PE cable material subjected to irradiation cross-linking at 125 DEG C for UL high-temperature electronic wire and preparation method of PE cable material

A technology for electronic wire and cable material, which is used in the field of UL high temperature electronic wire irradiated cross-linked PE cable material at 125°C and its preparation, which can solve the problem of reducing the tensile strength, elongation at break, and flame retardant efficiency of the cable material. It is not high, expensive and other problems, to achieve the effect of increasing the finish, low price and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

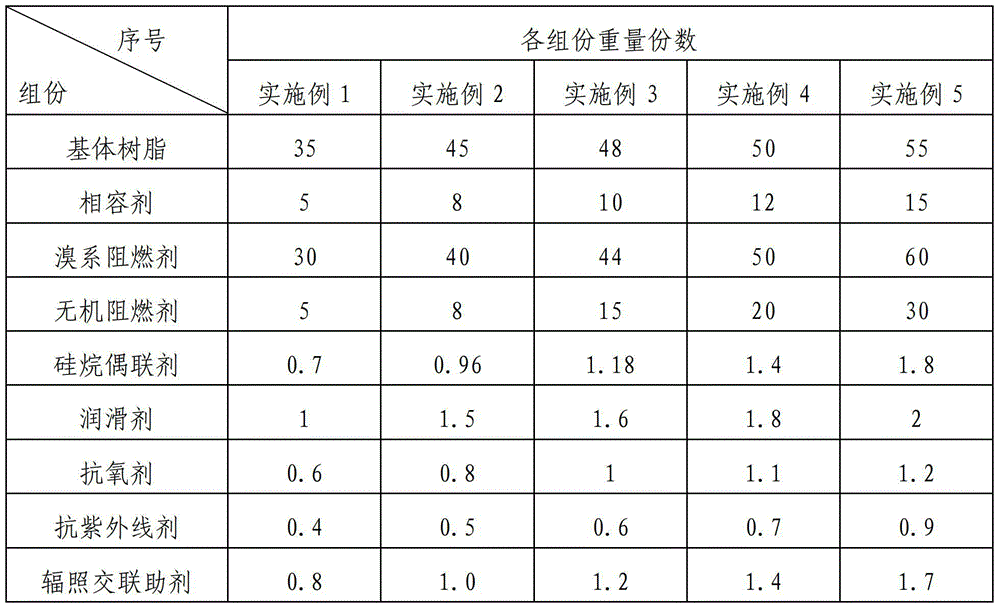

Embodiment 1

[0030] In Example 1: the weight parts of polyethylene A, polyethylene B, and ethylene-octene copolymer in the matrix resin are 12 parts, 17 parts, and 6 parts respectively; in the brominated flame retardant, decabromodiphenylethane The parts by weight of antimony trioxide and antimony trioxide are 22.5 parts and 7.5 parts respectively; the parts by weight of aluminum hydroxide and zinc borate in the inorganic flame retardant are 2.5 parts and 2.5 parts respectively; silicone masterbatch, The weight parts of polyethylene wax are 0.7 part and 0.3 part respectively; the main antioxidant and auxiliary antioxidant in the antioxidant are 0.3 part and 0.3 part respectively.

Embodiment 2

[0031] In Example 2: the weight parts of polyethylene A, polyethylene B, and ethylene-octene copolymer in the matrix resin are 16 parts, 22 parts, and 7 parts respectively; decabromodiphenylethane in the brominated flame retardant The parts by weight of antimony trioxide and antimony trioxide are 30 parts and 10 parts respectively; the parts by weight of aluminum hydroxide and zinc borate in the inorganic flame retardant are 4 parts and 4 parts respectively; the silicone masterbatch, The weight parts of the two polyethylene waxes are respectively 1.2 parts and 0.3 parts; the weight parts of the main antioxidant and the auxiliary antioxidant in the antioxidant are respectively 0.4 parts and 0.4 parts.

Embodiment 3

[0032] In Example 3: the weight parts of polyethylene A, polyethylene B, and ethylene-octene copolymer in the matrix resin are 17 parts, 23 parts, and 8 parts respectively; in the brominated flame retardant, decabromodiphenylethane The parts by weight of antimony trioxide and antimony trioxide are 33 parts and 11 parts respectively; the parts by weight of aluminum hydroxide and zinc borate in the inorganic flame retardant are 7.5 parts and 7.5 parts respectively; the silicone masterbatch, The weight parts of the two polyethylene waxes are respectively 1.2 parts and 0.4 parts; the weight parts of the main antioxidant and the auxiliary antioxidant in the antioxidant are respectively 0.5 parts and 0.5 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com