Method of positioning seals in turbomachinery utilizing electromagnetic bearings

A technology for electromagnetic bearings and seals, applied in the direction of bearing components, bearings, shafts and bearings, etc., can solve problems such as degradation, complex and expensive design, wear performance of seals, etc., and achieve long service life, less contact, and radial clearance Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

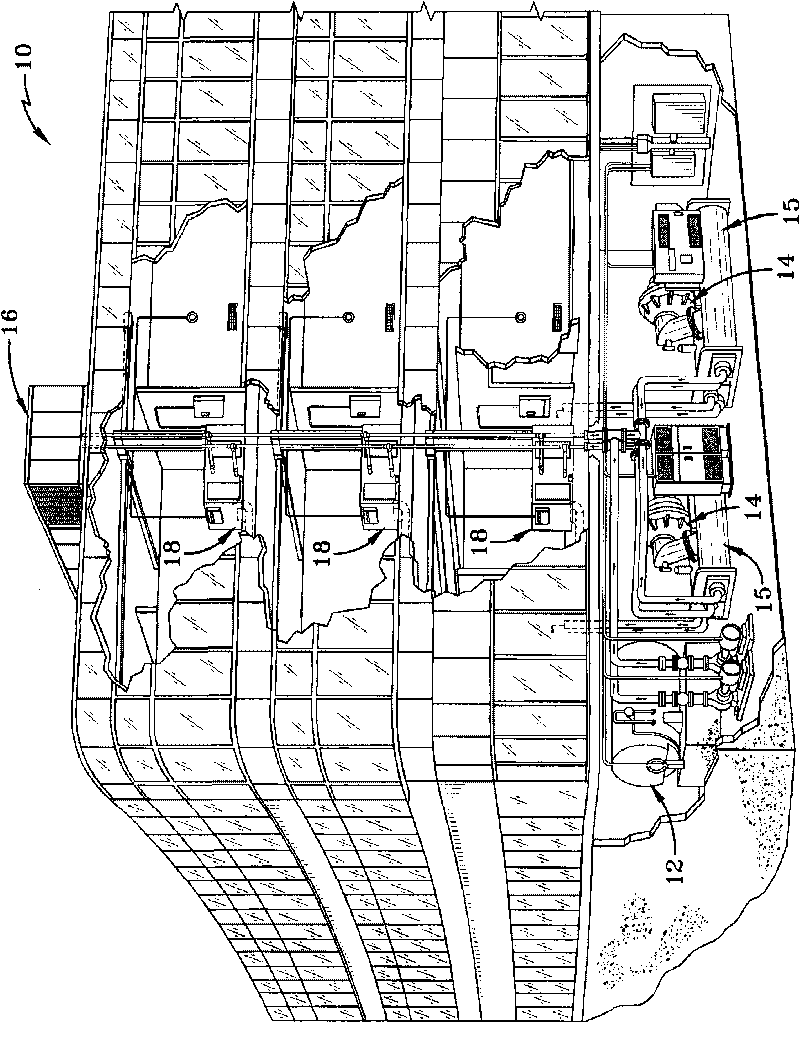

[0028] figure 1 A building 10 is shown equipped with a typical heating and cooling system. The heating and cooling system includes a boiler 12 and a centrifugal compressor 14 in the basement, as well as an evaporator and a condenser 15 . The centrifugal compressor 14 is equipped with electromagnetic bearings. Condenser 15 is in fluid communication with cooling tower 16, which is shown on a roof, although its location is not so limited. Each floor of the building 10 is equipped with an air conditioning system 18 to distribute air to each floor of the building.

