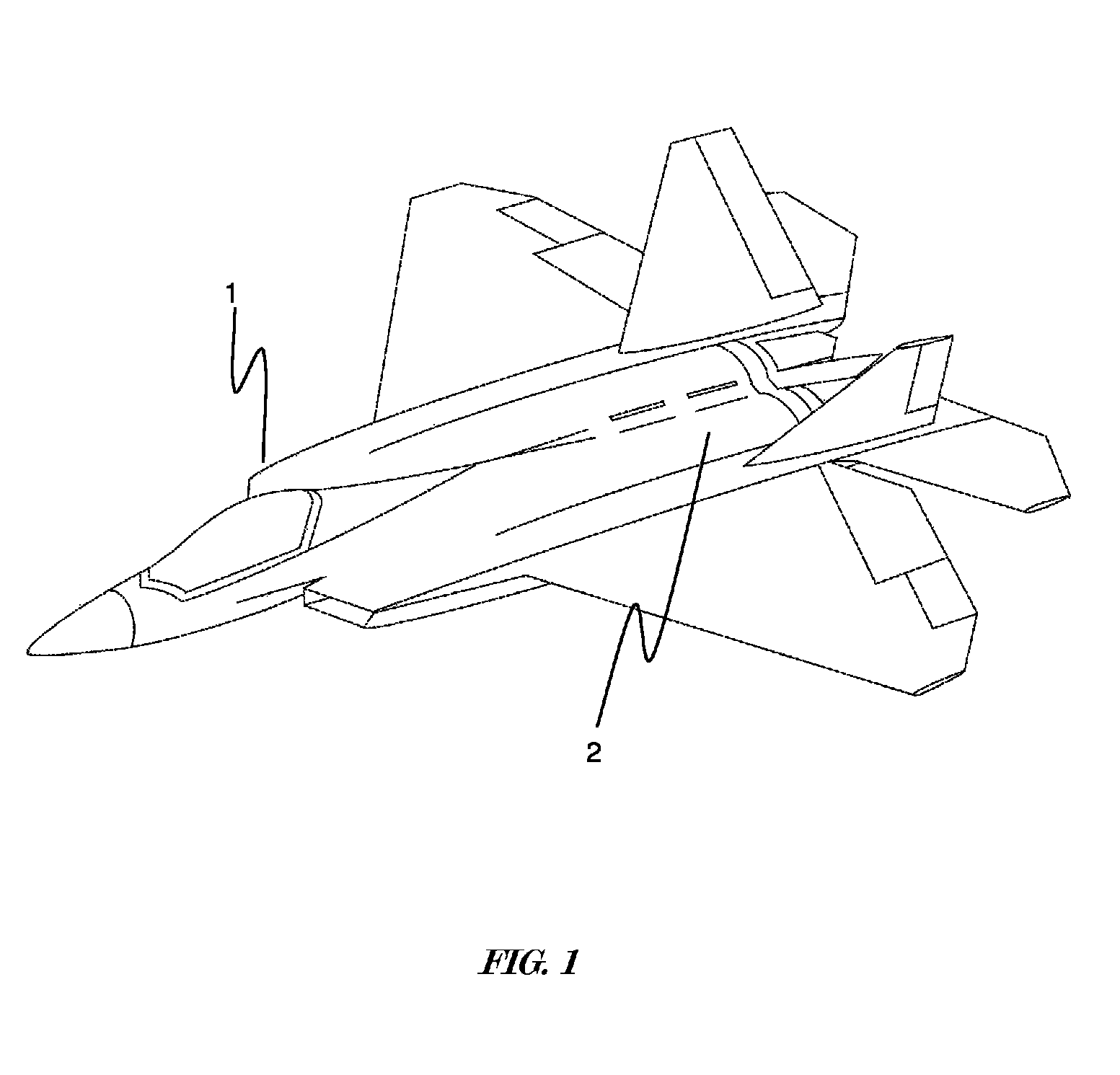

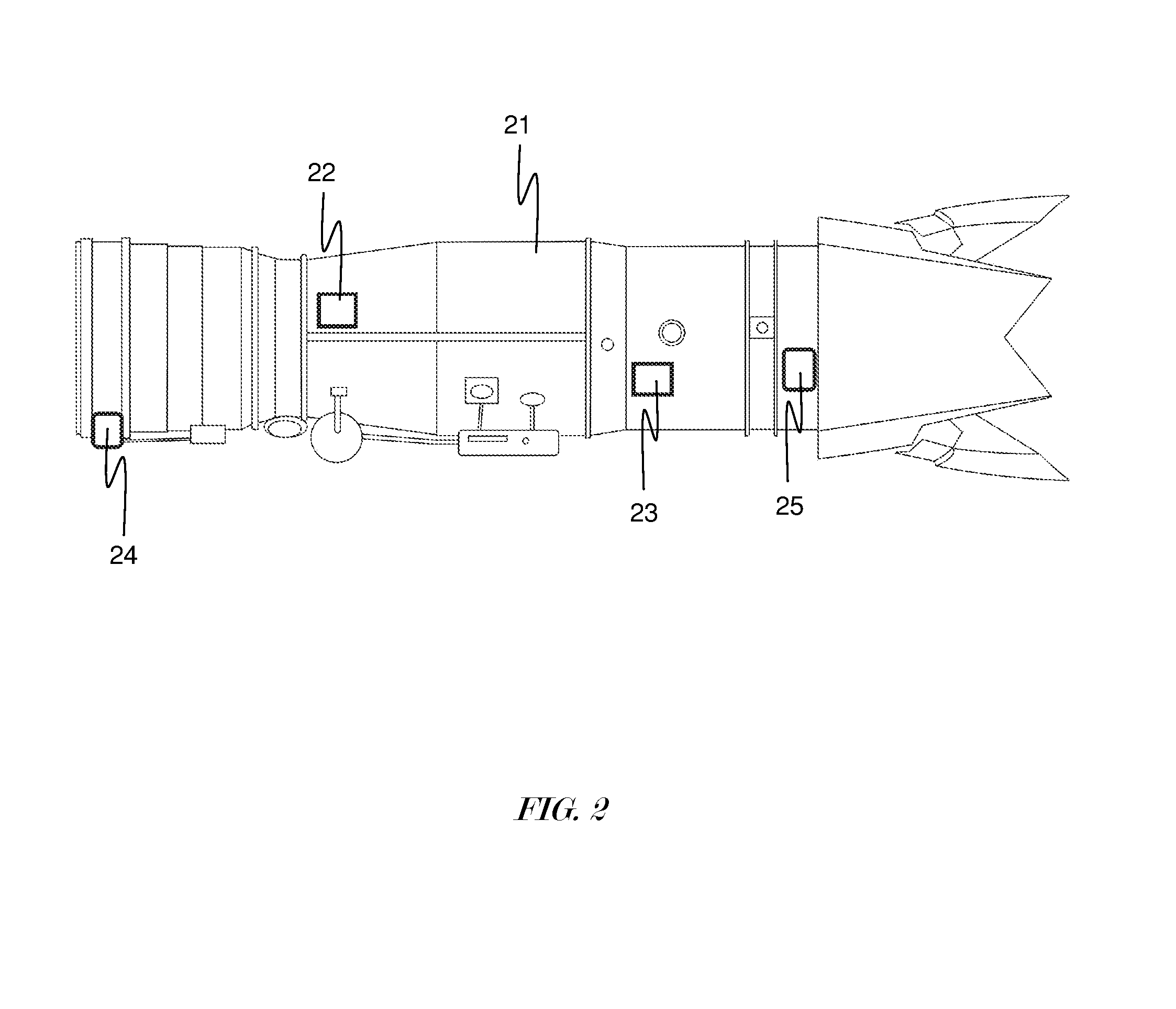

Onboard atomizing cooling system for creating negative pressure environment by virtue of ejector

PendingCN107466196AImprove spray cooling efficiencyCooling/ventilation/heating modificationsHeat flowEngineering

The invention relates to an onboard atomizing cooling system for creating a negative pressure environment by virtue of an ejector, which belongs to the field of cooling of onboard high heating density equipment, and mainly solves the high heating density continuous heat dissipation problem of the surface of onboard electronic equipment. The onboard atomizing cooling system mainly comprises a water tank (1), a water pump (2), a flow adjusting valve (3), a stop valve (4), a flow meter (5), a nozzle (6), a to-be-cooled surface (7), an atomizing chamber (8), a pressure meter (9), an engine tail gas entraining hole (10), an ejector nozzle section (11), an ejector mixing section (12), a exhausting hole (13), a heat pipe heat exchange box (14), an external environment hole (15) and a heat pipe (16). According to the onboard atomizing cooling system, engine tail gas is taken as an ejection air source, the negative pressure environment is created in the atomizing chamber, the surface of high-temperature electronic equipment is atomized and cooled by virtue of vaporization latent heat of water, and the cooling of the heat pipe and the heat-exchanged water vapor on the surface of the to-be-cooled surface are introduced, so that the closed atomizing cooling system can safely and stably work, has an energy-saving effect and can meet the cooling requirements in onboard complex environments.

