A kind of preparation method of densified aluminum titanate ceramics

A technology of aluminum titanate and densification, which is applied in the field of ceramic materials, can solve problems such as the complexity of the preparation process, achieve high purity, reduce intermolecular pores, and improve the effect of microstructure and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

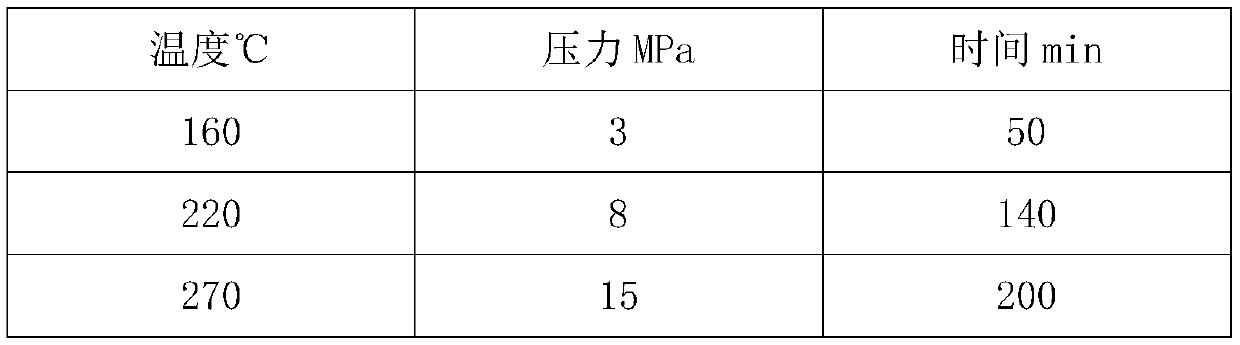

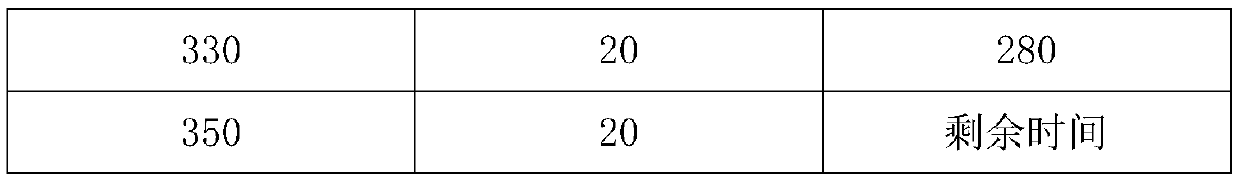

Method used

Image

Examples

Embodiment 1

[0054] A preparation method of densified aluminum titanate ceramics, the preparation steps are as follows:

[0055] Step 1, adding n-butyl titanate and n-butyl silicate to an aqueous ethanol solution with a dispersant, then adding aluminum nitrate, and ultrasonically stirring until completely dissolved to obtain a mixed aqueous ethanol solution;

[0056] Step 2, passing ammonia gas into the mixed ethanol aqueous solution, sealing and recirculating aeration reaction until the ammonia gas is completely dissolved, to obtain a dilute sol solution;

[0057] Step 3, adding the curing agent and dilute ferric chloride solution dropwise into the dilute sol solution, stirring until completely mixed evenly to obtain a mixed sol;

[0058] Step 4, putting the mixed sol into a vacuum distillation kettle for 2 hours of vacuum distillation to obtain a gel;

[0059] Step 5, put the gel into the mold, solidify and form under the condition of shaking and heating, and get the rough embryo after ...

Embodiment 2

[0072] A preparation method of densified aluminum titanate ceramics, the preparation steps are as follows:

[0073] Step 1, adding n-butyl titanate and n-butyl silicate to an aqueous ethanol solution with a dispersant, then adding aluminum nitrate, and ultrasonically stirring until completely dissolved to obtain a mixed aqueous ethanol solution;

[0074] Step 2, passing ammonia gas into the mixed ethanol aqueous solution, sealing and recirculating aeration reaction until the ammonia gas is completely dissolved, to obtain a dilute sol solution;

[0075] Step 3, adding the curing agent and dilute ferric chloride solution dropwise into the dilute sol solution, stirring until completely mixed evenly to obtain a mixed sol;

[0076] Step 4, put the mixed sol into a vacuum distillation kettle for 4 hours of vacuum distillation to obtain a gel;

[0077] Step 5, put the gel into the mold, solidify and form under the condition of shaking and heating, and get the rough embryo after demo...

Embodiment 3

[0090] A preparation method of densified aluminum titanate ceramics, characterized in that: the preparation steps are as follows:

[0091] Step 1, adding n-butyl titanate and n-butyl silicate to an aqueous ethanol solution with a dispersant, then adding aluminum nitrate, and ultrasonically stirring until completely dissolved to obtain a mixed aqueous ethanol solution;

[0092] Step 2, passing ammonia gas into the mixed ethanol aqueous solution, sealing and recirculating aeration reaction until the ammonia gas is completely dissolved, to obtain a dilute sol solution;

[0093] Step 3, adding the curing agent and dilute ferric chloride solution dropwise into the dilute sol solution, stirring until completely mixed evenly to obtain a mixed sol;

[0094] Step 4, put the mixed sol in a vacuum distillation kettle for 3 hours of vacuum distillation to obtain a gel;

[0095] Step 5, put the gel into the mold, solidify and form under the condition of shaking and heating, and get the ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com