Relay connector

A technology for relay connectors and coaxial connectors, applied in the direction of connection, test/measurement connectors, conductive connections, etc., can solve uneconomical, cumbersome melting soldering operations, and coaxial connector soldering operations cumbersome and other issues, to achieve the effect of reliable electrical connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

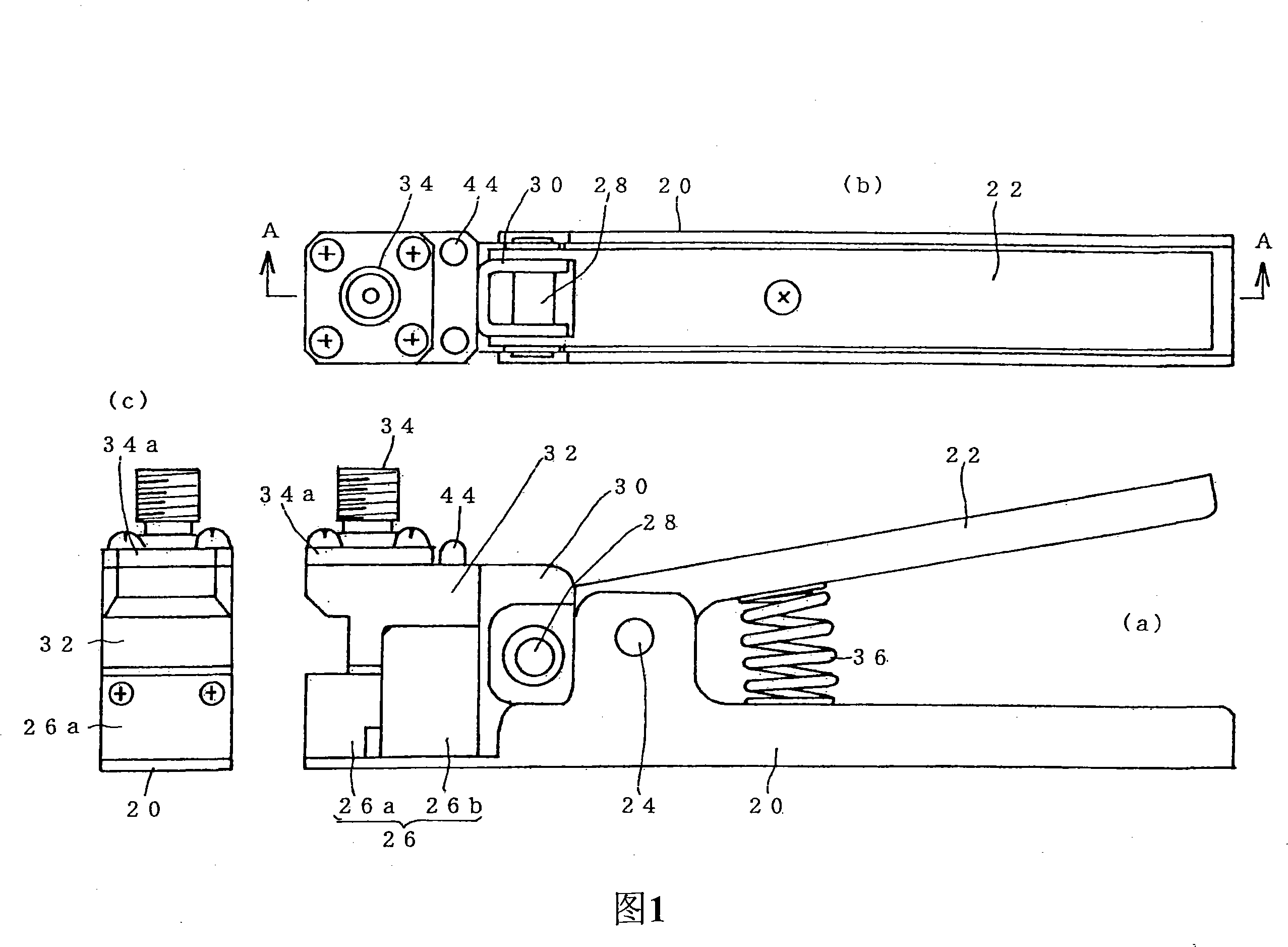

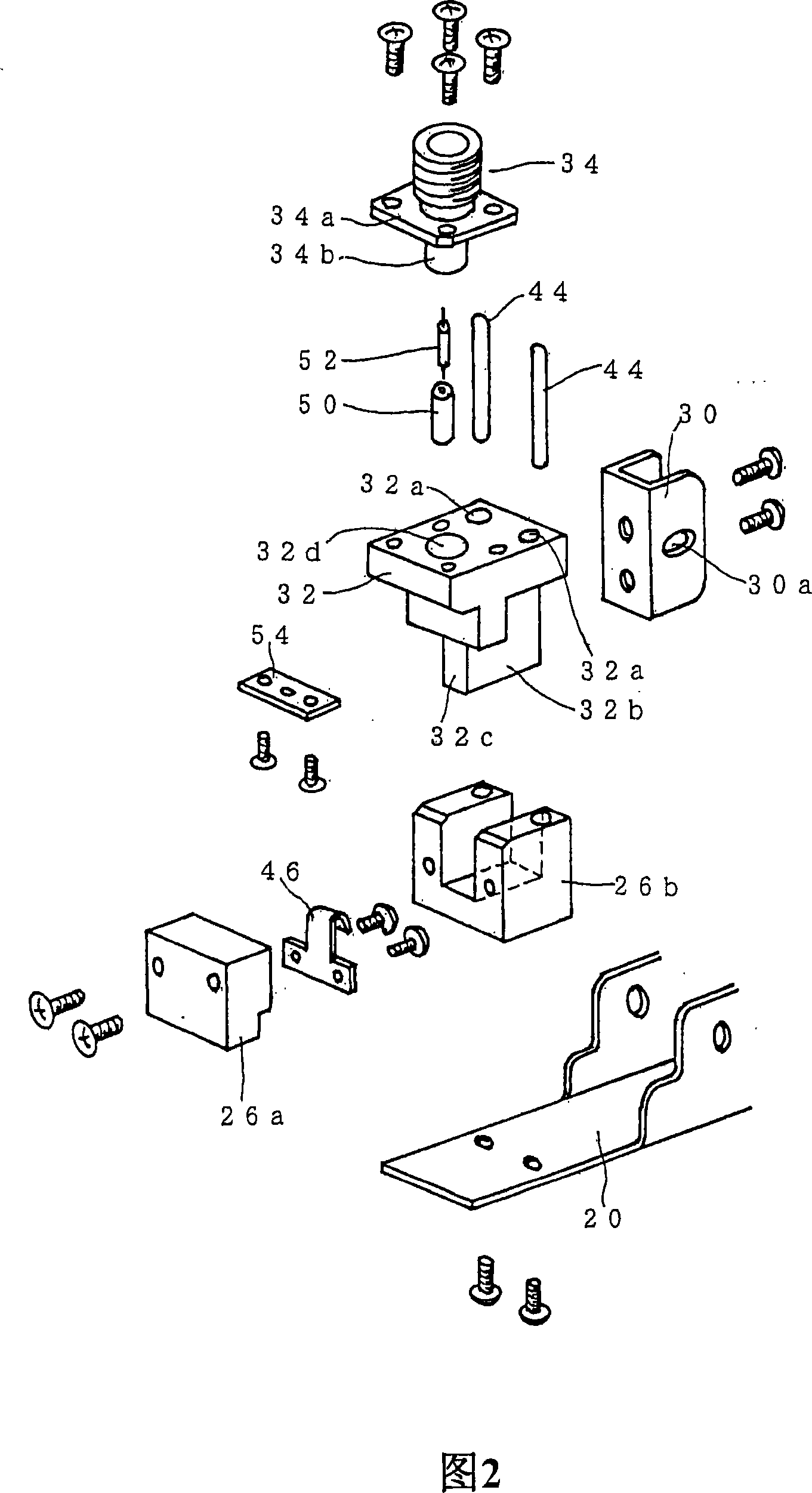

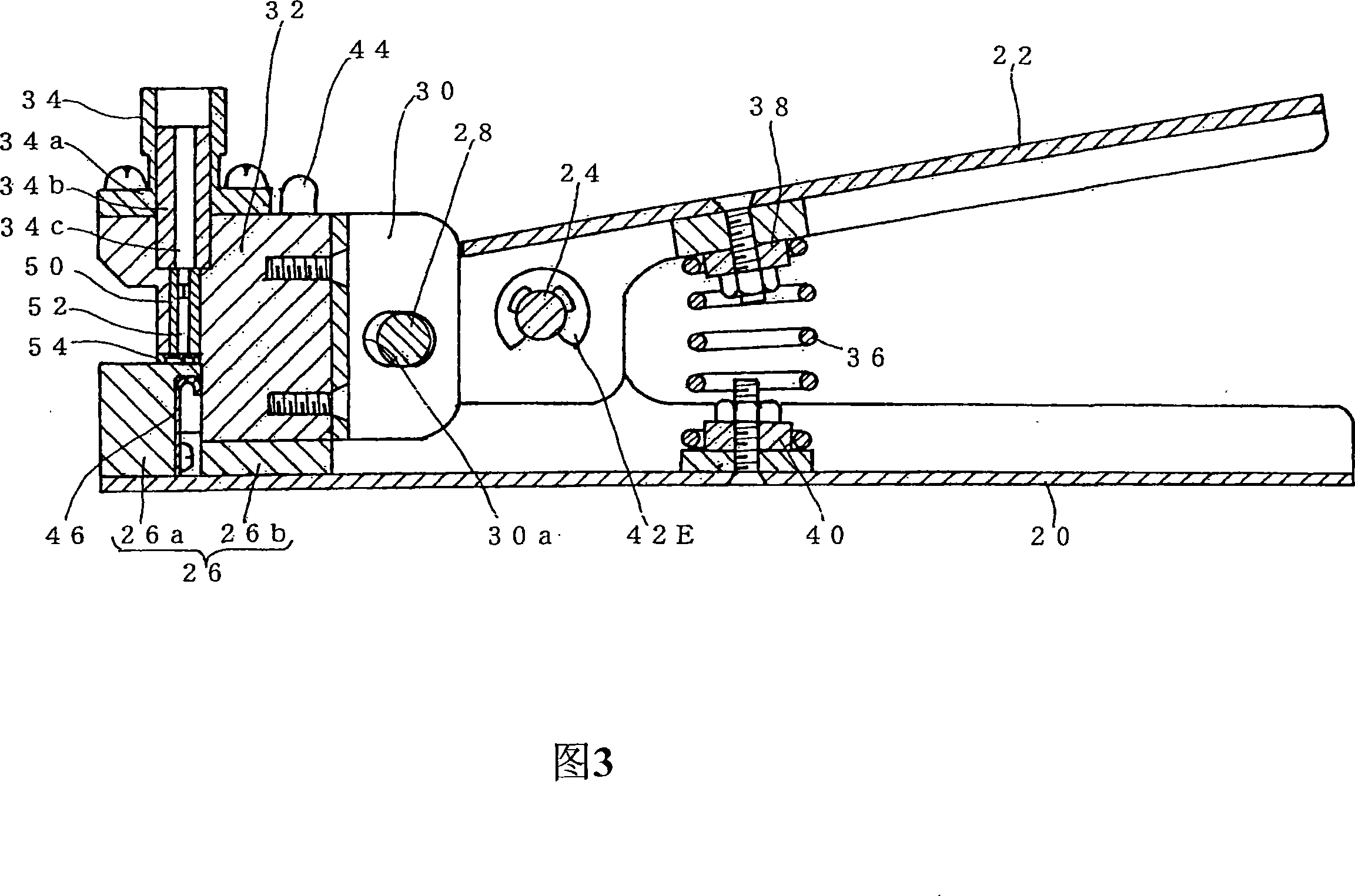

[0068] A first embodiment of the present invention will be described below with reference to FIGS. 1 to 7 . 1 is an external view of a first embodiment of the relay connector of the present invention, (a) is a front view, (b) is a top view, and (c) is a left side view. Fig. 2 is an exploded perspective view of main parts of Fig. 1 . Fig. 3 is a sectional view along A-A of Fig. 1 . 4 is a partially cutaway cross-sectional view in which the substrate is inserted in a state where the first operating lever and the second operating lever are held. 5 is a partially cutaway sectional view showing a state in which the first operating lever and the second operating lever are released to clamp the substrate after the substrate is inserted. Fig. 6 is a partially cutaway enlarged cross-sectional view showing the structure of a portion where an insulating tube is disposed. Fig. 7 is an exploded perspective view of a portion showing a structure in which a leaf spring is arranged. In FIG...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com