Owner:NANJING UNIV OF TECH

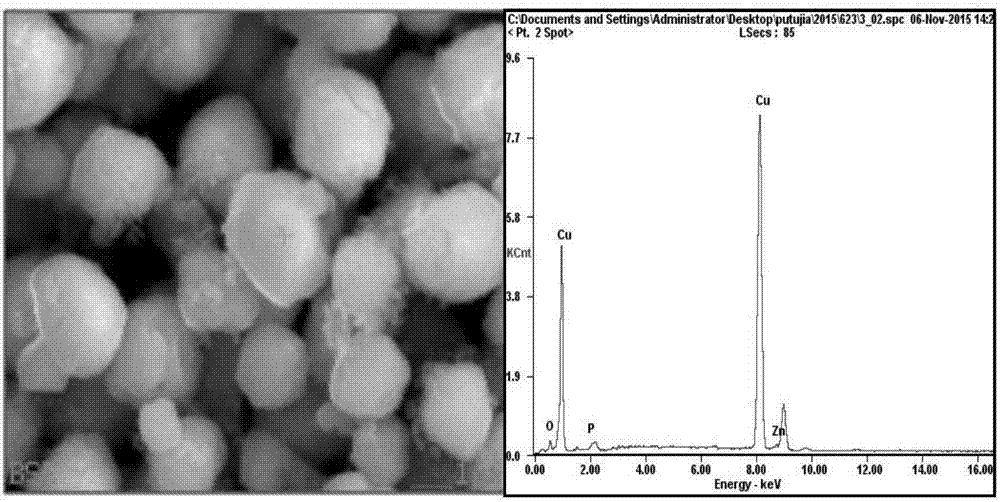

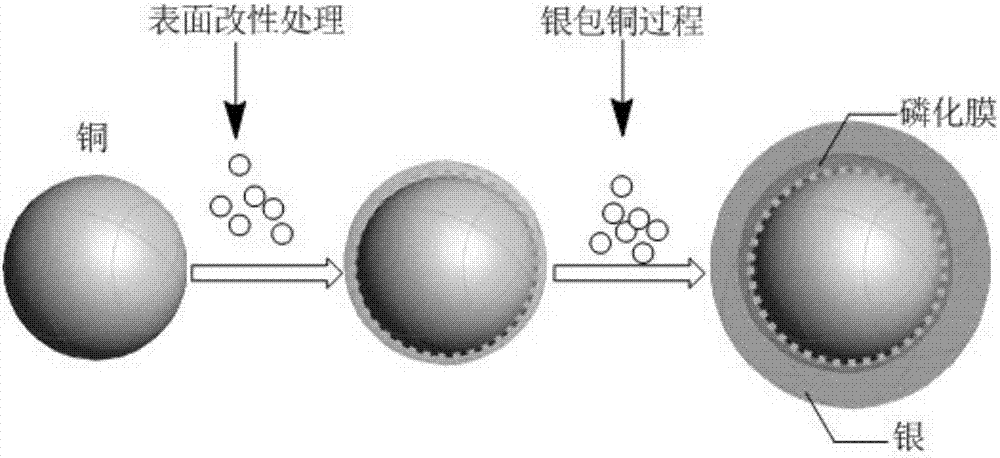

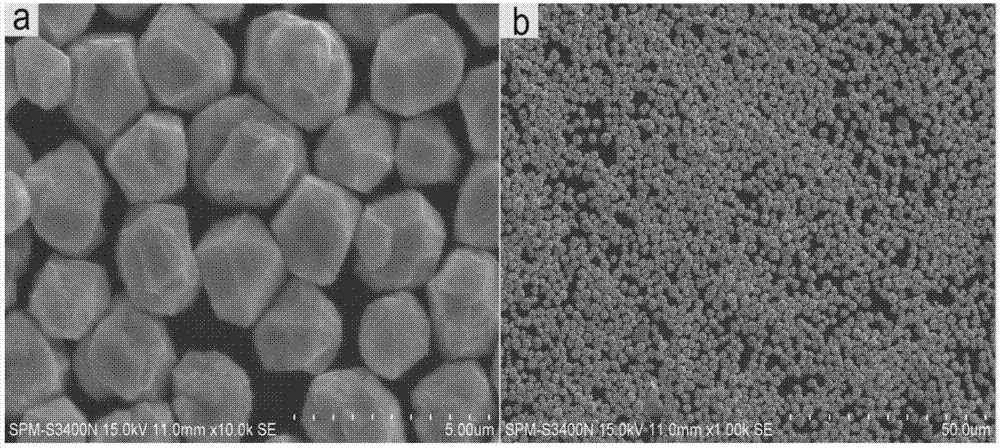

Preparation method for superfine copper-silver core shell composite powder for medium-high temperature electronic slurry

InactiveCN107498064AGood dispersionImprove antioxidant capacityTransportation and packagingConductive materialPhosphoric acidSlurry

The invention discloses a preparation method for superfine copper-silver core shell composite powder for medium-high temperature electronic slurry. Copper powder is prepared through a liquid phase chemical reduction method; the copper powder is washed through sulfuric acid, deionized water and ethanol, dried in the vacuum environment and then screened to obtain dried copper powder; zinc oxide, nitric acid and phosphoric acid are mixed, deionized water is added, and phosphating liquid is prepared; the dried copper powder is taken and added in the phosphating liquid to be stirred, washed through deionized water and ethanol to be neutral, filtered, and then dried in the vacuum environment, and thus finished copper powder is obtained; the finished copper powder, a dispersant, a reductant and a complexing agent are mixed, deionized water is added, and thus a disperse system solution of suspended copper powder is prepared; silver nitrate and a complexing agent are added to deionized water to prepare a silver nitrate solution; the silver nitrate solution is dropped into the disperse system solution, and thus silver-coated copper powder is obtained; and the silver-coated copper powder is washed through deionized water and ethanol, filtered, then dried in the vacuum environment and screened, and thus the copper-silver core shell composite powder is obtained. According to the copper-silver core shell composite powder obtained through the preparation method, silver on the surface of the copper-silver core shell composite powder is not likely to fall off, oxidation resistance is high, and the conductive property is stable.

Owner:昆明高聚科技有限公司

Novel oxidizing-resistant nanometer copper soldering paste and preparation method and application thereof

InactiveCN107267938APrevent oxidationPrevent surface oxidationTransportation and packagingSemiconductor/solid-state device detailsOxidation resistantHigh temperature electronics

The invention relates to novel oxidizing-resistant nanometer copper soldering paste and a preparation method and application thereof. By adopting a magnetron sputtering process, the surface of nanometer copper powder is evenly coated with a metal film. Silver, gold and the like can be selected as the components of the metal film as required; then a traditional nanometer copper soldering paste formula continues to be used, a proper amount of forming auxiliaries are added; and finally, the novel oxidizing-resistant nanometer copper soldering paste resistant to oxidizing and cracks is prepared. Compared with the prior art, according to the novel nanometer copper soldering paste, mutual connection between a chip and a substrate can be achieved by means of a low-temperature sintering process or a pressurizing low-temperature sintering process, a traditional nanometer copper soldering paste function is achieved; and oxidizing resistance, crack initiation resistance and an extending performance are achieved at the same time, the novel oxidizing-resistant nanometer copper soldering paste can be used in large-power high-temperature electronic device packaging, and is especially suitable for packaging of third-generation semiconductor devices, after packaging, a connector is good in performance, fault-free service under high temperature can be achieved for a long time, and the novel nanometer copper soldering paste is matched with an existing lead-free solder packaging process.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Method for preparing high conductive, high temperature electronic frame material

InactiveCN1872492AImprove performanceImprove plasticityFurnace typesOther manufacturing equipments/toolsMetallic materialsFiber crystal

A shaped electronic frame material with high electric conductivity and strength is made up of the metal material which is prepared by directional coagulation technique and has unidirectional fiber crystal structure and the shape similar to that of product, cold rolling by serially arranged at least 3 rolling mills, and in-line annealing before the last rolling mill.

Owner:宁波海王机电科技有限公司

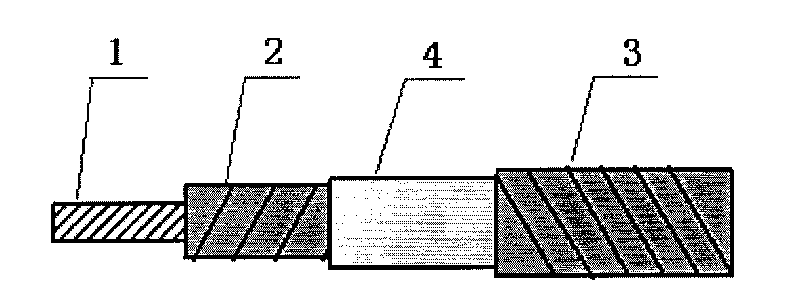

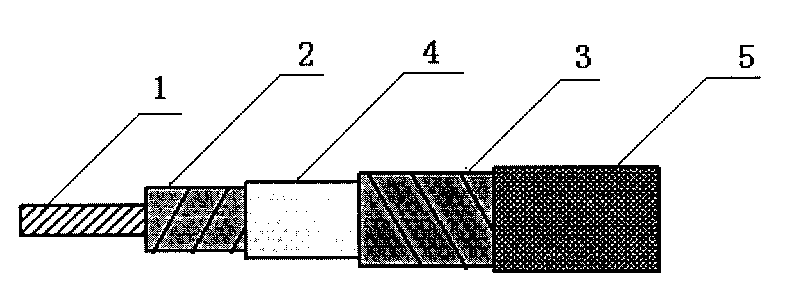

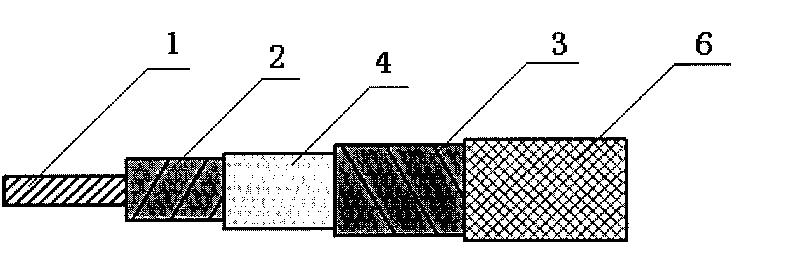

Airborne spray cooling system for cooling circulating water by using ram air and evaporative refrigeration cycle

PendingCN108834378ASemiconductor/solid-state device detailsSolid-state devicesEngineeringHigh temperature electronics

The invention discloses an airborne spray cooling system for cooling circulating water by using ram air and an evaporative refrigeration cycle, and belongs to the cooling field of airborne high-heat-flux-density equipment. The system is mainly used for solving the continuous heat dissipation of high-heat-flux-density surfaces such as an airborne radar chip and a laser weapon and mainly includes awater tank, a compressor, an evaporator, a cold water inlet, a cold water outlet, a refrigerant inlet, a refrigerant outlet, a phase change material, an expansion valve, a condenser, a phase change material heat exchanger, a ram air inlet, a spray chamber, a to-be-cooled surface, a nozzle, a flow meter, a flow control valve and a water pump. The system, by using the latent heat of vaporization ofwater, cools the surface of a high-temperature electronic device in the spray chamber, uses the ram air as a main cold source, uses an evaporative refrigeration cycle as an auxiliary cold source, usestwo phase change materials as an intermediate energy storage medium to correspond to the two cold sources, and selects a cold source combination mode according to the surface temperature. The systemis safe, stable, and energy-efficient in operation, and meets the cooling needs in airborne complex environments.

Owner:NANJING UNIV OF TECH

Radiation-resistant polyimide film insulating cable with high bonding strength and method for producing same

ActiveCN101719396AHigh temperature resistanceHigh bonding strengthPlastic/resin/waxes insulatorsInsulated cablesRadiation resistantNuclear power

The invention discloses a novel radiation-resistant polyimide film insulating cable with high bonding strength and a method for producing the same. The polyimide film insulating cable is produced by coating radiation-resistant and high-temperature resistant polyimide which is used as the binder on a winded polyimide film to carry out the semi-imidization for the binder, winding a second layer of polyimide film and carrying out postprocessing of solidification for the binder to form continous insulating layers. The polyimide film insulating cable has high temperature and radiation resisting performance and can be widely applied to the filed of the aviation, the aerospace, the nuclear power and the high-temperature electronic apparatus.

