Aluminum nitride porous ceramic and preparation method thereof

A technology of porous ceramics and aluminum nitride, which is applied in the field of aluminum nitride porous ceramics and its preparation, can solve the problems of high preparation cost and complex production process, and achieves low preparation cost, simple production process, superior economy and reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

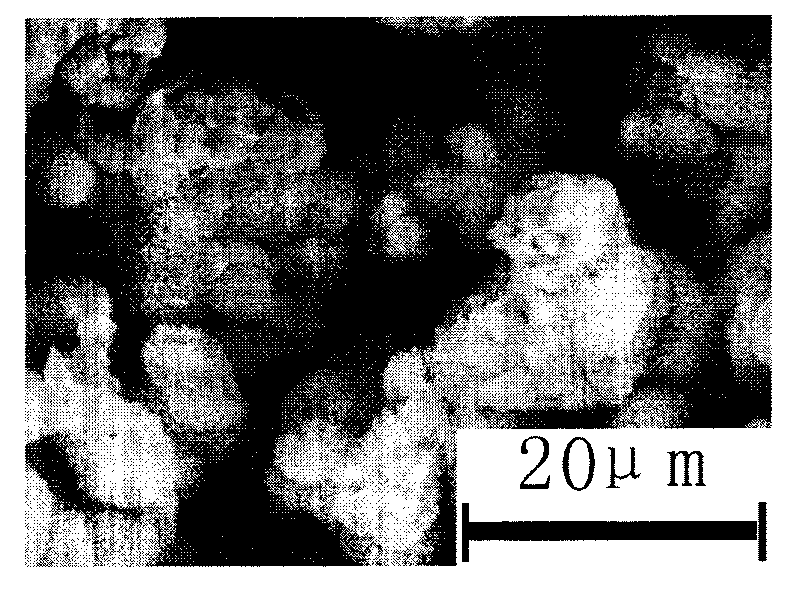

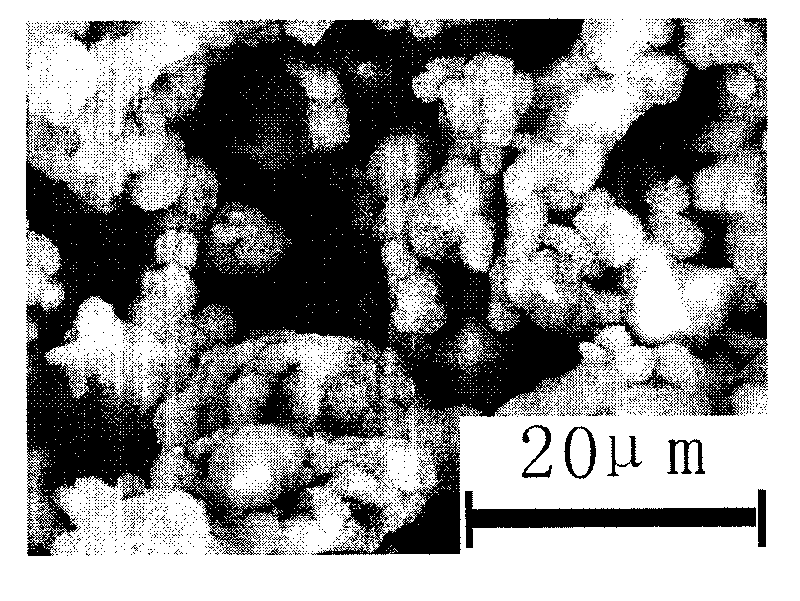

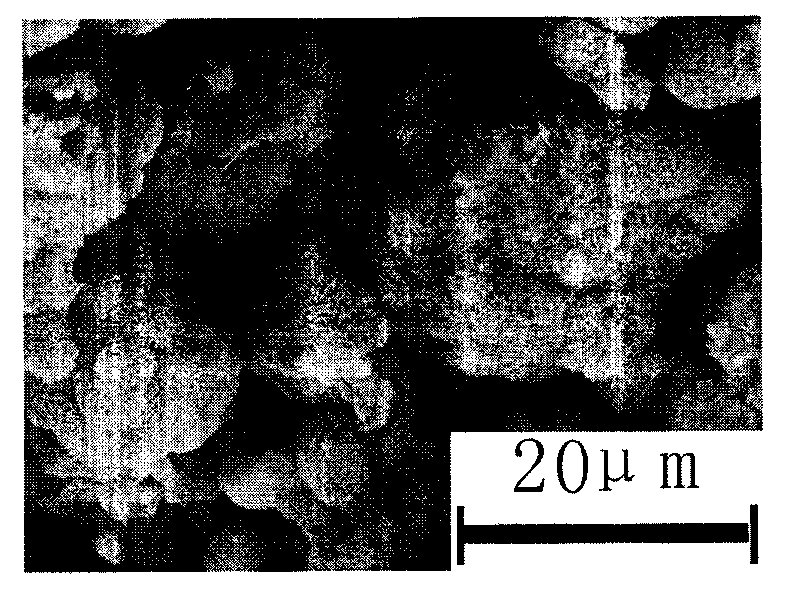

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with specific examples.

[0021] The composition of aluminum nitride porous ceramics is shown in Table 1. In Examples 1-21 shown in Table 1, the average particle size of alumina is generally controlled at 0.2-2 μm. If it is less than 0.2 μm, the powder is easy to agglomerate , It is not conducive to the carbothermal reduction reaction, and the aluminum nitride porous ceramics formed larger than 2 μm have too high porosity, coarse grains, and reduced mechanical properties. Therefore, the average particle size of alumina is preferably controlled between 0.2 and 2 μm.

[0022] The mass ratio of alumina to carbon black is preferably 2-4, if it is greater than 4, alumina will remain in the sintered body. The heat resistance and corrosion resistance of the obtained porous ceramics will be reduced; if it is less than 2, carbon will remain in the sintered body, which will affect the mechanical prope...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com