Patents

Literature

51results about How to "Extend the life of noodles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-temperature resistant turbine blade and production process thereof

ActiveCN104099516AImprove performanceImprove impact toughnessBlade accessoriesSolid state diffusion coatingChemical compositionSteam turbine blade

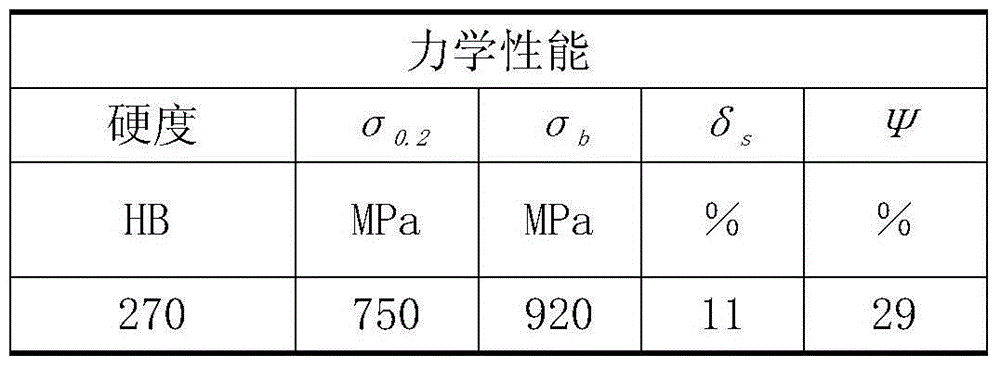

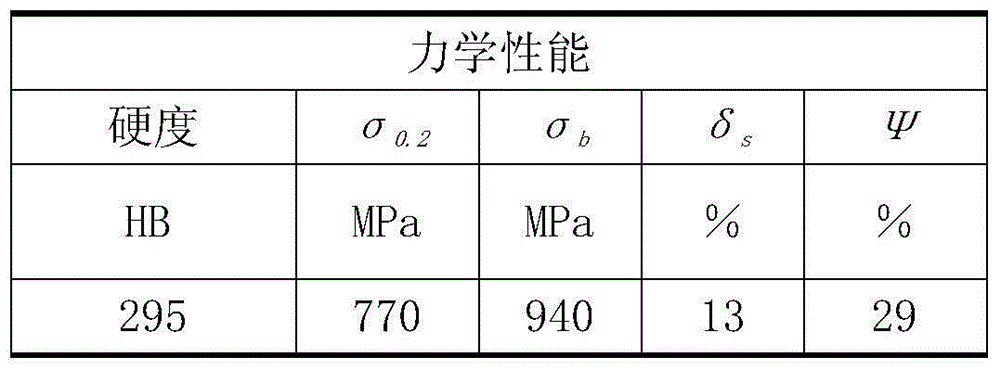

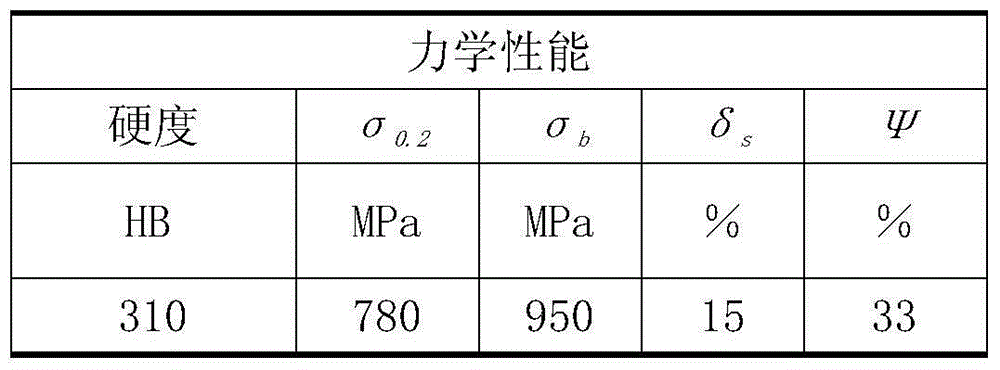

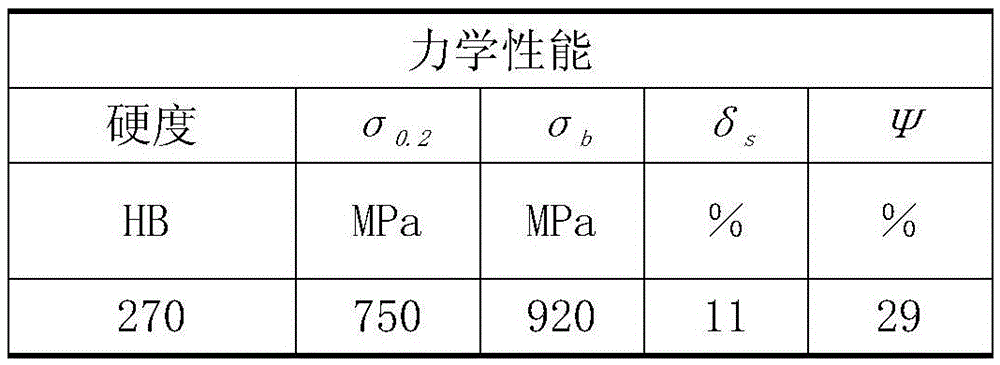

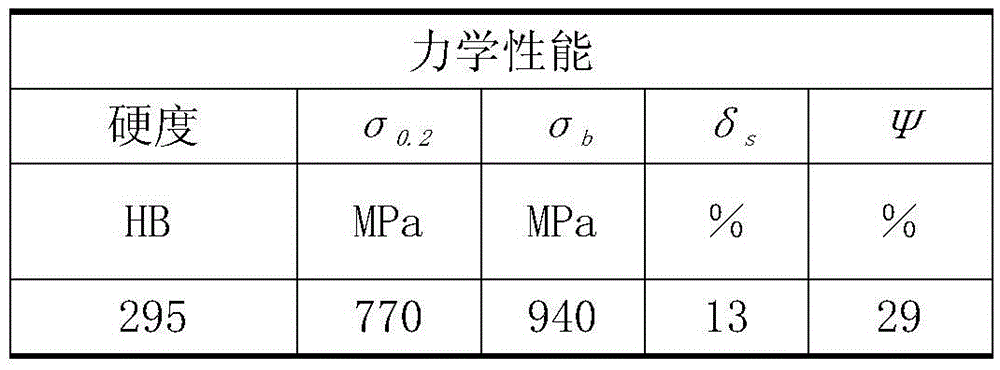

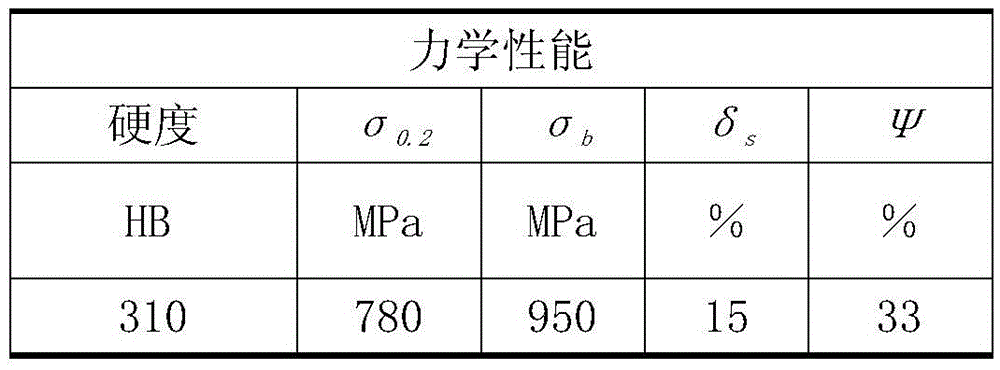

The invention discloses a high-temperature resistant turbine blade. The turbine blade comprises the following chemical components in percentage by weight: 0.19-0.21% of C, 0.55-0.57% of Mn, 0.20-0.22% of Si, 0.38-0.40% of Al, 0.30-0.32% of V, 0.40-0.42% of Ti, 0.12-0.14% of Ni, 0.06-0.08% of Sn, 0.25-0.27% of Zr, no more than 0.025% of S, no more than 0.025% of P, no more than 0.20% of Cu, 0.20-0.22% of lanthanide serial rare earth, and the balance Fe. The invention further designs a production process of the turbine blade. The production process has the advantages of simplicity and low cost, helps to largely improve the impact toughness of the blade, enhance the high temperature resistance of the blade and prolong the service life of the blade through the nitridation surface treatment.

Owner:南京赛达科技有限公司

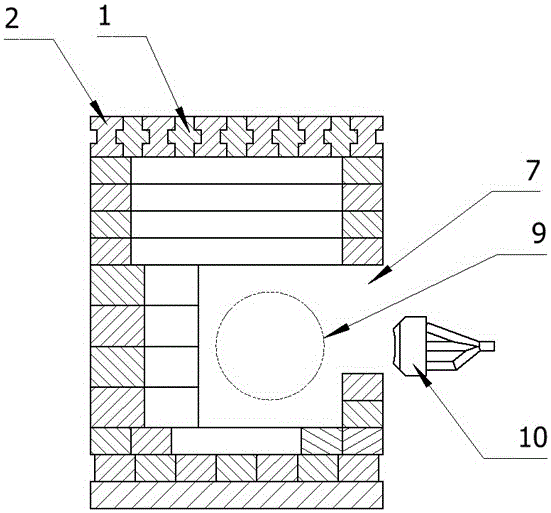

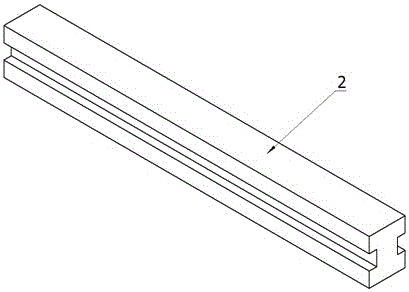

Hydraulic pump body casting process

InactiveCN104911458ANo shrinkage cavityHigh tensile strengthFoundry mouldsFoundry coresHydraulic pumpEngineering

The invention discloses a hydraulic pump body casting process, the process steps are as follows: moulding-casting material pretreatment-melting-spheroidizing treatment-pouring-heat treatment-stabilizing treatment-gas nitriding treatment-machining-inspection and storing-finished product; and the casting process is simple and practical, and low in cost, the casted hydraulic pump body is dense in tissue, free of shrinkage porosity and cavity, white cast and crack defects, good in tensile strength, and high in hardness.

Owner:SUZHOU JIN YUAN OIL MACHINERY

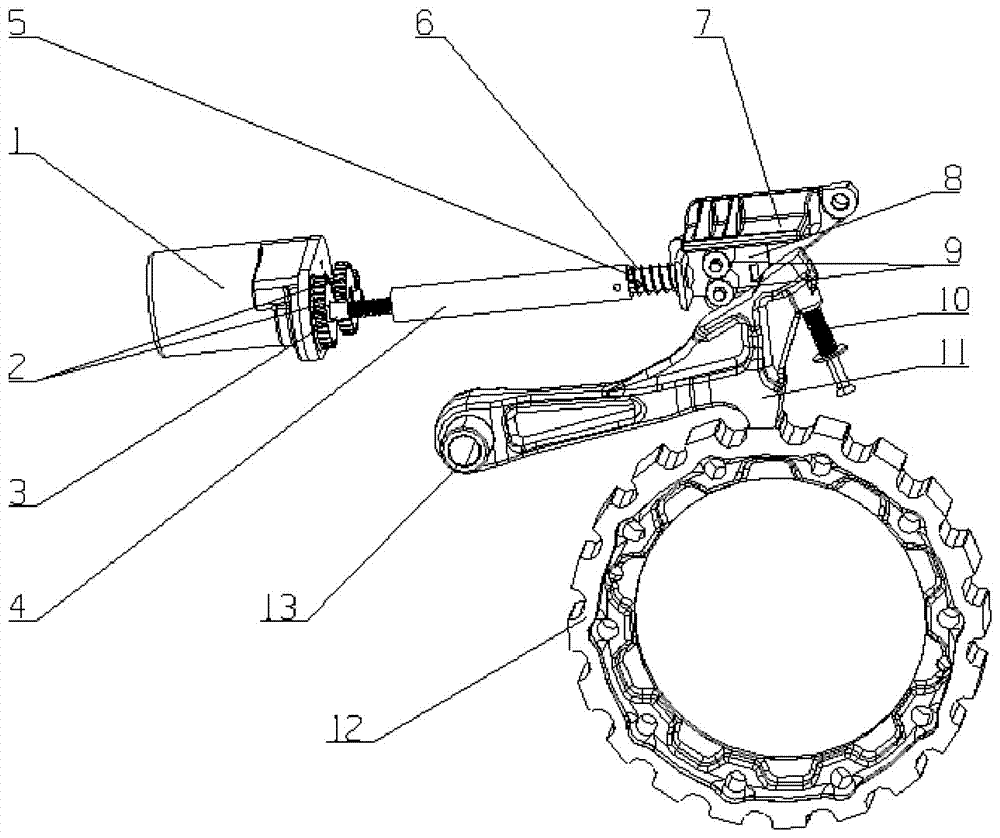

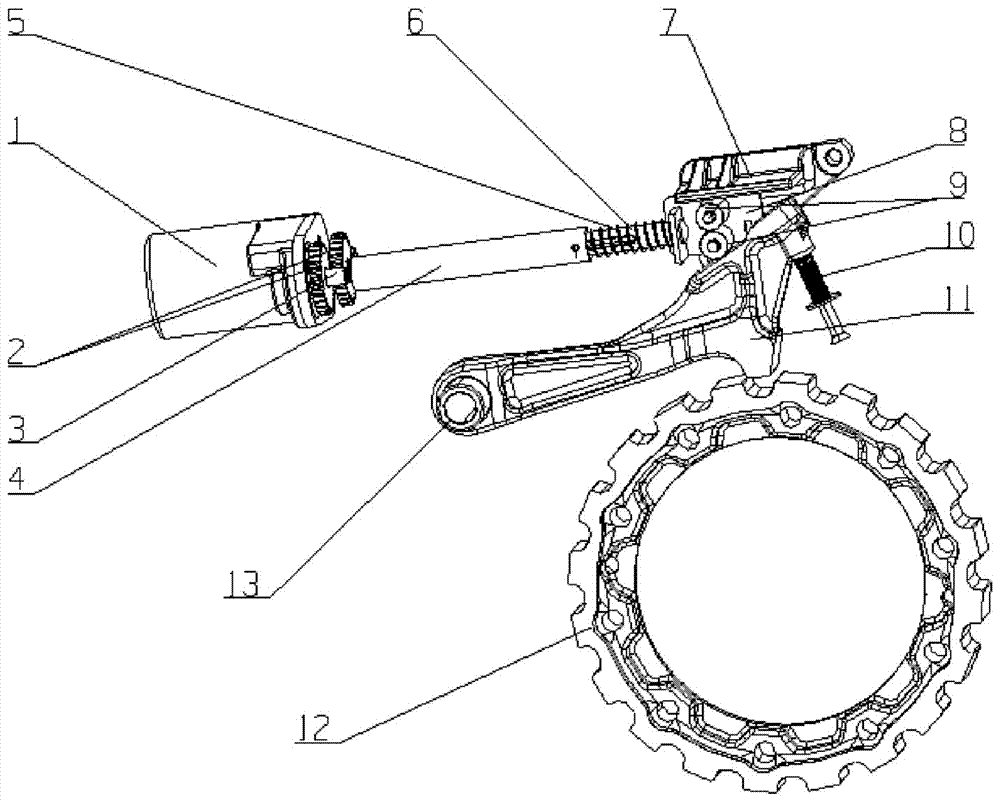

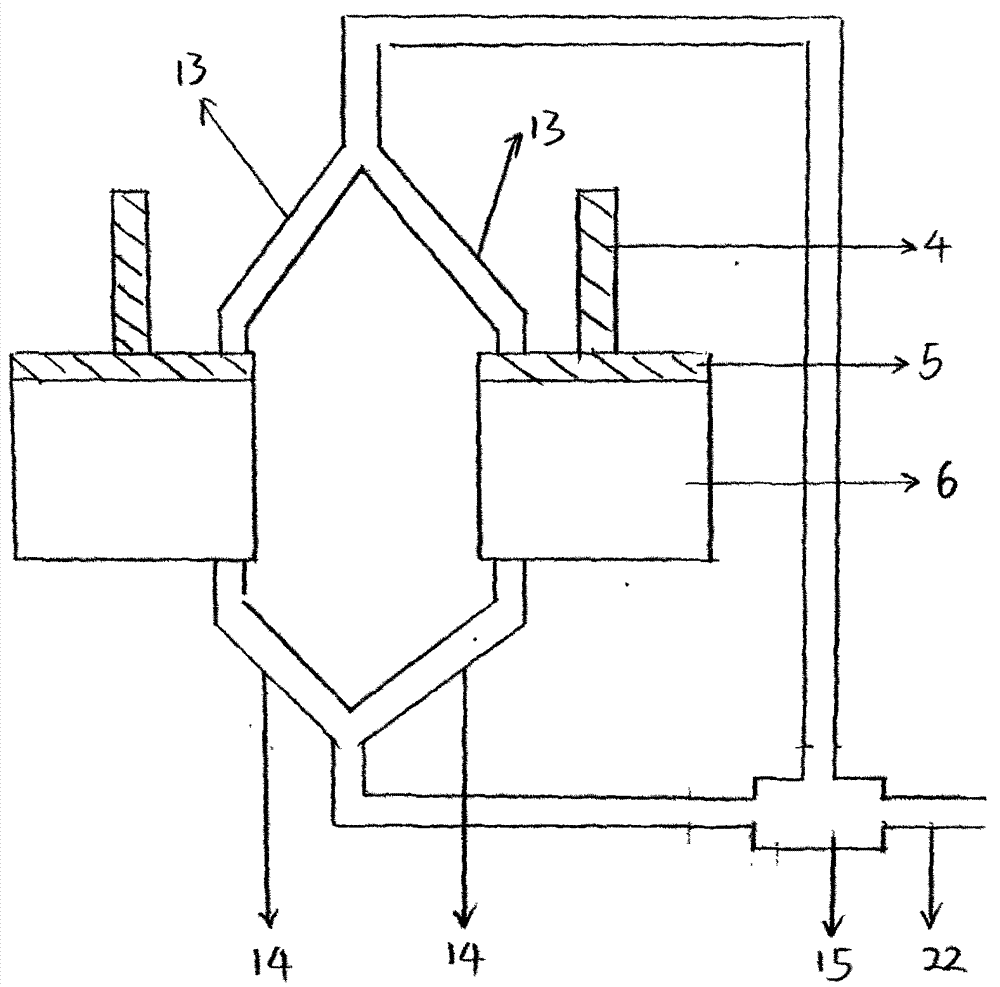

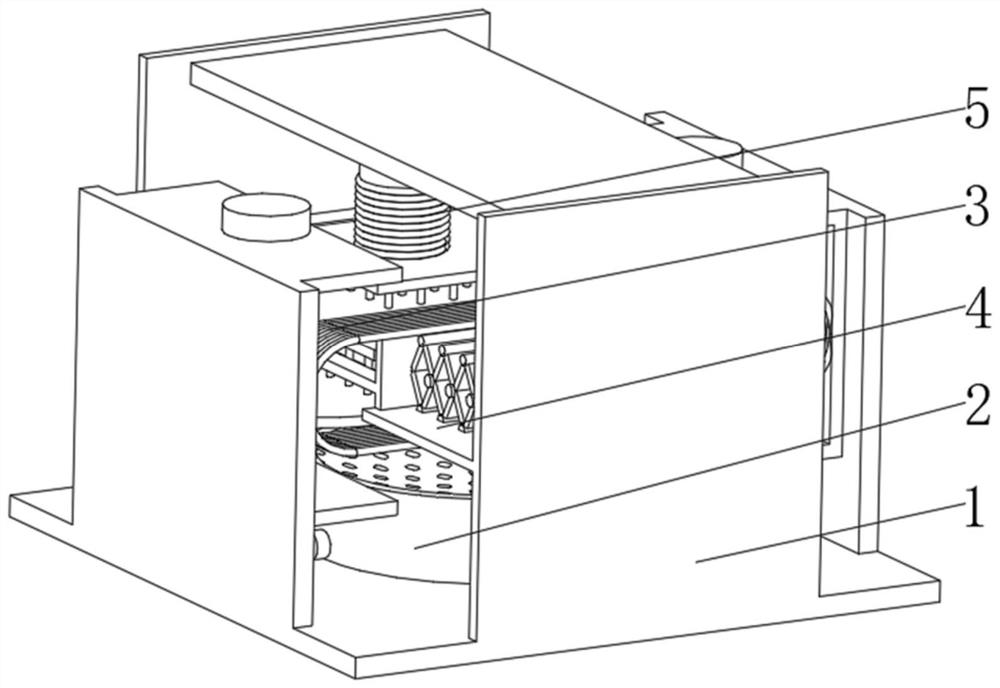

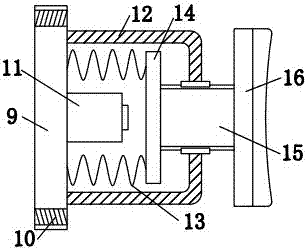

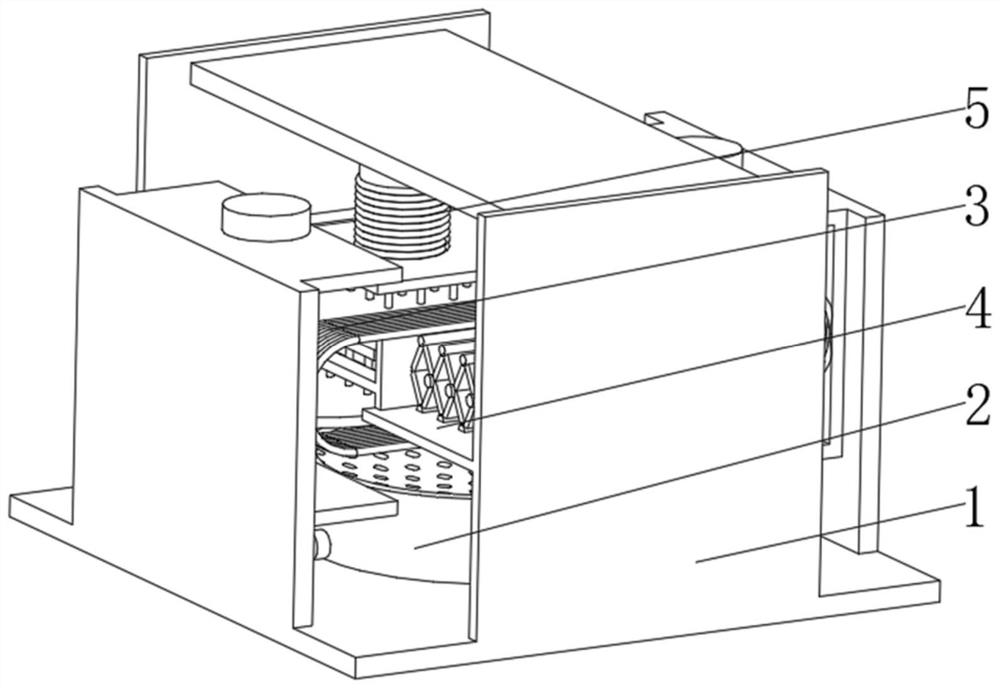

Electronic parking mechanism of automatic transmission

PendingCN107499292AReduce wearIncrease stiffnessBraking element arrangementsMechanical braking transmissionRatchetAutomatic transmission