Owner:SHANGHAI ELECTRIC CABLE RES INST

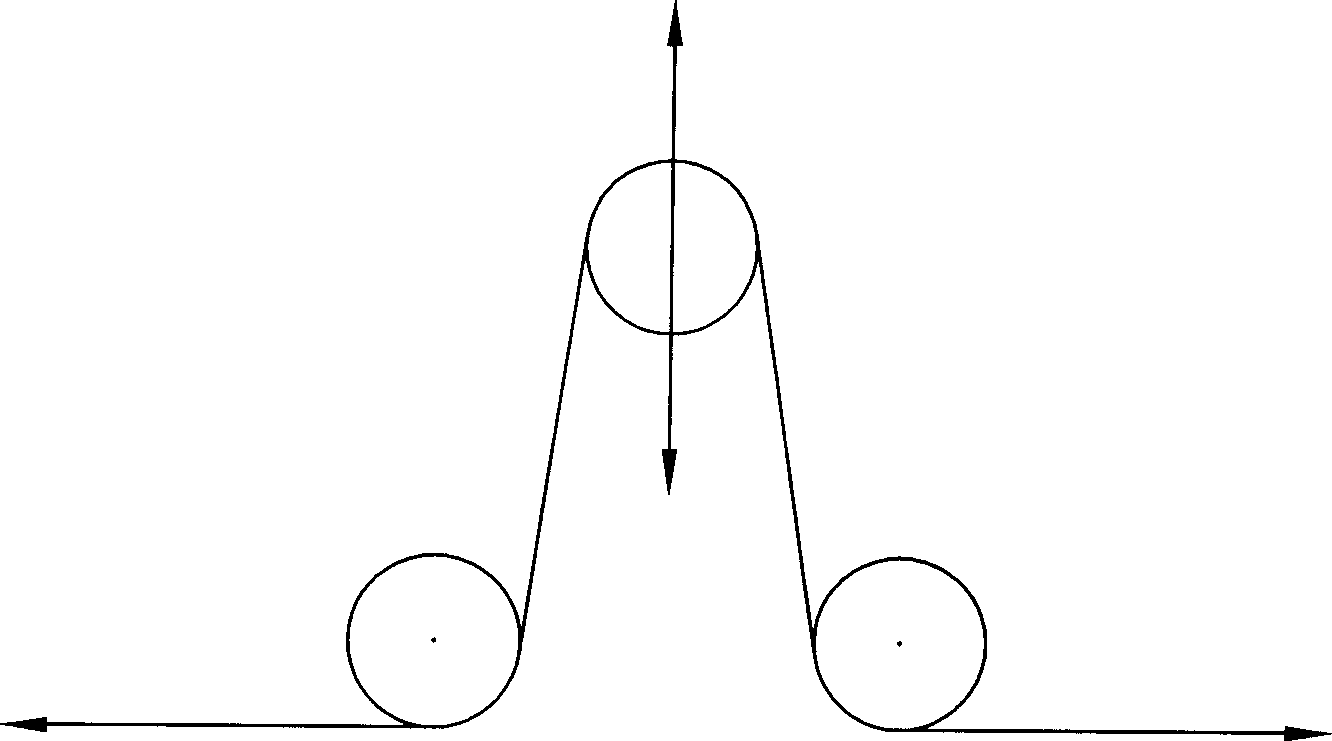

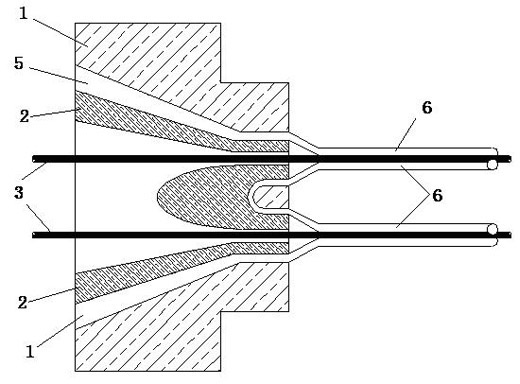

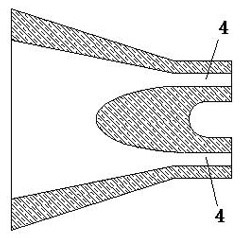

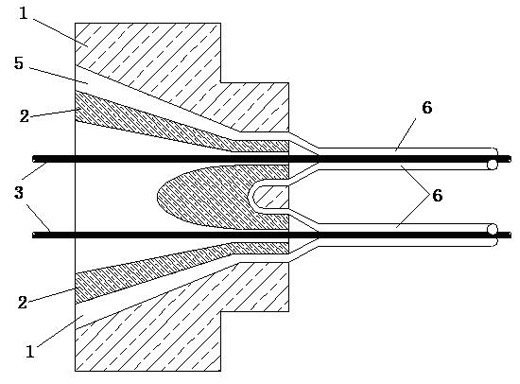

Superfine high-temperature electronic wire double-core extrusion process and die thereof

InactiveCN102024530AIncrease productivitySave energyInsulating conductors/cablesComing outProduction line

The invention discloses a superfine high-temperature electronic wire double-core extrusion process and a die thereof. The die comprises an inner die and an outer die which are matched with each other, wherein two core wires are released respectively from two wire-releasing frames at the same time and pass through two core wire holes of the inner die respectively; two glue outlet channels are formed between the inner die and the outer die and are communicated with the peripheries of the two core wires respectively; melt glue stock enters from the glue outlet channels; when the core wires pass through the outer die, the glue stock is wrapped on the surfaces of the core wires to form insulation layers; and cables wrapped by the insulation layers come out of the outer die, are cooled by a water groove and enter wire storage frames to be reeled respectively. The die is redeveloped and is provided with two core wire extruding channels, two wire-releasing frames matched with the two core wire extruding channels and three wire-reeling shafts; and two electronic wires can be produced at one time through one production line, so that the two cores can be extruded at the same time, the production efficiency is increased manyfold and is improved greatly, requirements are met, energy is saved, and production cost is greatly reduced.

Owner:广东联升传导技术有限公司

High-temperature sensor interface and network

The present invention is a sensor interface or network of interfaces that utilizes high-temperature electronics to operate at elevated temperatures for applications that include but are not limited to aircraft and automobile engines, vehicle frames, refineries, nuclear and chemical production plants, and in downhole drilling for petroleum and natural gas. The interface or network provide connectors for a variety of sensors with analog and digital outputs, and can in turn provide data to an automated electronic control system or a monitor. Because the sensor interface may be placed in so-called “hot zones” nearer to the sensors being monitored than other systems that use conventional electronics, the sensor interface can increase noise immunity, increase reliability, decrease cost, reduce weight, and increase space.

Owner:ORBITAL RES

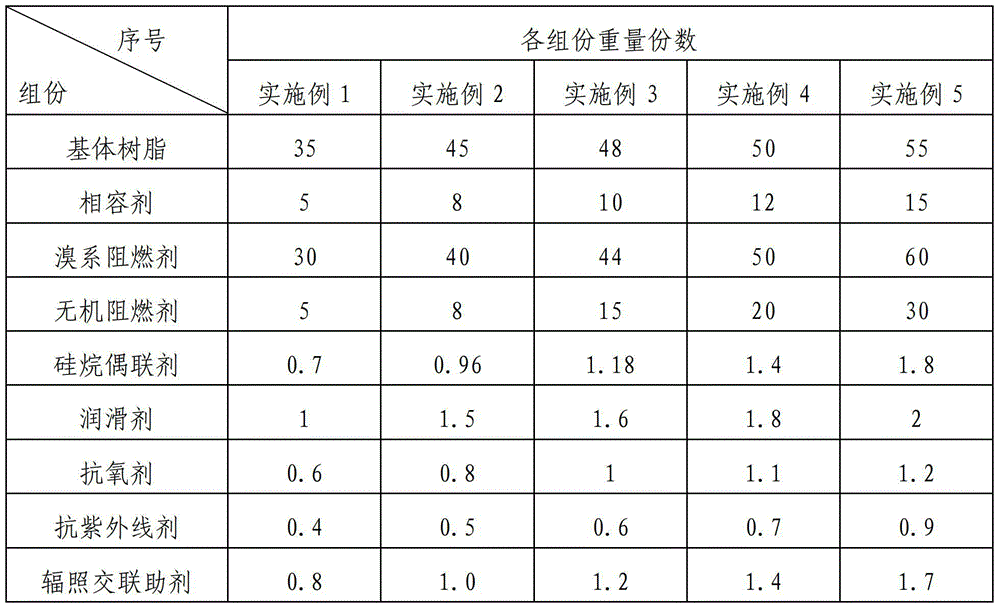

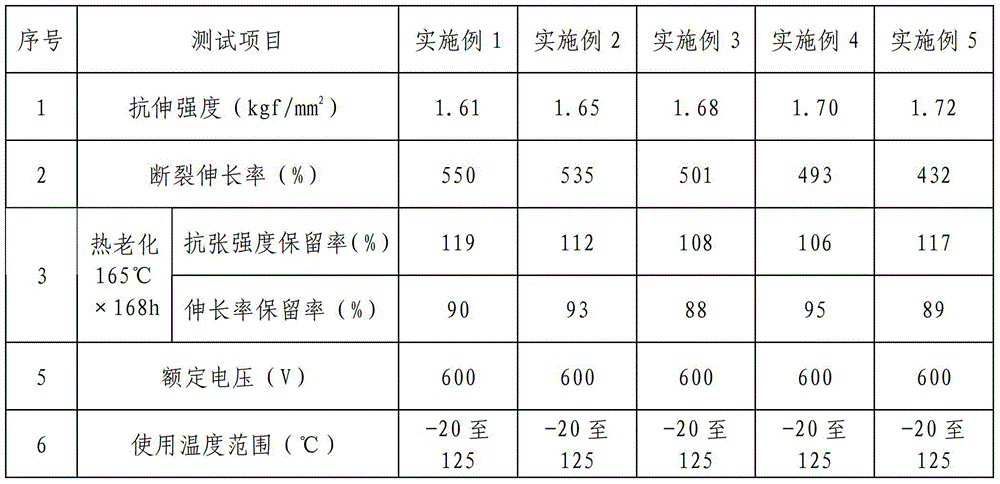

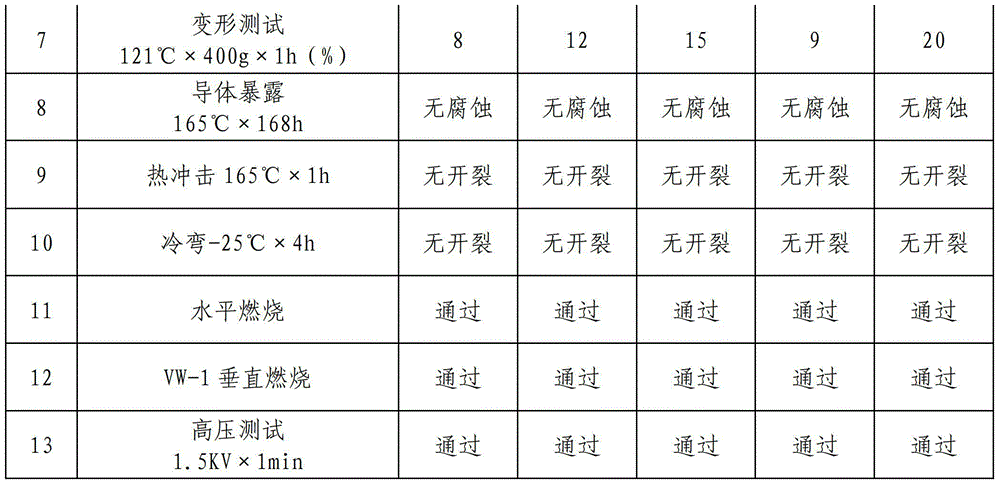

PE cable material subjected to irradiation cross-linking at 125 DEG C for UL high-temperature electronic wire and preparation method of PE cable material

