Water-soluble catalytic cracking metal passivator and preparation method thereof

A metal deactivator and catalytic cracking technology, which is applied in catalytic cracking, catalyst protection, chemical instruments and methods, etc., can solve problems such as long reaction time, environmental pollution, equipment corrosion, etc., and achieve short reaction time, convenient use, and high quality stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

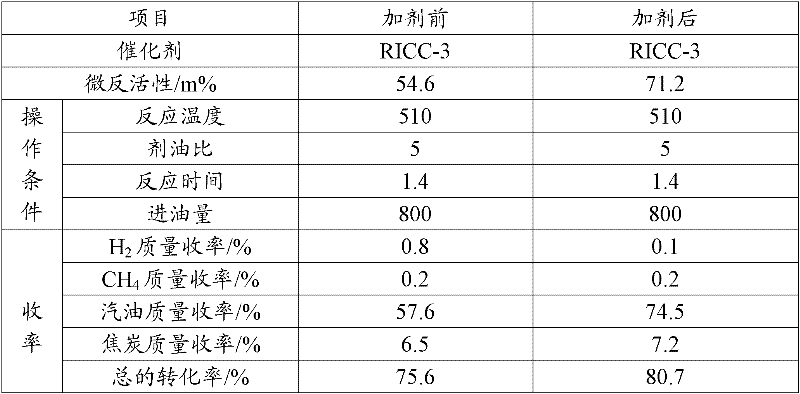

Image

Examples

Embodiment 1

[0017] A water-soluble catalytic cracking metal passivation agent, including nickel passivation agent and vanadium passivation agent, the nickel passivation agent is antimony pentoxide hydrosol, and the vanadium passivation agent is organic acid salt aqueous solution of lanthanum or cerium; the content of antimony is 30% , the content of lanthanum is 0%, the balance of water.

[0018] The specific preparation steps of this passivator include:

[0019] Preparation of nickel passivation agent Under normal pressure, put 30g of antimony trioxide in 20g of 85% triethanolamine aqueous solution, add 30g of 30% hydrogen peroxide under constant stirring, and react at 80°C until the product becomes a transparent and uniform liquid.

Embodiment 2

[0021] A water-soluble catalytic cracking metal passivator, including nickel passivation agent and vanadium passivation agent, nickel passivation agent is antimony pentoxide hydrosol, and vanadium passivation agent is organic acid salt aqueous solution of lanthanum or cerium; the content of antimony is 22% , the content of cerium is 1%, the balance of water.

[0022] The specific preparation steps of this passivator include:

[0023] (1) Preparation of passivating nickel agent Under normal pressure, place 30g of antimony trioxide in 18g of 85% triethanolamine aqueous solution, add 45g of 30% hydrogen peroxide under constant stirring, and react at 150°C until the product is transparent homogeneous liquid;

[0024] (2) Preparation of vanadium passivation agent Under normal pressure, 153g mass fraction is 30% citric acid solution and 20g cerium carbonate water bath heating to 60 ℃ reaction;

[0025] (3) Compounding of nickel passivating agent and vanadium passivating agent Mix ...

Embodiment 3

[0027] A water-soluble catalytic cracking metal passivating agent, including nickel passivating agent and vanadium passivating agent, the nickel passivating agent is antimony pentoxide hydrosol, and the vanadium passivating agent is organic acid salt aqueous solution of lanthanum or cerium; the content of antimony is 17% , the content of lanthanum is 4%, the balance of water.

[0028] The specific preparation steps of this passivator include:

[0029] (1) Preparation of nickel passivation agent Under normal pressure, place 30g of antimony trioxide in 35g of 85% triethanolamine aqueous solution, add 40g of 30% hydrogen peroxide under constant stirring, and react at 130°C until the product is transparent homogeneous liquid;

[0030] (2) Preparation of vanadium passivation agent Under normal pressure, 89g of acetic acid solution with a mass fraction of 25% was heated to 100°C in a water bath with 20g of lanthanum oxide to react;

[0031] (3) Compounding of nickel passivating ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com