Feeding deep-sea optical cable

A deep-sea, optical cable technology, applied in the direction of light guide, optics, optical components, etc., can solve the problems of difficult filling of water blocking materials, long maintenance time, poor radial water blocking ability, etc., so as to improve the longitudinal water blocking ability and reduce maintenance. cost, the effect of improving impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

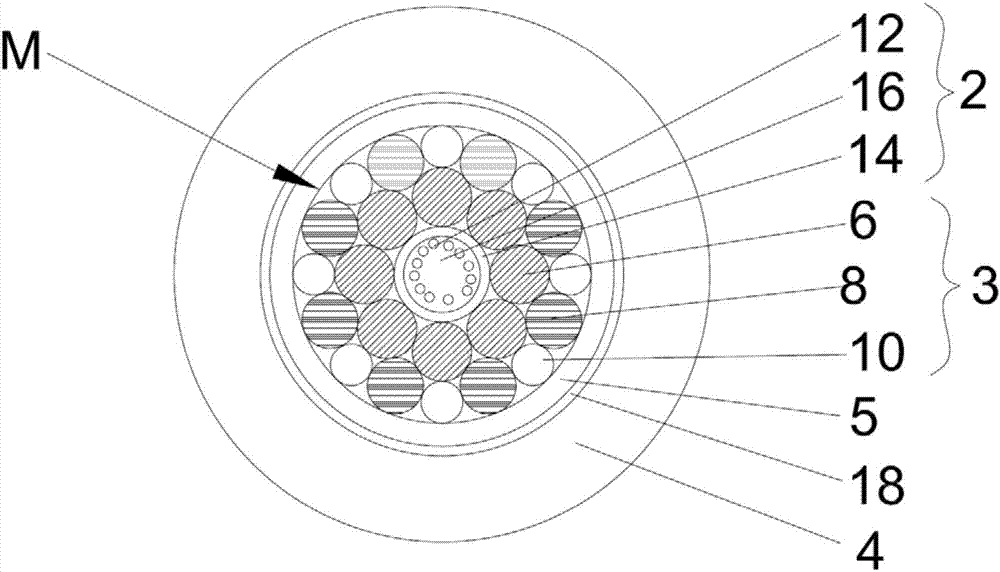

[0039] like figure 1 As shown, this embodiment discloses a feeding deep-sea optical cable, including an optical unit 2, an armor layer 3 twisted outside the optical unit 2, a feed layer 5 coated on the outside of the armor layer 3, and a coating The adhesive layer 18 on the outer side of the feed layer 5 and the high-density polyethylene insulating layer 4 covering the outer side of the adhesive layer 18 .

[0040] The optical unit 2 includes an optical fiber 12 and a stainless steel tube 14 coated on the outside of the optical fiber 12 , and the gap between the optical fiber 12 and the stainless steel tube 14 is filled with fiber paste 16 .

[0041] The armor layer 3 includes an inner twisted layer and an outer twisted layer, the inner twisted layer is twisted outside the stainless steel pipe 14, the outer twisted layer is twisted outside the inner twisted layer, and the feed layer 5 is covered outside the outer twisted layer;

[0042] The above-mentioned inner twisted layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com