ActiveCN104530545AEffective adjustment of viscosityImprove the finishPlastic/resin/waxes insulatorsCross-linkLow-density polyethylene

The invention belongs to the preparation of cable materials and particularly relates to a PE cable material subjected to irradiation cross-linking at 125 DEG C for UL high-temperature electronic wire and preparation method of the PE cable material. The PE cable material is prepared from an effective amount of matrix resin, a compatilizer, a bromine flame retardant, an organic flame retardant, a silane coupling agent, a lubricants, an antioxidant, an anti-UV agent, and an irradiation crosslinking aid by virtue of carrying out surface activation treatment on the flame retardant, mixing in a mixer, granulating and the like, wherein the matrix resin comprises linear low-density polyethylene A, linear low-density polyethylene B and an ethylene-octene copolymer. By the preparation method, the defect that such mechanical properties as tensile strength and elongation at break of the cable material due to large filling amount of the flame retardant in the prior art can be inevitably reduced, the PE cable material has the advantages that the technical indicators such as tensile strength and elongation at break of the prepared electronic line are higher than the existing standard and the product has good flame retardant property and surface degree of finish, low cost and the like, and the situation that UL high-temperature electronic wire manufacturers can only use expensive imported cable materials to meet needs is broken.

Owner:HEBEI XINHAI GAOKE NEW MATERIAL TECH CO LTD

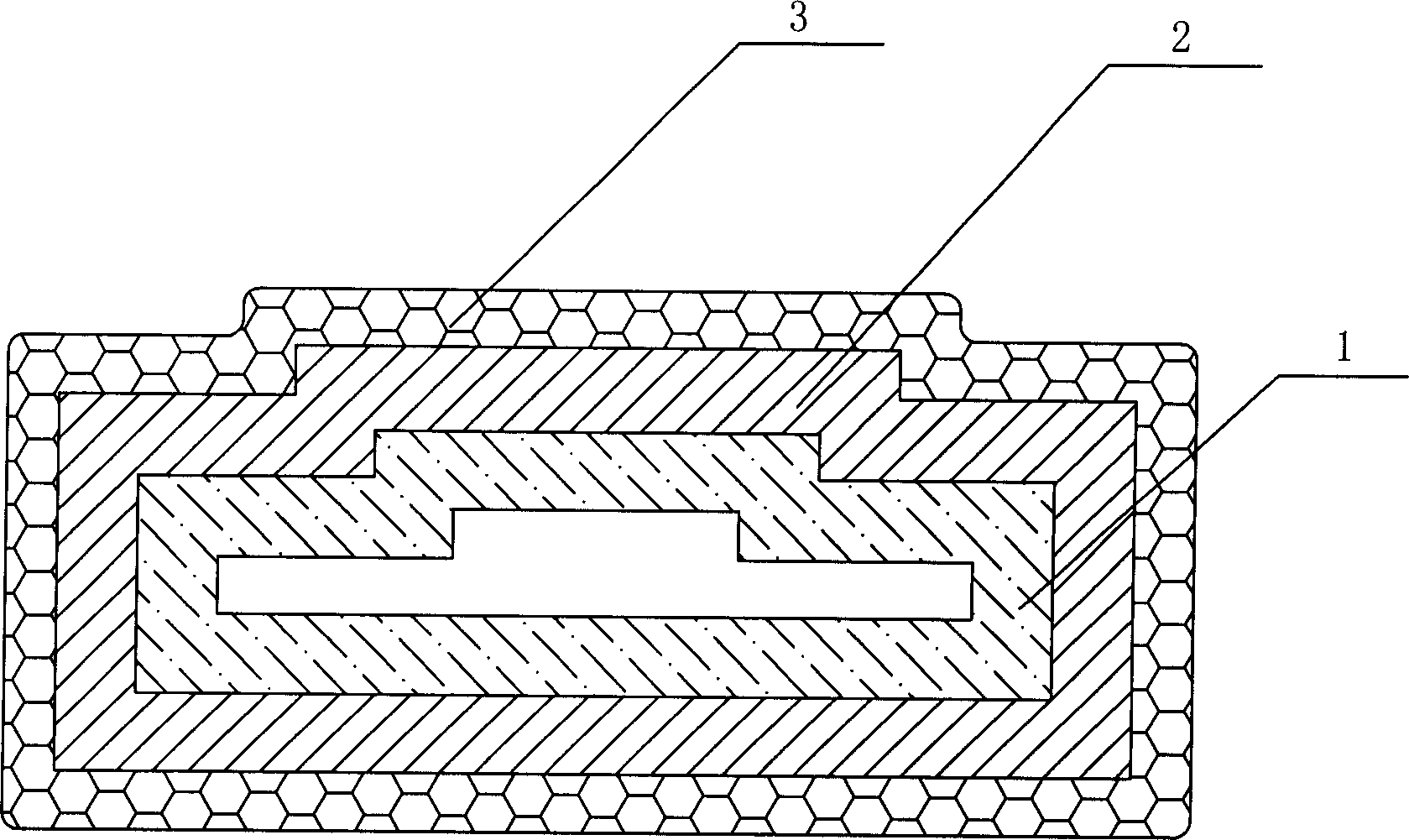

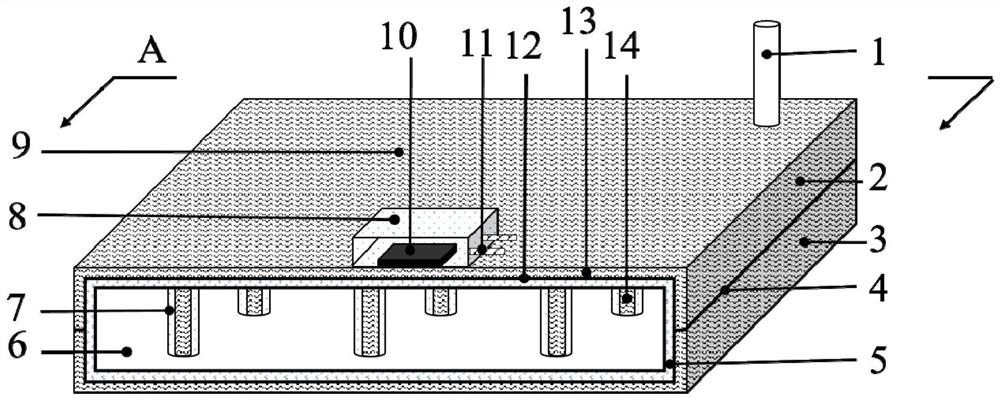

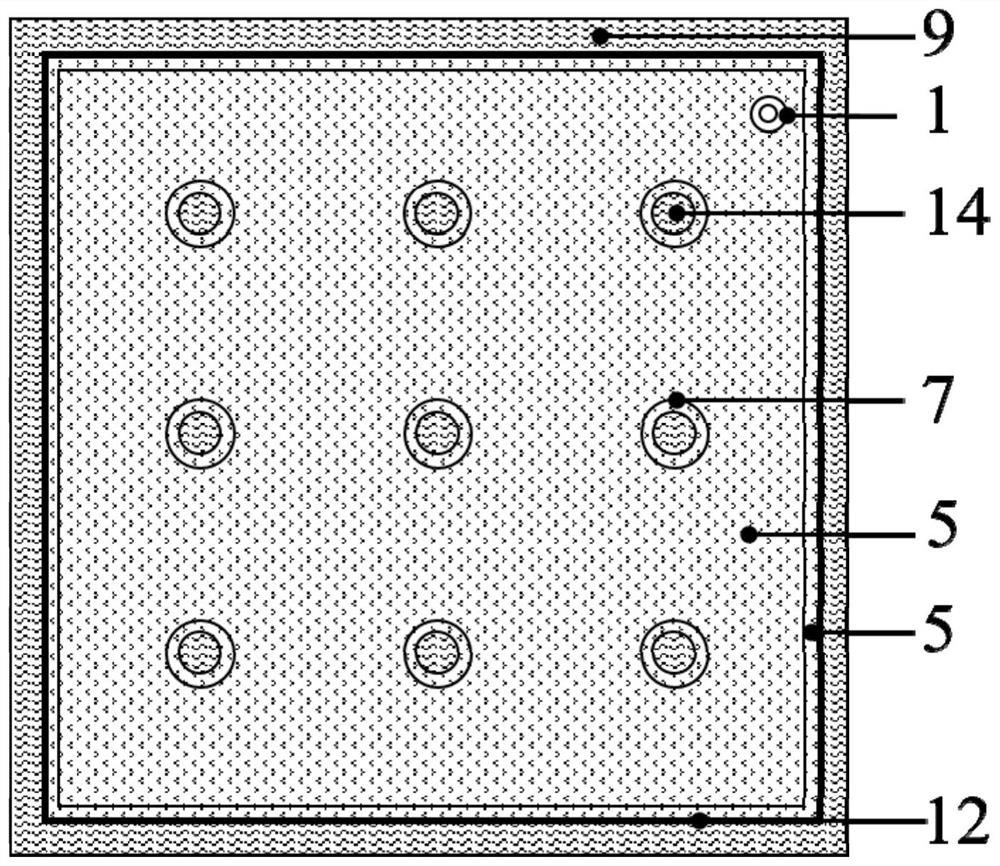

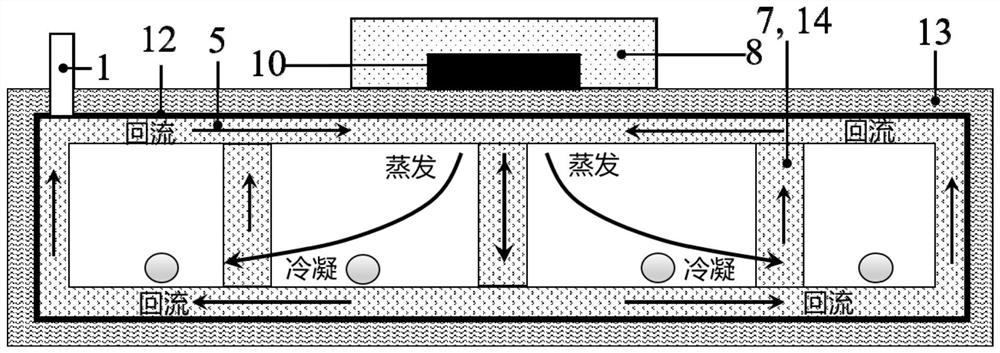

High-temperature electronic packaging substrate material device based on gas-liquid phase change and preparation method thereof

InactiveCN111725144AHigh strengthAchieve ultra-thinSemiconductor/solid-state device detailsSolid-state devicesThermal dilatationPorous medium

The invention relates to a high-temperature electronic packaging substrate material device based on gas-liquid phase change and a preparation method thereof. The device comprises a substrate shell forming a closed cavity, a porous medium which covers the inner wall of the substrate shell and is provided with a gas flow channel, and a liquid filling port which is formed in the substrate shell and is connected with the porous medium, a power device is further arranged on the upper surface of the substrate shell, and a liquid working medium capable of generating gas-liquid phase change after being heated is infiltrated in the porous medium. Compared with the prior art, the novel packaging substrate material developed by the invention can meet the requirements of high-power third-generation semiconductor chip-level and module-level high-temperature packaging, namely, reliable packaging can be carried out at the high temperature of 400 DEG C, in addition, the ultrathin packaging substrate shell can be realized, and the heat transfer resistance is reduced; and stress and the like caused by uneven temperature distribution and mismatching of thermal expansion coefficients in a high-temperature working state can be reduced.