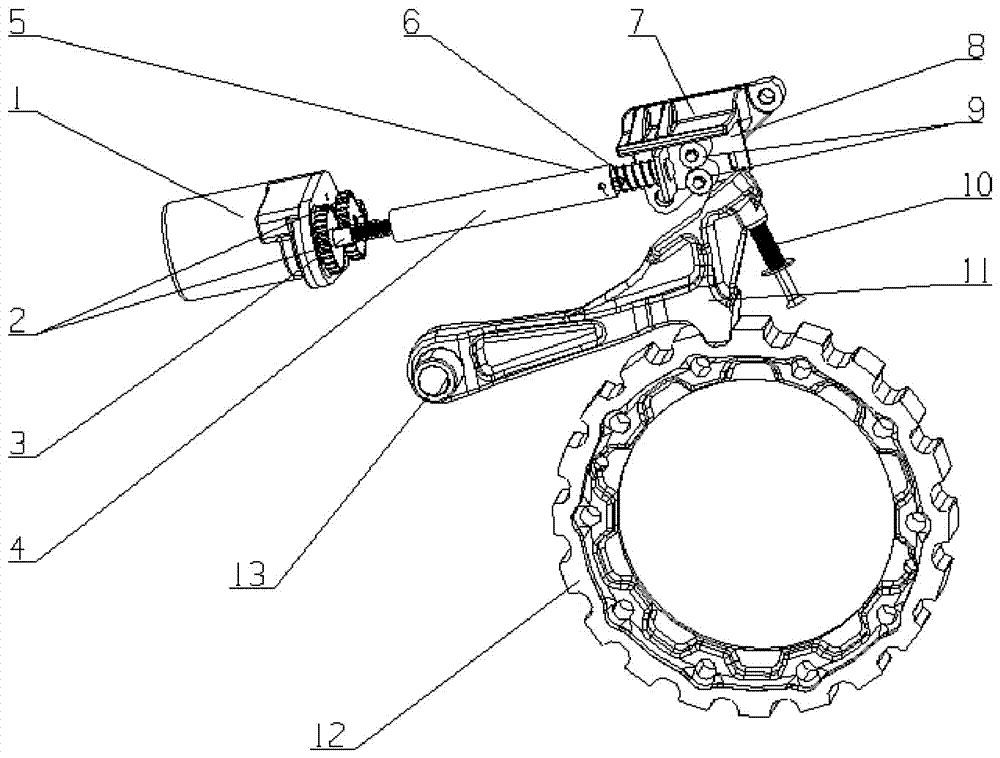

The invention relates to an electronic parking mechanism of an automatic transmission. The electronic parking mechanism comprises a parking motor, a parking ratchet wheel and a parking pawl, wherein the parking motor is installed and fixed to a transmission box body, a rotary shaft of the parking motor is connected with a screw through a speed-reducing gear mechanism, the screw is matched with one end of an internal threaded sleeve in a threaded mode, a linear telescopic push rod is arranged inside the other end of the internal threaded sleeve through sliding fit and extends out, a roller is arranged at the outward extending end of the linear telescopic push rod, the outward extending section of the linear telescopic push rod is sleeved with a compression spring, the upper end face of the roller on the linear telescopic push rod is in contact with a lower-end guiding face of a guiding plate fixed to the transmission box body, the tail end of the parking pawl is a fixed end, the fixed end is hinged to the transmission box body, the head end of the parking pawl is a free end, downward extending pawl teeth are arranged at the lower portion of the free end, a sloping surface is arranged at the upper portion of the free end, toothed grooves are uniformly distributed in the circumference of the parking ratchet wheel, and an unlocking reset device is arranged on the transmission box body and corresponds to the free end of the parking pawl.

Owner:CHONGQING TSINGSHAN IND +1

Garbage truck body

InactiveCN103496538AIsolate Corrosion DamageExtend the life of noodlesRefuse vehiclesTruckBase metal alloy

The invention discloses a garbage truck body which comprises a garbage truck body itself. An anti-corrosion layer is arranged on the inner surface of the garbage truck body. An insulating layer is arranged on the outer surface of the anti-corrosion layer and is smaller than the garbage truck body itself in thickness. The anti-corrosion layer is made of aluminum-base metal alloy. The insulating layer is made of phenolic resin materials. According to the garbage truck body, the anti-corrosion layer is arranged on the inner surface of the garbage truck body, and the insulating layer is arrange outside the anti-corrosion layer so as to effectively insulate corrosion damage of collected garbage to the truck body itself, prolong the service life of a garbage truck, and reduce maintenance cost.

Owner:陈玉婷

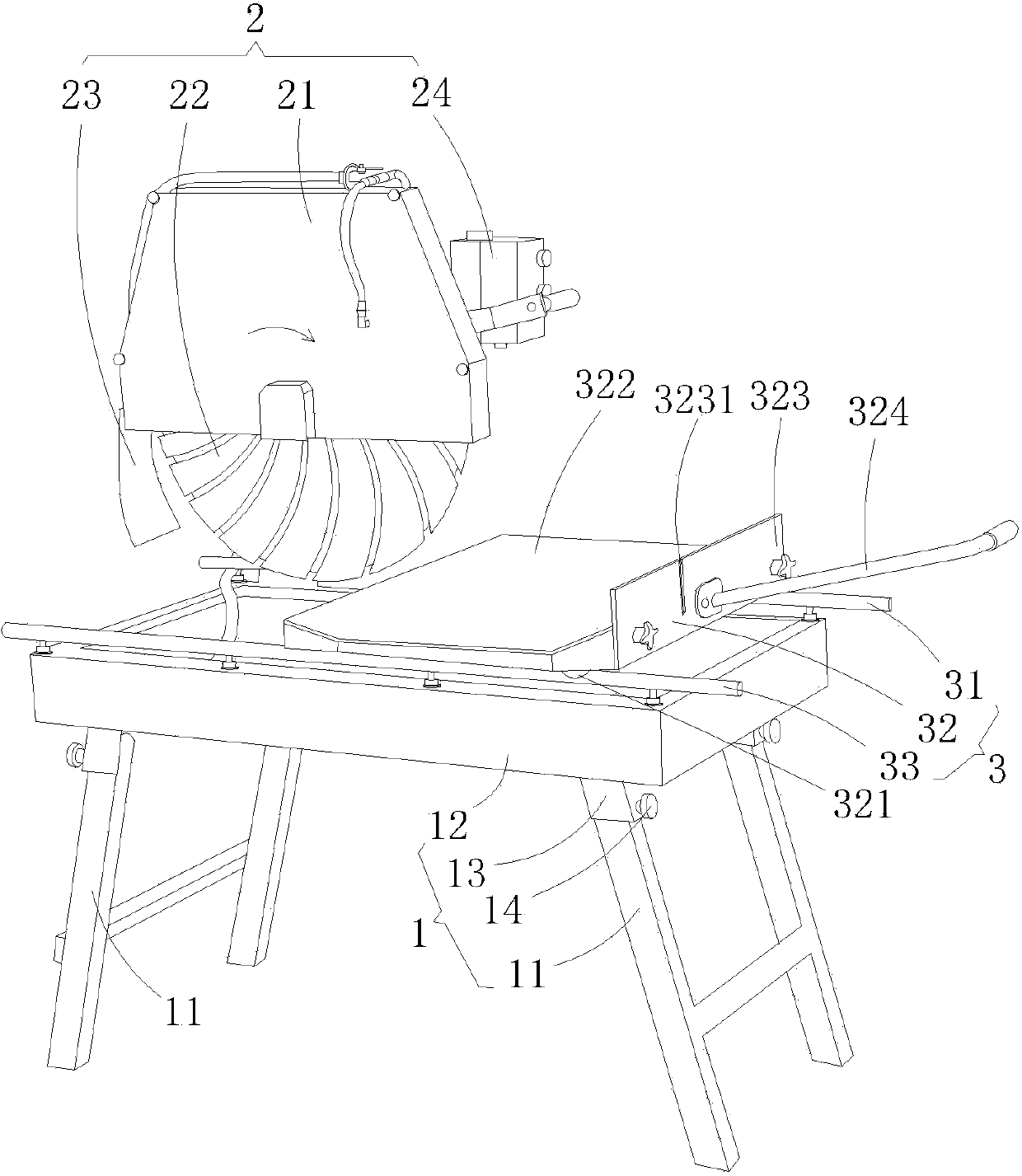

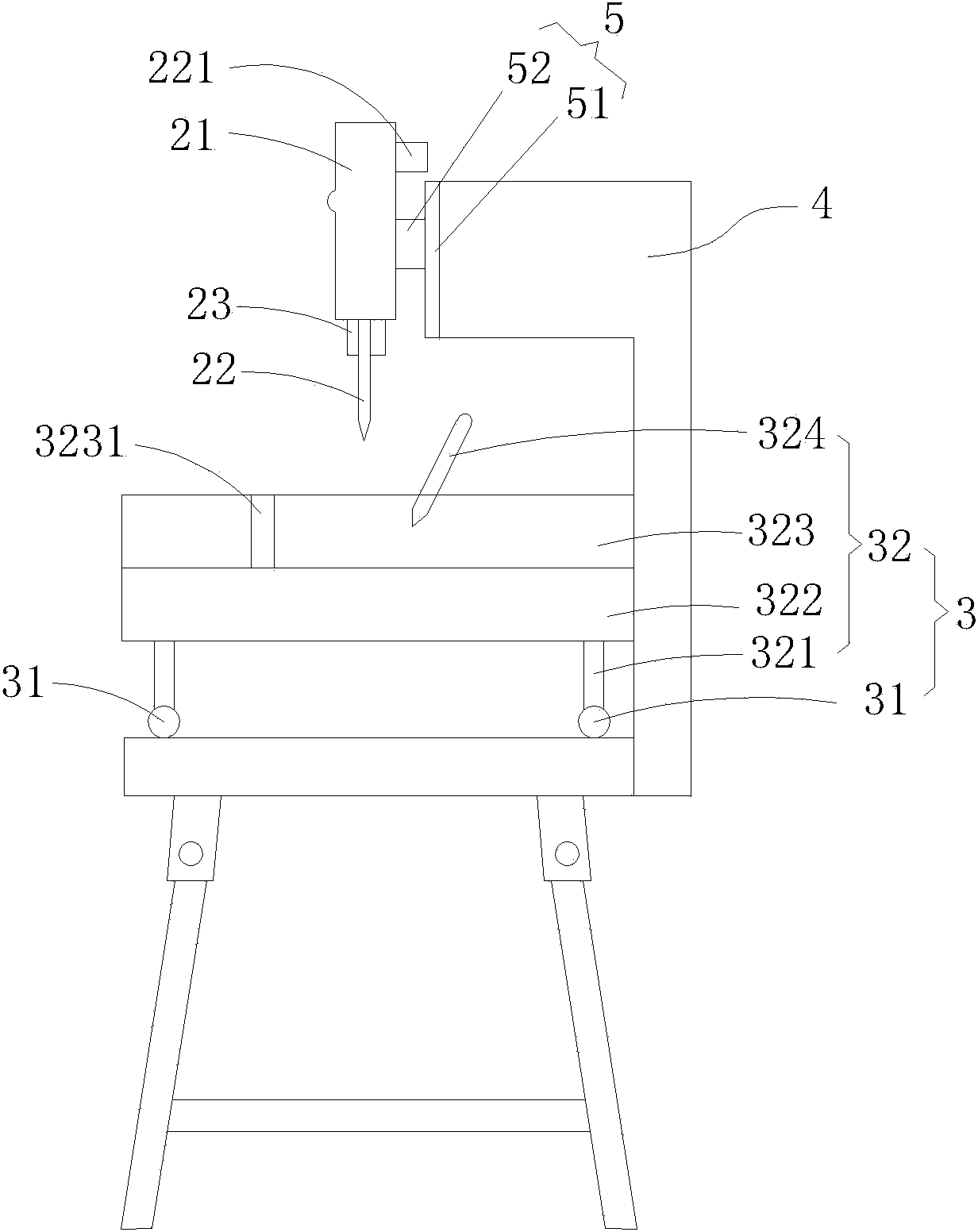

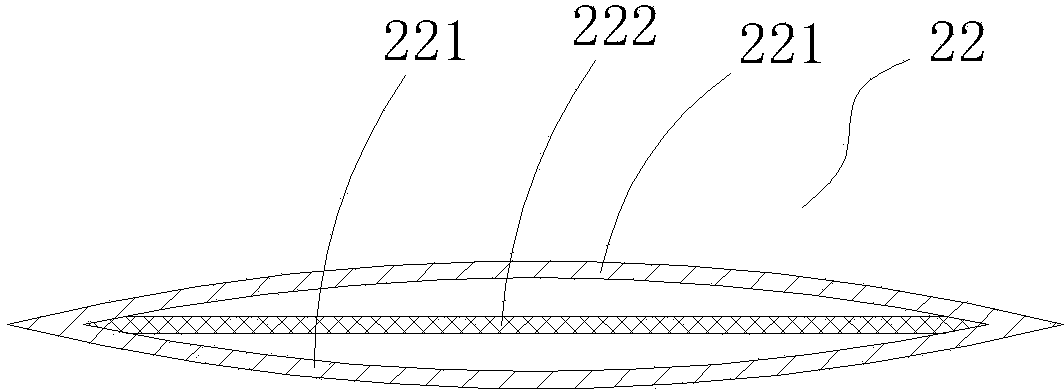

Small stone cutting machine

InactiveCN103737728AImprove securityAchieve chip removal effectStone-like material working toolsToughnessWorkbench

The invention discloses a small stone cutting machine which comprises a frame, a cutting device and a mobile workbench. The mobile workbench is fixed on the frame and can parallelly move on the workbench. One side of the workbench extends upwards to form an L-shaped cutter support. A lifting mechanism is disposed on the inner side of the cutter support. The cutting device is fixed on the lifting mechanism and is capable of being ascended and descended through the lifting mechanism. Three layers of single saw blades are connected to form an integrated saw blade structure. The arc pieces fixed on two sides of a central support piece are single cutters of different materials, rigidity and toughness requirements can be satisfied, an arc guide groove is formed in the surface of each arc piece, and chip removing during work can be achieved, the service life of equipment is prolonged, and safety of operators is guaranteed.

