Busbar for assembled battery and assembled battery

A technology for battery packs and bus bars, which can be applied to battery pack components, small-sized batteries/battery packs, battery boxes/jackets, etc., and can solve problems such as poor welding and jointing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

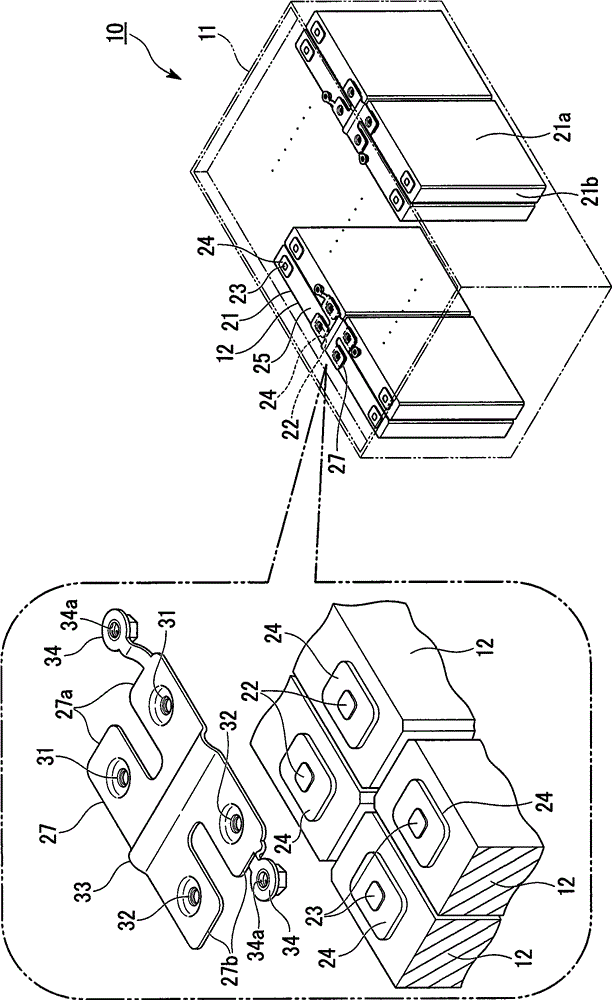

[0022] A battery pack according to an embodiment will be described below with reference to the drawings.

[0023] Such as figure 1 As shown, the battery pack 10 of this embodiment includes: a housing 11 made of resin or the like; and a plurality of secondary batteries 12 accommodated inside the housing 11 .

[0024] Each battery of a plurality of secondary batteries 12 is, for example, a non-aqueous electrolyte secondary battery such as a lithium-ion battery, comprising: a flat substantially square-shaped outer container 21 formed of aluminum or an aluminum alloy; An electrode body (not shown) in the outer container 21 .

[0025] Each secondary battery 12 is interposed between a terminal insulator 24 made of an insulator such as synthetic resin or glass, and has an electrode body connected to the positive electrode at both ends in the longitudinal direction of the terminal surface 25 (for example, the upper end surface in the vertical direction). The positive terminal 22 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com