Lead zirconate titanate piezoelectric ceramic and preparation method thereof

A technology of piezoelectric ceramics and lead zirconate titanate, which is applied in the field of piezoelectric materials, can solve the problems that the holding time affects the ceramic structure and densification, the secondary growth of grains, the performance of ceramics, and the volatilization of toxic elements lead, etc., to achieve shortening The effect of high temperature sintering time, improving ceramic density and inhibiting grain boundary migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

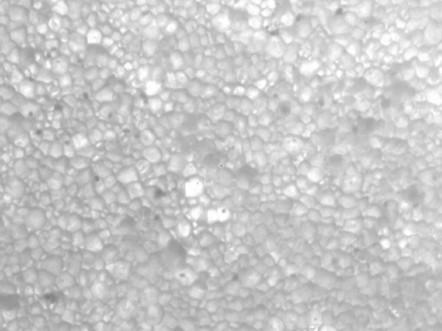

Image

Examples

Embodiment 1

[0031] A lead zirconate titanate piezoelectric ceramic, the lead zirconate titanate piezoelectric ceramic is composed of the following parts by weight of raw materials: 63.15 parts of lead tetroxide, 3 parts of barium sulfate, 2 parts of strontium carbonate, 0.4 parts of niobium pentoxide, 0.45 parts of antimony pentoxide, 20 parts of zirconium dioxide, 11 parts of titanium dioxide.

[0032] The method for preparing lead zirconate titanate piezoelectric ceramics includes the following steps:

[0033] (1) Weigh the raw materials, ball mill, dry, and pass through a 60-mesh sieve to obtain powder;

[0034] (2) Pre-fire the above powder at 1030℃ to form a block;

[0035] (3) Crush the material block, ball mill again, dry, pass through a 50-mesh sieve, add binder and roll film forming, punching to obtain green sheet;

[0036] (4) Debinding and open firing the green sheet at 600℃ to obtain a green body;

[0037] (5) The first time the green body is sintered at a temperature of 1300℃, the hold...

Embodiment 2

[0045] The difference between Example 2 and Example 1 is that the ratio of the lead zirconate titanate piezoelectric ceramic raw materials of Example 2 and Example 1 is different, and the others are the same.

[0046] The lead zirconate titanate piezoelectric ceramic is composed of the following raw materials in parts by weight: 55 parts of lead tetroxide, 6 parts of barium sulfate, 0.2 parts of strontium carbonate, 0.9 parts of niobium pentoxide, 0.2 parts of antimony pentoxide, and zirconium dioxide 25 parts, 8 parts of titanium dioxide.

Embodiment 3

[0048] The difference between Example 3 and Example 1 is that the ratio of the raw materials of the lead zirconate titanate piezoelectric ceramics of Example 3 and Example 1 is different, and the others are the same.

[0049] The lead zirconate titanate piezoelectric ceramic is composed of the following raw materials in parts by weight: 75 parts of lead tetroxide, 1 part of barium sulfate, 8 parts of strontium carbonate, 0.1 part of niobium pentoxide, 1 part of antimony pentoxide, zirconium dioxide 15 parts, 15 parts of titanium dioxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| relative permittivity | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com