Preparation method for superfine copper-silver core shell composite powder for medium-high temperature electronic slurry

An electronic paste, medium and high temperature technology, applied in conductive materials, conductive materials, circuits, etc., can solve the problems that affect the performance of silver-coated copper powder, silver easily falls off, copper powder is exposed, and achieves strong oxidation resistance and electrical conductivity. Stable performance and good dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

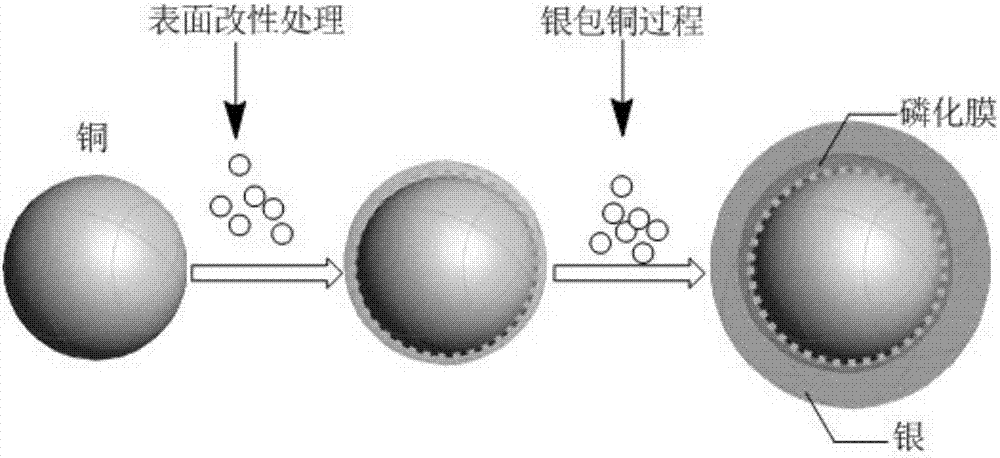

[0022] The medium-high temperature electronic paste in the present invention refers to the electronic paste at 300-900°C, and the preparation method of ultrafine copper-silver core-shell composite powder for medium-high temperature electronic paste comprises the following steps:

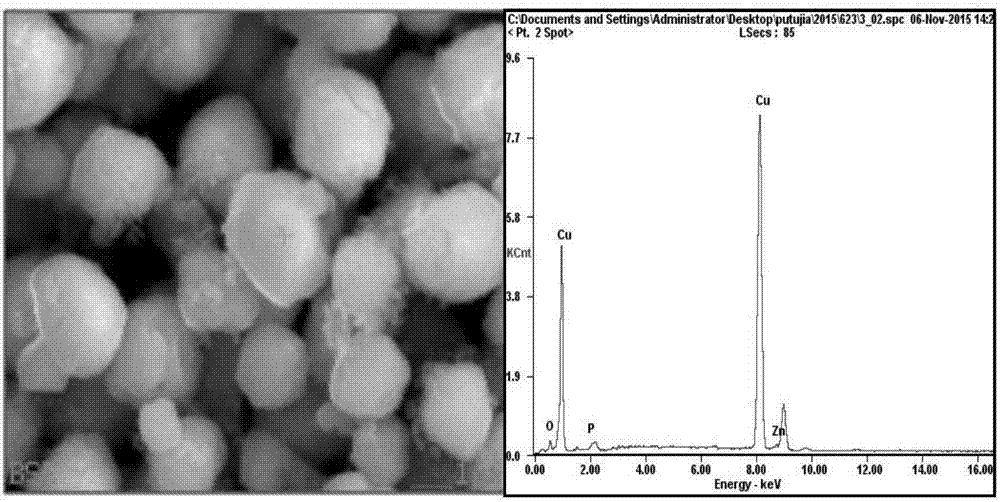

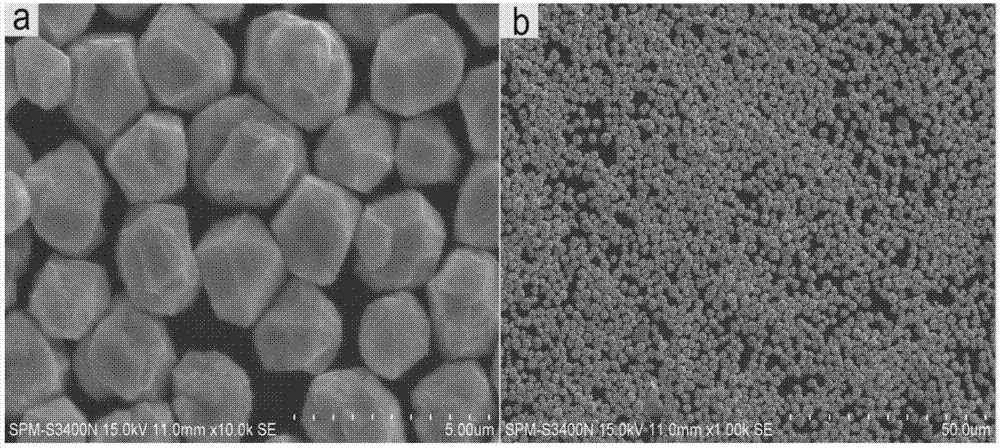

[0023] (1) Prepare copper powder: dissolve copper source and complexing agent in deionized water to prepare oxidation solution; dissolve dispersant and reducing agent in deionized water to prepare reduction solution, adjust the pH of reduction solution to 4-9; Add it into the reducing solution, react at 70°C-90°C for 1h-3h to obtain copper powder, wash the copper powder with 5% sulfuric acid, deionized water, and ethanol in sequence, filter and dry in vacuum to obtain the following: figure 2 The dry copper powder shown; the copper source is copper nitrate, copper chloride or copper sulfate with a volume concentration of 0.5mol / L-1.2mol / L; the complexing agent is ammonia, EDTA-2Na, sodium tartrate, O...

Embodiment 1

[0028] A method for preparing ultrafine copper-silver core-shell composite powder for medium-high temperature electronic paste, comprising the following steps:

[0029](1) prepare copper powder: the copper nitrate solution that volume concentration is 0.5mol / L, the ammoniacal liquor that consumption is copper nitrate solution quality 1% is dissolved in deionized water and is mixed with oxidation solution; Consumption is copper nitrate solution quality 2% Polyvinylpyrrolidone and a reducing agent are dissolved in deionized water to prepare a reducing solution. The reducing agent is a mixture of ascorbic acid, hydrazine hydrate, formaldehyde, sodium hypophosphite, and sodium borohydride, ascorbic acid: hydrazine hydrate: formaldehyde: sodium hypophosphite: borohydride The molar ratio of sodium is 1:2.5:1.1:4:1; the pH of the reducing solution is adjusted to 4; the oxidizing solution is added to the reducing solution and reacted at 70°C for 1 hour to obtain copper powder. Sulfuri...

Embodiment 2

[0033] A method for preparing ultrafine copper-silver core-shell composite powder for medium-high temperature electronic paste, comprising the following steps:

[0034] (1) Prepare copper powder: the copper nitrate solution that volume concentration is 0.8mol / L, the ammoniacal liquor that consumption is copper nitrate solution quality 1%, the sodium tartrate that consumption is copper nitrate solution quality 1% are dissolved in deionized water and are mixed with oxidation solution; the amount of polyvinylpyrrolidone and reducing agent that are 4% of the copper nitrate solution mass is dissolved in deionized water to prepare a reducing solution, and the reducing agent is a mixture of ascorbic acid, hydrazine hydrate, formaldehyde, sodium hypophosphite, sodium borohydride, ascorbic acid : Hydrazine hydrate: formaldehyde: sodium hypophosphite: sodium borohydride molar ratio is 1:2.5:1.1:4:1; adjust the pH of the reducing solution to 9; add the oxidizing solution to the reducing s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com