Owner:XIAMEN ZHONGHENG MACHINERY MFG

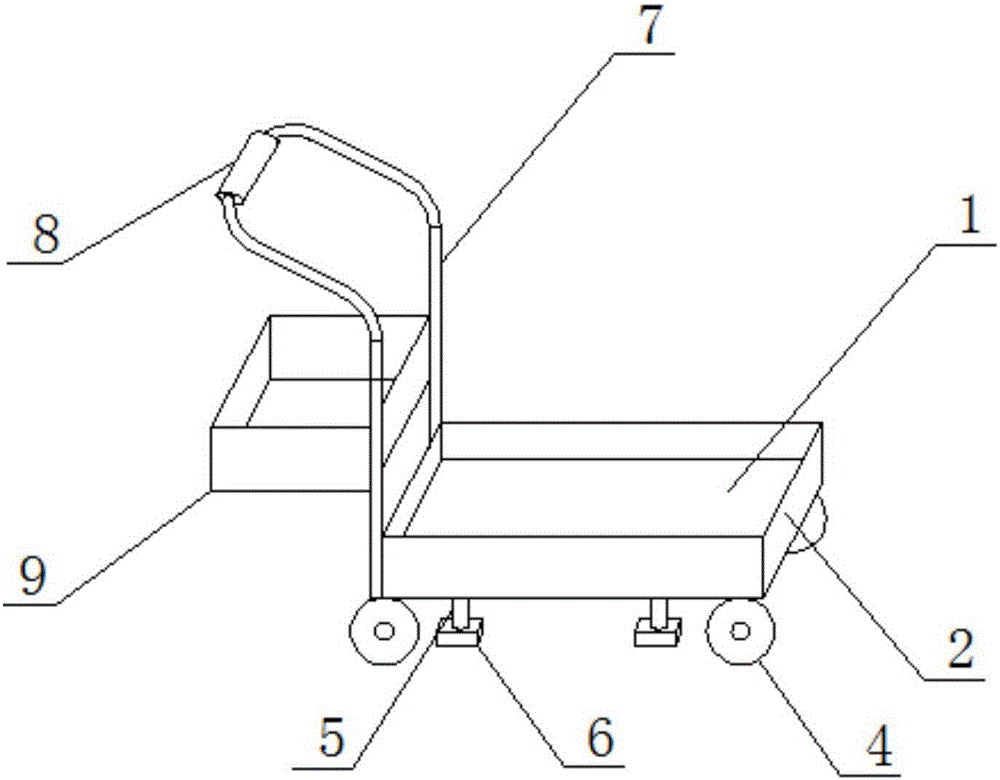

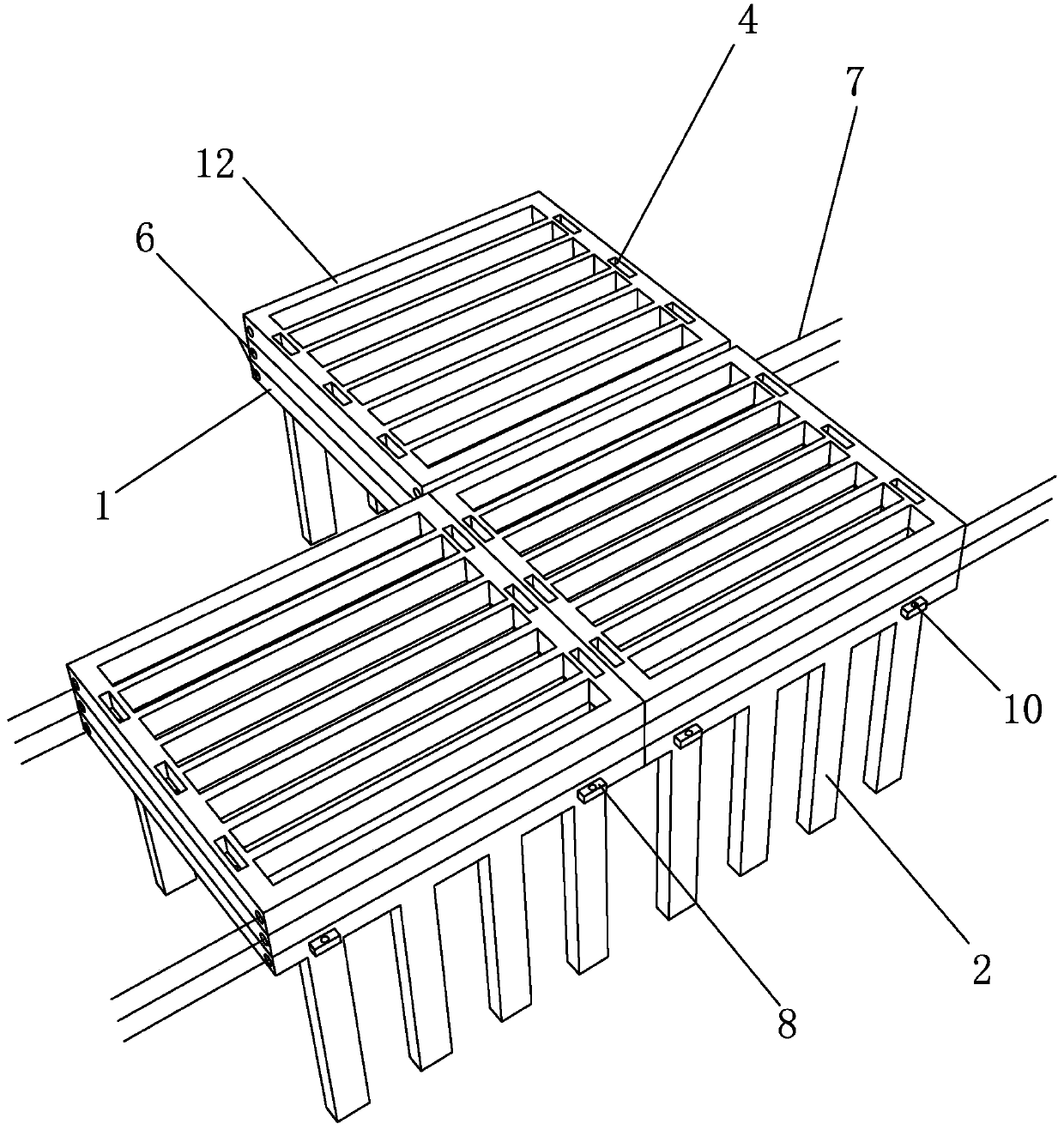

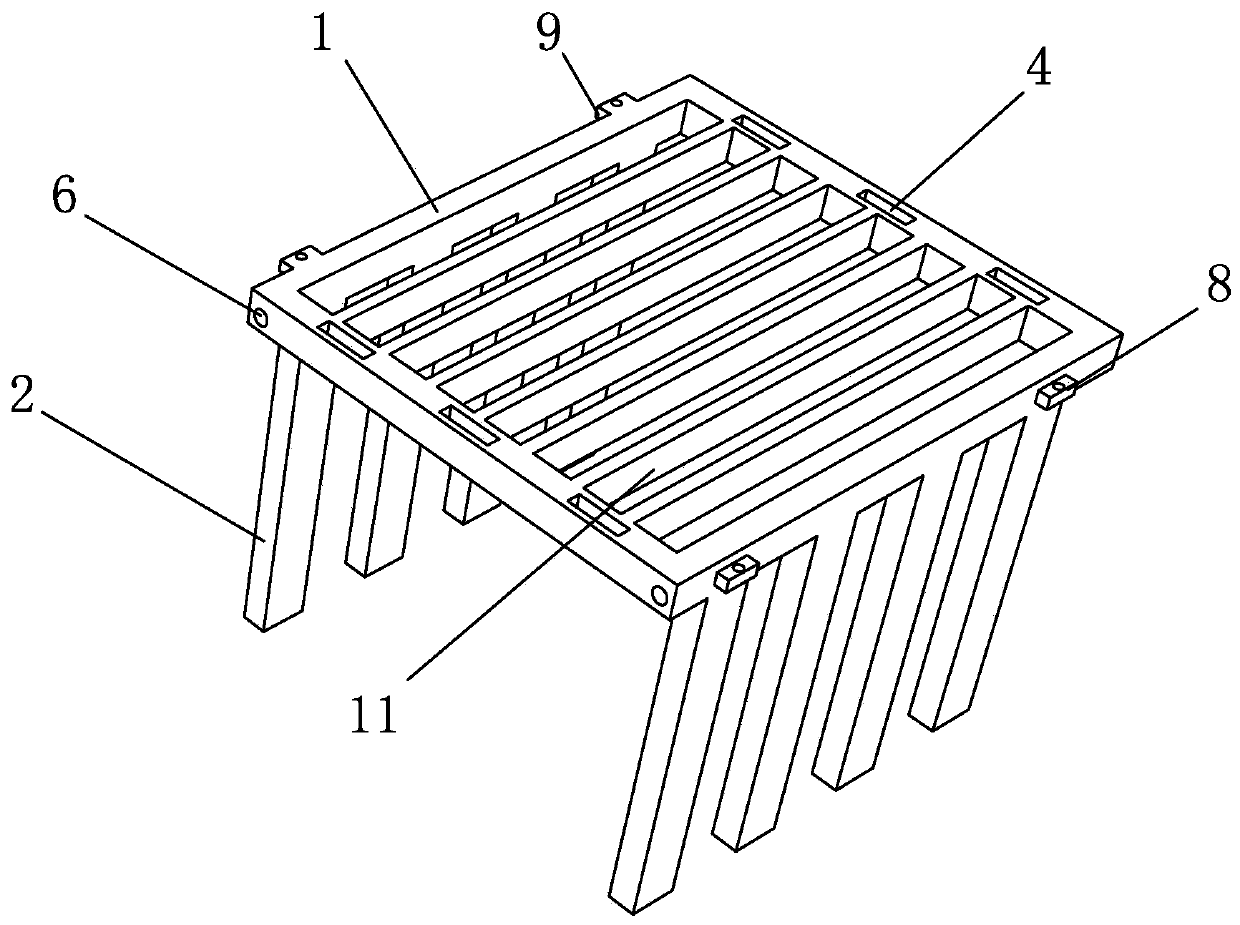

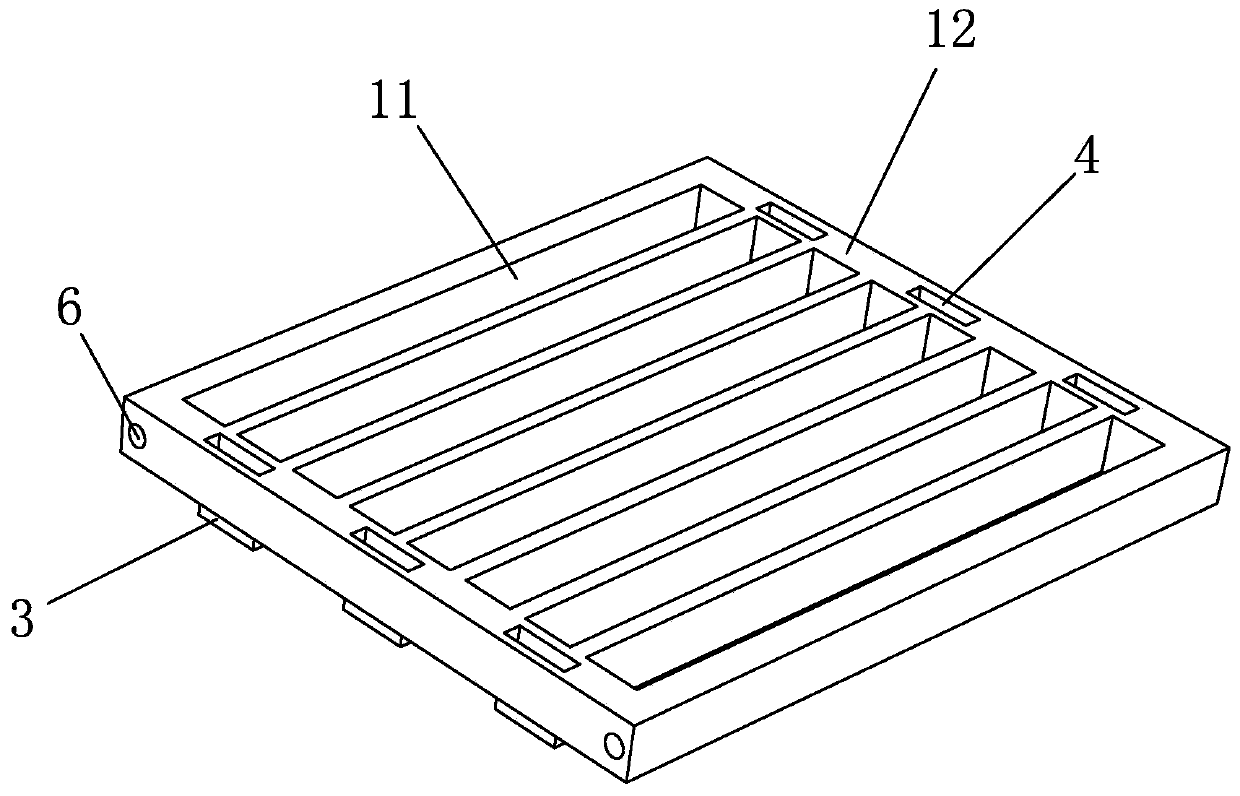

Cargo conveying trolley

InactiveCN106335530ANot easy to slidePrevent fallingSledgesHand carts with multiple axesEngineeringObject storage

The invention discloses a cargo conveying trolley. The cargo conveying trolley comprises a push handle (7), a trolley body (2), at least four pulley wheels (4) and at least four supporting mechanisms; the at least four pulley wheels (4) are arranged on a lower surface of the trolley body (2) at intervals; an upper surface of the trolley body (2) is partially concave downward to form an object storage groove (1); the push handle (7) is fixedly connected with a side face of the trolley body (2); the at least four supporting mechanisms are arranged on a lower surface of the trolley body (2) at intervals. According to the cargo conveying trolley provided by the invention, the problems of a cargo conveying trolley in the prior art that the trolley body is supported by the pulley wheels all the time, the pulley wheels are easy to damage after being used for long time, the service life of the cargo conveying trolley is shortened, the cargo conveying trolley is easy to slide when cargoes on the trolley are transported and the transportation is inconvenient are solved.

Owner:芜湖德鑫汽车空调有限公司

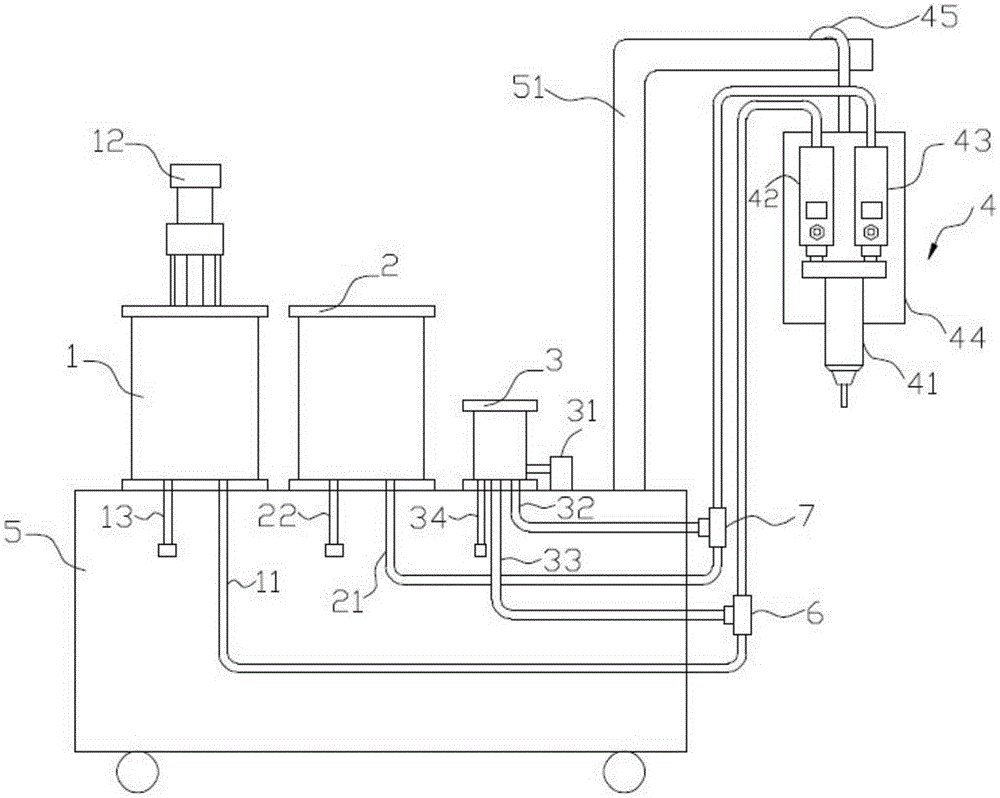

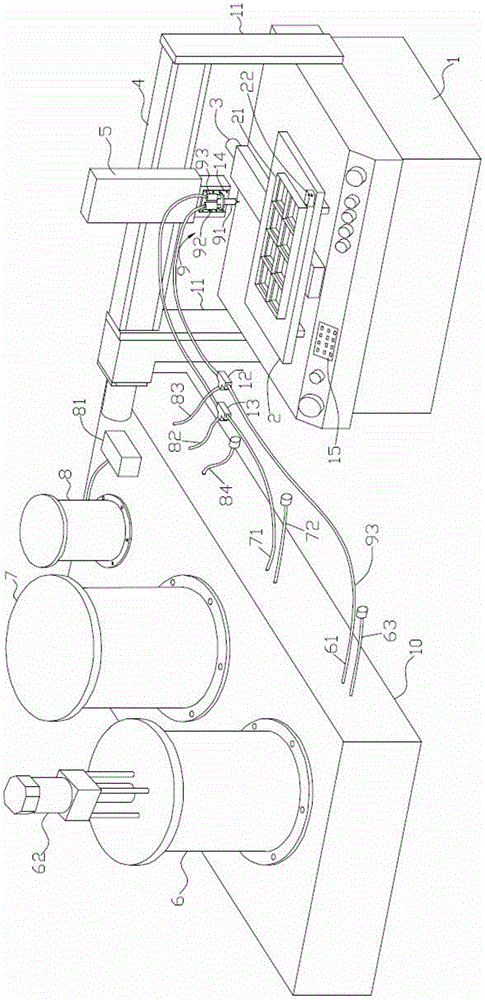

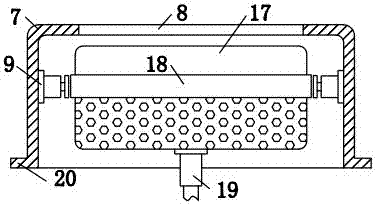

Mixing device for glue pouring machine

InactiveCN105396756AReduce wasteWell mixedLiquid surface applicatorsCoatingsEngineeringHigh pressure

The invention discloses a mixing device for a glue pouring machine. The mixing device comprises a glue charging barrel, a curing agent charging barrel, a cleaning solution charging barrel, a mixing part and a control box, wherein the glue charging barrel, the curing agent charging barrel and the cleaning solution charging barrel are all arranged above the control box; a pressure pump is arranged on the cleaning solution charging barrel; a first liquid outlet and a second liquid outlet are formed in the cleaning solution charging barrel; a third liquid outlet is formed in the curing agent charging barrel; a fourth liquid outlet is formed in the glue charging barrel; the fourth liquid outlet and the second liquid outlet are communicated with the mixing part through a first switching valve; the third liquid outlet and the first liquid outlet are communicated with the mixing part through a second switching valve; a bracket is arranged on the control box; and the mixing part is hung on the bracket. According to the mixing device disclosed by the invention, materials are supplied to a mixing tube through a set proportion of the glue charging barrel and the curing agent charging barrel; the materials are mixed when being used, so that mixing is uniform, the dosage is accurate, and raw material waste is reduced; and as residual glue in the mixing device is cleaned through a high-pressure cleaning solution, the service life of equipment is prolonged.

Owner:JIANGYIN LEXU PHOTOELECTRIC CO LTD

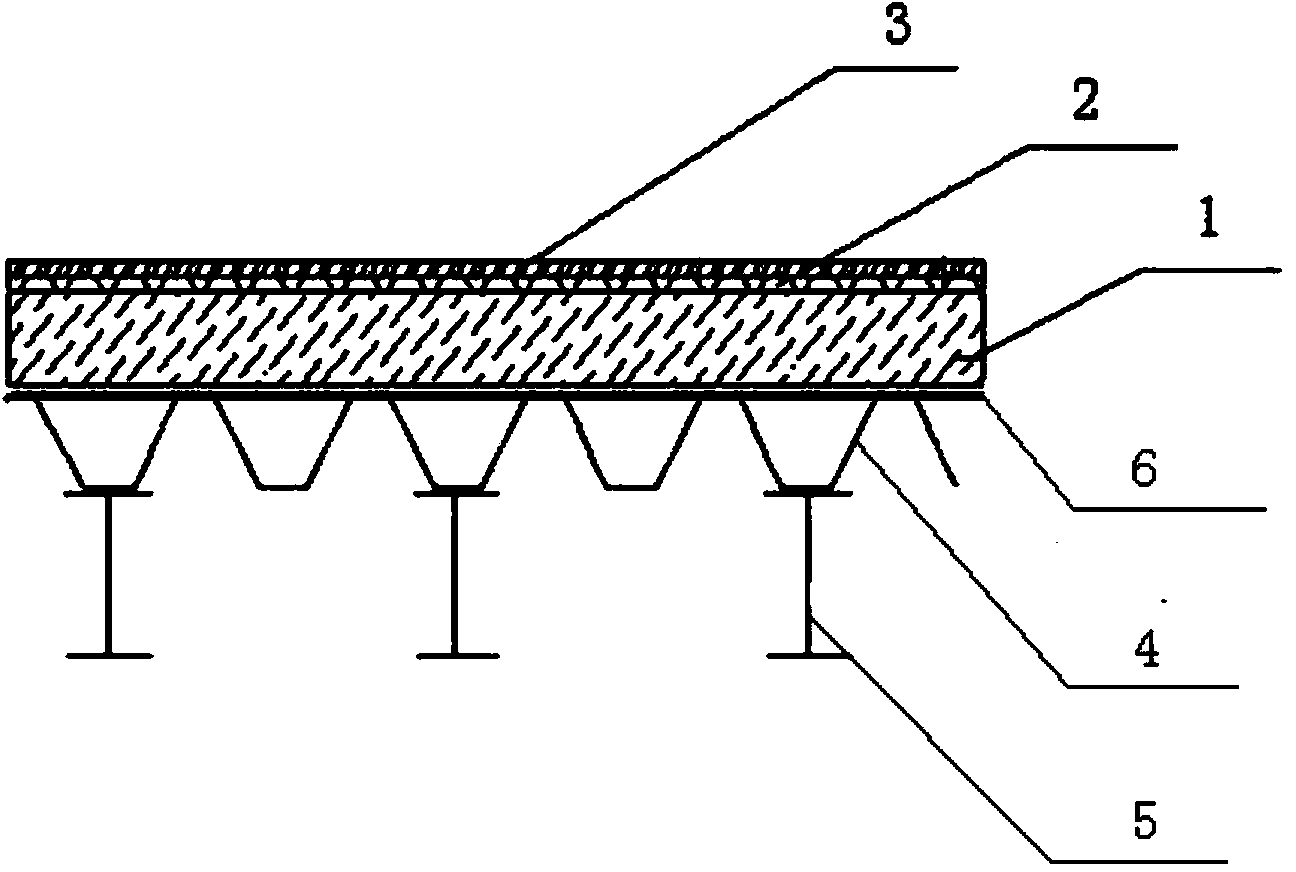

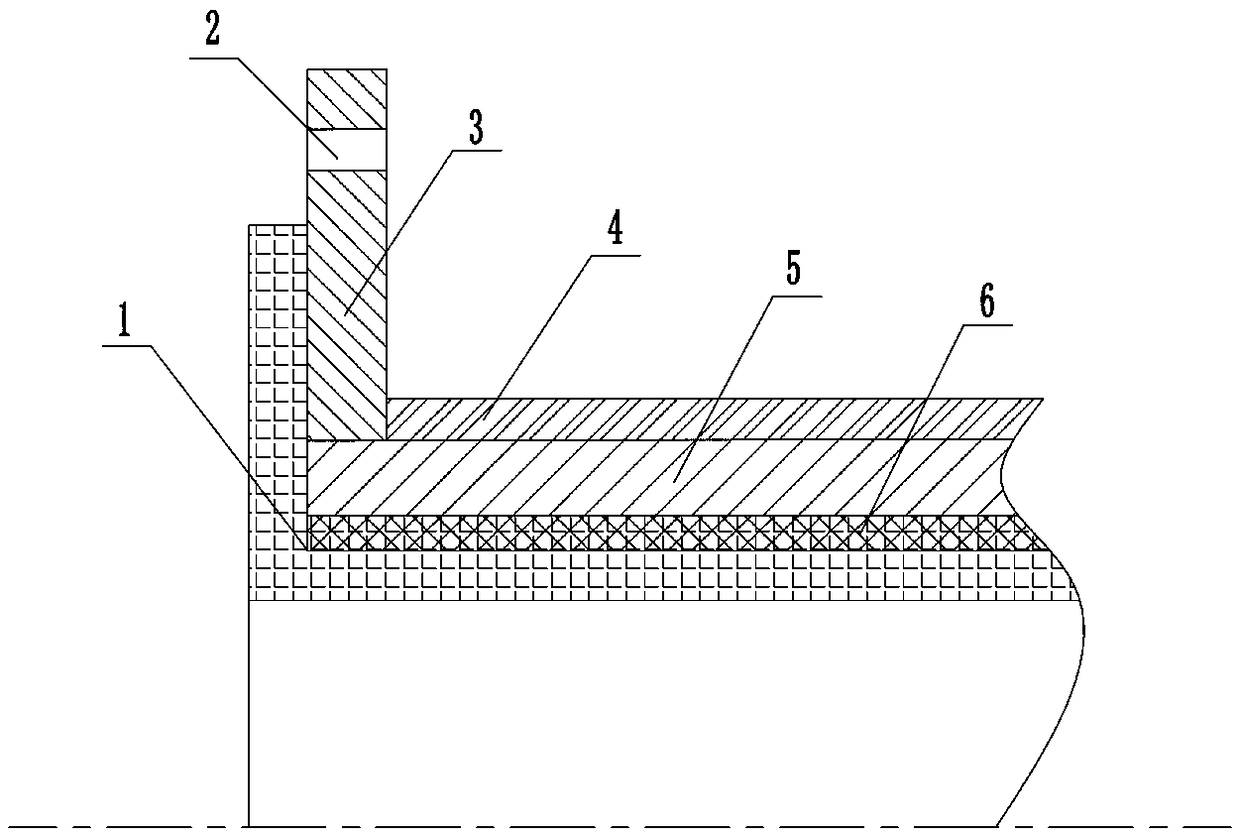

Hot rolling workshop roof heat preservation structure and method

InactiveCN103967225AExtend the life of noodlesImprove roof waterproof performanceBuild-up roofsRoof covering insulationsUltimate tensile strengthStrength reduction