Owner:SHANGHAI JIAO TONG UNIV

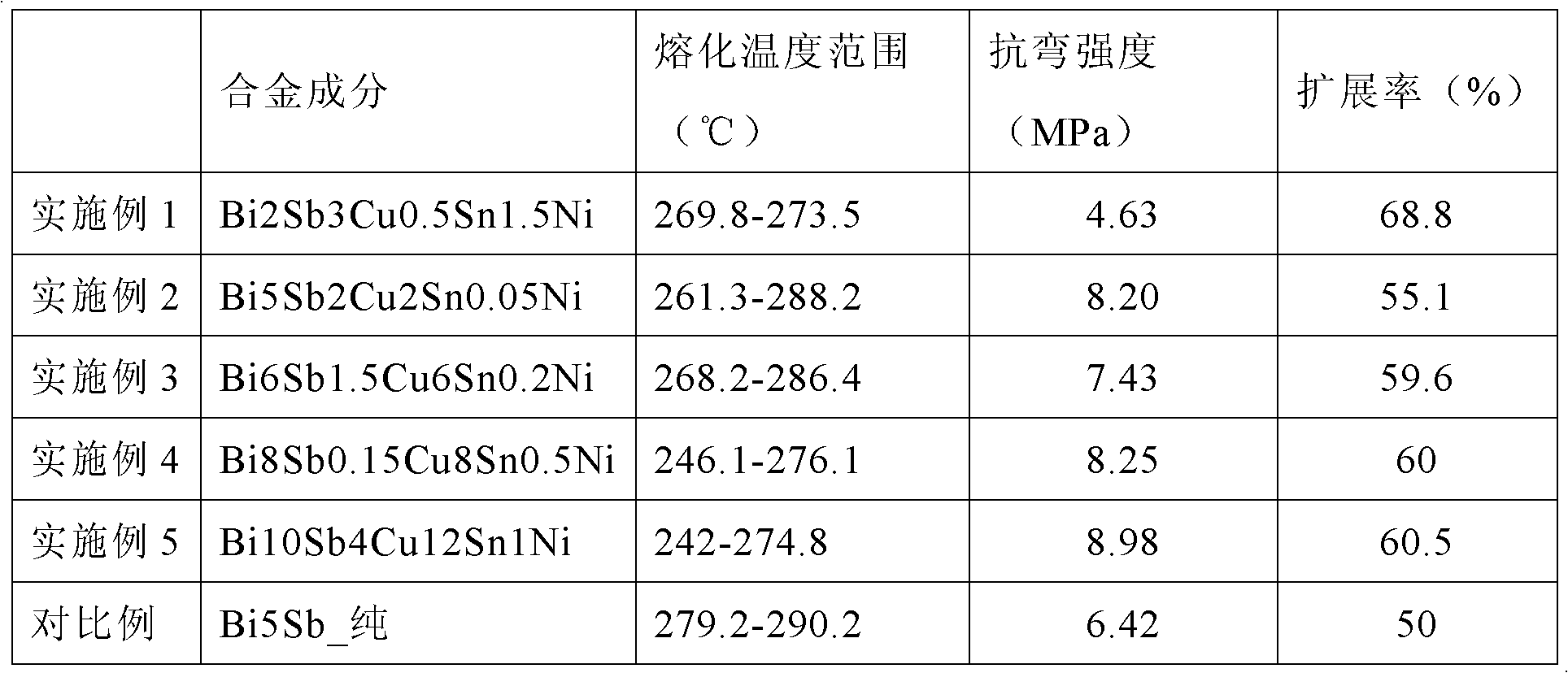

Pb-free solder for high-temperature electronic packaging and preparation method thereof

ActiveCN102430873ANo pollution in the processImprove mechanical propertiesWelding/cutting media/materialsSoldering mediaRare earthHigh temperature electronics

The invention relates to Pb-free solder for high-temperature electronic packaging, which has good wetting properties, mechanical properties and oxidation resistance and high welding strength. The Pb-free solder comprises 1-12% by weight of Sb, 0.01-5% by weight of Cu, 0-15% by weight of Sn, 0.01-2% by weight of Ni, 0-0.1% by weight of X and the balance of Bi, wherein the X is one or more of the Ga, P and mixed rare earth. The Pb-free solder disclosed by the invention is suitable for electronic packaging.

