Pb-free solder for high-temperature electronic packaging and preparation method thereof

A technology for electronic packaging and lead-free solder, applied in manufacturing tools, welding equipment, metal processing equipment, etc., can solve the problems of poor brazing performance, high tensile strength, difficult processing, etc. good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

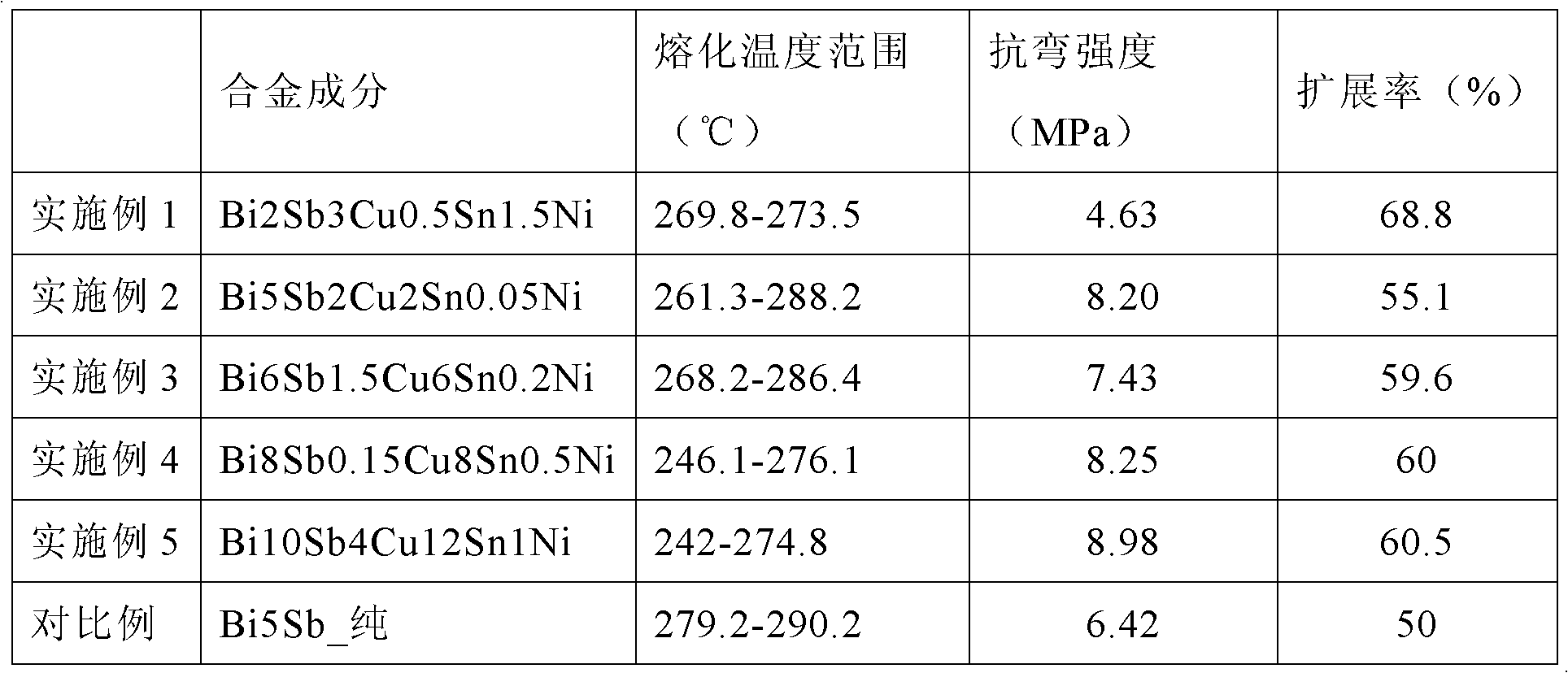

Embodiment 1

[0024] Mix the raw materials according to the following weight percentages: Sb 2%, Cu 3%, Sn 0.5%, Ni 1.5%, Ga, P and mixed rare earth 0.05%, the balance being Bi, and put them in a vacuum melting furnace at 850-1100℃ Keep the temperature for 1-2h, in order to ensure the uniformity of the alloy structure, fully stir and cast and solidify to obtain the brazing alloy. Compared with the comparative example, the melting point is lowered and the spreading performance is improved.

Embodiment 2

[0026] The raw materials are mixed according to the following weight percentages: Sb 5%, Cu 2%, Sn 2%, Ni 0.05%, Ga, P and mixed rare earth 0.01%, and the balance is Bi. Put them in a vacuum melting furnace at 850-1100°C. 1-2h, in order to ensure the uniformity of the alloy structure, fully stir and cast and solidify to obtain the solder alloy before being discharged. Compared with the comparative example, the melting point is lowered, and the spreading performance and mechanical properties are improved.

Embodiment 3

[0028] The raw materials are proportioned according to the following weight percentages: Sb 6%, Cu 1.5%, Sn 6%, Ni 0.2%, Ga, P and mixed rare earth 0.08%, the balance is Bi, and put them in a vacuum melting furnace at 850-1100℃ Keep the temperature for 1-2h, in order to ensure the uniformity of the alloy structure, fully stir and cast and solidify to obtain the brazing alloy. Compared with the comparative example, the melting point is lowered, and the spreading performance and mechanical properties are improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com