Disclosed are a hot rolling workshop roof heat preservation structure and method. The hot rolling workshop roof heat preservation structure comprises an expanded steel diamond mesh, a rock wool insulation board, a tire base cloth type SBS waterproof roll and a cold bonding type SBS waterproof roll, the expanded steel diamond mesh is arranged on color steel tiles, the rock wool insulation board is arranged on the expanded steel diamond mesh, the tire base cloth type SBS waterproof roll is connected with the rock wool insulation board through anchoring parts, and the tire base cloth type SBS waterproof roll is covered with the cold bonding type SBS waterproof roll. Compared with the prior art, the structure and method have the advantages that the service life of a roof heat preservation layer is prolonged, the water prevention performance of a roof is improved, equipment accidents caused by rain leakage are avoided, and safety accidents caused by strength reduction of the color steel tiles of the roof are avoided.

Owner:ANGANG STEEL CO LTD

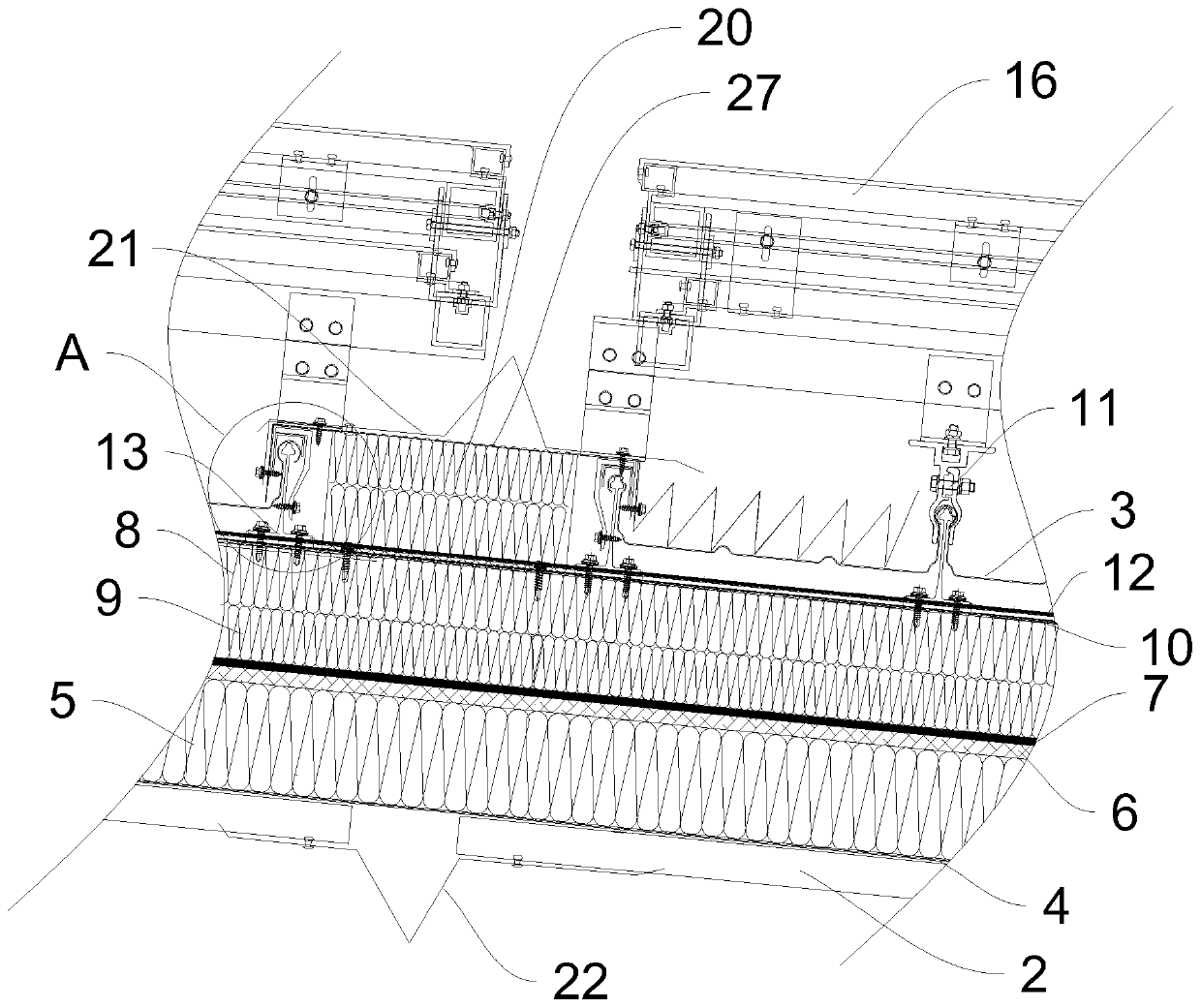

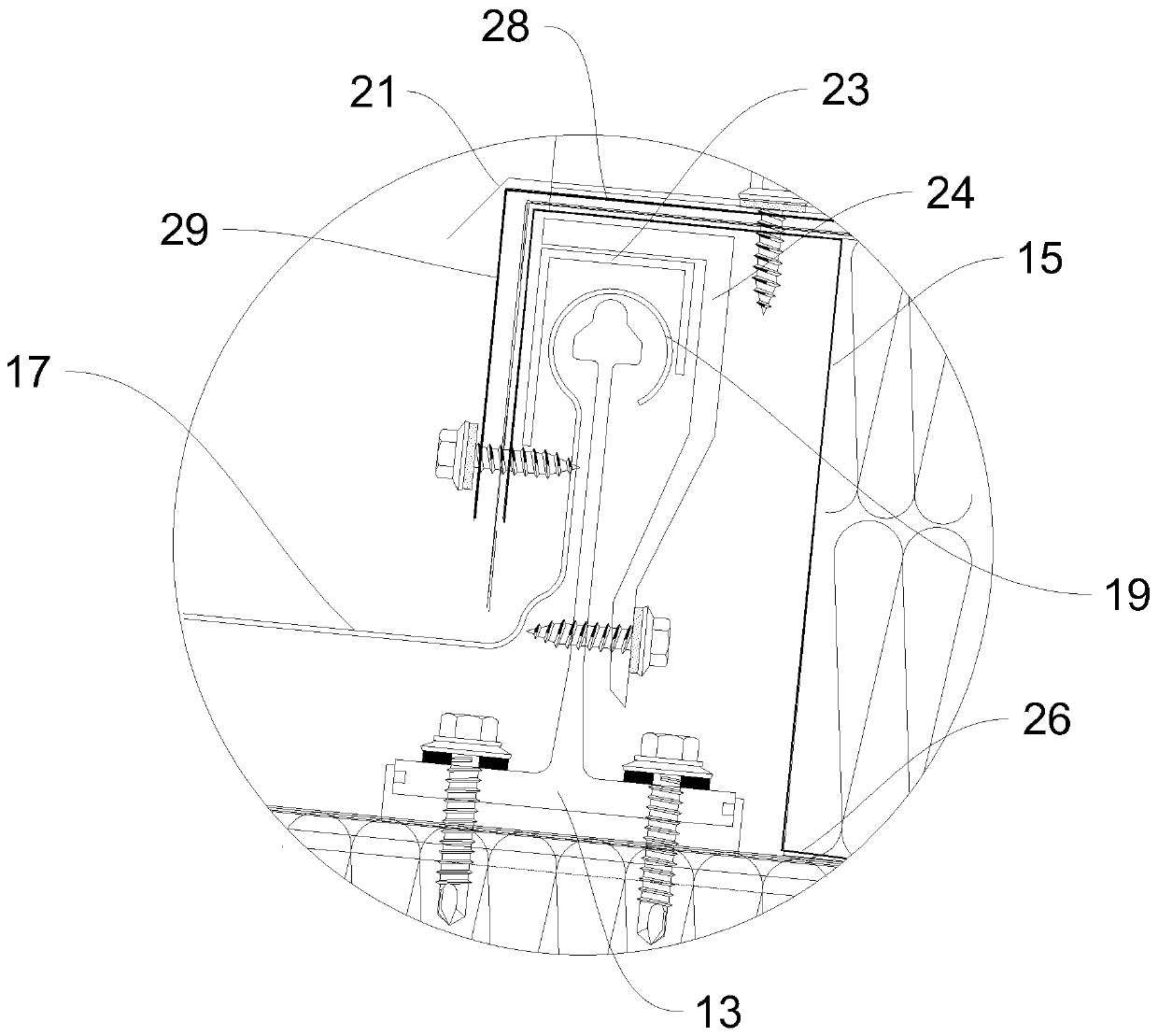

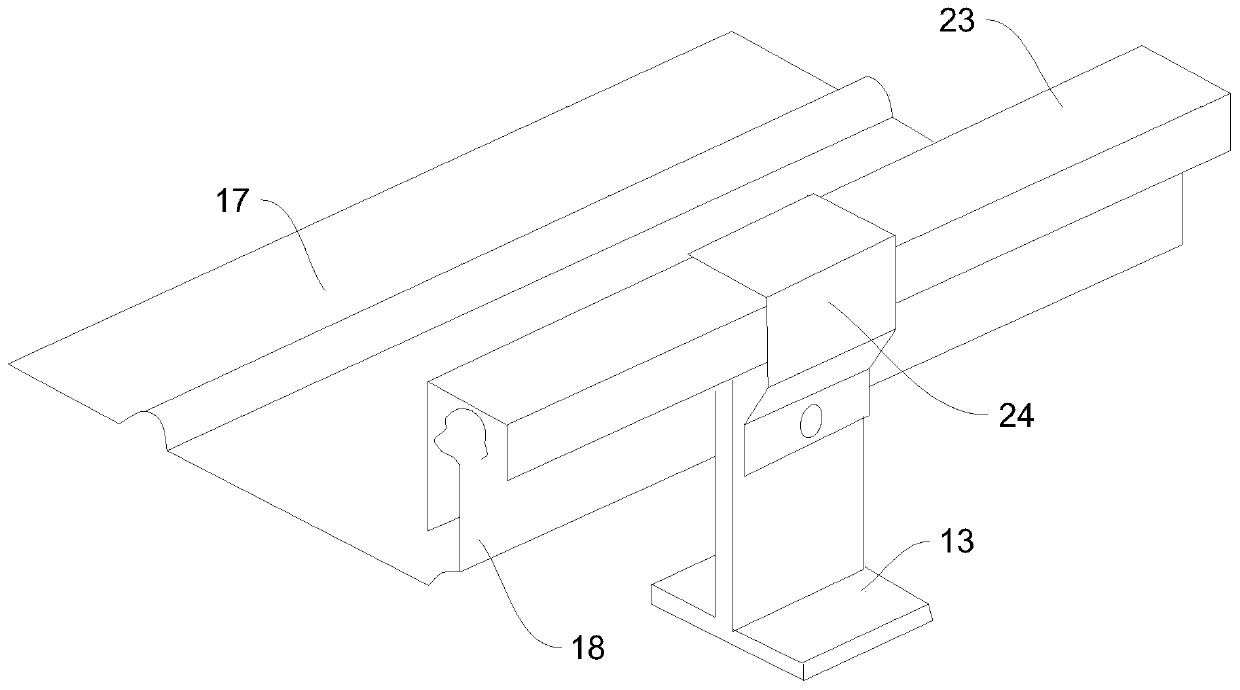

Metal roof

InactiveCN111042417AExtended service lifeLeak into avoidRoof covering using slabs/sheetsBuilding roofsInsulation layerClassical mechanics

The invention relates to the technical field of buildings, in particular to a metal roof. The metal roof comprises a roof plate, wherein the roof plate comprises a bottom plate layer, a sandwich layerand a surface plate layer which are sequentially arranged from bottom to top, the sandwich layer comprises a dustproof layer, a sound absorption layer, a supporting layer, a steam insulation layer, afirst heat preservation layer and a first waterproof layer which are sequentially arranged from bottom to top, a primary purline is arranged below the bottom plate layer, a secondary purline is arranged above the primary purline, the secondary purline is embedded in the sandwich layer, the upper side wall of the secondary purline is provided with a fixing seat for allowing the surface plate layerto be mounted, the fixing seat is arranged above the sandwich layer, a joist is arranged above the roof plate, the joist is fixed on the upper side wall of the surface plate layer through a fixture,and a decorative plate is arranged above the joist. The metal roof has the advantages that heat preservation and heat insulation, noise reduction and water proofing can be realized, and the service life is long.

Owner:CHINA RAILWAY SIXTH GROUP

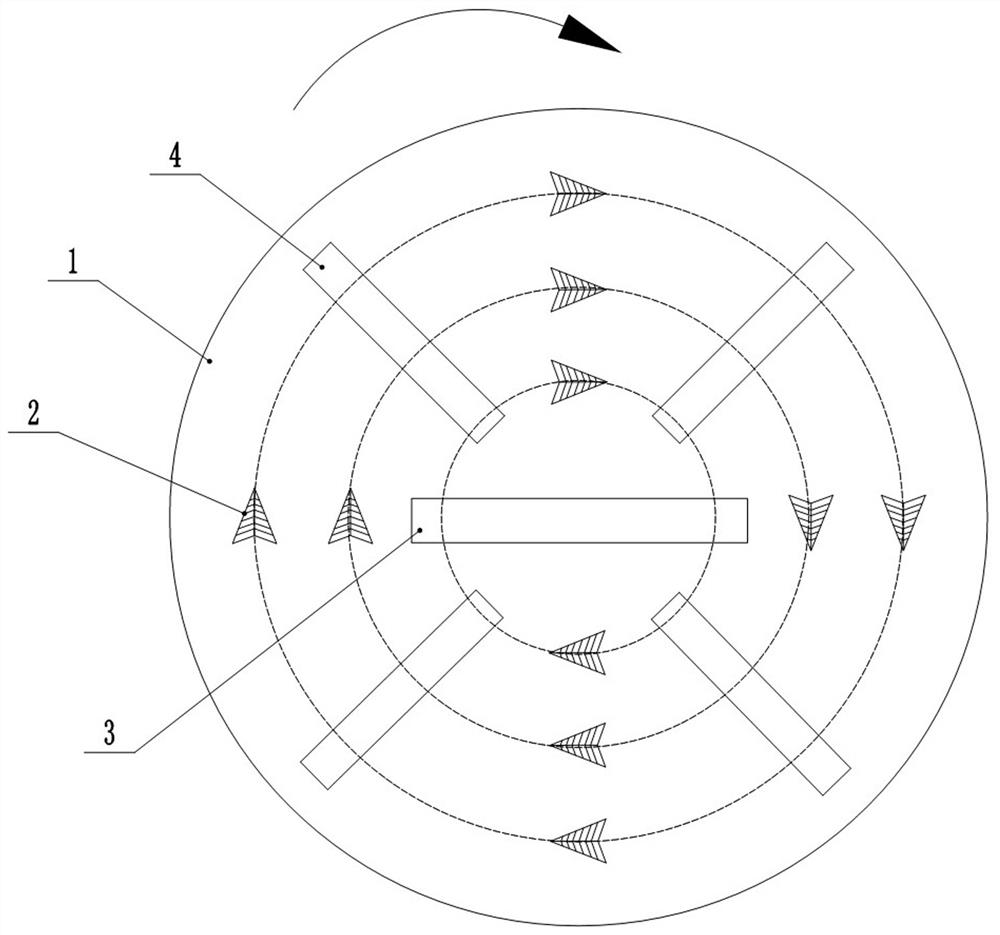

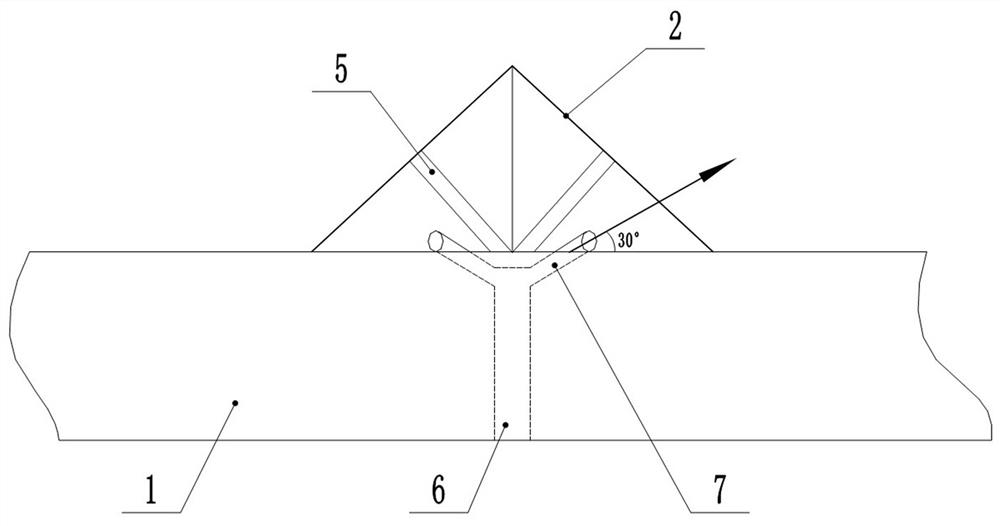

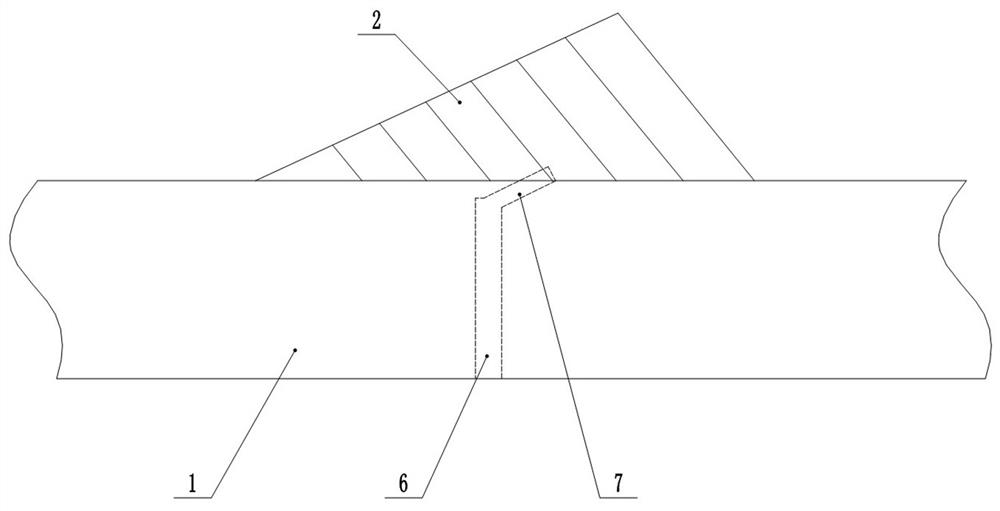

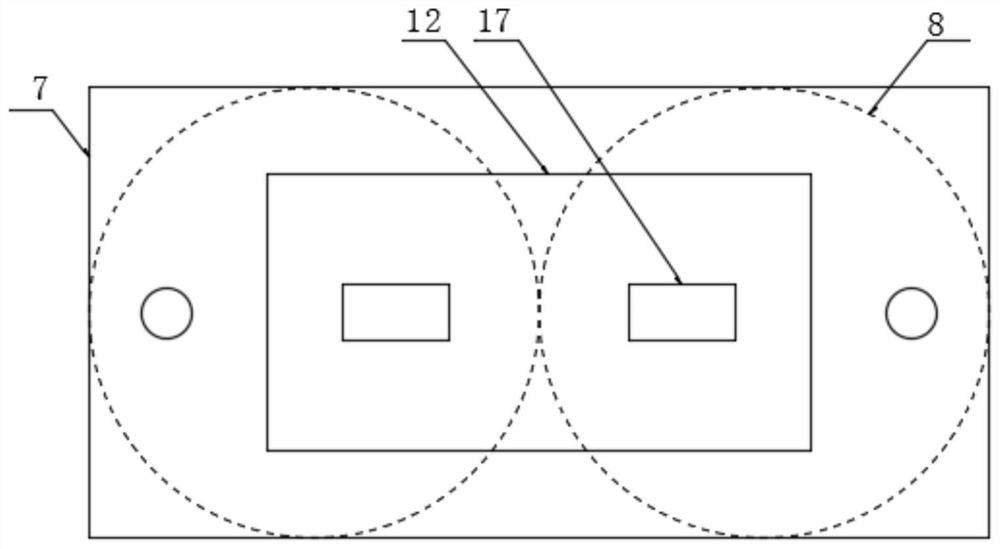

Tunnel boring machine cutterhead for assisting rock breaking through high-pressure water jet

