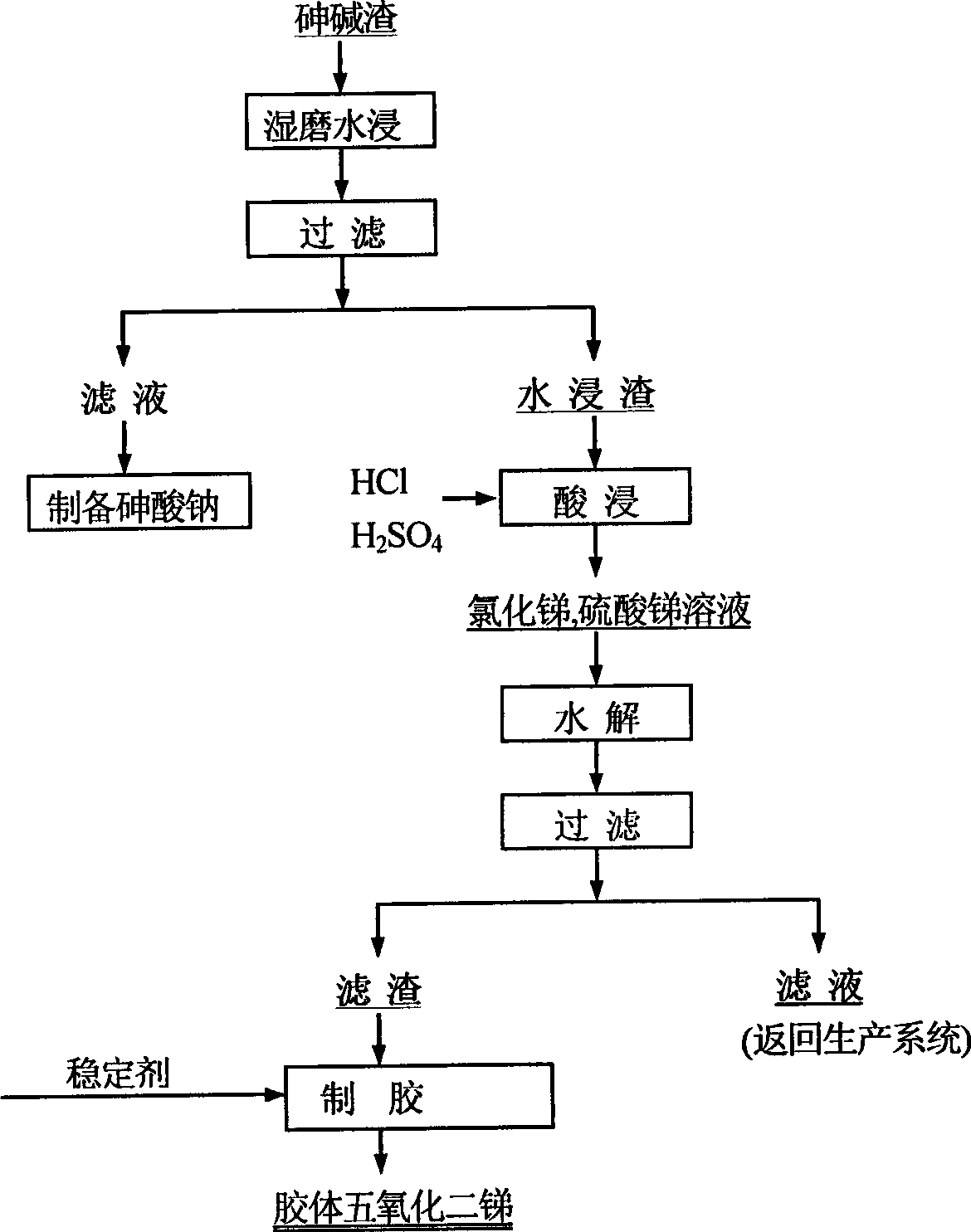

Method for comprehensively processing stibium smelt arsenic alkaline residue and producing colloid antimony peroxide