Owner:ZHEJIANG ASIA GENERAL SOLDERING & BRAZING MATERIAL

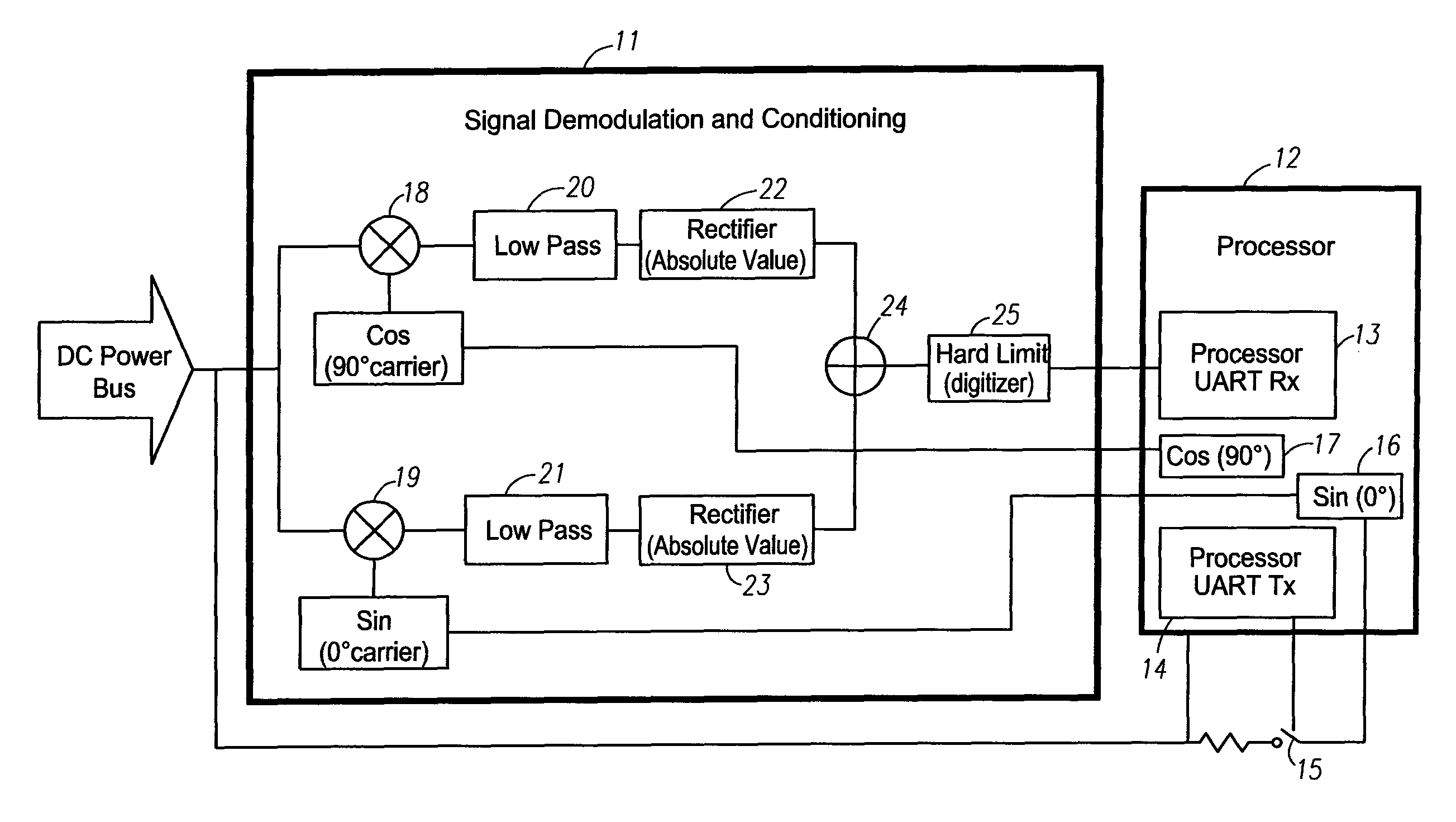

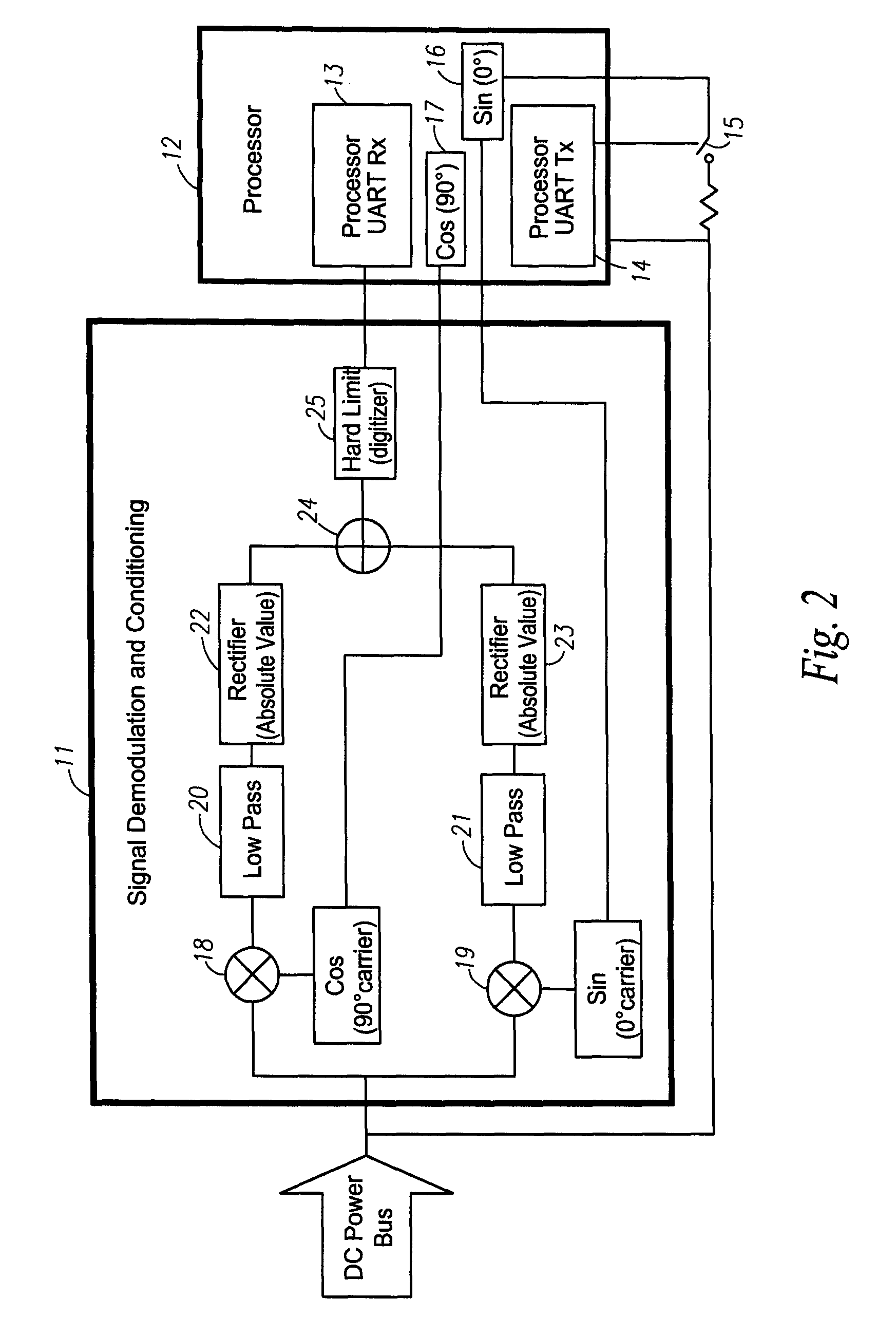

Circuit for communication over DC power line using high temperature electronics

InactiveUS8704654B1Frequency-division multiplex detailsModulated-carrier systemsAudio power amplifierData signal

A high temperature communications circuit includes a power conductor for concurrently conducting electrical energy for powering circuit components and transmitting a modulated data signal, and a demodulator for demodulating the data signal and generating a serial bit stream based on the data signal. The demodulator includes an absolute value amplifier for conditionally inverting or conditionally passing a signal applied to the absolute value amplifier. The absolute value amplifier utilizes no diodes to control the conditional inversion or passing of the signal applied to the absolute value amplifier.

Owner:NASA

Metal-insulator-metal (MIM) switching devices

InactiveUS8044442B2Easy constructionIncreased maximum operating speedCircuit-breaking switches for excess currentsNanoelectromechanical switchesMetal-insulator-metalHigh temperature electronics

Owner:RGT UNIV OF CALIFORNIA

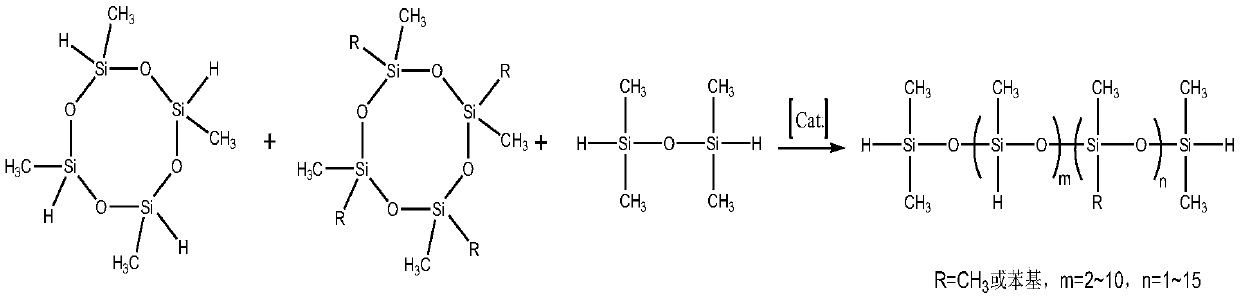

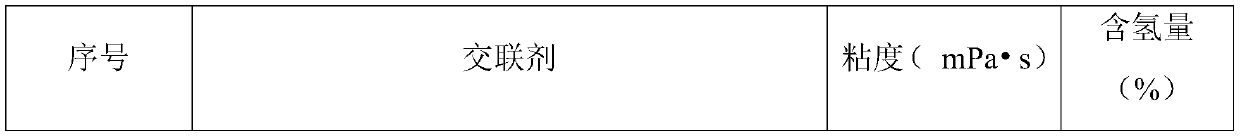

Single-component temperature-resistant heat-conducting silicon mud composition and preparation method thereof

ActiveCN110982277AImprove temperature resistanceEasy to useHeat-exchange elementsPtru catalystSilanes

The invention discloses a single-component temperature-resistant heat-conducting silicon mud composition and a preparation method thereof. The single-component temperature-resistant heat-conducting silicon mud composition is prepared from the following raw materials in parts by weight: 100 parts of vinyl polysiloxane, 0.5-6 parts of a cross-linking agent, 100-1300 parts of a heat-conducting filler, 5-100 parts of a flame retardant material, 0.1-8 parts of a silane coupling agent, 1-12 parts of a temperature-resistant auxiliary agent, 0.01-0.5 parts of an inhibitor, and 0.1-0.9 parts of a platinum catalyst. The single-component temperature-resistant heat-conducting silicon mud composition is addition-type heat-conducting cement gum with low cross-linking degree, has low volatility and long-term resistance to the temperature of 230 DEG C without drying compared with general heat-conducting silicone grease and heat-conducting gel, and can be used for heat management of ultra-high-temperature electronic devices. The composition has high thermal conductivity and flame retardancy, and can be used for heat dissipation of high-power devices to protect the stable operation of the devices.

Owner:CHENGDU GUIBAO SCI & TECH

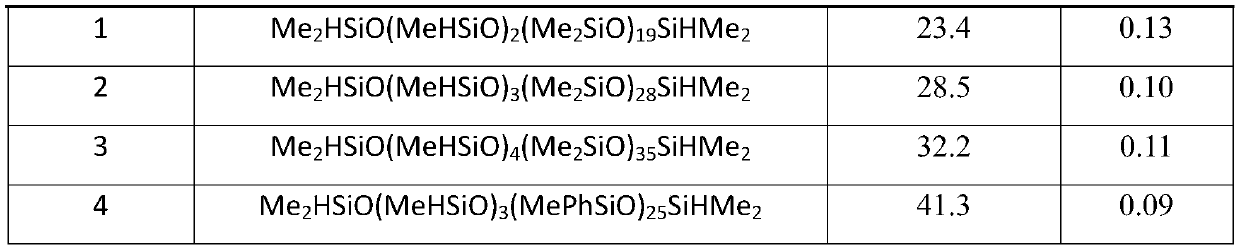

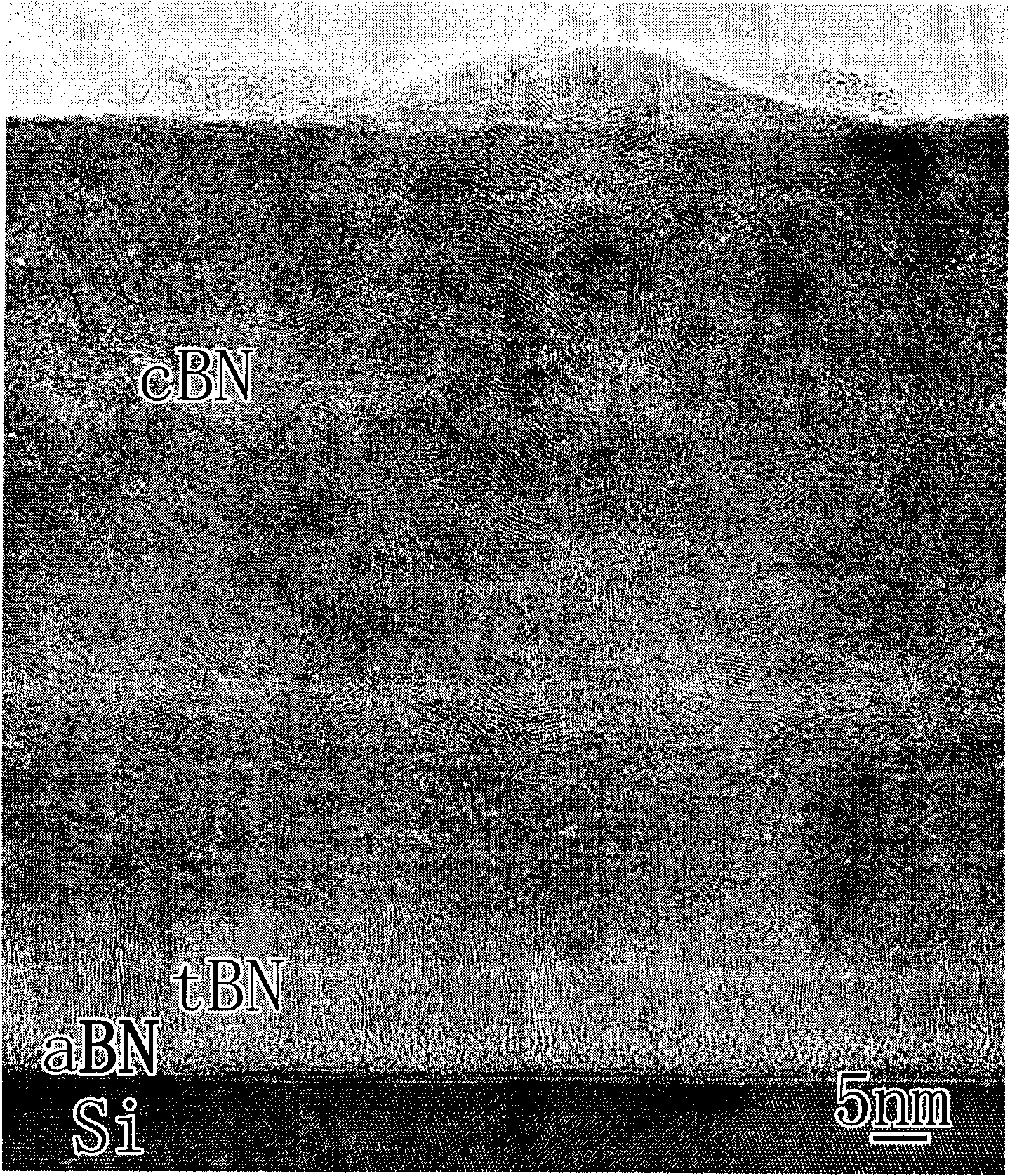

Release method of residual compression stress in nanocrystalline cubic boron nitride pellicle

ActiveCN101565822ANovel processReduce surface roughnessVacuum evaporation coatingSputtering coatingShielding gasRoom temperature

The invention discloses a release method of residual compression stress in a nanocrystalline cubic boron nitride pellicle. The cubic boron nitride pellicle is put in a heating chamber that is first vacuumized to at least 10Torr and kept with invariable vacuum degree, or vacuumized to at least 10Torr after protective gas is filled in and subsequently heated up to between 1000-1300 DEG C with the temperature kept for 1-5h and then cooled to room temperature. The method can be applied to releasing the residual compression stress of the cubic boron nitride pellicle deposited on various substrates without changing the composition, structure and surface topography of the cubic boron nitride pellicle, thus greatly improving the bonding force of the cubic boron nitride pellicle on various substrates and leading the cubic boron nitride pellicle to be applied not only to preparing a cutter, sharper and the like for processing iron-based alloy, but also to the fields of protective film of optical elements, high temperature electronic devices and the like.