ActiveCN112160763AHighlight substantiveSignificant progressTunnelsTunnel boring machineHigh pressure water

The invention provides a tunnel boring machine cutterhead for assisting rock breaking through a high-pressure water jet. The cutterhead comprises a cutterhead body, a first hob assembly, a second hobassembly and a scraper, wherein the first hob assembly, the second hob assembly and the scraper are arranged on the cutterhead body. Each of the first hob assembly and the second hob assembly comprises a rotating shaft and a plurality of hobs arranged on the rotating shaft. The scraper is plowshare-shaped, a spray pipe used for introducing high-pressure water is arranged on the cutter head body and located below the scraper, a pair of spray heads is arranged at the end of the spray pipe, and the included angle between the spray direction of the spray heads and the surface of the cutter head body is 30 degrees. The rotating areas of the first hob assembly and the second hob assembly are intersected. The first hob assembly is provided with hobs which move along the spraying track of each spray head on the tunnel face. According to the cutterhead, the scraper, the hob and the high-pressure water jet are mutually combined to efficiently crush the tunnel face in the tunneling process, so that the service life of the scraper and the hob can be prolonged, and the tunneling efficiency of the tunnel is greatly improved.

Owner:STATE KEY LAB OF SHIELD & TUNNELING TECH +1

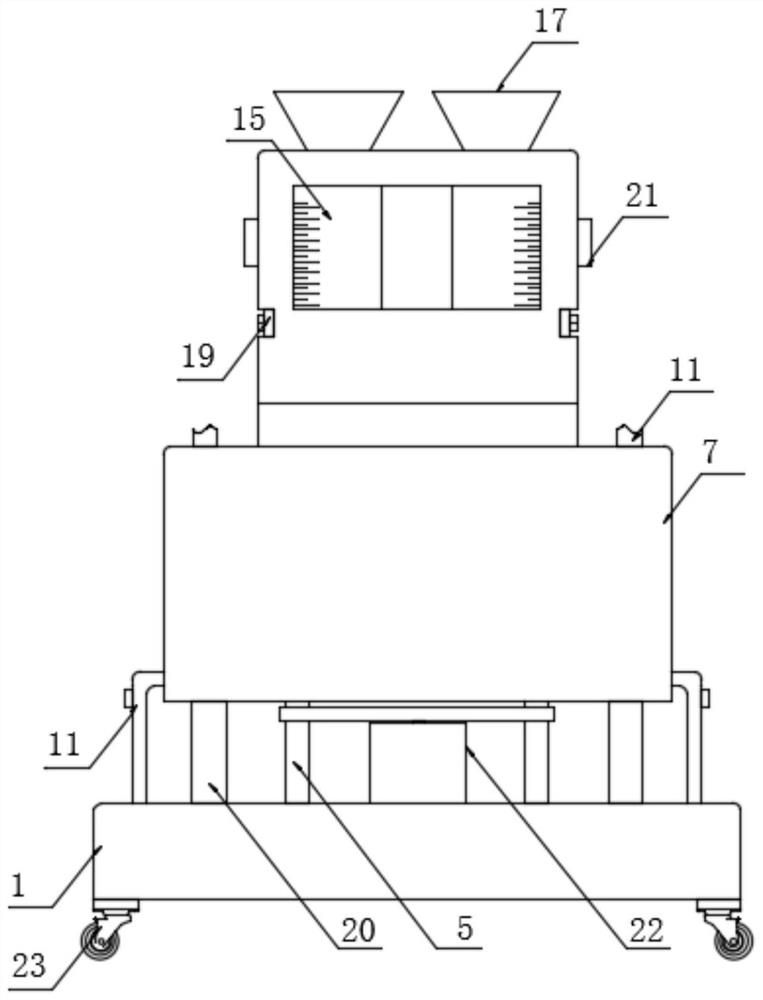

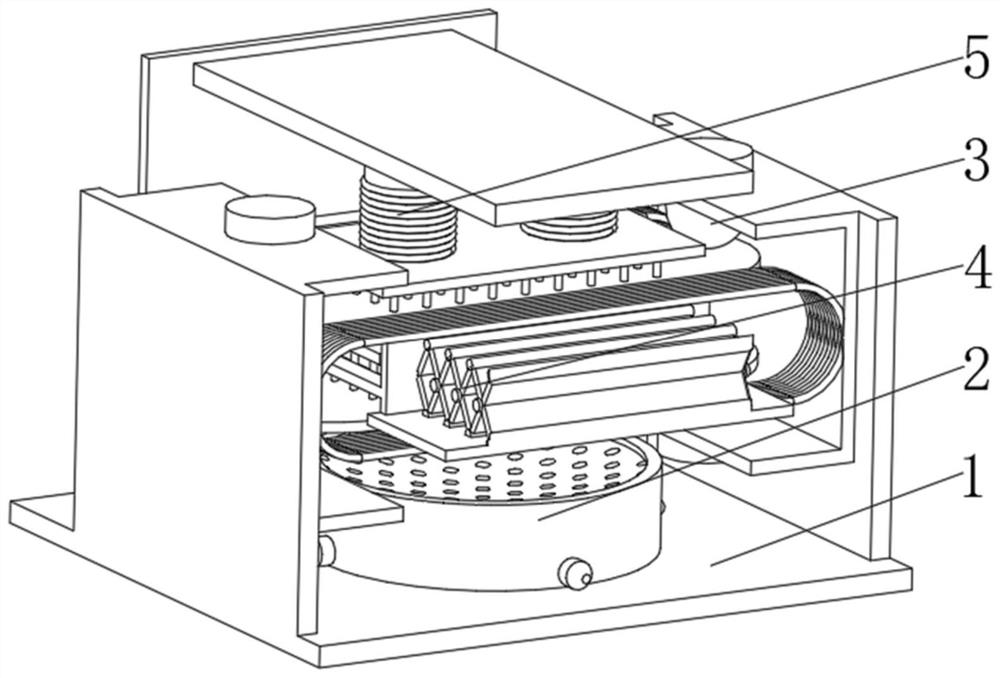

Improvement device for saline-alkali soil

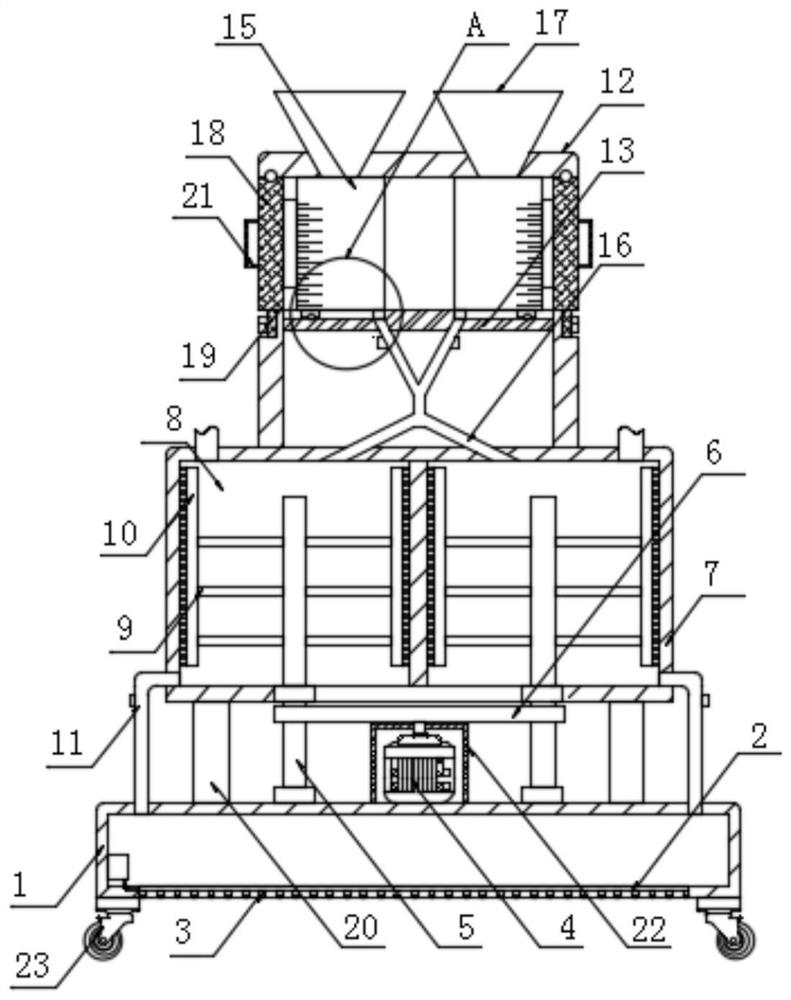

ActiveCN112586126AQuality improvementWell mixedSoil lifting machinesTransportation and packagingWater storageSoil science

The invention discloses an improvement device for saline-alkali soil, and relates to the field of environmental governance. The improvement device for the saline-alkali soil comprises a base, a cavityis formed in the interior of the base, a water storage pipeline is fixedly installed on the bottom wall of the cavity, a booster pump is fixedly installed at one end of the water storage pipeline, aplurality of evenly-distributed water spray gun heads are fixedly installed on the bottom pipe wall of the water storage pipeline, the bottom ends of the plurality of water spraying gun heads fixedlypenetrate through the bottom wall of the cavity and extend to the exterior of the base, a stirring mechanism is arranged above the base, two sets of symmetrically-arranged universal wheels are fixedlyinstalled at the bottom of the base, the stirring mechanism comprises a motor, an output shaft of the motor is fixedly sleeved with a first chain wheel, and two rotating rods are rotationally mountedat the top of the base through two first bearings. According to the improvement device for the saline-alkali soil, chemicals are mixed more uniformly, the chemical mixing quality can be improved, theinterior of the device can be automatically cleaned, a large amount of manpower is saved, the use cost of the device is reduced, and the working efficiency of the device is improved.

Owner:湖南博川农业发展有限责任公司

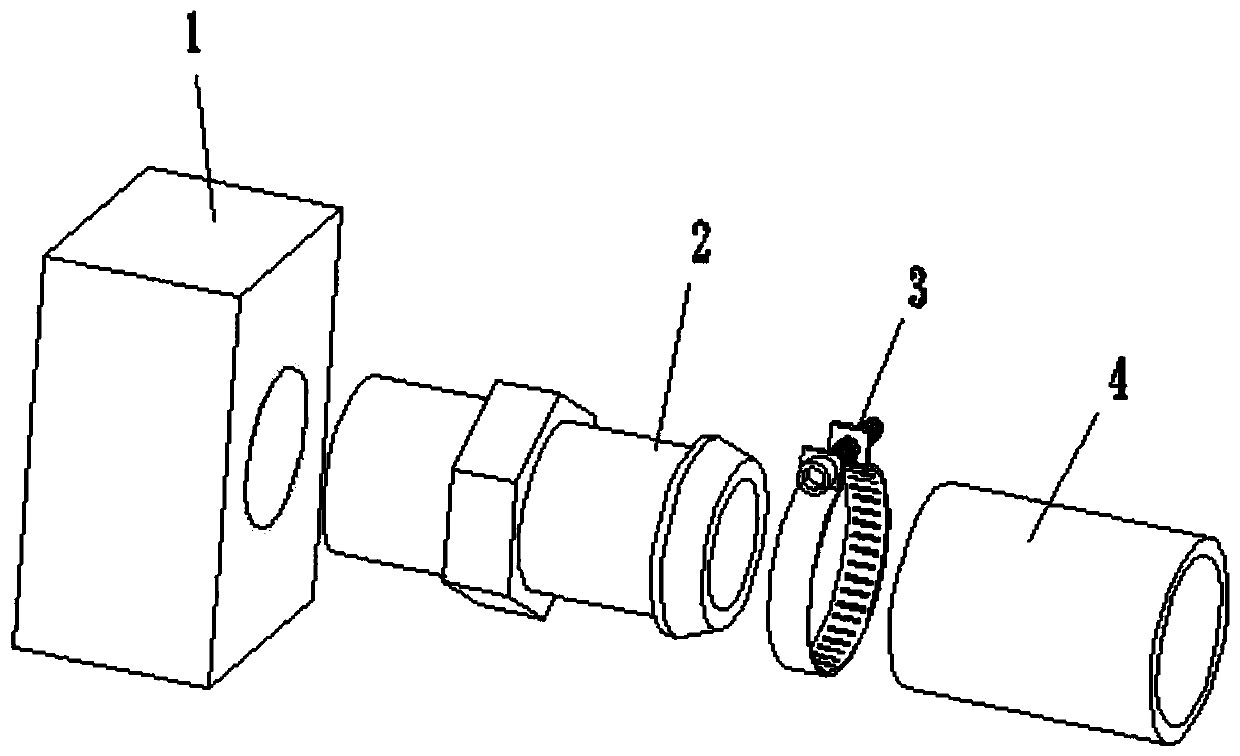

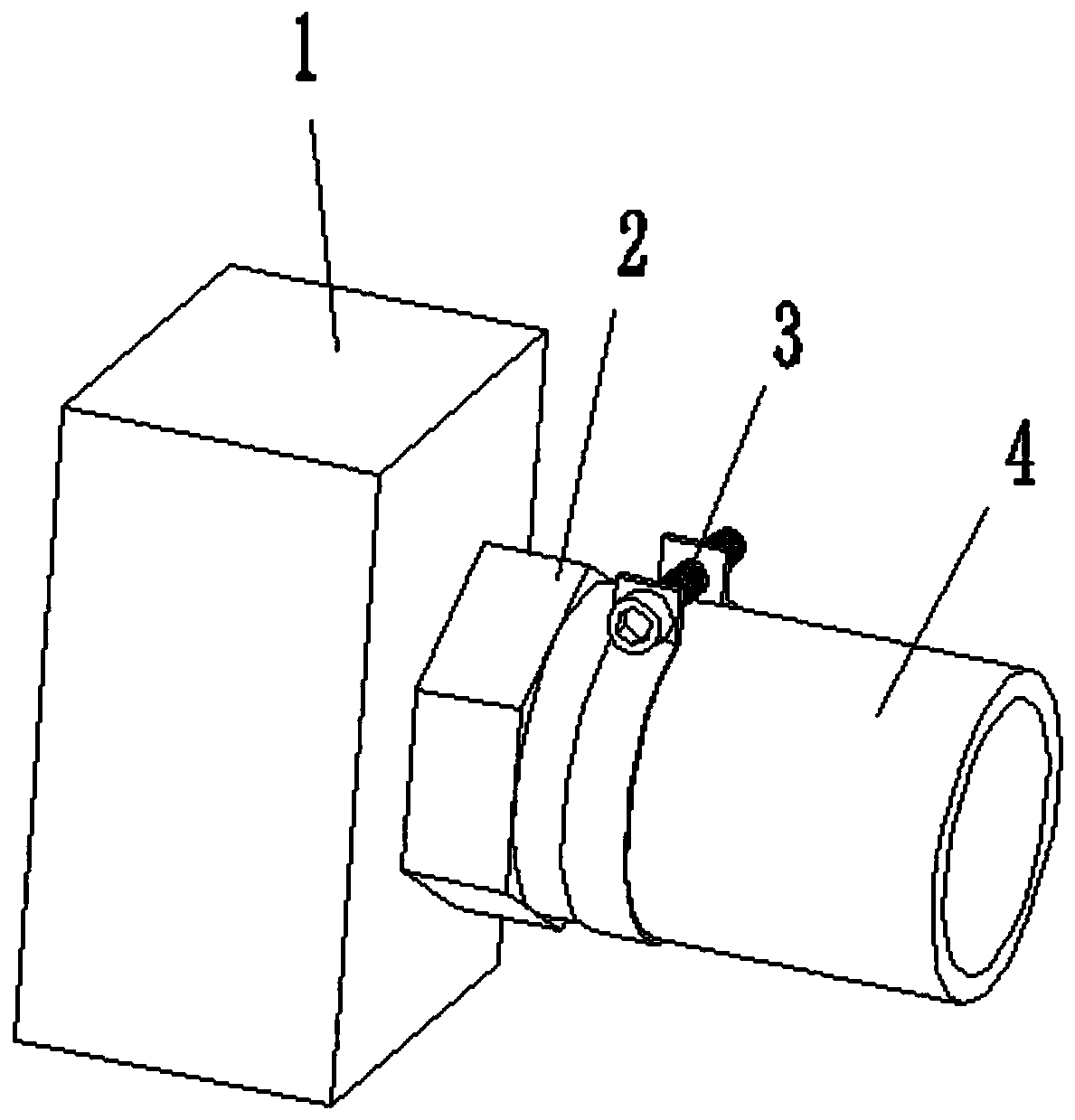

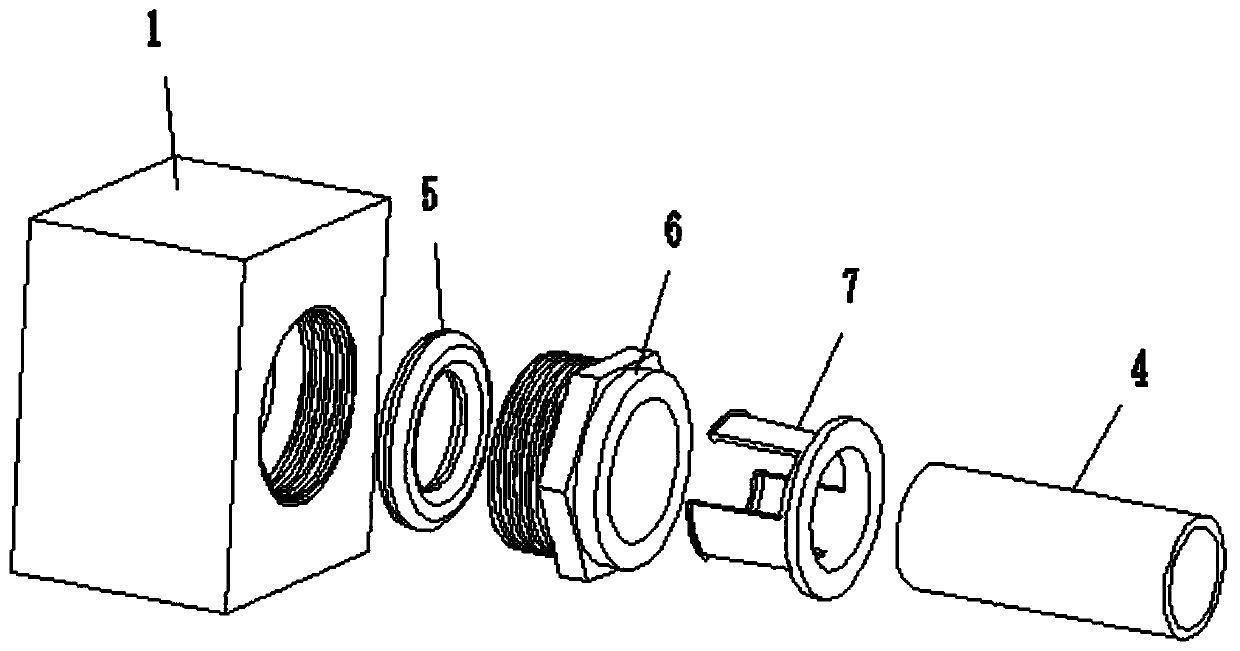

Motor cooling water pipe joint and driving motor

PendingCN110792867ASolve the problem of broken sealExtend the life of noodlesCorrosion preventionPipe protection against corrosion/incrustationDrive motorWater pipe

The invention discloses a motor cooling water pipe joint and a driving motor. The motor cooling water pipe joint comprises a machine shell water pipe joint, a hoop, a water pipe, a sealing ring, a joint outer ring and a check buckle; and the sealing ring is arranged on the inner side of the machine shell water pipe joint, the joint outer ring is connected with one end of the inner side of the machine shell water pipe joint, the inner side of the joint outer ring is sleeved with the check buckle, and the inner side of the check buckle is provided with the water pipe. According to the motor cooling water pipe joint and the driving motor, the sealing property and the fastening property of the motor cooling water pipe can be ensured through the sealing ring in the water pipe joint and the check buckle arranged on the water pipe in a sleeving manner; and compared with a traditional hoop for fixing, the joint is less prone to loosening, the problem that in the long-term use process of the water cooling motor, the sealing property of the water pipe is damaged due to the fact that the cooling water pipe joint partially falls off can be solved, and the service life of the joint is effectively prolonged, so that the motor is better protected.

