Release method of residual compression stress in nanocrystalline cubic boron nitride pellicle

A technology of cubic boron nitride and compressive stress, applied in gaseous chemical plating, ion implantation plating, coating, etc., can solve environmental pollution and other problems, and achieve the effect of mild environment, simple equipment and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

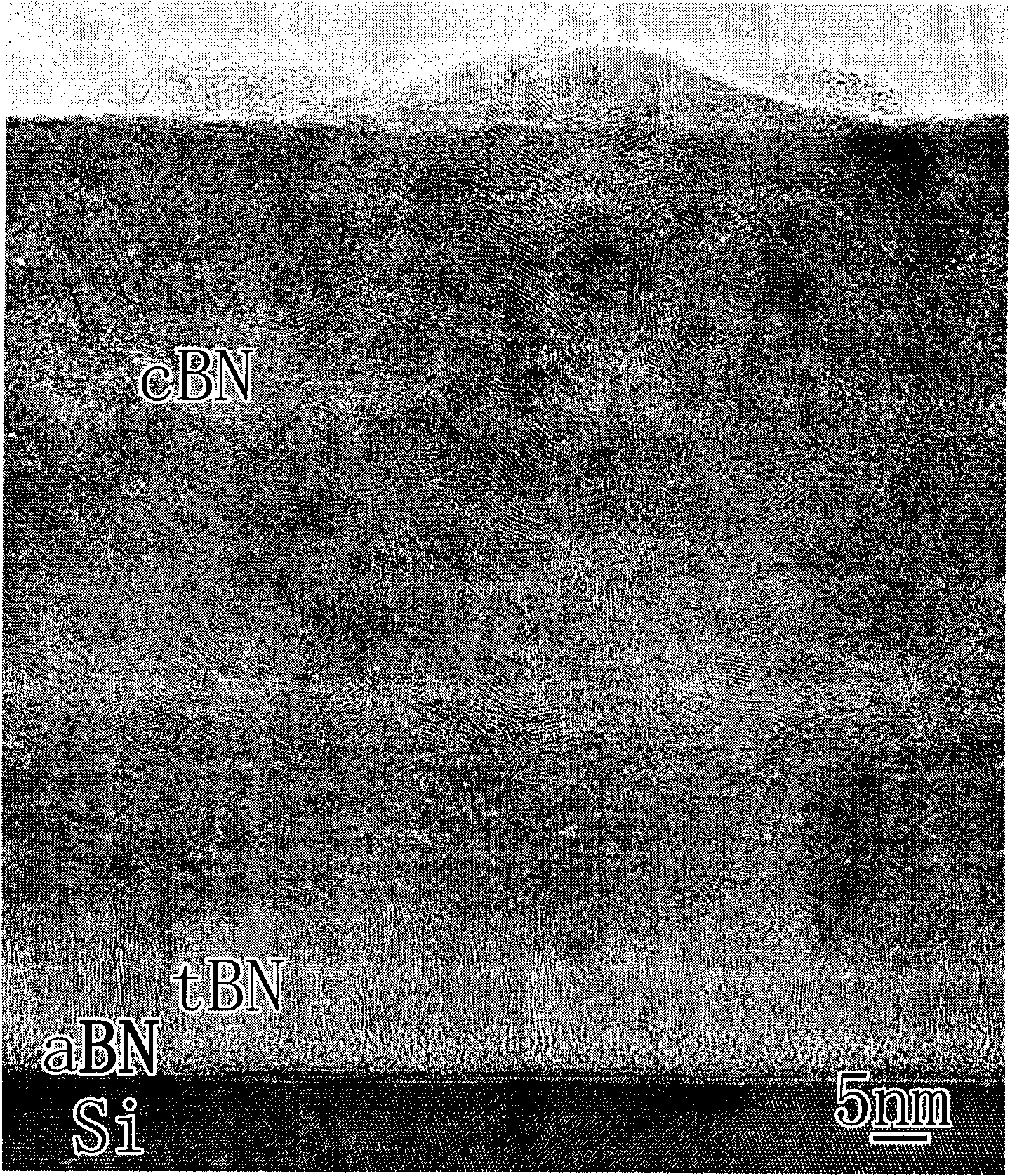

[0018] The cubic boron nitride thin film deposited on the single crystal silicon substrate by PECVD method (the thickness of the non-cubic phase layer in the initial stage of the film is ~ 7nm, and the thickness of the cubic phase layer is 100nm) is put into the heating chamber and evacuated to 10 -6 Torr, then charged with H 2 , to evacuate the heating chamber to 10 -4 Torr, the heating chamber was heated to 1200°C for 2 hours and then cooled to room temperature. The residual compressive stress of the example cubic boron nitride film was reduced from ~6GPa to less than 4GPa. figure 1 Shown is its high-resolution electron microscope photo. It can be seen from the figure that the cubic boron nitride film still maintains a typical layered structure.

[0019] The cubic boron nitride film was stored in the air for more than 10 months without peeling off from the substrate. However, the cubic boron nitride film that has not undergone this treatment begins to peel off after being...

Embodiment 2

[0021] Put the cubic boron nitride film deposited on the silicon carbide substrate by PECVD method (the thickness of the non-cubic phase layer in the initial stage of the film is ~500nm, and the thickness of the cubic phase layer is 100nm), put it into the heating chamber and evacuate it to 10 -7 Torr, then charge N 2 , to evacuate the heating chamber to 10 -4 Torr, the heating chamber was heated to 1150°C for 3 hours and then cooled to room temperature. The residual compressive stress of the cubic boron nitride film in this example was reduced from ~5GPa to less than 3GPa. The cubic boron nitride film was stored in the air for more than 10 months without peeling off from the substrate. The cubic boron nitride film without this treatment began to peel off after being stored in the air for 2 days.

Embodiment 3

[0023] The cubic boron nitride film deposited on the sapphire substrate by PECVD method (the thickness of the non-cubic phase layer in the initial stage of the film is ~ 10nm, and the thickness of the cubic phase layer is 200nm) is placed in a heating chamber and evacuated to 10 -7 Torr, then filled with Ar, the heating chamber was evacuated to 10 -5 Torr, the heating chamber was heated to 1250°C for 2 hours and then cooled to room temperature. The residual compressive stress of the cubic boron nitride film in this example was reduced from ~6GPa to less than 4GPa. The cubic boron nitride film was stored in the air for more than 10 months without peeling off from the substrate. However, the cubic boron nitride film without this treatment began to peel off after being stored in the air for 1 hour.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| compressive stress | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com