Flame-retardant PET heat-conducting material for heater and preparation method thereof

A heat-conducting material and heater technology, applied in the field of engineering plastics, can solve problems such as the lack of heat-conducting fillers, and achieve the effects of increasing high-temperature oxidation resistance, improving strength, and improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

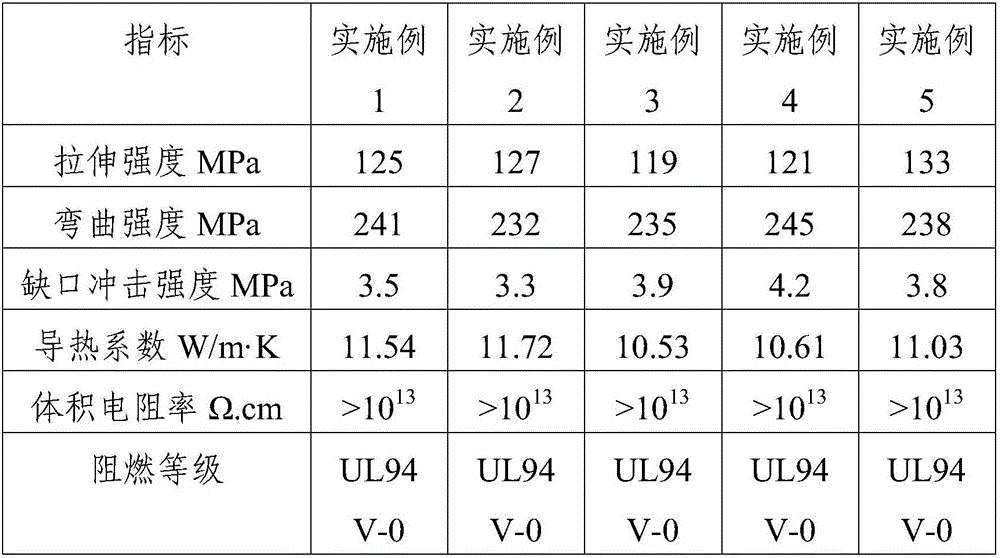

Examples

Embodiment 1

[0019] A flame-retardant PET heat-conducting material for a heater, which is composed of the following raw materials in parts by weight: 70 parts of PET, 18 parts of PBT, 0.5 parts of talc powder, 16 parts of zinc oxide, 5 parts of magnesium oxide, 9 parts of nano-boron nitride, and 9 parts of nano-boron nitride. 3 parts of silicon oxide, 3 parts of hollow glass microspheres, 4 parts of titanate coupling agent, 12 parts of calcium stearate, 1.5 parts of dioctyl phthalate, 4 parts of colloidal antimony pentoxide, silicone resin barrier 6 parts of fuel, 2 parts of polytetrafluoroethylene, 5 parts of stabilizer.

[0020] Preferably, the stabilizer is a mixture of organotin heat stabilizer, ultraviolet absorber UV-P and antioxidant.

[0021] A preparation method for a flame-retardant PET heat-conducting material for a heater, specifically comprising the following steps:

[0022] (1) Weighing and drying: Weigh each raw material according to weight ratio, dry PET at 150°C for 3 hou...

Embodiment 2

[0027] A flame-retardant PET heat-conducting material for a heater, which is composed of the following raw materials in parts by weight: 65 parts of PET, 20 parts of PBT, 0.4 parts of talc powder, 18 parts of zinc oxide, 3 parts of magnesium oxide, 10 parts of nano-boron nitride, and 10 parts of nano-boron nitride. 2 parts of silicon oxide, 4 parts of hollow glass microspheres, 3 parts of titanate coupling agent, 2.5 parts of calcium stearate, 1 part of dioctyl phthalate, 5 parts of colloidal antimony pentoxide, polysiloxane 4 parts of alkane flame retardant, 3 parts of polytetrafluoroethylene, 3 parts of stabilizer.

[0028] Preferably, the stabilizer is a mixture of organotin heat stabilizer, ultraviolet absorber UV-9 and antioxidant.

[0029] A preparation method for a flame-retardant PET heat-conducting material for a heater, specifically comprising the following steps:

[0030] (1) Weighing and drying: Weigh each raw material according to weight ratio, dry PET at 130°C f...

Embodiment 3

[0035] A flame-retardant PET heat-conducting material for a heater, which consists of the following raw materials in parts by weight: 75 parts of PET, 15 parts of PBT, 0.6 parts of talc powder, 15 parts of zinc oxide, 6 parts of magnesium oxide, 8 parts of nano-boron nitride, and 8 parts of nano-boron nitride. 4 parts of silicon oxide, 2 parts of hollow glass microspheres, 6 parts of titanate coupling agent, 1.5 parts of calcium stearate, 2 parts of dioctyl phthalate, 3 parts of colloidal antimony pentoxide, polysiloxane 7 parts of alkane flame retardant, 2 parts of polytetrafluoroethylene, 6 parts of stabilizer.

[0036] Preferably, the stabilizer is a mixture of organotin heat stabilizer, ultraviolet absorber UV-9 and antioxidant.

[0037] The preparation method of flame-retardant PET for heater specifically comprises the following steps:

[0038] (1) Weighing and drying: Weigh each raw material according to weight ratio, dry PET at 140°C for 3 hours, and dry PBT at 115°C f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com