Owner:GREE ELECTRIC APPLIANCES INC

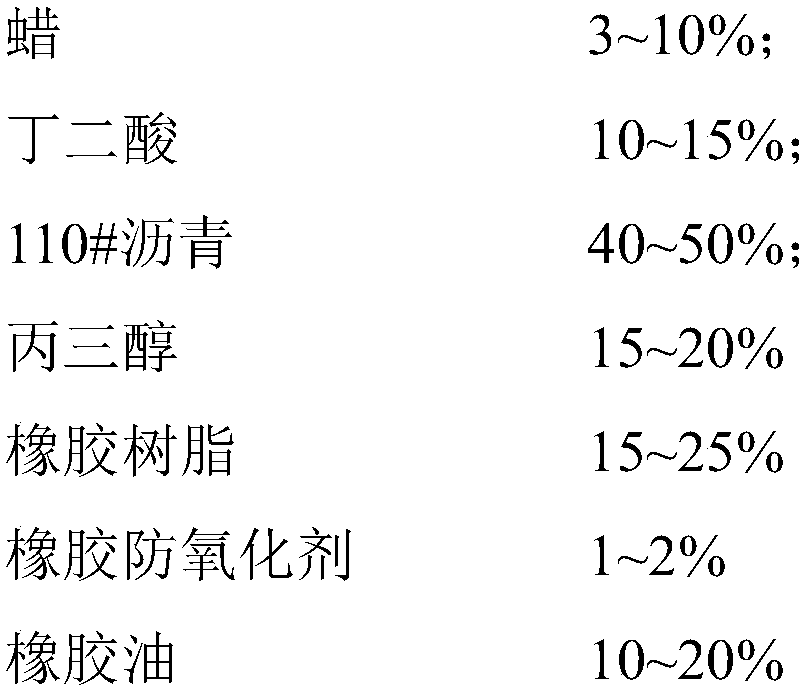

High-performance cold patch asphalt, cold patch material based on waste asphalt pavement material and preparation methods of cold patch asphalt and cold patch material

Owner:SHANDONG TRANSPORTATION INST +1

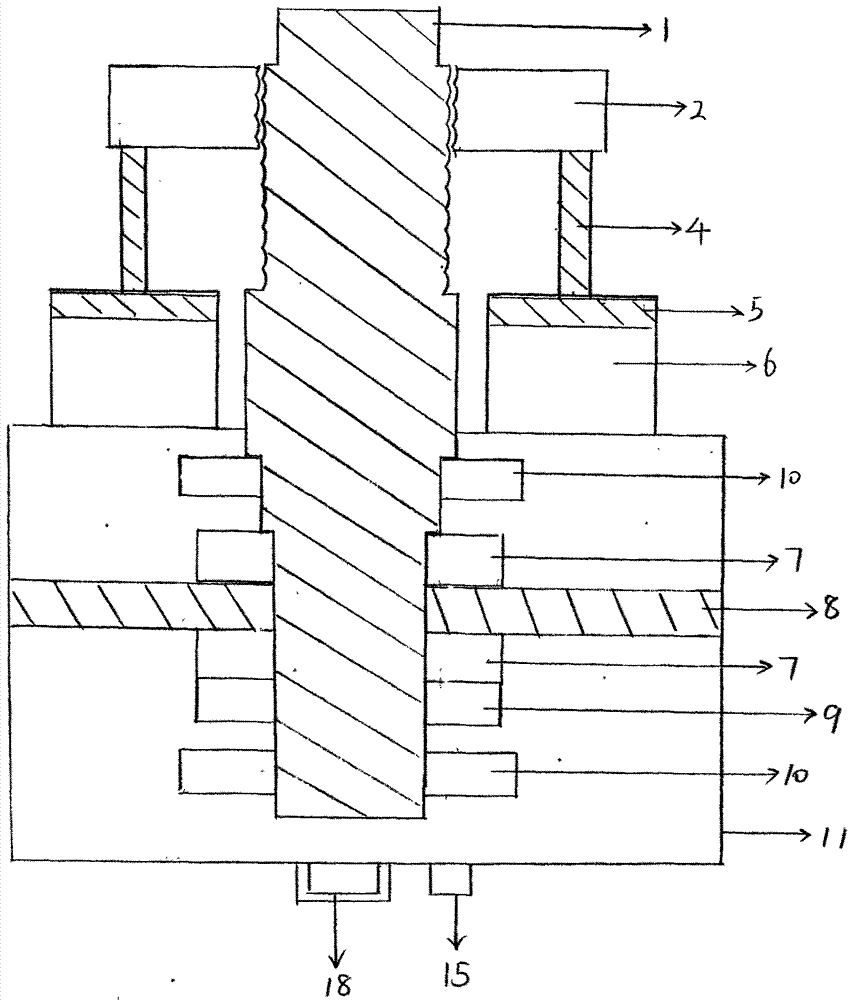

A spiral wire rotation wrench and design solution

The invention belongs to the field of screwing tools, discloses a screw rod rotating spanner and a design scheme, and particularly relates to a jackhammer used for dissembling or assembling steel plate screws of automobile tires. A jackhammer tool used at present is complex in structure, large in gravity, high in air pressure requirement, large in high-pressure air consumption and loss and high in noise when used. According to the screw rod rotating spanner, the spanner is driven to rotate by rotation of a screw of a screw rod set; the lower end of the screw is located in a spanner body, the screw is fixed by a set of pressure bearings to move vertically, and the screw rod is prevented from moving in the tangential direction of the screw rod by a set of ball bearings; vertical rotating power of the spanner comes from vertical movement of a nut, pushed by a set of same air cylinders, of the screw rod, the air cylinders are fixed to the spanner body, the nut can not rotate and can only move vertically along with a pull rod to drive the screw to rotate in the telescoping process of the air cylinders, and when the pull rod rotates, the nut can be rotated by installing a sleeve head at the end of the pull rod.

Owner:浙江舟水建设有限公司

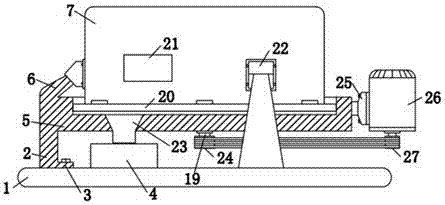

Self-cleaning glue-pouring machine

The invention discloses a self-cleaning glue-pouring machine. The self-cleaning glue-pouring machine comprises a machine cabinet, a workbench, an X-axis movement mechanism, a Y-axis movement mechanism, a Z-axis movement mechanism, a glue barrel, a curing agent barrel, a cleaning fluid barrel, a mixing device and a control cabinet, wherein the X-axis movement mechanism is mounted on the machine cabinet; the workbench is arranged on the X-axis movement mechanism in a sliding mode; supporting frames are arranged on the two sides of the machine cabinet; the Y-axis movement mechanism is fixed to the supporting frames; the Z-axis movement mechanism is arranged on the Y-axis movement mechanism in a sliding mode; the mixing device is mounted on the Z-axis movement mechanism; the glue barrel, the curing agent barrel and the cleaning fluid barrel are arranged above the control cabinet; the cleaning fluid barrel is provided with a pressure pump, a first fluid outlet and a second fluid outlet; the curing agent barrel is provided with a third fluid outlet; the glue barrel is provided with a fourth fluid outlet; the fourth fluid outlet and the second fluid outlet are communicated with the mixing device through a first switchover valve, and the third fluid outlet and the first fluid outlet are communicated with the mixing device through a second switchover valve. The self-cleaning glue-pouring machine has the self-cleaning and automatic-glue-pouring functions and can be used once being assembled.

Owner:JIANGYIN LEXU PHOTOELECTRIC CO LTD

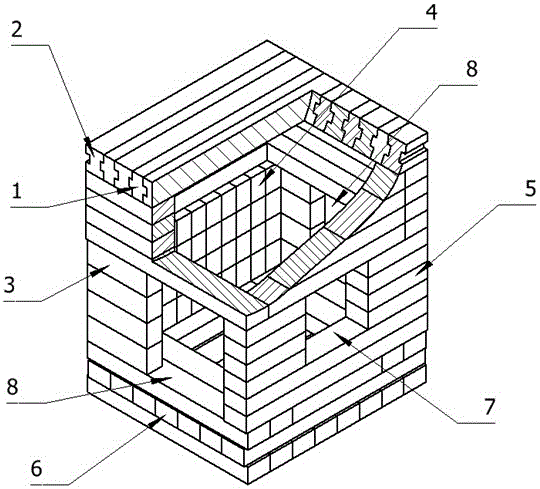

Glass rod sintering furnace used for making optical fiber preform

InactiveCN106587589APrevent fallingExtend the life of noodlesGlass making apparatusBrickCombustible gas

The invention relates to a glass rod sintering furnace used for making optical fiber preform. The furnace comprises a box-shaped furnace body, the furnace body comprises two side surfaces, a front surface, a back furnace, a bottom surface and a top surface, the two side surfaces are correspondingly provided with rod traversing windows, the front surface of the furnace body is provided with a combustible gas blast burner window, and the top surface is obtained through splicing and inserting quartz glass strip-shaped bricks laterally respectively provided with tenons and grooves. The furnace can prevent falling of fractured top bricks and avoid damages of processed pieces and interruption of processing, so the working reliability of the sintering furnace is enhanced, and the service life of the sintering furnace is prolonged; mutual embedded connection of the strip-shaped top bricks through the tenons and the grooves forms the seamless quartz glass top surface and improves the heat insulation performance of the sintering furnace; the top surface strip-shaped bricks adopt the grooves or the tenons with a symmetric equal section structure, so the fracture risk of the quartz glass strip-shaped top bricks is reduced, thereby further prolonging the service life of the glass rod sintering furnace; and the furnace has a reasonable structure, and is convenient to make and maintain.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

A construction method for anti-shattering protective panels

ActiveCN108396708BReasonable and ingenious structural designAvoid shockCoastlines protectionArchitectural engineeringWater flow

The invention discloses a fracture-resisting face protection plate construction method. The Fracture-resisting face protection plate construction method comprises the following steps of a, excavationof foundation pit; b, basement treatment; c, face protection plate laying, wherein (1) a fixed steel plate and a heightened steel plate are laid, and (2) concrete is poured; and d, detection. The fracture-resisting face protection plate construction method is simple and reasonable in construction method, the fixed steel plate, the heightened steel plate and the concrete are fused together, the face protection plate is formed, and therefore the overall structure of the face protection plate is firm and reliable, and the face protection plate is effectively prevented from moving. The wave preventing and water flow impact resisting capability of the face protection plate is better, and the service life of the face protection plate is prolonged. The face protection plate can resist scouring ofwater flow better, meanwhile, no formwork needs to be arranged during actual construction, the construction period is shortened, and the labor intensity is reduced.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

A high temperature resistant steam turbine blade and its production process

ActiveCN104099516BImprove performanceImprove impact toughnessBlade accessoriesSolid state diffusion coatingChemical compositionHeat resistance

Owner:南京赛达科技有限公司

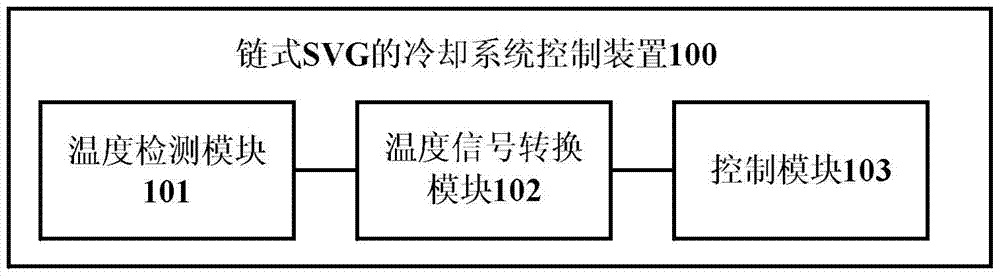

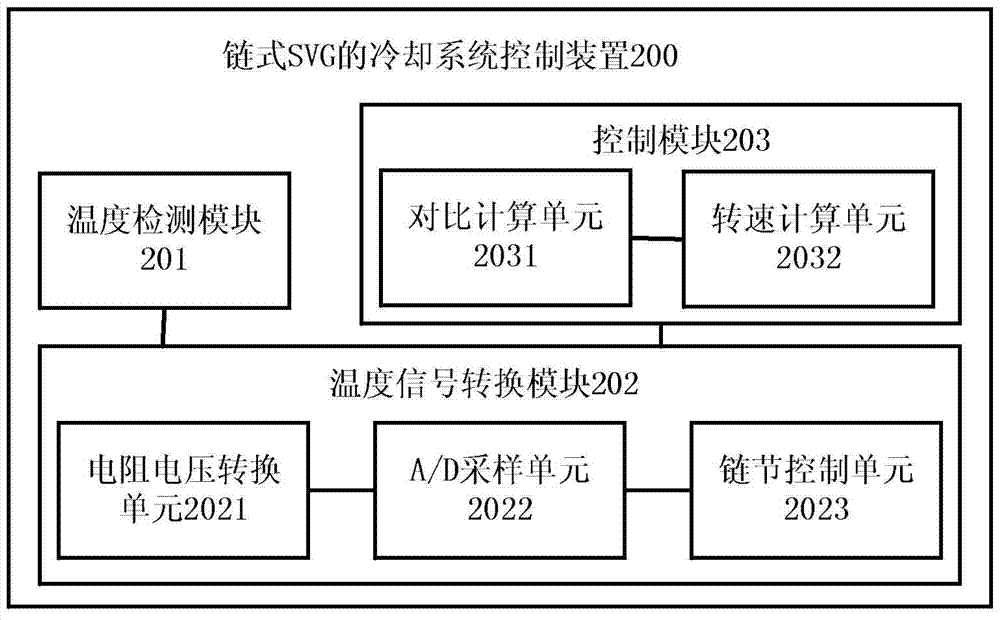

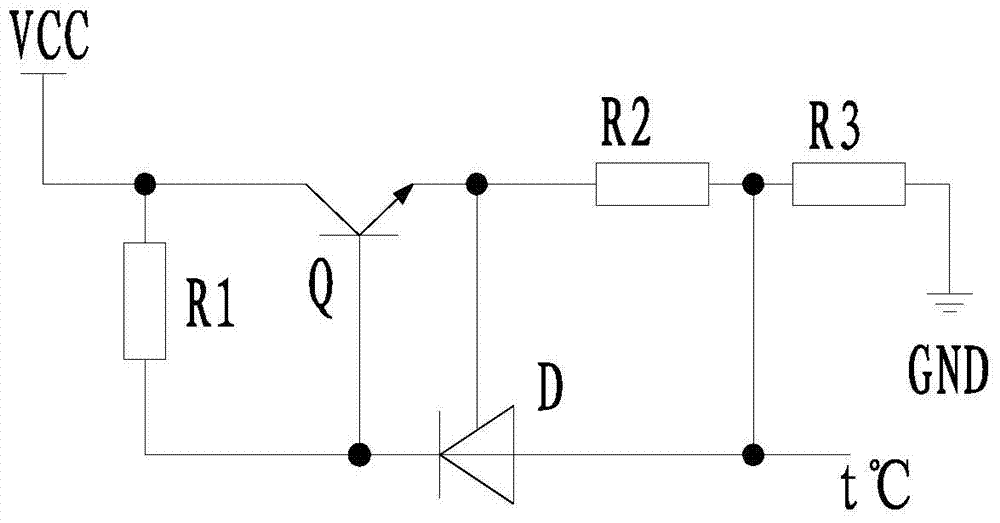

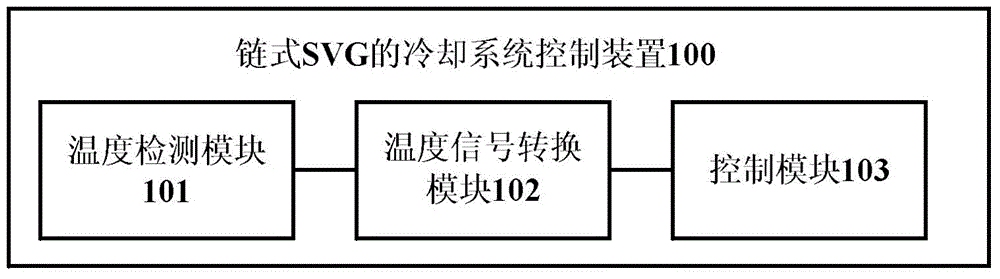

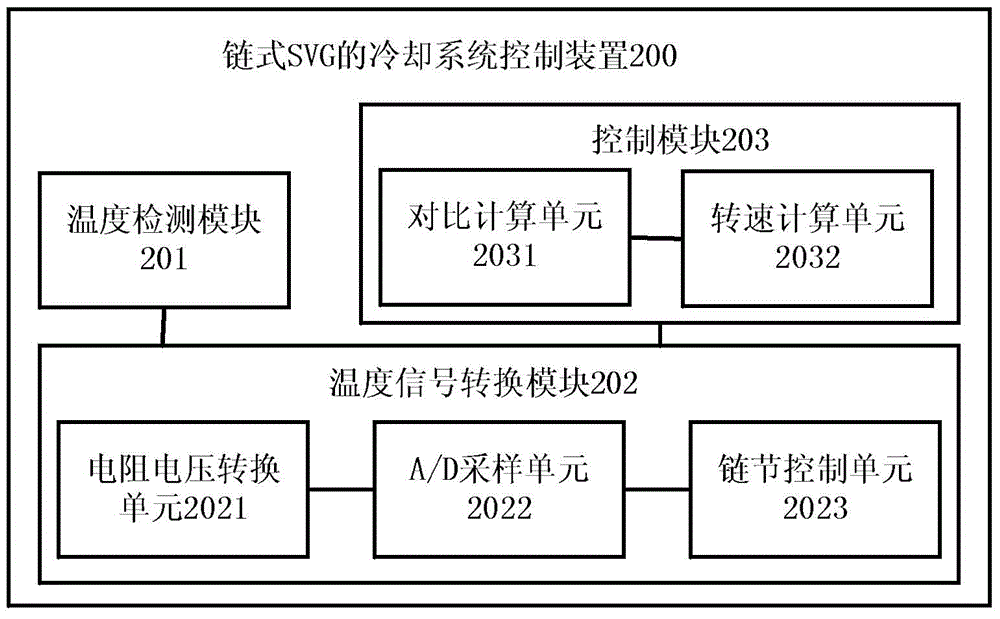

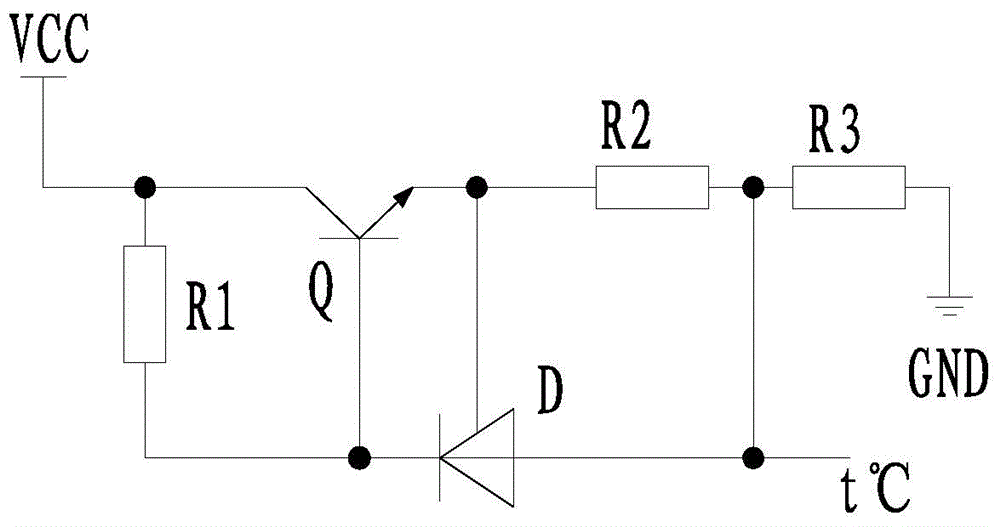

Chained svg cooling system control device and method

ActiveCN104953491BReduce the number of startsImprove work efficiencySemiconductor/solid-state device detailsSubstation/switching arrangement cooling/ventilationCore temperatureEngineering

The invention discloses a chain SVG cooling system control device and method. The device includes: a temperature detection module installed on the edge-gate bipolar transistor IGBT core of the chain link unit of the chain SVG, which is used to detect the temperature of the IGBT core in real time and generate a temperature signal; a temperature signal conversion module is used to detect according to the temperature The temperature signal generated by the module determines the temperature of the IGBT core; the control module is used to control the air volume of the cooling fan according to the current temperature of the IGBT core. The present disclosure provides devices and methods, which can track the IGBT core temperature in real time, ensure that the chain link unit of the chain SVG works at the optimal temperature state, and improve the highest work efficiency; it can effectively reduce the number of starts of the fan, increase the service life, and improve the performance of the fan. Work efficiency, reduce energy loss, and can control the fan speed, reduce the noise caused by fan operation.

