Ultrahigh flame-retardant AN-VDC copolymer fiber and production method thereof

A technology of flame-retardant acrylic and production methods, which is applied in the manufacture of fire-resistant and flame-retardant filaments to achieve the effect of improving flame-retardant performance

Inactive Publication Date: 2011-08-17

FUSHUN RAYVA FIBER

View PDF4 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

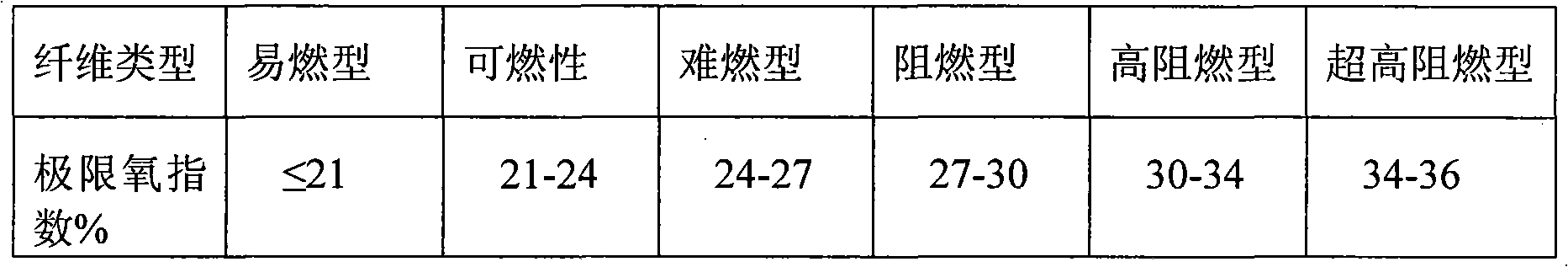

[0008] The technical problem to be solved by the present invention is to overcome the limitation of ordinary acrylic fiber to improve the flame retardant performance, and to provide an ultra-high flame retardant acrylic fiber, the copolymer of which not only contains antimony pentoxide, but also contains decabromine Diphenylethane, thereby greatly improving its limiting oxygen index, and maintaining other properties of the fiber while enhancing the flame retardancy of the fiber

