Radiation-resistant polyimide film insulating cable with high bonding strength and method for producing same

A polyimide film and insulated cable technology, which is applied in the direction of insulated cables, insulated conductors, organic insulators, etc., can solve the problems of large loss of mechanical strength, low temperature resistance of perfluoroethylene propylene, and poor radiation resistance. Achieve the effects of improving temperature resistance, high radiation resistance, high temperature resistance and radiation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

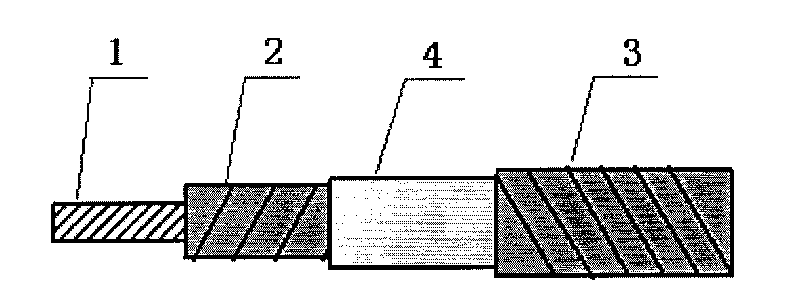

[0033] like figure 1 As shown, a layer of polyimide film 2 is first wrapped around the conductor 1, and then the adhesive 4 is applied. The adhesive 4 uses 1,2,4,5-benzenetetracarboxylic dianhydride / 3,3 - Diaminobenzophenone, and cured at 180°C for 5 minutes; then wrapping the second layer of film 3, and cured at 300°C for 10 minutes, so that the two layers of film are bonded together to form a high temperature resistant, radiation resistant Insulated cables.

Embodiment 2

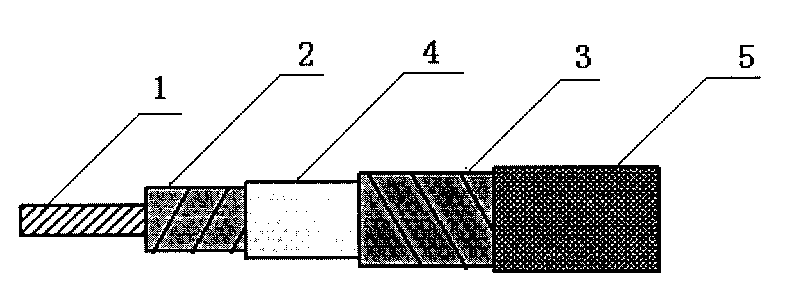

[0035] First wrap a layer of polyimide film 2 around the conductor, and then apply adhesive 4, which uses 3,3',4,4'-biphenyltetracarboxylic dianhydride / 4,4 -Diphenyl ether diamine, and cured at 150°C for 10 minutes; then wrap the second layer of film 3, and perform the second coating, the coating is a polyimide protective layer 5, using 3, 3', 4,4'-benzophenonetetracarboxylic dianhydride / 3,3-diaminodiphenylmethane, and cured at 320°C for 10 minutes to bond the two layers of film together to form a high temperature and radiation resistant tape Sheathed insulated cables.

Embodiment 3

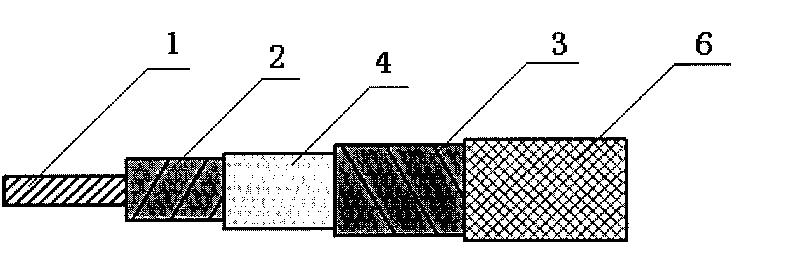

[0037] First wrap a layer of polyimide film 2 around the conductor, and then apply adhesive 4, which uses 3,3',4,4'-diphenyl ether tetracarboxylic dianhydride / 3,3 -diaminobenzophenone, and cured at 180°C for 5 minutes; then wrapped the second layer of film 3, and cured at 300°C for 10 minutes, so that the two layers of films are bonded together, The braided shielding layer 6 is silver-plated copper wire to form a shielded cable with continuous high temperature resistance, radiation resistance and high bonding strength.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com