Owner:杭州天柱科技有限公司

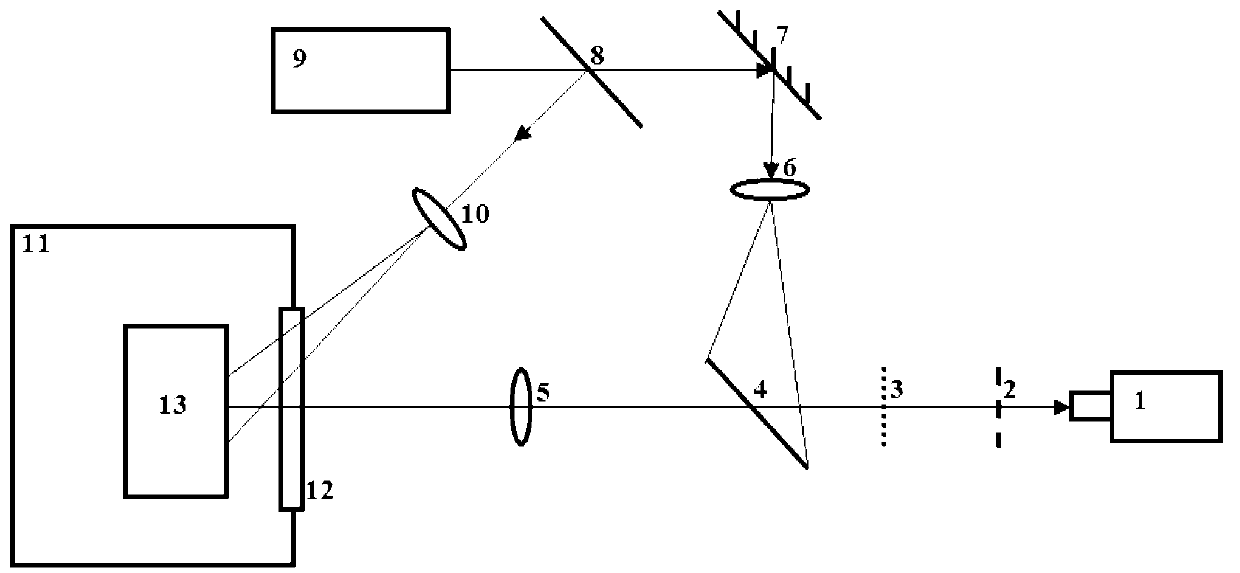

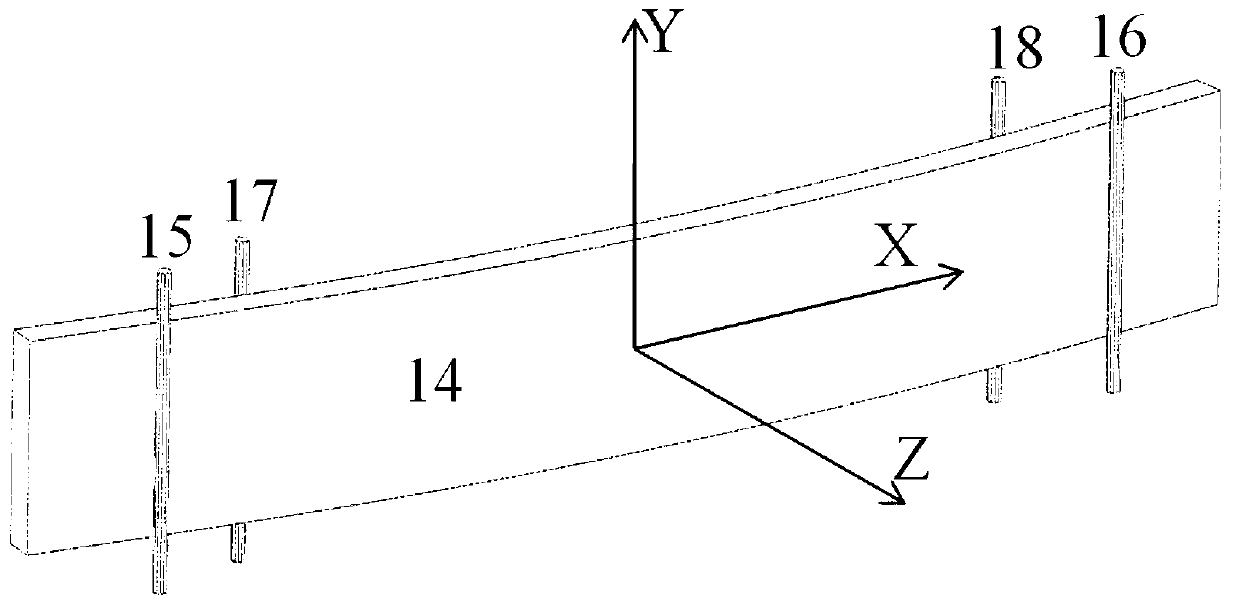

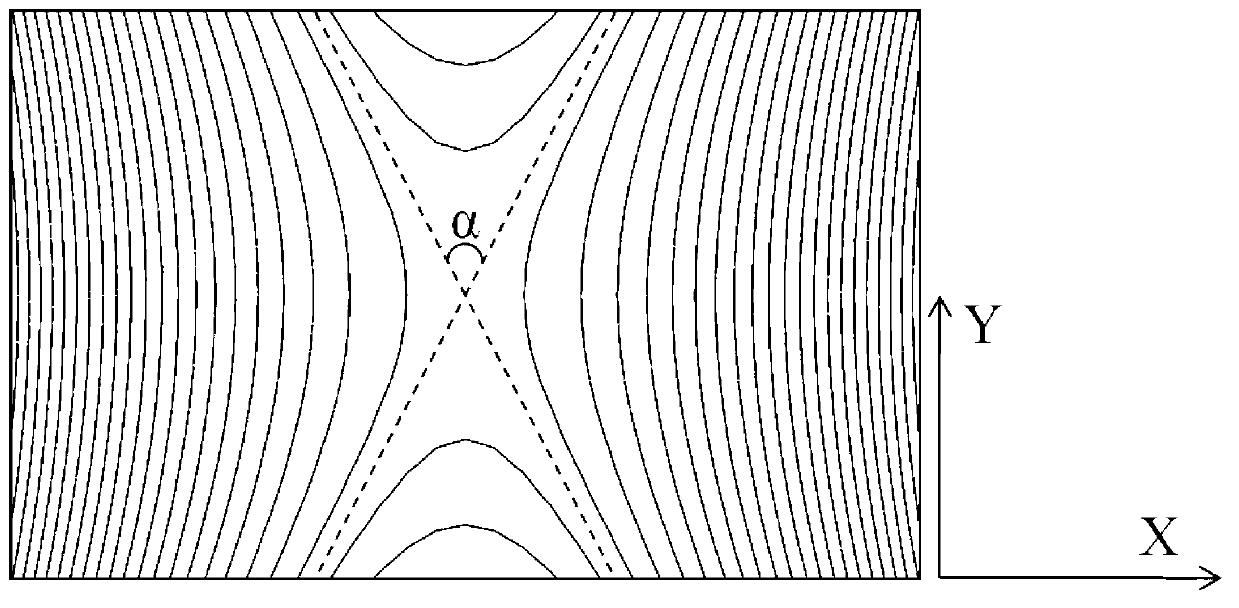

Experimental apparatus and method for measuring poisson ratio of material under high temperature

InactiveCN102980813AHigh measurement temperatureOvercome the disadvantages of more cumbersome proceduresMaterial strength using tensile/compressive forcesExperimental methodsHigh temperature electronics

The invention discloses an experimental apparatus and method for measuring a poisson ratio of a material under high temperature, belonging to the technical field of experimental mechanics and high-temperature tests. The experimental apparatus and method adopts a method combining high-temperature electronic speckling and four-point phase bending to measure the poisson ratio of the material under the high temperature, and is in particular applicable to measuring the poisson ratio of the material under the ultra-temperature (more than 1600 DEG C). The experimental method comprises the steps of: recording interference speckle fields generated by object light and reference light by adopting non-contact measurement and a CCD (Charge Coupled Device) after a four-point bent sample is irradiated by laser, and measuring the off-plane displacement before and after the four-point bending of the sample by adopting an electronic speckling technology, thus directly obtaining the poisson ratio of the material under the high temperature according to a bar chart of the off-plane displacement, so that a problem that the poisson ratio of the material under the high temperature is difficultly measured can be solved.

