High-temperature electronic packaging substrate material device based on gas-liquid phase change and preparation method thereof

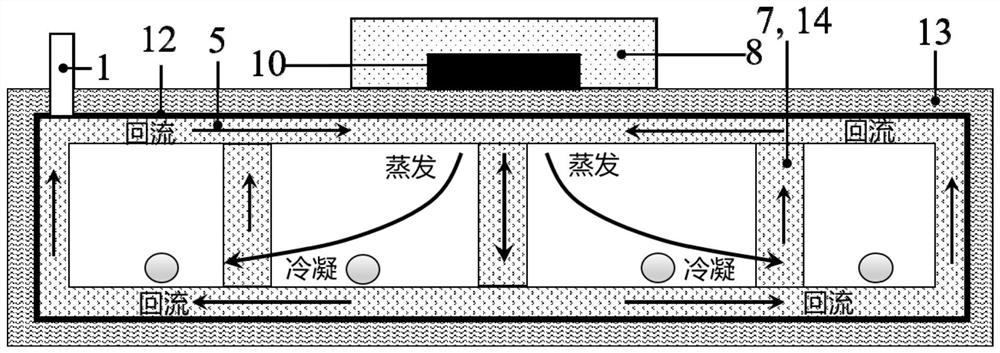

A technology of electronic packaging and gas-liquid phase, which is applied in the field of high-temperature electronic packaging substrate material devices and its preparation, can solve the problems of excessive thermal resistance and uneven stress distribution, achieve high thermal conductivity, uniform temperature distribution, and improve heat transfer capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] In addition, the present invention also proposes a method for preparing a high-temperature electronic packaging substrate material device based on gas-liquid phase transition, including the following steps:

[0048] (1) The upper shell 2 and the lower shell 3 with a symmetrical structure that can form the airtight cavity 6 are prepared by mechanical processing;

[0049] (2) Paste the porous medium 5 on the inner wall surfaces of the upper casing 2 and the lower casing 3;

[0050] (3) Carrying out surface modification treatment to the porous medium 5, so that it has a super-wetting surface;

[0051] (4) sealing the upper shell 2 and the lower shell 3 after assembling, and obtaining the substrate shell 9 with the airtight cavity 6;

[0052] (5) Process the liquid filling pipe 1 connected to the porous medium 5 on the substrate housing 9, and fill the liquid working medium into the porous medium 5, and then seal the liquid filling pipe 1 after vacuuming;

[0053] (6) Mou...

