Antimony carbon negative electrode material of sodium ion battery, preparation therefor and application method thereof

A technology of sodium ion battery and carbon negative electrode material, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of battery capacity decay, electrode damage, uneven size of metal antimony particles, etc., to reduce the large volume change and diameter size Uniform, low-equipment generation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

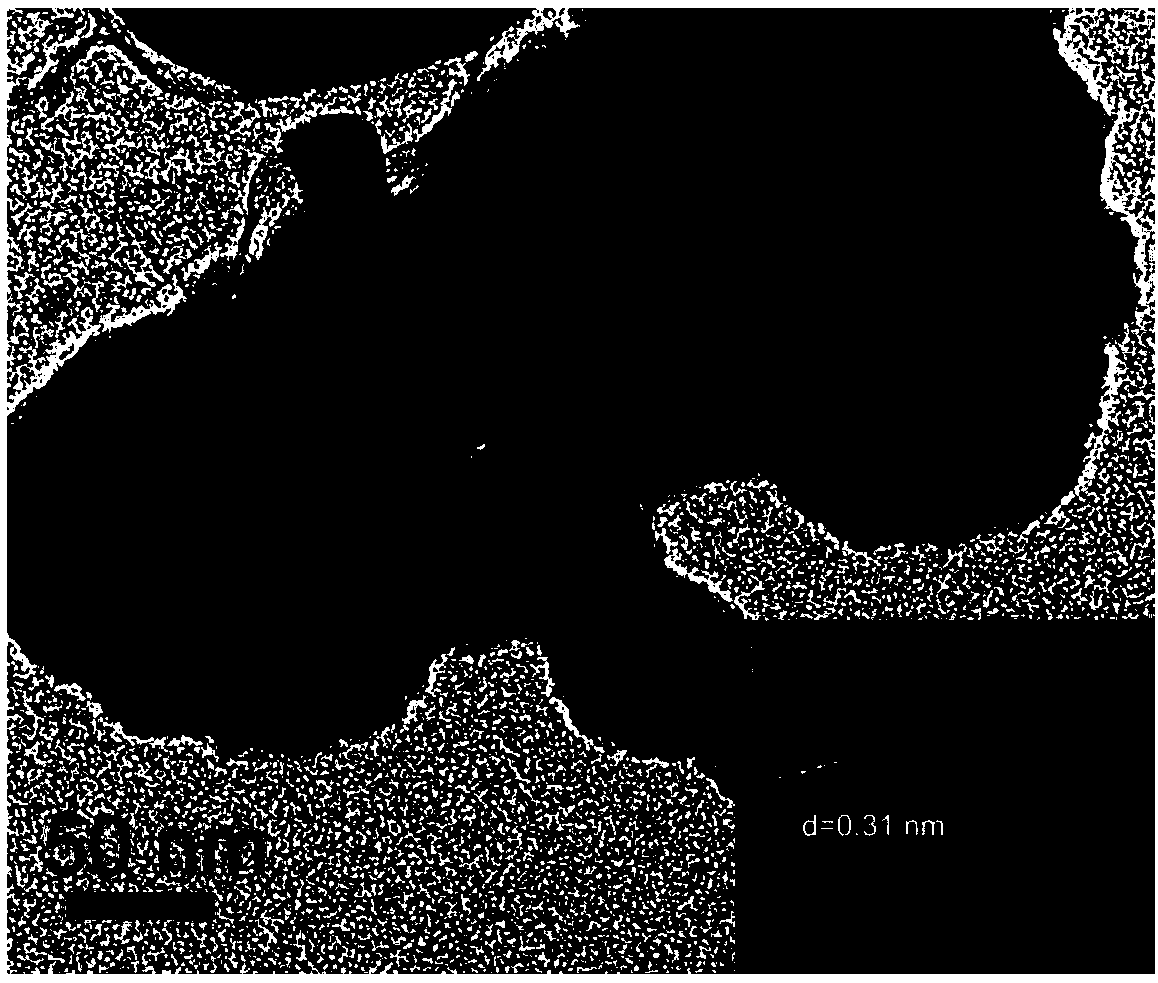

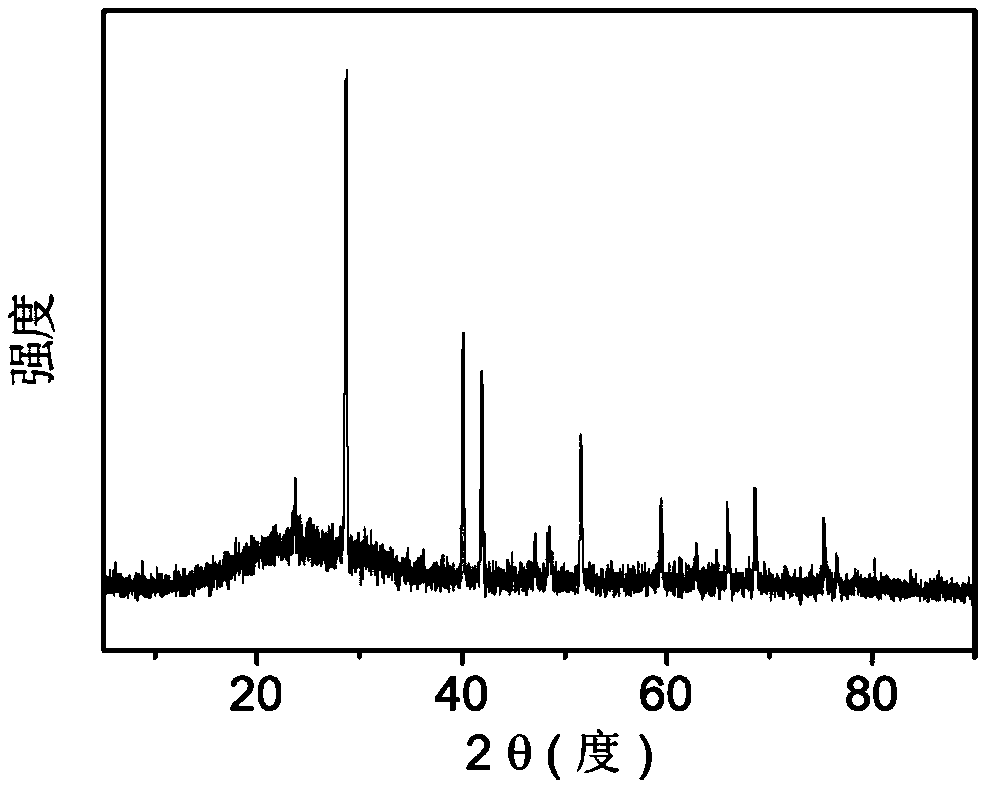

[0030] Dissolve 3 g of polyethylene glycol 2000 as a carbon source in 20 ml of methanol solution, add 15 g of nanometer antimony pentoxide colloidal solution, and stir evenly. Spray drying is performed at a temperature of 450° C., and the powder is collected to obtain a precursor material. The above materials were calcined for 3 hours at 500° C. in a 5% hydrogen-argon gas mixture to obtain a carbon layer-coated antimony carbon negative electrode material (see attached figure 1 As shown), it can be seen from the figure that the nano-antimony particles are coated with carbon materials, forming a good spherical composite structure. Composite X-ray diffraction patterns of amorphous carbon and characteristic peaks of metal antimony (as attached figure 2 shown), indicating the successful preparation of antimony-carbon composites.

Embodiment 2

[0032] Dissolve 1 g of polyethylene glycol 2000 as a carbon source in 20 ml of methanol solution, add 15 g of nanometer antimony pentoxide colloidal solution, and stir evenly. Spray drying is performed at a temperature of 450° C., and the powder is collected to obtain a precursor material. The above materials were calcined in 5% hydrogen-argon mixed gas at 500° C. for 3 hours to obtain a carbon layer-coated antimony carbon negative electrode material.

Embodiment 3

[0034] Dissolve 2 g of polyethylene glycol 2000 as a carbon source in 20 ml of methanol solution, add 15 g of nanometer antimony pentoxide colloidal solution, and stir evenly. Spray drying is performed at a temperature of 450° C., and the powder is collected to obtain a precursor material. The above materials were calcined in 5% hydrogen-argon mixed gas at 500° C. for 3 hours to obtain a carbon layer-coated antimony carbon negative electrode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com