A comprehensive treatment, arsenic-alkali slag technology, applied in the field of environmental engineering, can solve problems such as operational safety threats, environmental pollution, and complex processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

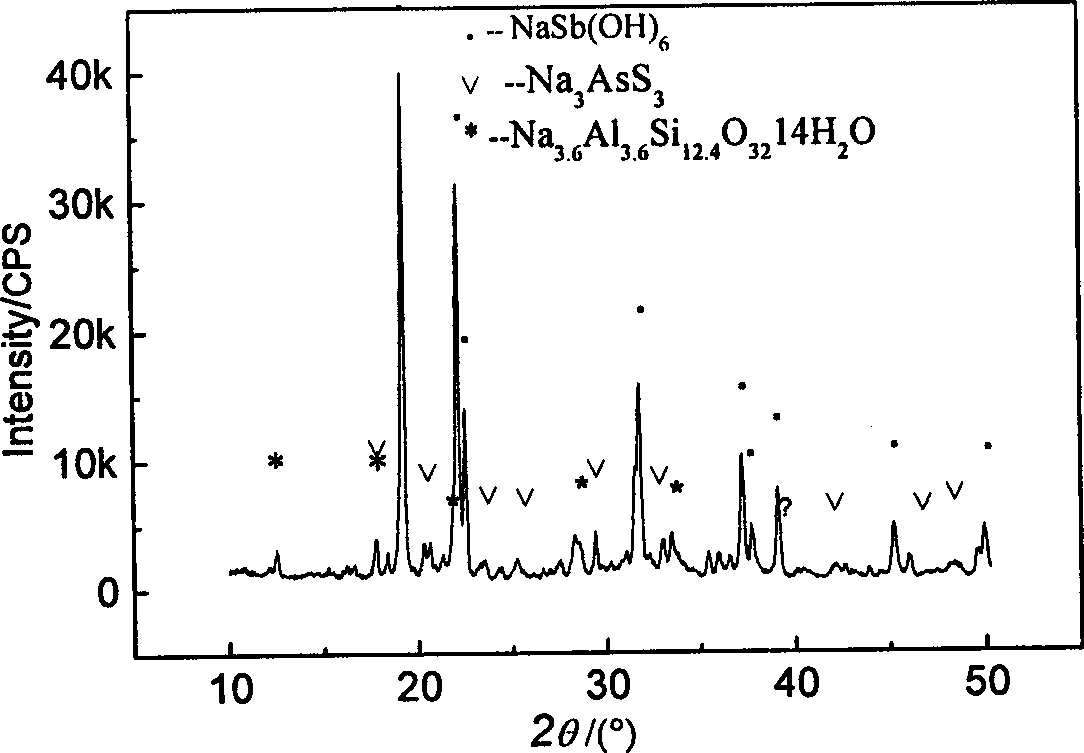

[0053] (1) Properties of arsenic-alkali slag

[0054] The arsenic-alkali slag used in the embodiment of the present invention (phase analysis is as attached figure 1 Shown) is taken from Shanxing Antimony Industry in Xikuangshan, Hunan Province. Due to long-term exposure to the air, it absorbs a large amount of water and is difficult to break. Therefore, the arsenic-alkali slag must be dried first. During the laboratory research, the arsenic-alkali slag was dried, crushed, and ground to a size below 0.3 mm for later use. Chemical analysis shows that the percentages of arsenic and antimony are 6.37% and 33.32%, respectively, of which trivalent antimony is 17.37%, elemental antimony is 4.55%, and pentavalent antimony is 11.4%.

[0055] (2) Flooding

[0056] Under the conditions of controlling the liquid-solid ratio to 6:1, the temperature at 40°C, the stirring speed at 400rpm, and the leaching time of 40 minutes, the arsenic-alkali slag was leached in water. The antimony leach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com