Method for comprehensively processing stibium smelt arsenic alkaline residue and producing colloid antimony peroxide

A comprehensive treatment, arsenic-alkali slag technology, applied in the field of environmental engineering, can solve the problems of high dust concentration, complex process, unsatisfactory traditional wet treatment effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

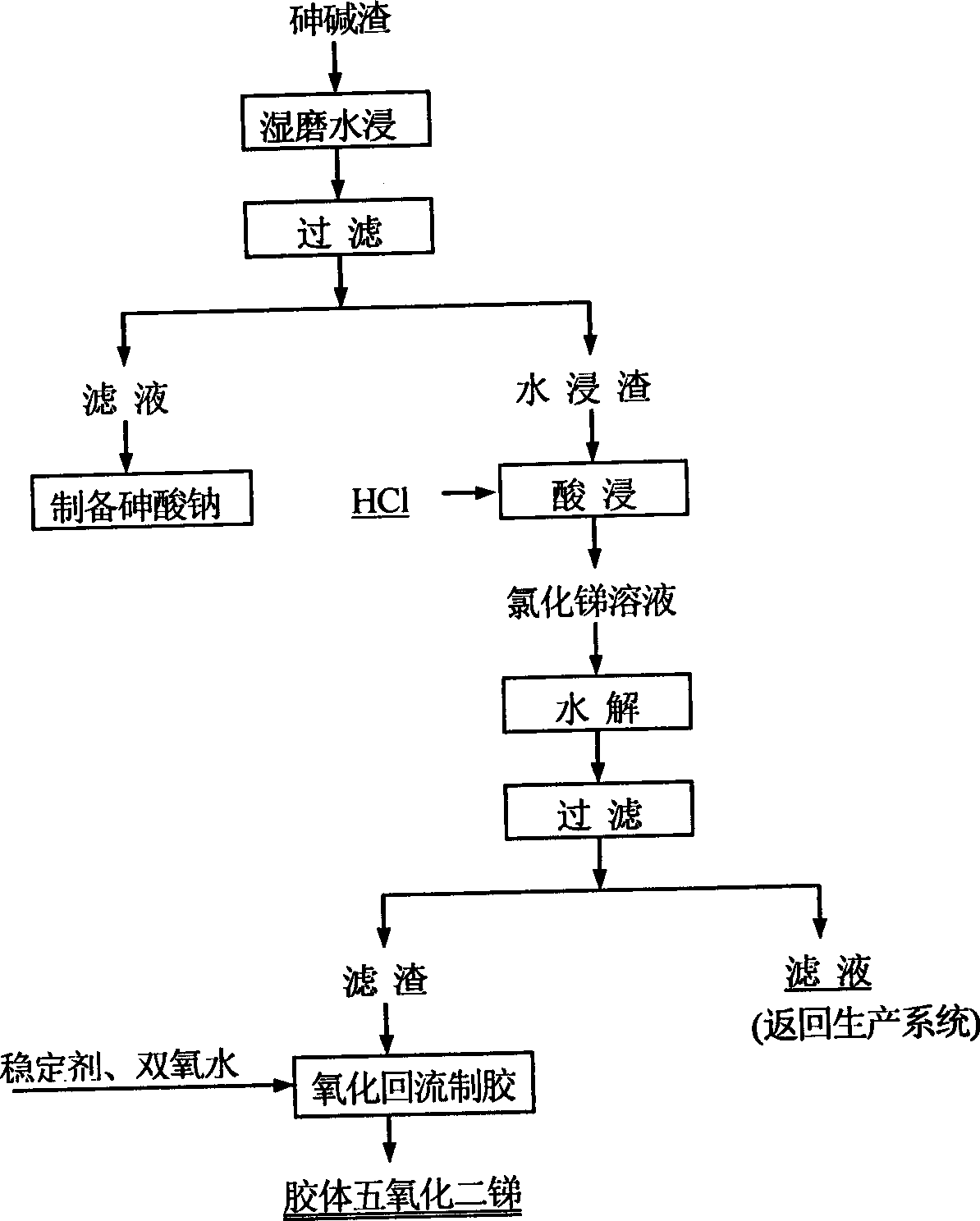

Method used

Image

Examples

Embodiment 1

[0053] (1) Properties of arsenic-alkali slag

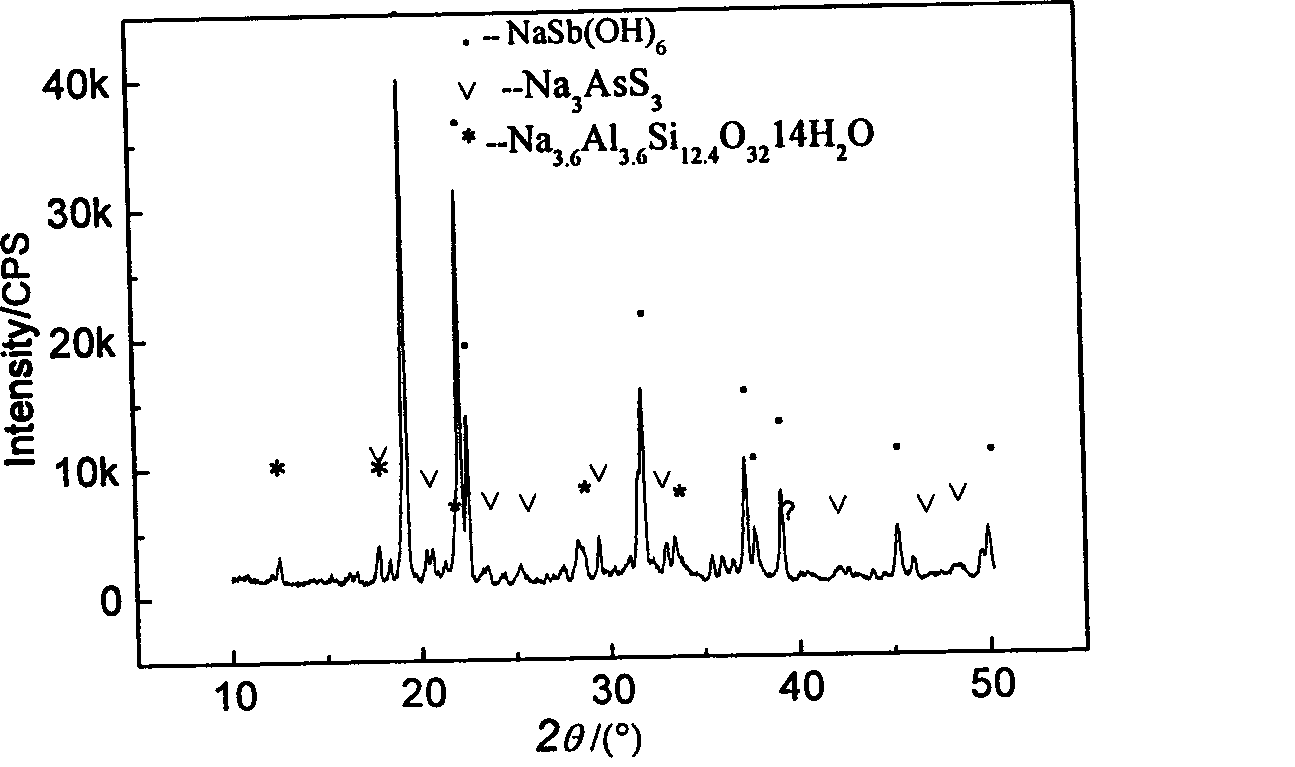

[0054] The arsenic-alkali slag used in the embodiment of the present invention (attached figure 2 ) is obtained from the Xingxing Antimony Industry in Xikuangshan, Hunan Province. Due to long-term exposure to the air, it absorbs a large amount of water and is difficult to break. Therefore, the arsenic-alkali slag must be dried first. During the laboratory research, the arsenic-alkali slag was dried, crushed, and ground to a size below 0.3 mm for later use. Chemical analysis shows that the percentages of arsenic and antimony are 6.37% and 33.32%, respectively, of which trivalent antimony is 17.37%, elemental antimony is 4.55%, and pentavalent antimony is 11.4%.

[0055] (2) Flooding

[0056] Under the conditions of controlling the liquid-solid ratio to 6:1, the temperature at 40°C, the stirring speed at 400rpm, and the leaching time of 40 minutes, the arsenic-alkali slag was leached in water. The antimony leaching rate was 4.09%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com