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example 1

[0055] Weight ratio of antimony pentoxide in fiber 6.5

[0056] Weight ratio of decabromodiphenylethane in fiber 6.5

[0057] Fiber limiting oxygen index measured value: 35.8

example 2

[0059] Weight ratio of antimony pentoxide in fiber 7

[0060] Weight ratio of decabromodiphenylethane in fiber 6.5

example 3

[0063] Weight ratio of antimony pentoxide in fiber 10

[0064] Weight ratio of decabromodiphenylethane in fiber 6.5

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Login to View More

Abstract

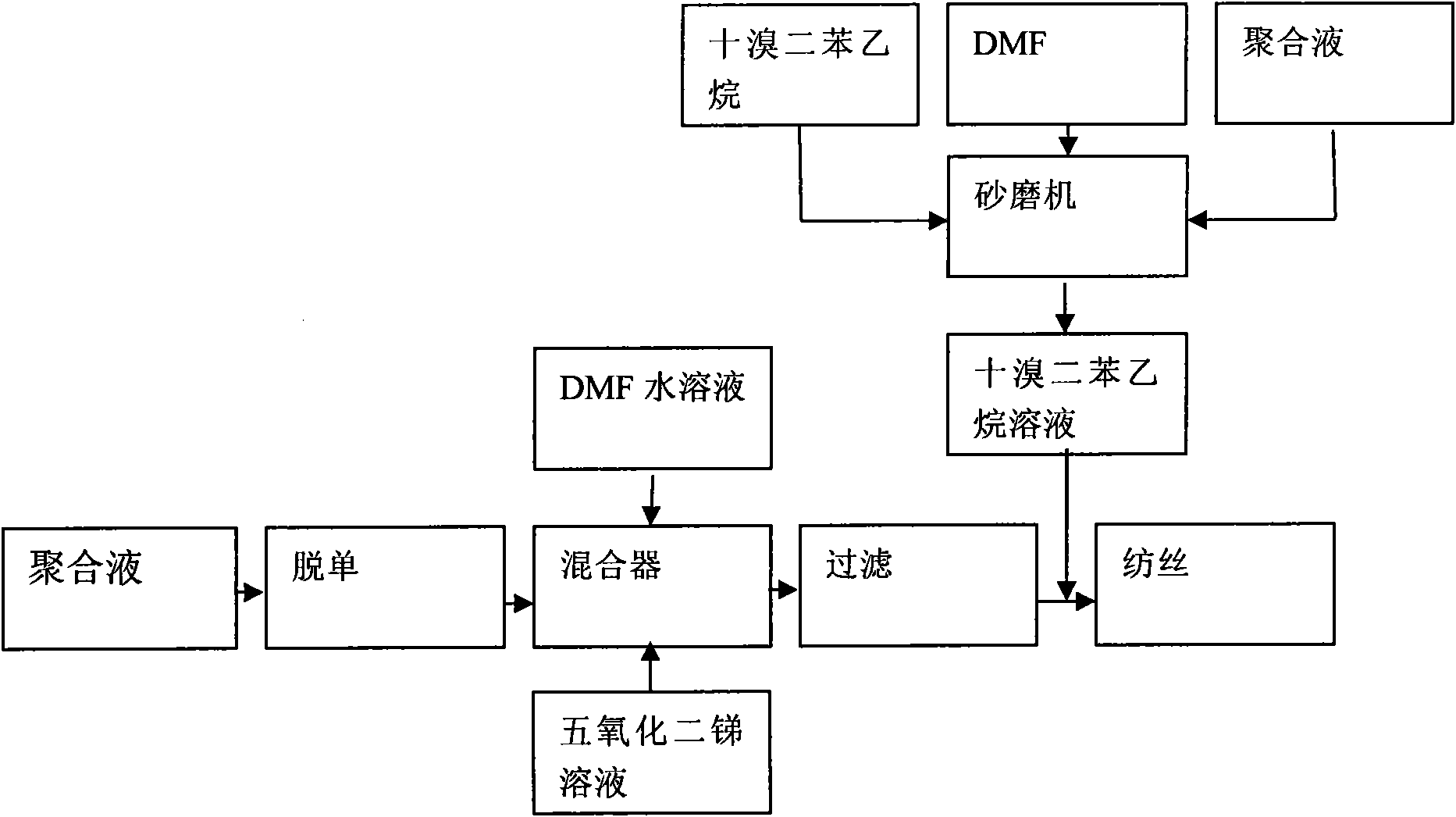

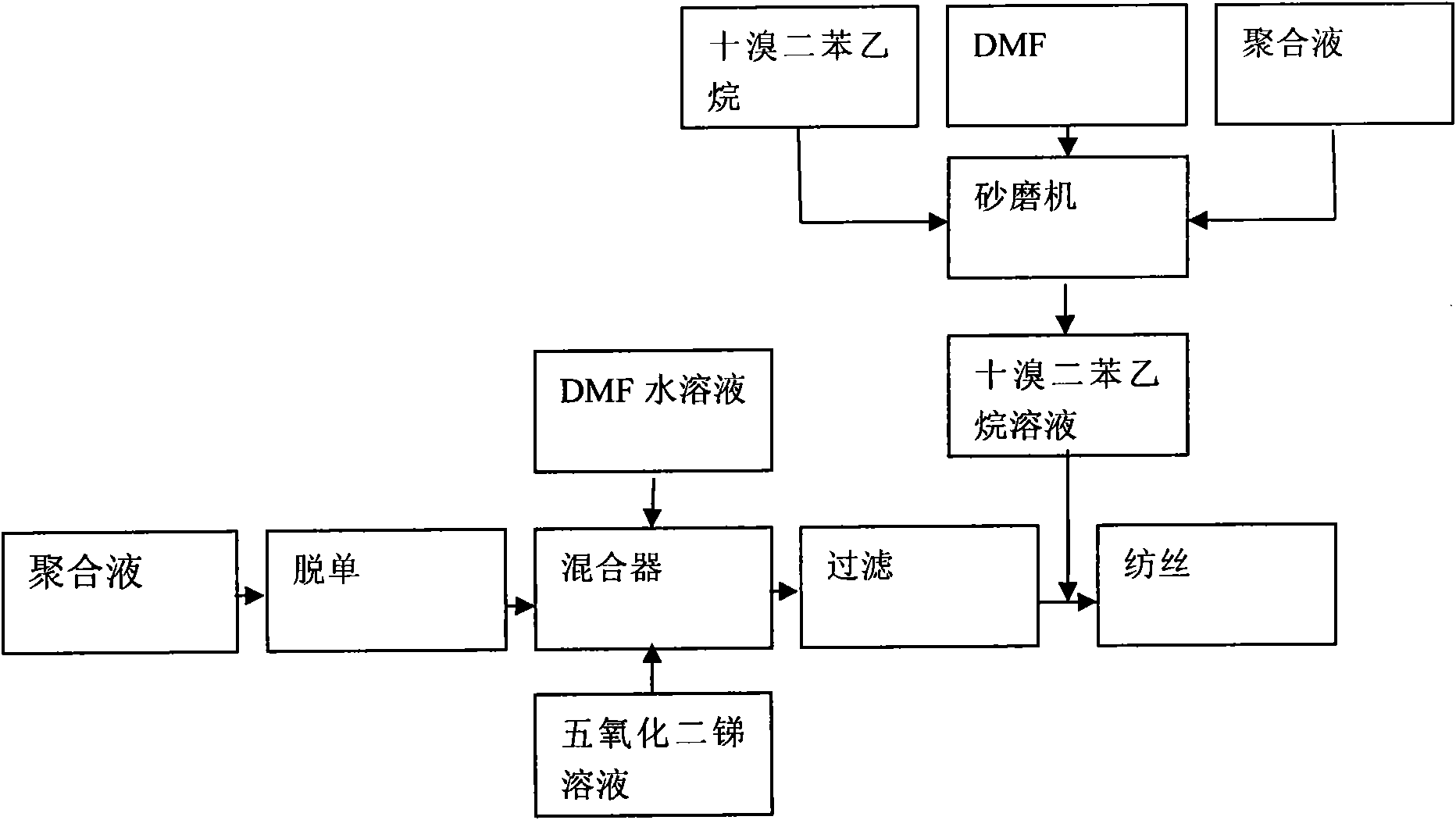

The invention discloses an ultrahigh flame-retardant AN-VDC copolymer fiber and a production method thereof. Chemical compositions of the copolymer fiber contain acrylonitrile, vinylidene chloride, acrylamide methyl propane sodium sulfonate, antimony peroxide and decabromdiphenylethane, wherein the weight ratio of the antimony peroxide in the fiber is 6.5 to 10%, and the weight ratio of the decabromdiphenylethane in the fiber is 5.5 to 10%. The production method of the fiber comprises the following steps of: fully mixing the decabromdiphenylethane, a polymerizing liquid and dimethyl fomamide which are ground and filtered to be prepared into a decabromdiphenylethane solution; adding an antimony peroxide colloidal solution and a dimethyl fomamide aqueous solution into polymerizing liquid undegoing demonomerisation, filtering the mixed liquor after being fully mixed, and then continuously adding the prepared decabromdiphenylethane