Free-standing turbine blade

a free-standing turbine blade technology, applied in the direction of liquid fuel engines, vessel construction, marine propulsion, etc., can solve the problems of additional vibrational resonance modes of blades, unwanted humming of diffusers, unwanted mechanical loading of blades, etc., and achieve the effect of low gap losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

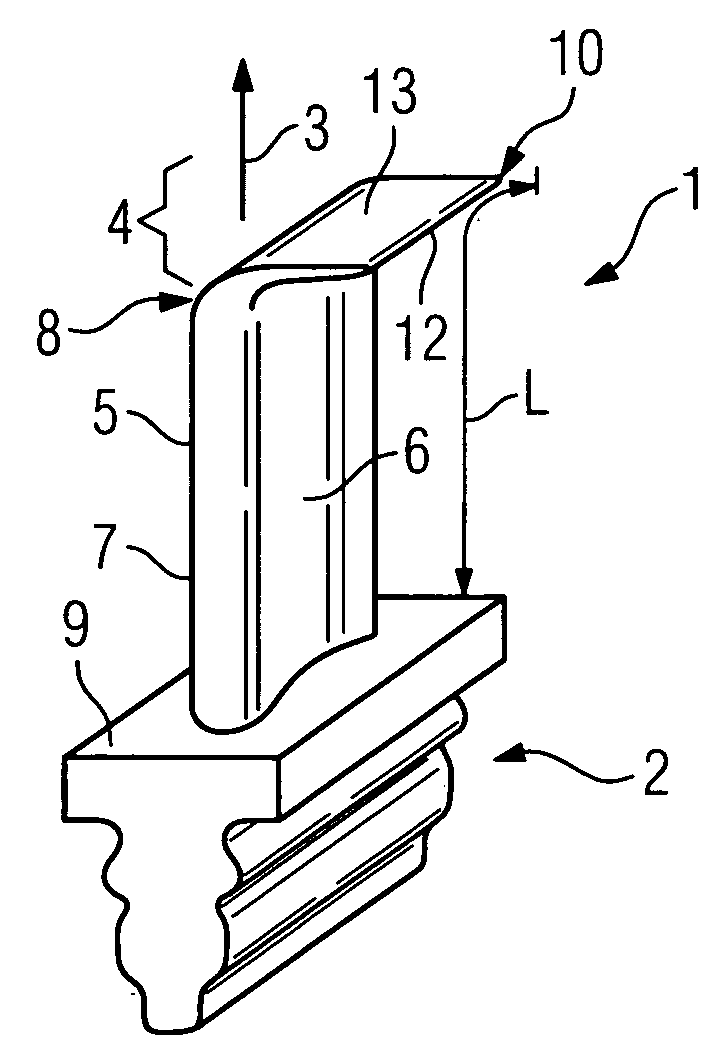

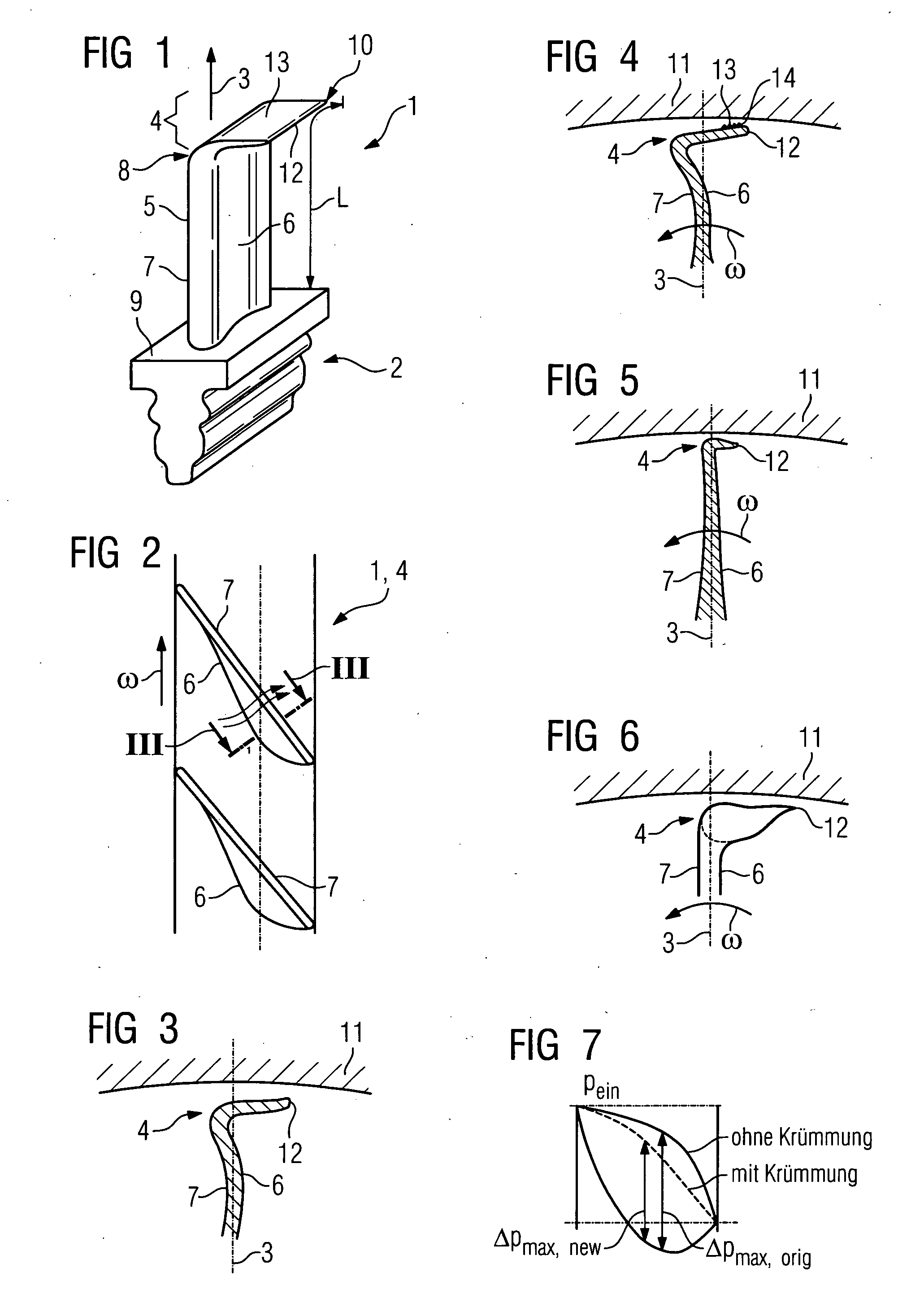

[0023]In FIG. 1, a turbine blade 1 is to be seen in perspective view. The turbine blade has a blade root 2 which is suitable for fastening in a rotor, which is not shown. In this case, the blade root has a so-called fir-tree root shape. Further embodiments for the blade root 2 are known, such as the hook-type root embodiment or T-shaped root embodiment. Such turbine blades 1 can be used in turbomachines such as steam turbines, gas turbines or compressors. The turbine blade 1 is formed along a radial direction 3 and has a blade tip 4 and also a blade profile with a pressure side 6 and a suction side 7.

[0024]The blade tip 4 of the turbine blade 1 has a curvature 8. The curvature 8 in this case is localized on the upper region of the blade tip 4. The curvature 8 is formed as a bend, as a result of which the blade tip is formed in the manner of a winglet, which is known from aircraft construction. The blade 1 has an overall length L which can be calculated from the surface of the blade ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com