Owner:SHANDONG HADA ELECTRIC

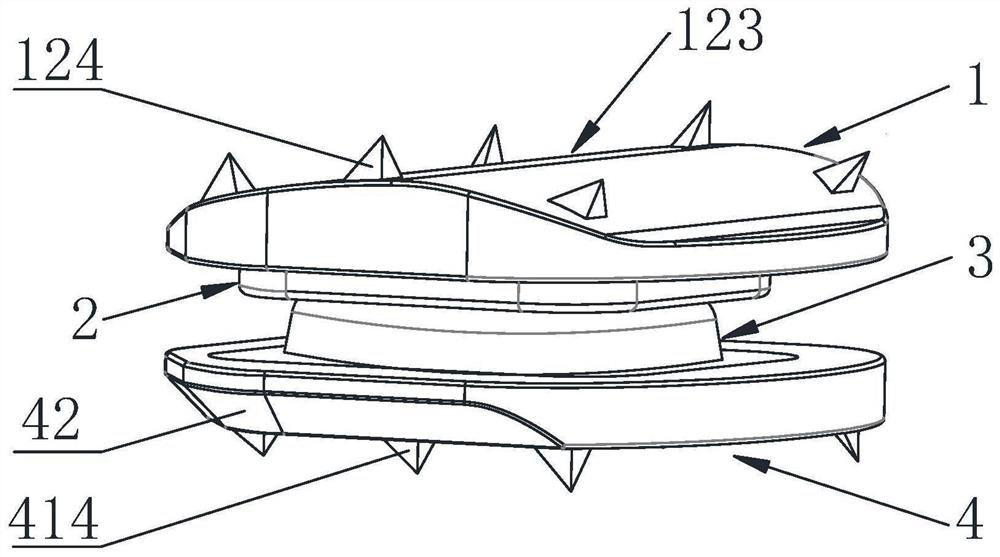

High bionic intervertebral motion preservation device

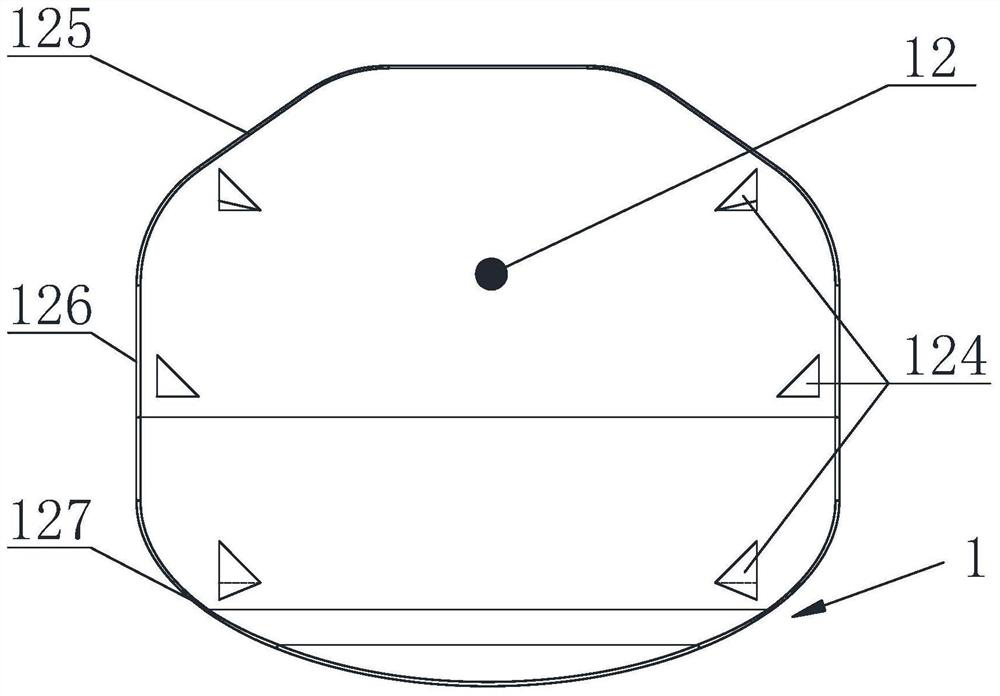

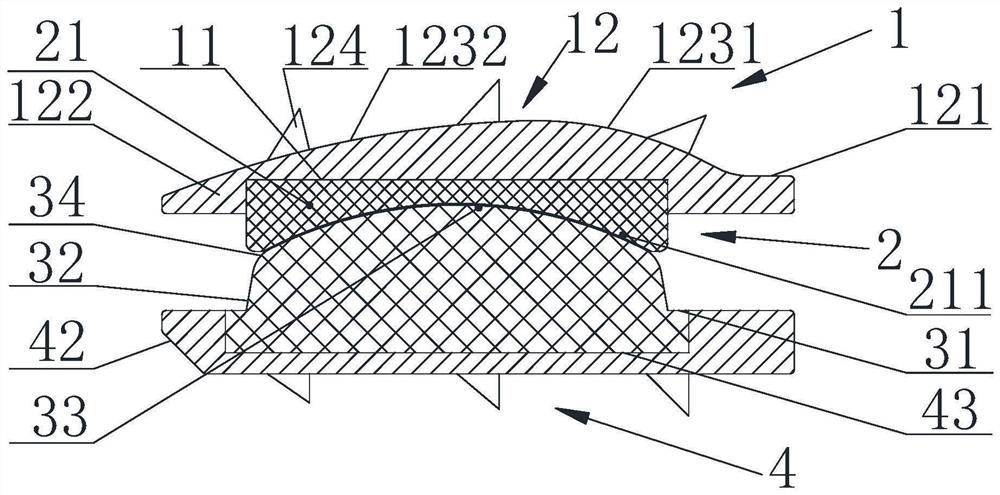

ActiveCN108969157BReduce the amount of resectionIncrease contact areaSpinal implantsAnatomyCentre of rotation

The invention relates to a highly bionic intervertebral motion preservation device. The highly bionic intervertebral motion preservation device includes an upper bone plate and a lower bone plate, and a spherical friction pair composed of a lining and a nucleus pulposus is embedded between the upper bone plate and the lower bone plate; the spherical friction pair is in a clearance fit, and the inner lining The spherical surface radius of the concave coronal friction spherical groove is greater than that of the nucleus pulposus convex friction ball top friction spherical surface; the inner lining is stationary or rotates or translates relative to the upper bone plate, and the nucleus pulposus is stationary or rotates relative to the lower bone plate Or translation, the center of rotation of the spherical friction pair formed by the inner lining and the nucleus pulposus has no axial movement or can move freely in the front, back, left and right directions.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

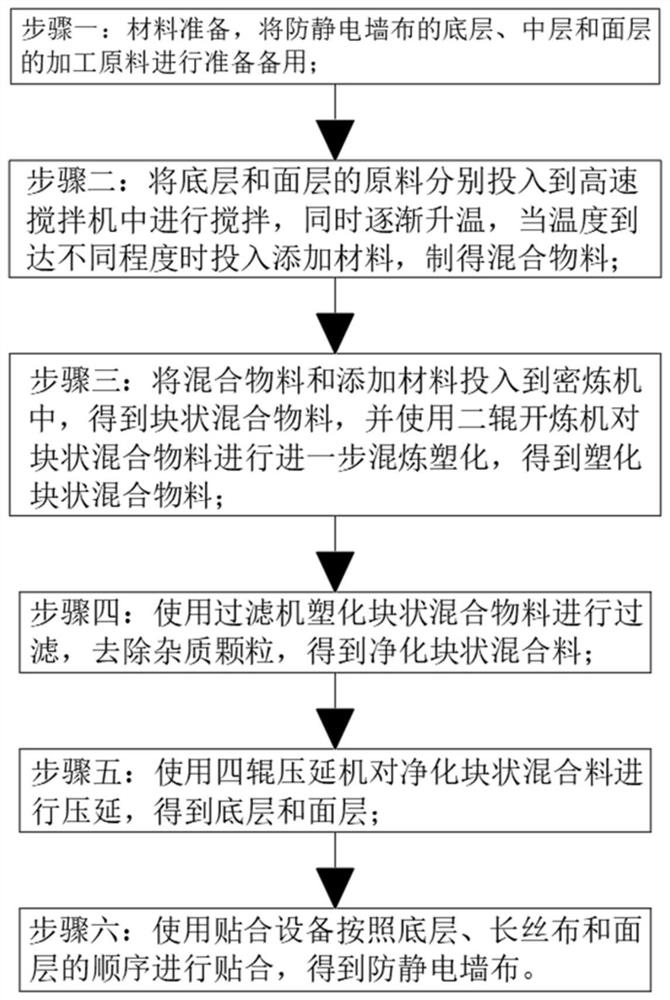

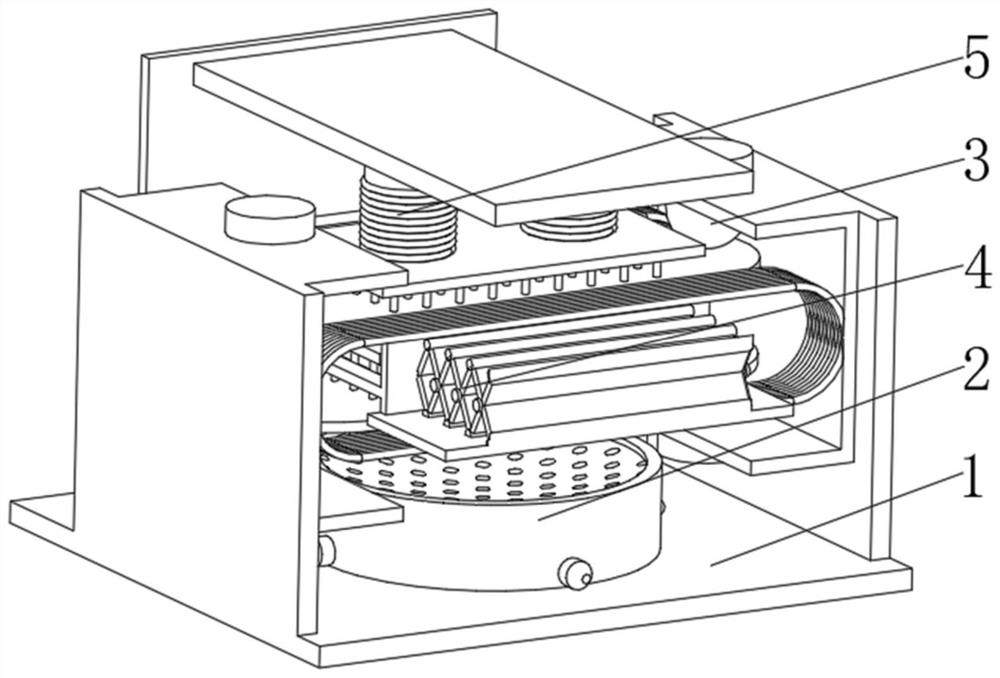

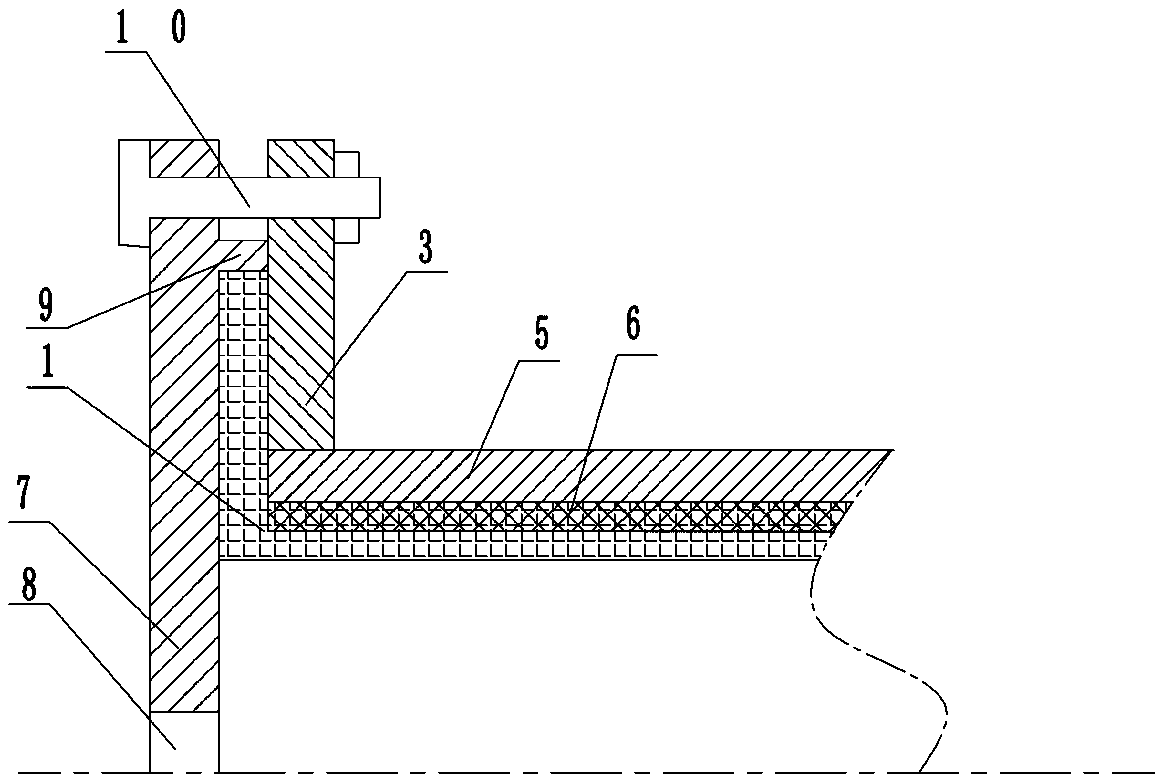

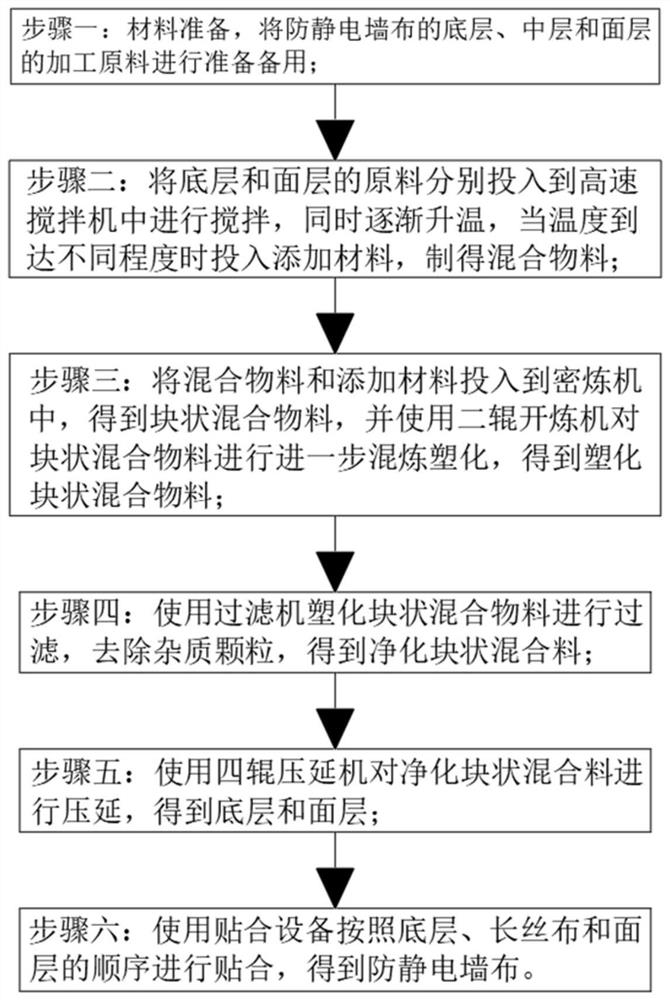

Production process of anti-static wall cloth

ActiveCN113580615APromote exchangeAvoid Thermal Fatigue LossLaminationLamination apparatusPlasticultureProcess engineering

The invention discloses a production process of an anti-static wall cloth. The production process comprises the following steps that 3, a mixed material and an additive material are put into an internal mixer to obtain a blocky mixed material, and the blocky mixed material is further mixed and plasticized by using a two-roller open mill to obtain a plasticized blocky mixed material; 4, the plasticized blocky mixed material is filtered by using a filter to remove impurity particles so as to obtain a purified blocky mixed material; 5, the purified blocky mixed material is calendered by using a four-roller calender to obtain a bottom layer and a surface layer; and 6, laminating the bottom layer, a filament cloth and the surface layer in sequence is achieved by using laminating equipment to obtain the anti-static wall cloth. The invention relates to the technical field of wall cloths. According to the production process of the anti-static wall cloth, the finished product produced by the production process has uniform holes and pore channels which are communicated with one another, so that the finished product has strong adsorption capacity, the anti-static wall cloth is free of peculiar smell, and the filament cloth is selected for enhancing the overall stability of the anti-static wall cloth.