Owner:TSINGHUA UNIV

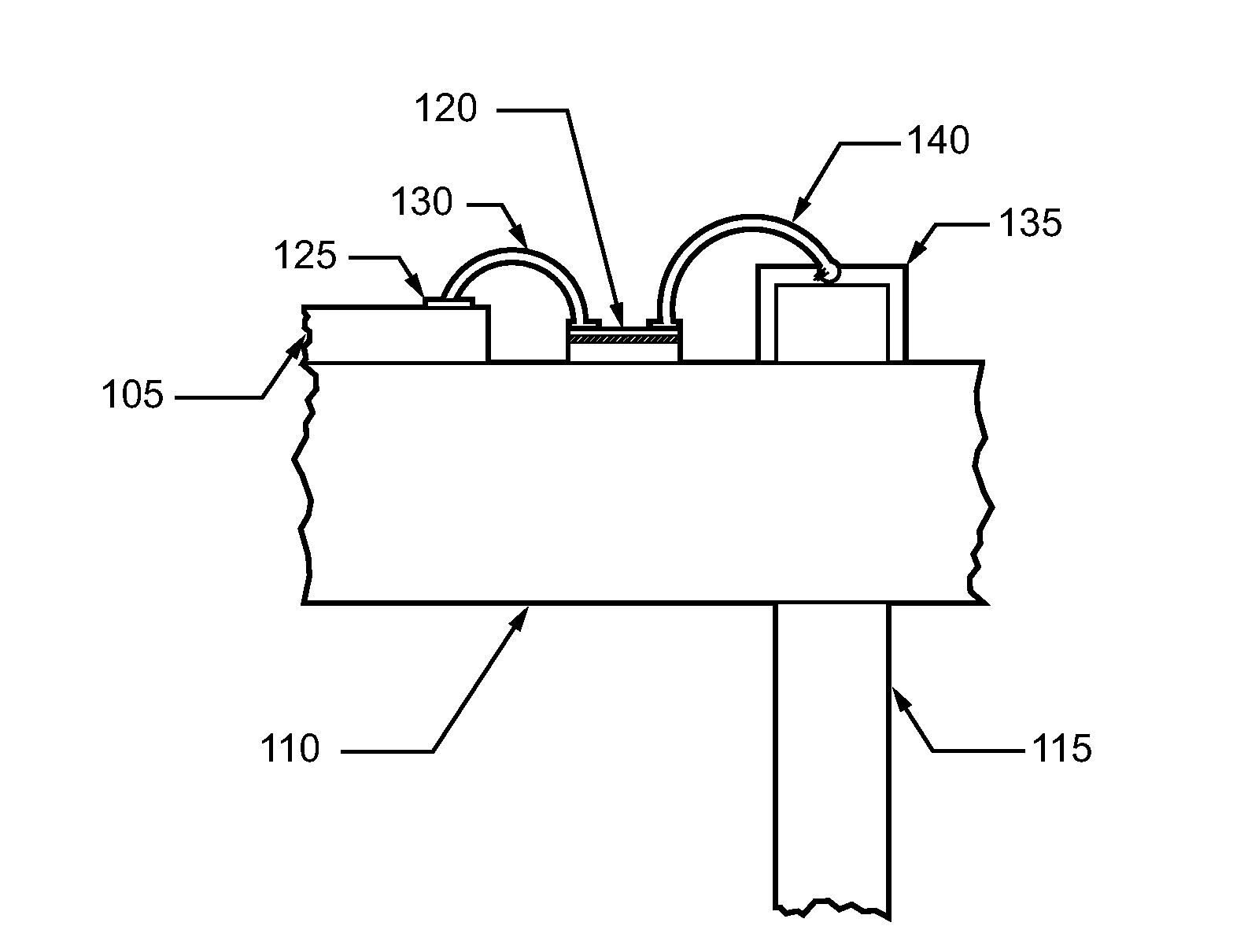

High temperature interconnect assemblies for high temperature electronics utilizing transition pads

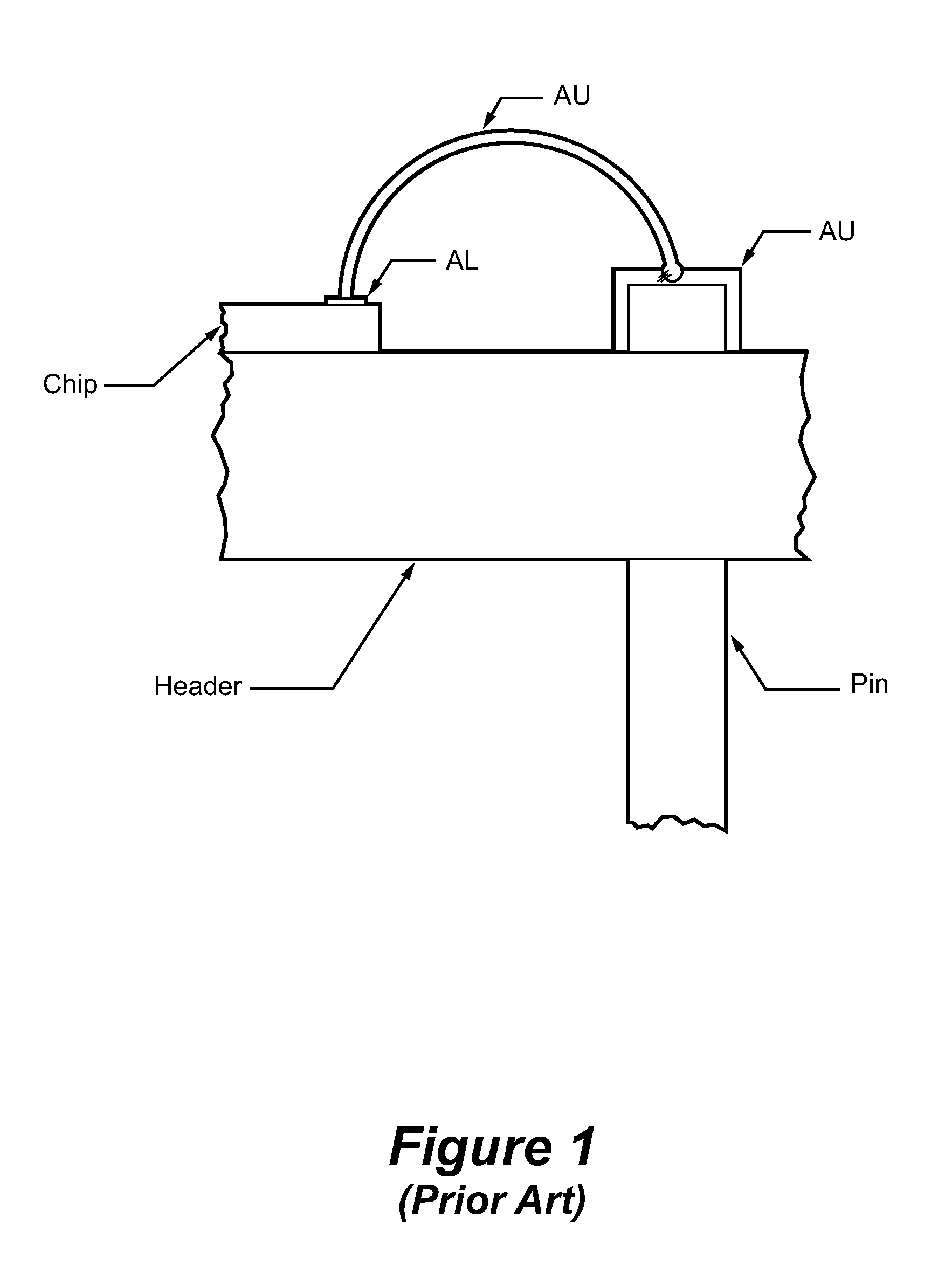

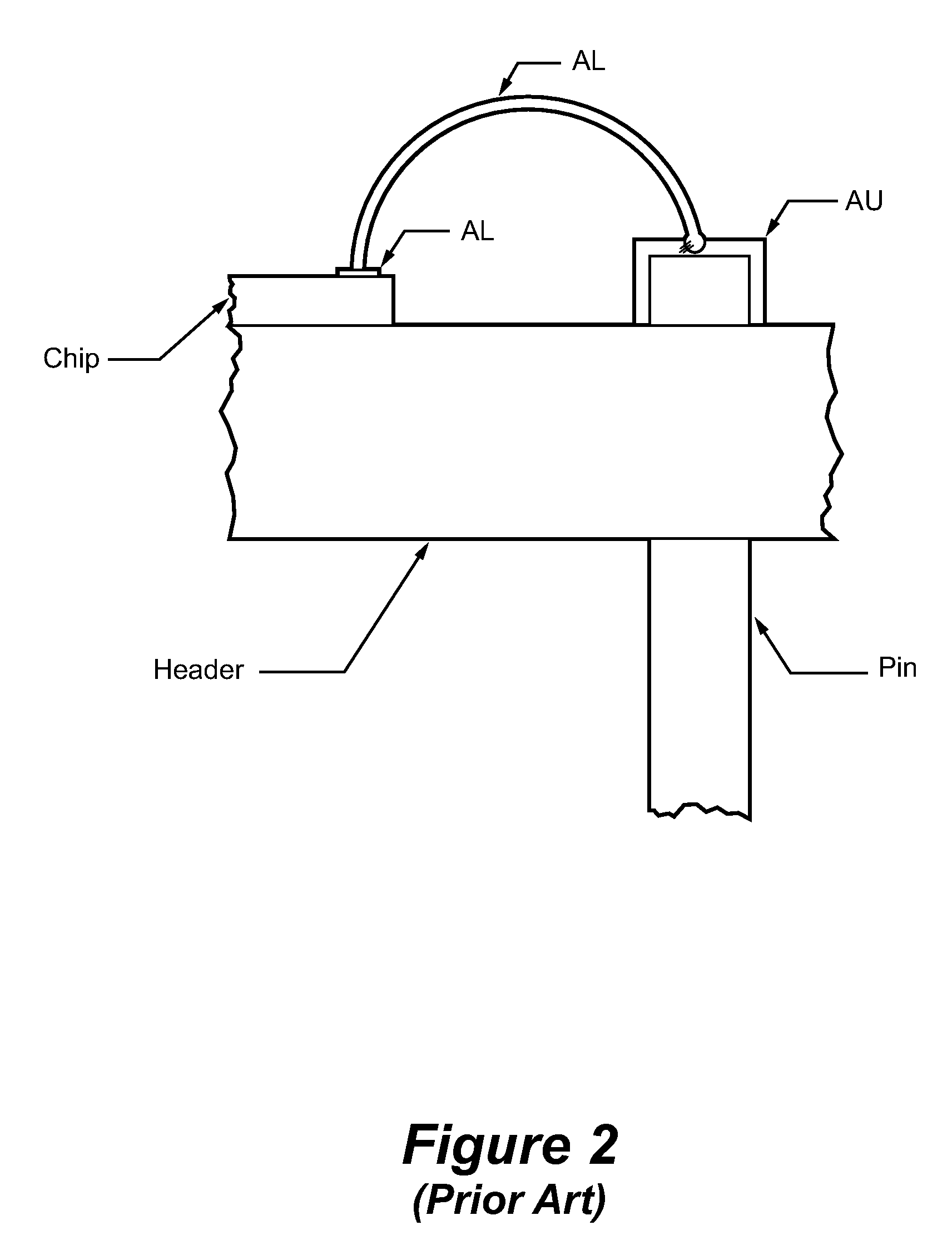

ActiveUS20140048936A1Facilitate communicationSemiconductor/solid-state device detailsSolid-state devicesState of artEngineering

An interconnect assembly that operates in environments well exceeding 200° C. without degradation and / or failure. The interconnect assembly of the present invention eliminates the incompatible metal interfaces of the prior art and relies on aluminum first-metal wire to electrically connect to first-metal pads on a chip and a second-metal wire to electrically connect to second-metal plated contacts on a package. Both wire types are then electrically connected together utilizing a high temperature transition pad disposed between the chip and contacts on the package, therefore eliminating incompatible metal interfaces of the prior art.

Owner:KULITE SEMICON PRODS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com