Embodiment 1

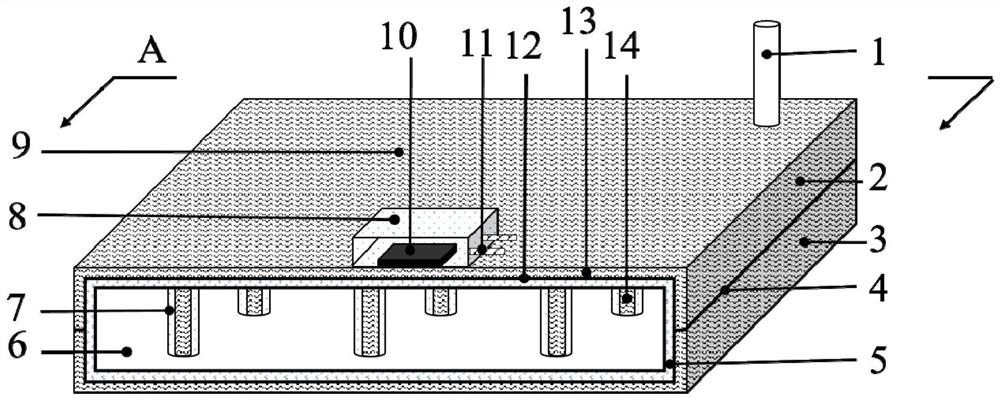

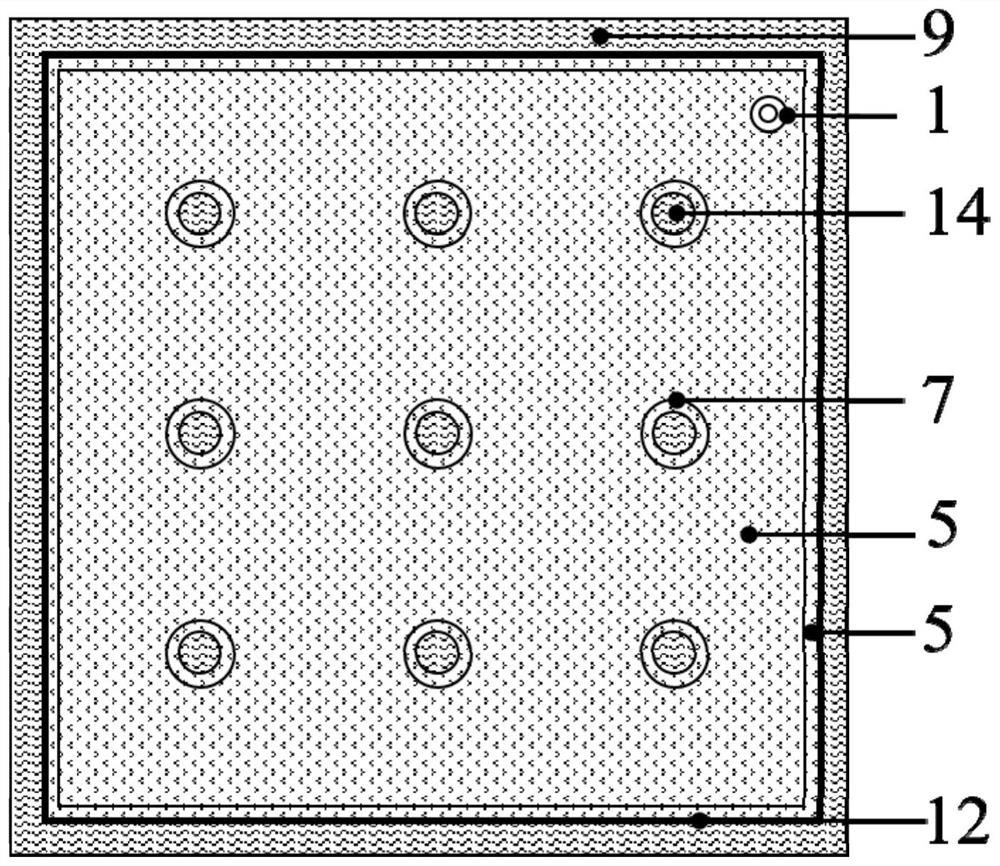

[0061] A high-temperature electronic packaging substrate material based on gas-liquid phase change heat transfer, its structure please refer to Figure 1-Figure 3 , Figure 5 etc., its preparation method is as follows:

[0062] Step 1, shell molding: the upper shell 2 and the lower shell 3 with support columns 14 and symmetry planes 13 are prepared from a molybdenum-copper alloy plate (MoCu15) with a thickness of 1.5 mm by machining.

[0063] Step 2. Cleaning of the inner and outer surfaces of the substrate shell material: First, use acetone and ultrasonic cleaning to remove impurities such as organic matter and particulate matter remaining on the surface of the substrate material shell (time: 30 minutes); then use cathodic degreasing to completely clean the shell. Grease on the surface of the body (time: 20s); then use ammonia solution to remove molybdenum oxide on the surface (time: 10s), and use dilute sulfuric acid to remove surface copper oxide (time: 10s); finally rinse...

Embodiment 2

[0076] In this embodiment, the thermal expansion rate of the high-temperature electronic packaging substrate based on gas-liquid phase change heat transfer can be coordinated and regulated through the thermal expansion performance of the shell material itself and the uniform temperature performance of the rapid diffusion of gas-liquid phase change. The rate-controllable electronic packaging substrate material is processed into housings of different sizes (square, circular, rectangular, with a thickness of 1-3mm), and the rest are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com