Exhaust back pressure wave adjustment device for supercharged diesel engine

A technology of exhaust back pressure and diesel engine, which is applied in the field of experimental research on the working performance of diesel engines, and can solve the problems that the exhaust back pressure adjustment device cannot reflect the exhaust back pressure waveform and cannot be adjusted and controlled.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

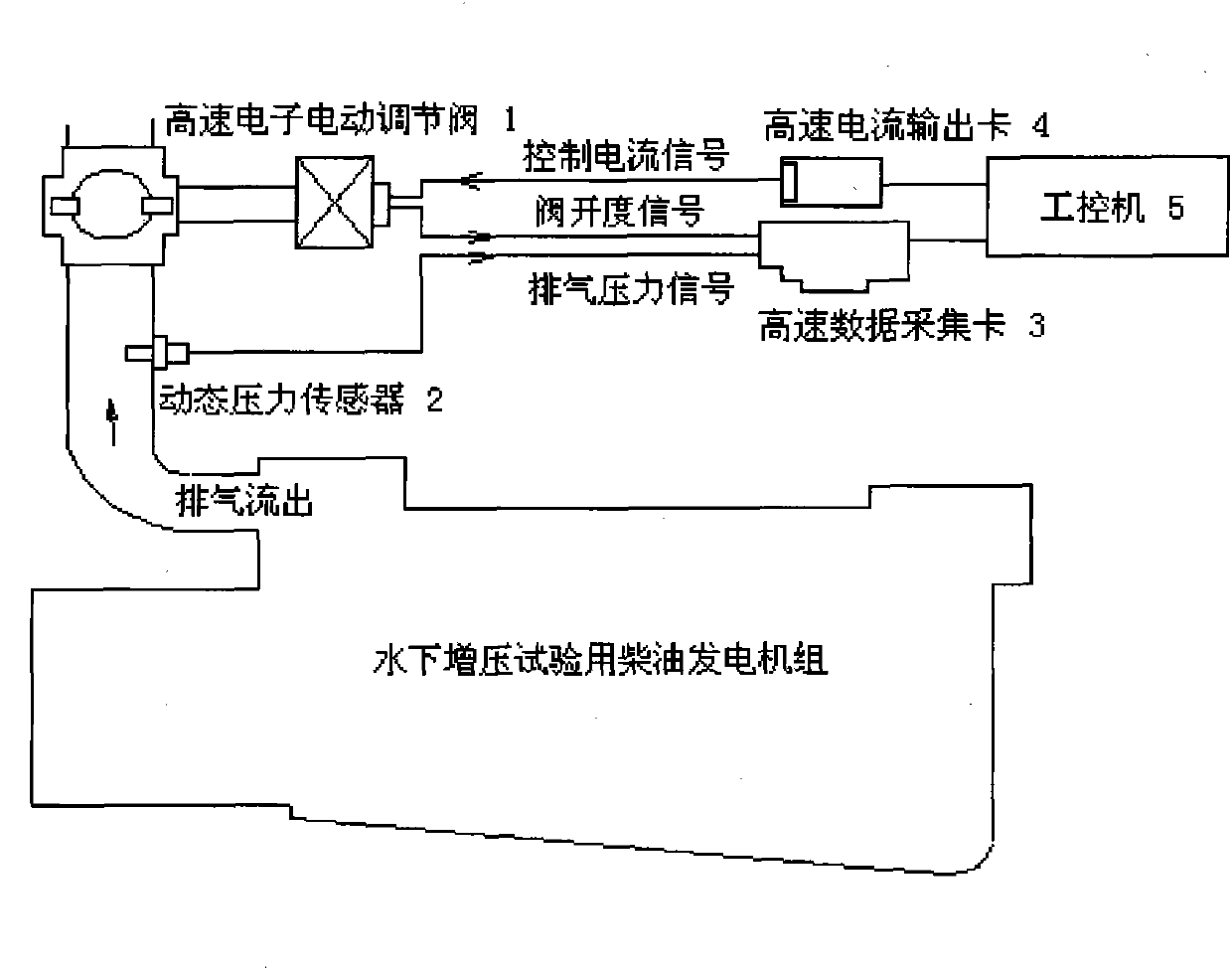

[0020] see figure 1 As shown, in an embodiment of the present invention, the supercharged diesel engine exhaust back pressure wave regulating device includes: a high temperature electronic electric control valve 1, a dynamic pressure sensor 2, and an industrial computer 5; the industrial computer 5 is provided with A high-speed data acquisition card 3 and a high-speed current output card 4 are installed with control software.

[0021] The high-temperature electronic electric regulating valve 1 is the exhaust back pressure regulating valve, which is arranged on the exhaust pipe of the diesel generator set used for the underwater pressurization test. In order to shorten the opening and closing time of the valve and meet the frequency requirement of the exhaust back pressure wave, the diameter of the exhaust back pressure regulating valve is selected according to the minimum allowable value under the design value of the exhaust flow and back pressure, so as to reduce the Core (d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com