solution on line to the mixed liquor, and finally sending the mixed liquor to a spinning working procedure. As the ultrahigh flame-retardant AN-VDC copolymer fiber has excellent fire resistance, environmental protection and combination properties, the fiber is increasingly and widely applied in various fields, in particular to the field of a specific flame-retardant fabric.

Description

Technical field: [0001] The invention relates to an acrylic fiber, in particular to an ultra-high flame-retardant acrylic fiber and a production method thereof. Background technique: [0002] Acrylic fiber, also known as modified acrylic fiber, refers to a fiber-forming material with an acrylonitrile content (referring to the weight content ratio, the same meaning hereinafter) as 35-85%, and its chemical structure is composed of acrylonitrile (ACN) monomer , vinylidene chloride (VDC) monomer and sodium acrylamidomethyl propane sulfonate (SAMPS) monomer are copolymerized. One of the characteristics of acrylic fiber is that it has a natural soft feel similar to natural fibers, excellent water absorption performance and good comfort. The physical properties of its wool fiber are similar to animal hair, with smooth hand feeling, good resilience and warmth retention. It is more durable than wool; another feature of acrylic fiber is that it has excellent dyeing performance, high ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): D01F6/54D01F1/07C08F220/48C08K3/22C08K5/03

Inventor 郑桂花陆建明乔振芝费继伟

Owner FUSHUN RAYVA FIBER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com