Radial protective bearing

A technology for protecting bearings and rolling bearings, which is applied to bearing components, shafts, bearings, rigid supports of bearing components, etc., can solve problems such as protecting bearings from burning out, protecting bearings from poor impact resistance, and complex structures, and achieving simplified structures. Effect of reducing energy and increasing lifespan

Active Publication Date: 2011-08-10

NANJING CIGU TECH CORP LTD

View PDF4 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The existing protective bearings have poor ability to resist impact, and serious accidents often occur in which the protective bearings burn out and damage the equipment

In the traditional structure, the elastic damper is used to absorb the impact energy due to the radial gap between the rotor assembly and the inner ring of the rolling bearing. The structure is very complicated, and the impact problem is not fundamentally solved.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

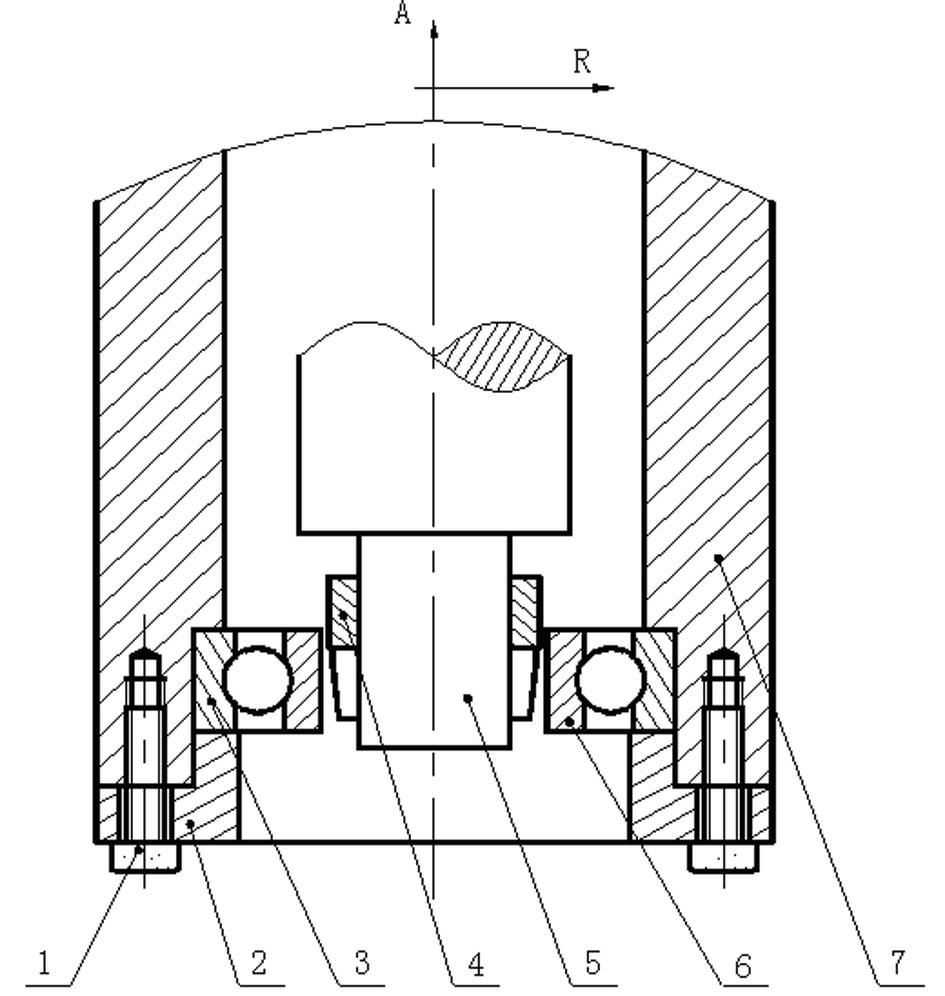

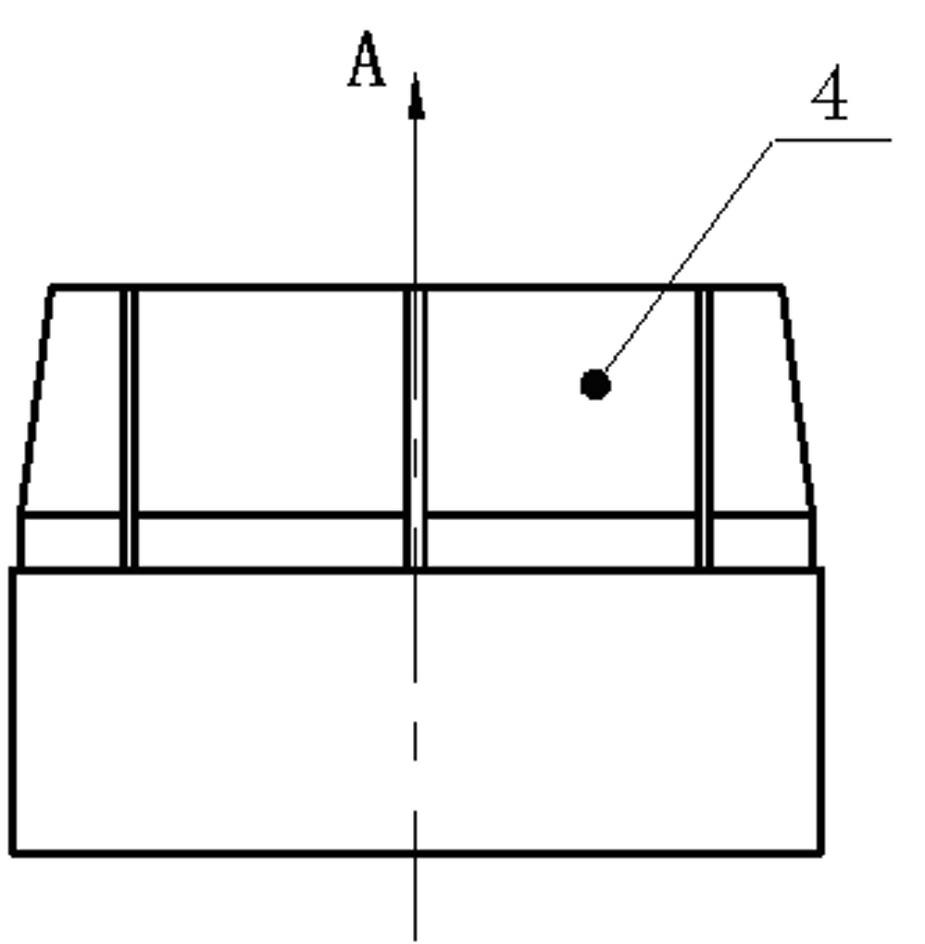

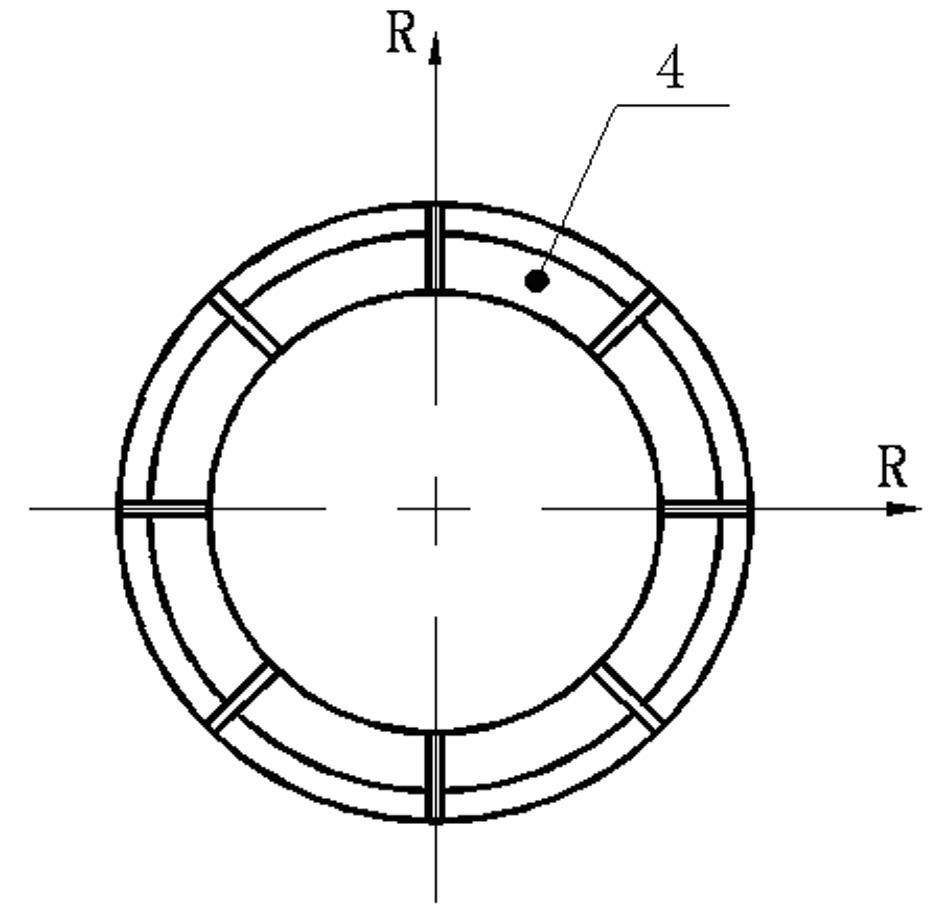

The invention relates to a radial protective bearing belonging to the field of magnetic suspension bearing systems. The radial protective bearing comprises a bolt (1), an end cover (2), a rolling bearing, a slotting protective jacket (4), a rotor assembly (5) and a base (7). The radial protective bearing can bear a radial load. A radial gap between the rotor assembly (5) and a rolling bearing inner ring (6) is reduced through the slotting protective jacket under an eccentric force because a slotting section deforms along the radial direction, and a cantilever beam structure is formed, thus the energy generated by impact is reduced and the structure of the radial protective bearing is greatly simplified, and the service life of the protective bearing is prolonged.

Description

technical field The invention provides a radial protection bearing and belongs to the field of magnetic suspension bearing systems. Background technique In the magnetic suspension bearing system, in order to ensure the reliability and safety of the system, a set of protective bearings (also called auxiliary bearings, or spare bearings, or emergency bearings) is generally required, one of which is the radial protection bearing radial load The purpose of the bearing is to temporarily support the high-speed rotating rotor in the radial direction when the magnetic suspension bearing fails, so as to protect the magnetic suspension equipment from damage. Since the rotating speed of the magnetic suspension bearing is generally very high, and there is a large radial gap between the rotor assembly and the inner ring of the rolling bearing, the rotor assembly will produce a large impact when it falls onto the protective bearing. The existing protective bearings have poor ability to r...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F16C35/04

Inventor 倪欣徐龙祥董继勇

Owner NANJING CIGU TECH CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com