Tooth-roller crusher

A technology of crushers and toothed rollers, which is applied in the direction of grain processing, etc., can solve problems such as the inability to eliminate the accumulated error of the screw post and the screw nut, damage the quality of the roller surface, and the radial movement of the screw, so as to achieve high stability and prevent movement. The effect of moving and improving assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

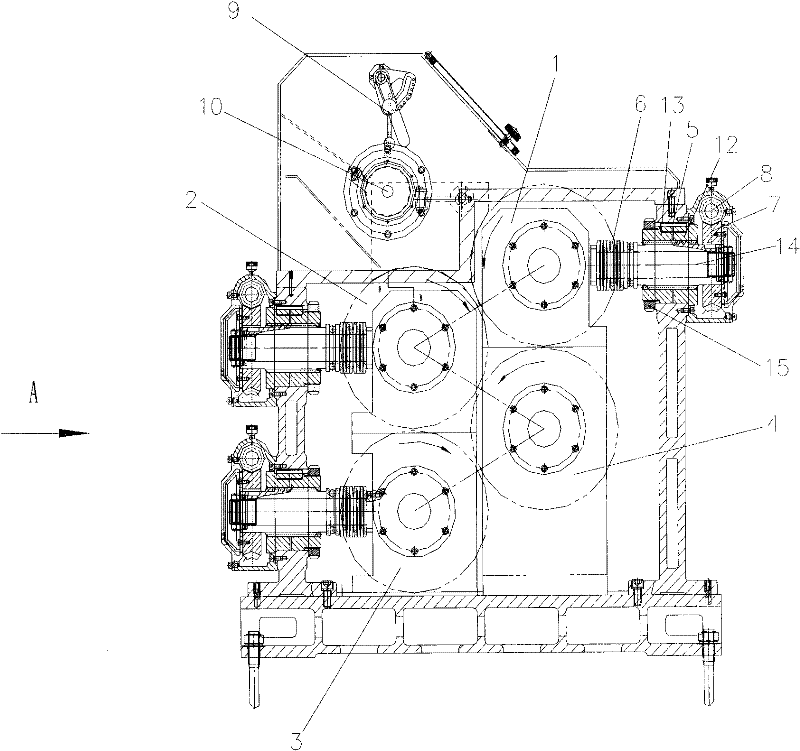

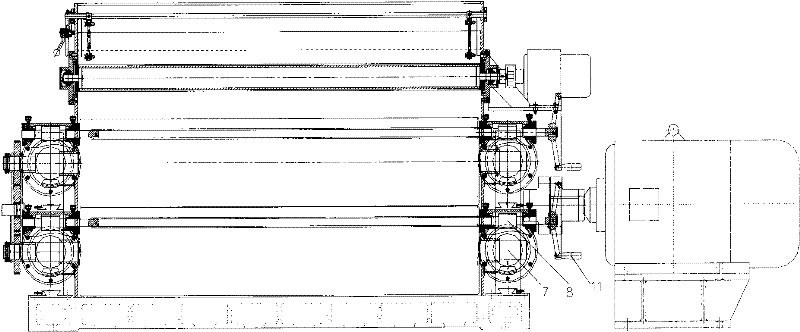

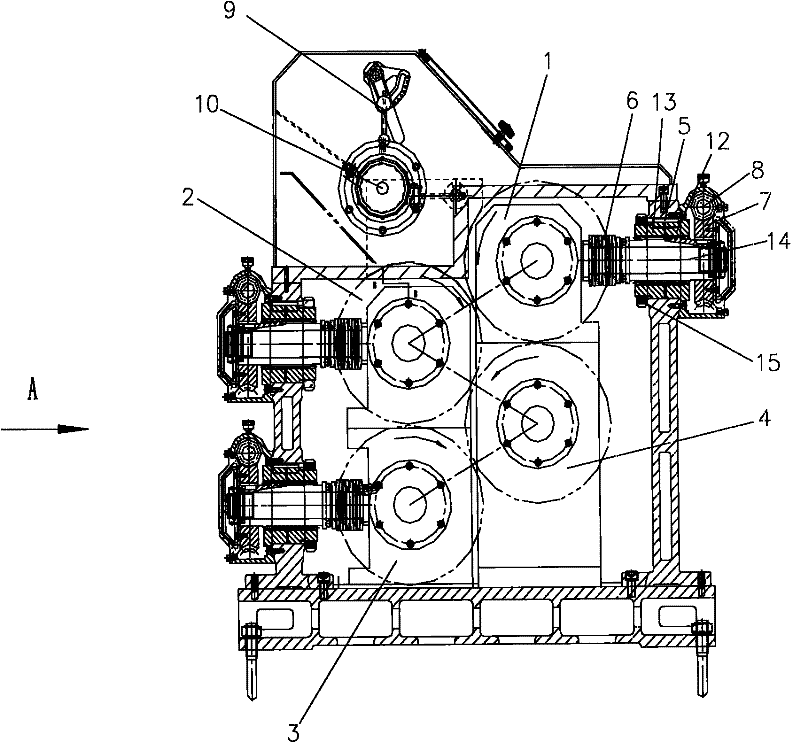

[0012] Such as figure 1 , 2 As shown, a toothed roller crusher is provided with a material inlet, a toothed roller and a roller spacing adjustment device, and a material retaining door 9 with a strong magnetic field is provided at the material inlet, and a feeder is provided below the material retaining door. Material roll 10. There are also four toothed rollers, of which the first toothed roller 1 and the second toothed roller 2 are opposite rollers, the third toothed roller 3 and the fourth toothed roller 14 are opposite rollers, and the second toothed roller 2 and the fourth toothed roller 14 is also a roll press fit, and an inter-roller spring is set between all said pairs of rolls. The fourth toothed roller is a fast roller, which is driven by a motor through a coupling; the first, second and third toothed rollers are slow rollers, which are driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com