Slipper-type radial flexible compensation mechanism of rolling piston-like fluid machine

A technology of rolling piston and compensating mechanism, which is applied to rotary piston type/swing piston type pump components, components of pumping devices for elastic fluids, mechanical equipment, etc., can solve problems such as radial gap leakage, and reduce the The effect of leakage, improving efficiency and reducing leakage loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0019] The structural principle and working principle of the present invention will be described in detail below in conjunction with the accompanying drawings.

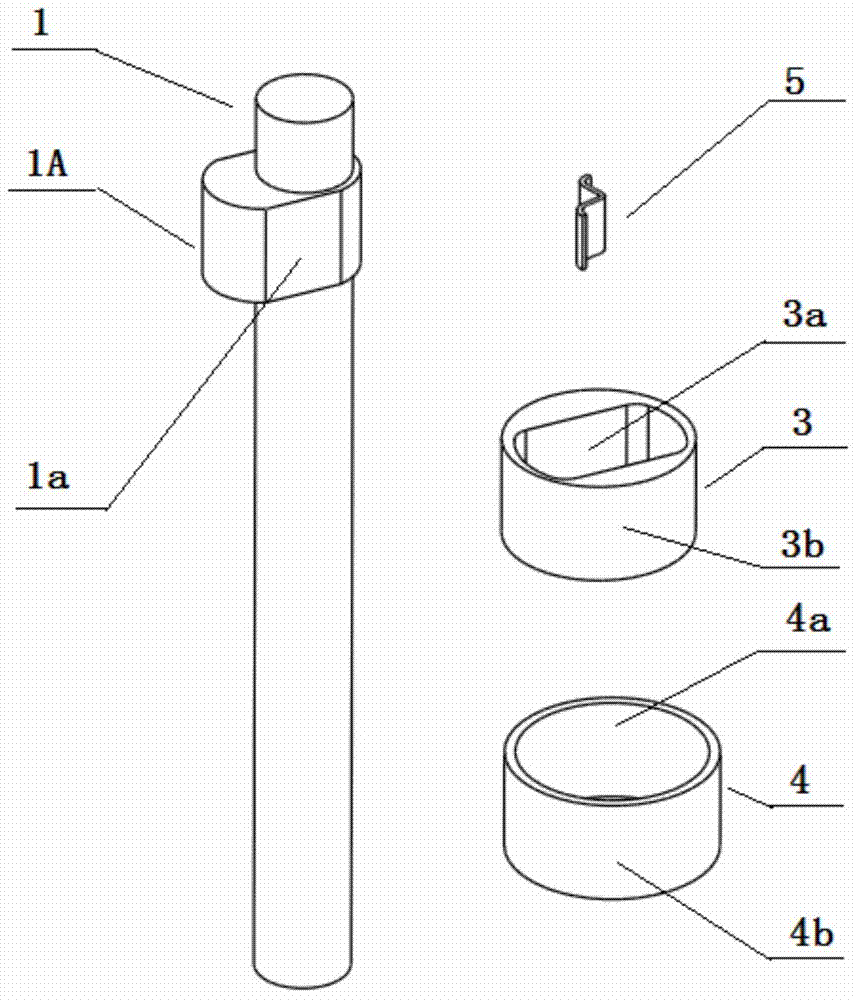

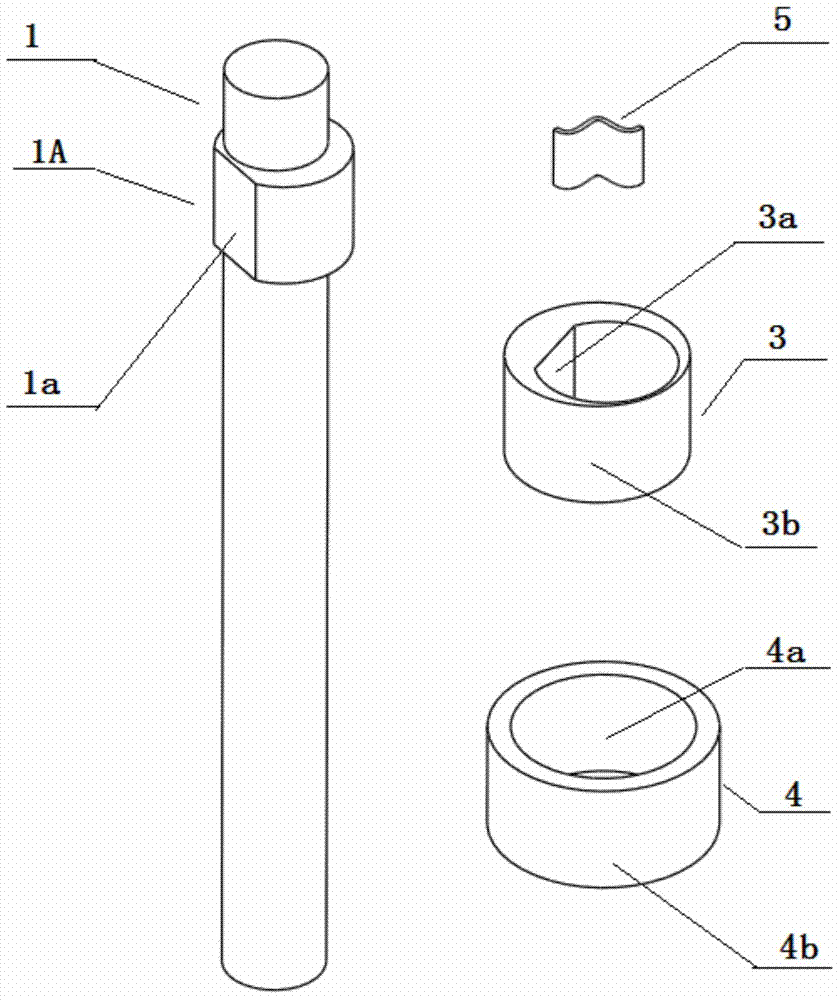

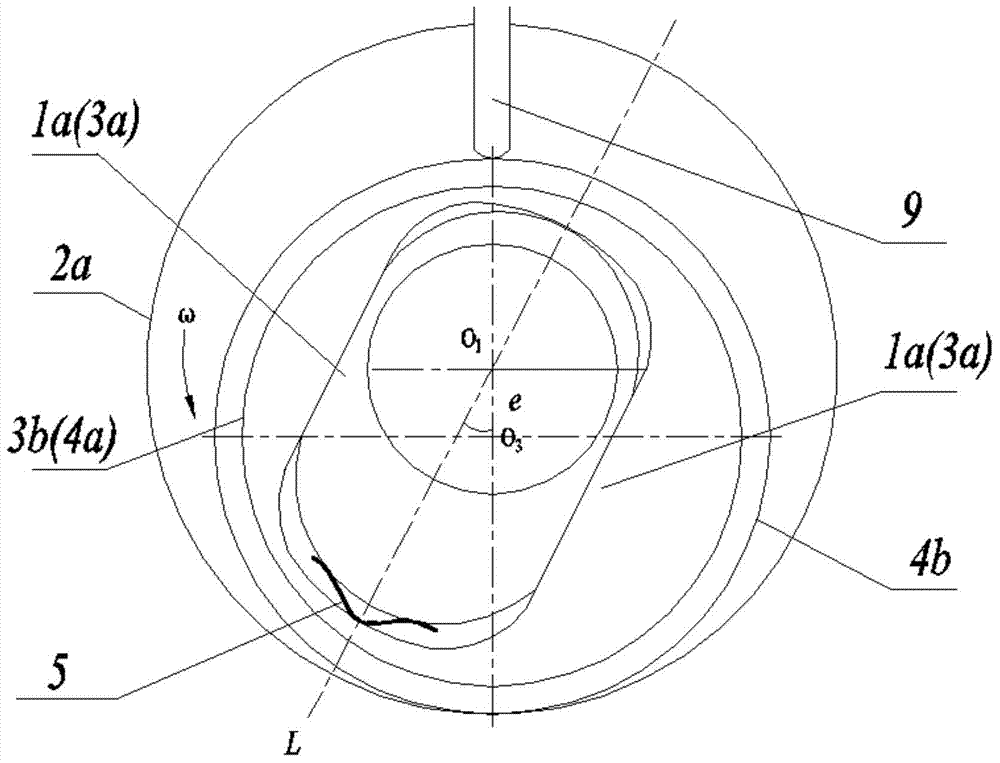

[0020] Referring to Figures 1 and 2, a sliding-piston type fluid machine radial flexible compensation mechanism includes a crankshaft 1, a cylinder 2, a sliding sleeve 3, a piston 4 and a butterfly spring plate 5; the crankshaft 1 passes through the cylinder 2. The part of the crankshaft 1 located inside the cylinder 2 is the crankshaft eccentric part 1A. The sliding sleeve 3 is sleeved outside the crankshaft eccentric part 1A. A plane 1a parallel to the crankshaft axis is provided on the outer surface of the crankshaft eccentric part 1A. The plane 1a should be in The front side of the crankshaft rotation direction, the other side is an arc or a plane, the inner surface of the sliding sleeve 3 has a plane 3a that matches the plane 1a, which can slide relatively and transmit pressure; the outer circle 3b of the sliding sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com