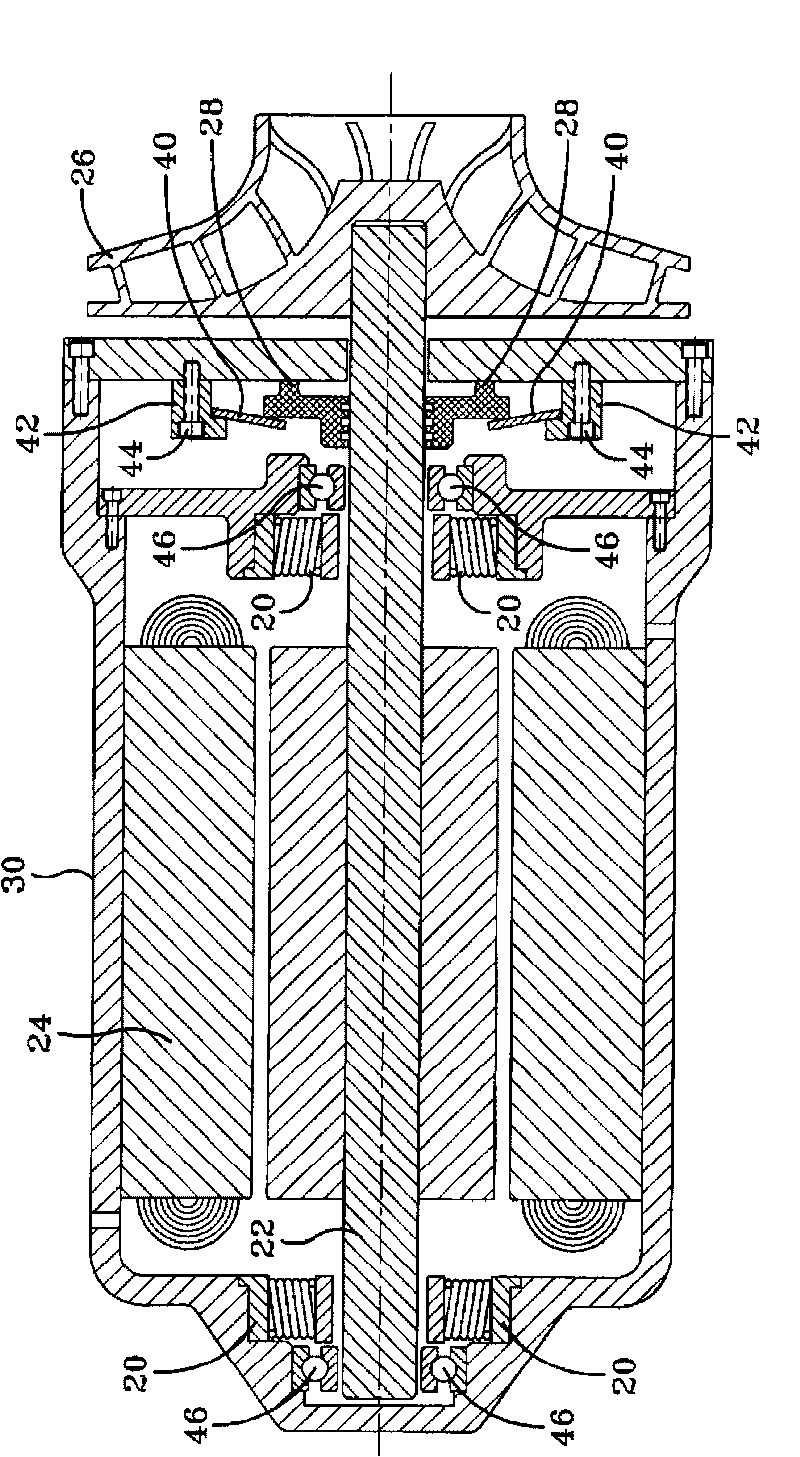

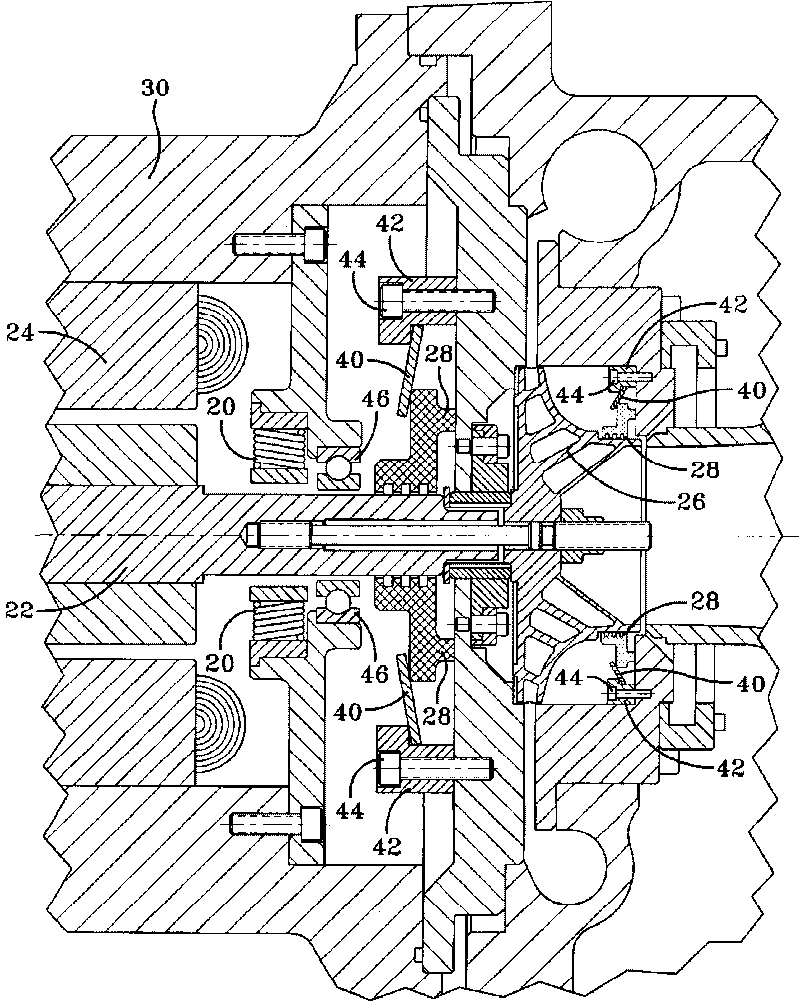

[0029] figure 2 for figure 1 A cross-sectional view of the centrifugal compressor 14. The centrifugal compressor 14 is similar to other prior art centrifugal compressors except that it is equipped with electromagnetic bearings 20 around each end of a shaft 22 . When powered, the electromagnetic bearing 20 suspends the shaft 22 within the bearing 20 and the motor 24 so that the shaft 22 can rotate the impeller 26 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com