Owner:绍兴寿春针纺织有限公司

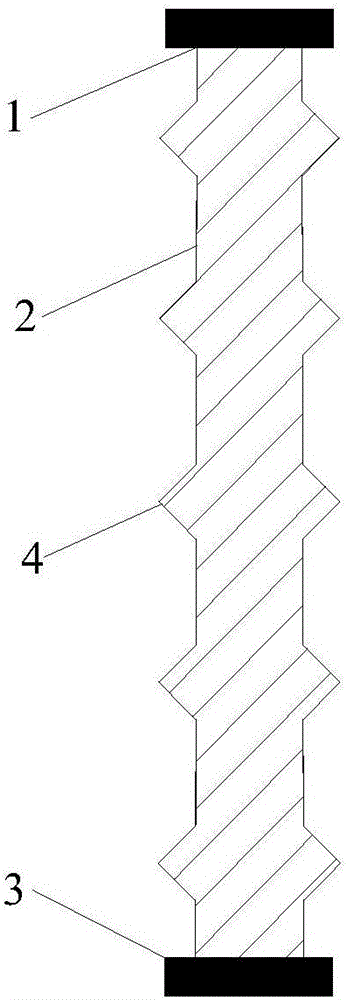

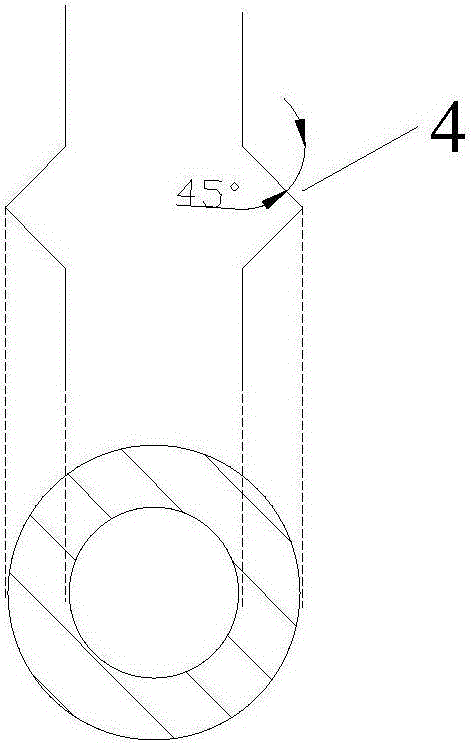

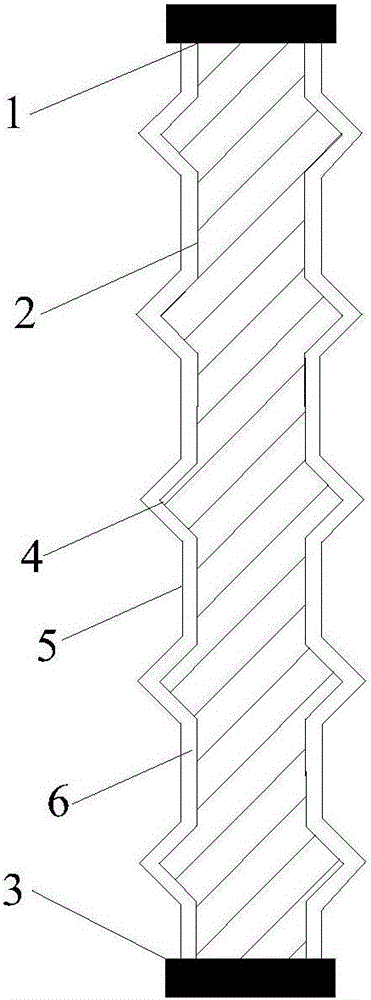

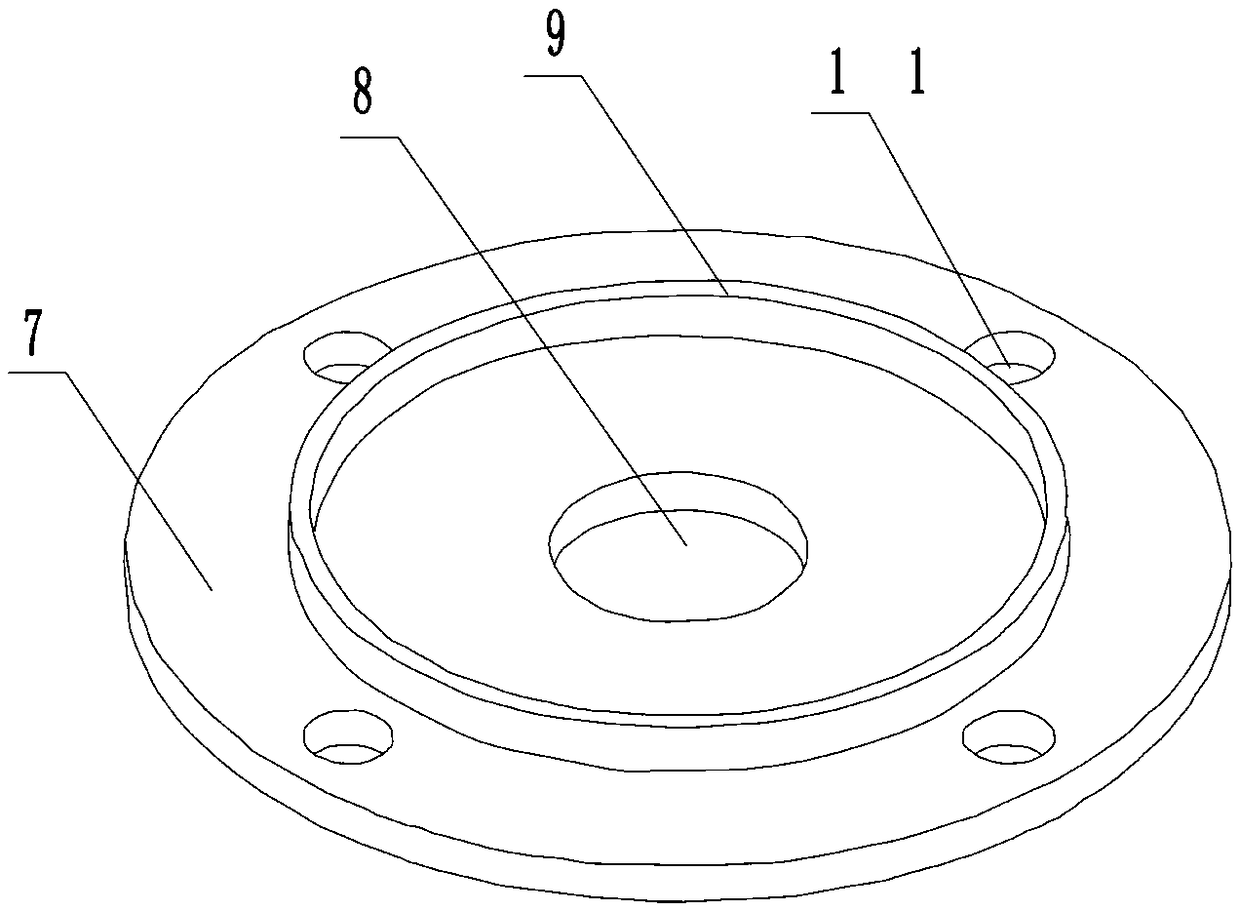

Insulating sleeve

InactiveCN106128662AAvoid damageExtend the life of noodlesInsulating bodiesEngineeringLiquid nitrogen

The embodiment of the invention discloses an insulating sleeve. The insulating sleeve comprises a first flange, a first insulating cylinder and a second flange, wherein the first flange and the second flange are the same in size; the first flange and the second flange are positioned at two ends of the first insulating cylinder; the first flange and the second flange are fixedly connected with the first insulating cylinder; and the first insulating cylinder is uniformly provided with bulges with 45-degree angles. According to the insulating sleeve provided by the invention, the insulating cylinder is uniformly provided with the bulges with the 45-degree angles, and liquid nitrogen is subjected to damage caused by flashover for several times, so that the service life of the insulating sleeve is prolonged.

Owner:YUNNAN POWER GRID CO LTD ELECTRIC POWER RES INST +1

car filter

InactiveCN112112747BExtend the life of noodlesConvenience to workMachines/enginesAir cleaners for fuelStructural engineeringFilter effect

The invention discloses a filter for an automobile, which relates to the technical field of auto parts and includes a filter frame, the upper surface of the filter frame is fixedly connected with an air intake plate mechanism through screws, and both sides of the lower surface of the filter element shell are fixedly connected There are side plates, and the two side plates are respectively fixedly connected to the opposite inner surface of the filter element shell by screws, and the inner surface of the filter element shell is fixedly connected with a plurality of equally spaced card slot plates, and the first filter screen is connected to the inner surface of the filter element shell. The upper part is inserted into a plurality of draw-in slot plates, and the second filter screen is inserted into a plurality of draw-in slot plates from the lower part of the filter element housing, and the first filter screen and the second filter screen are interlaced, and the first filter screen and the second filter screen are The nets are all fixedly connected to the card slot plate, and the lower surface of the filter frame is fixedly connected with a dust sticking mechanism through screws. In the present invention, the first filter net and the second filter net form a double-layer filter, which has a better filtering effect and can effectively reduce Dust gets into the engine.

Owner:蚌埠市浩宇滤清器有限公司

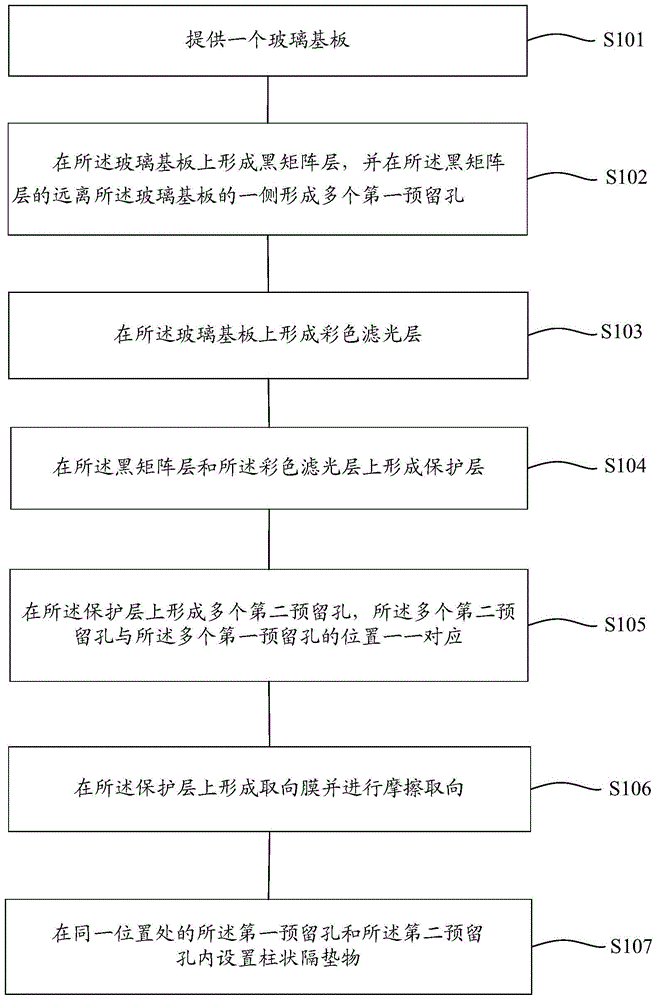

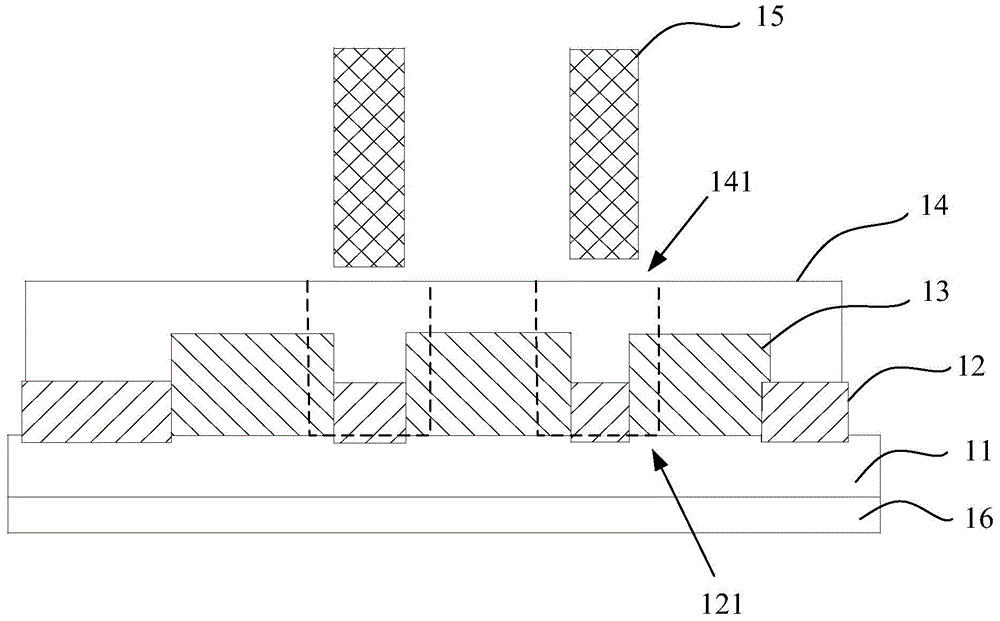

A method for manufacturing a color filter substrate, a color filter substrate, and a liquid crystal display panel

ActiveCN104216164BImprove production yieldReduce manufacturing costNon-linear opticsLiquid-crystal displayColor film

The invention discloses a colored-film substrate, a manufacturing method thereof and a liquid crystal display panel and relates to the technical field of liquid crystal display. The colored-film substrate, the manufacturing method thereof and the liquid crystal display panel can be used for solving the problem that the colored-film substrate is low in rate of manufactured finished product and high in cost due to the influence caused by structures of columnar spacers. The manufacturing method of the colored-film substrate, disclosed by the invention, comprises the steps: providing a substrate; forming a black matrix layer on the substrate, and forming a plurality of first preserved holes in one side, far away from the substrate, of the black matrix layer; forming a colored light filtering layer on the substrate; forming protective layers on the black matrix layer and the colored light filtering layer; forming a plurality of second preserved holes in the protective layers, wherein the second preserved holes and the first preserved holes are corresponding in location; forming oriented films on the protective layers, and carrying out frictional orientation; arranging the columnar spacers in the first and second preserved holes of the same locations.

Owner:BOE TECH GRP CO LTD +1

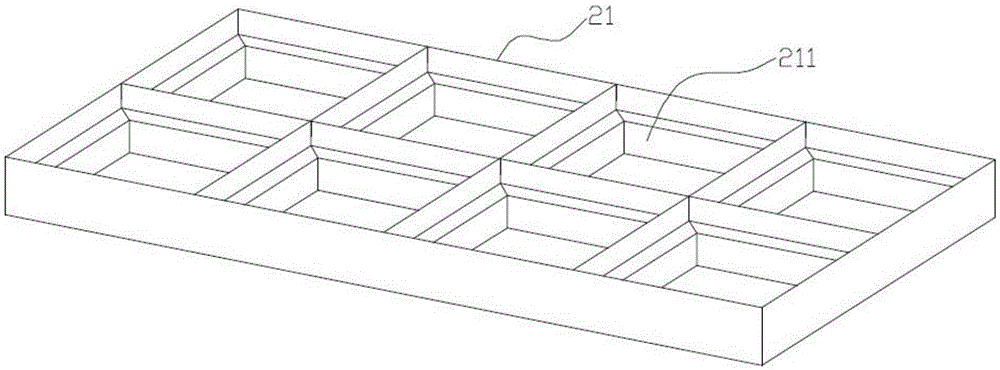

Industrial dewaterer

InactiveCN107142640AControl speedReduce the incompatibility of turning speed upTextile treatment machine partsLiquid/gas/vapor removal by centrifugal forcePulp and paper industryWater collection

The invention discloses an industrial dehydrator in the field of dehydrator technology, comprising a base, three sets of outriggers are connected to the top of the base, and a mounting plate is connected to the bottom of the outriggers, and the mounting plate is connected to the top of the base through bolts. connected, the top of the base is equipped with a water collection tank, the top of the legs is connected with a support plate, the top of the support plate is connected with three sets of brackets, and the top of the support plate is connected with a dehydration shell through three sets of brackets, so There is a feeding trough on the top of the dehydration shell, the left and right side walls of the inner cavity of the dehydration shell are connected with connecting seats, and the upper and lower sides of the connecting seat are provided with screw holes. The setting is convenient for controlling the speed of the dehydrator, reducing the discomfort of the motor starting to rotate and increasing the speed, and increasing the service life of the device. The electromagnet is used as the power source of the friction plate, and the degree of automation is high.

Owner:泰州国鑫机械制造有限公司

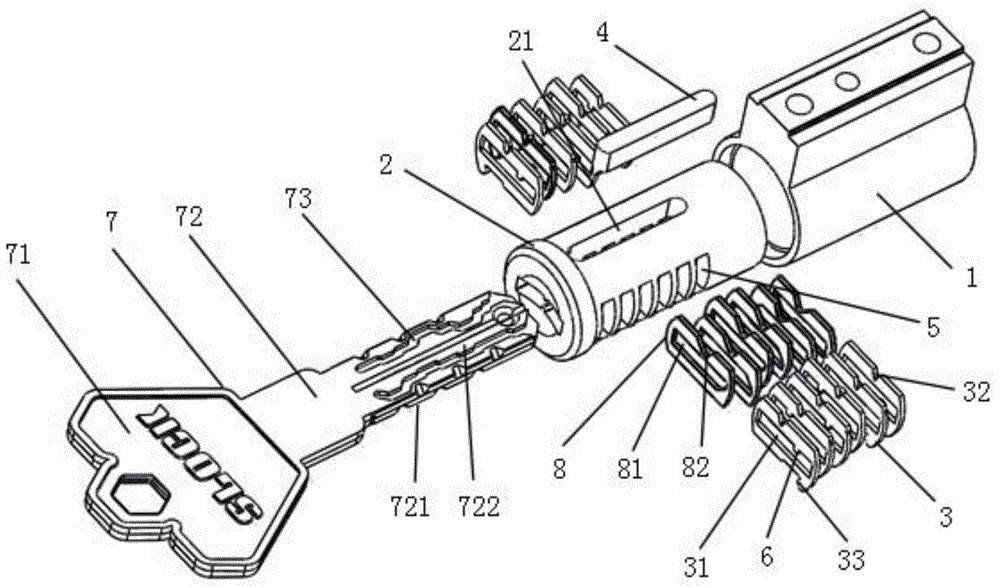

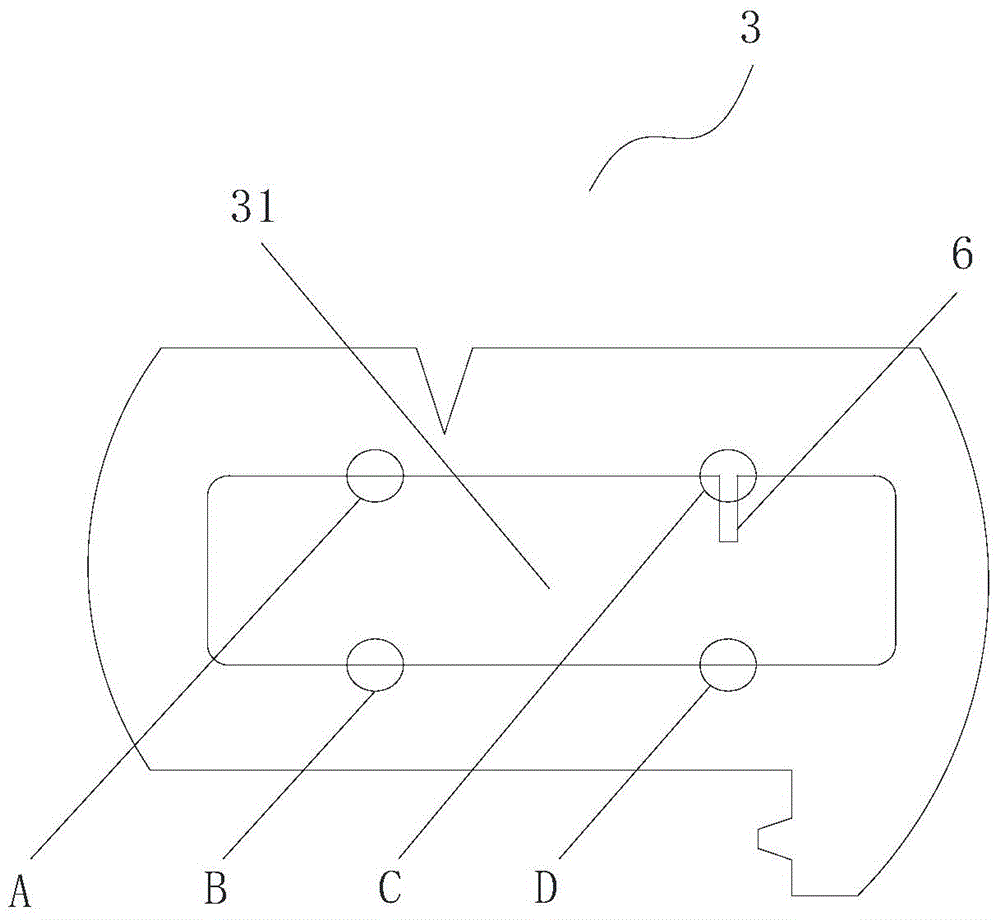

Vane lock cylinder

InactiveCN105155927AExtended service lifeExtend the life of noodlesKeysCylinder locksEngineeringKeyhole

The invention discloses a vane lock cylinder. The vane lock cylinder comprises an outer lock liner, an inner lock liner, number slices and a lock pin. The inner lock liner is rotationally arranged in the outer lock liner. A plurality of slotted holes are formed in the inner lock liner in parallel in the axial direction and perpendicular to the axis. Each slotted hole is provided with a pair of number slices. Each number slice is provided with a keyhole, lock teeth and a reset spring making the number slice move towards the outside of the corresponding slotted hole. One side of each number slice is a lock edge. An unlocking groove is formed in each lock edge. A groove seam corresponding to the unlocking grooves is formed in the inner lock liner. A lock groove corresponding to the groove seam is formed in the outer lock liner. The lock pin is movably arranged in a cavity formed through the groove seam and the lock groove. The vane lock cylinder is characterized in that a lifting slice used for separating the two corresponding number slices is arranged in each pair of number slices. Each lifting slice is provided with a keyhole and an unlocking groove. Compared with the prior art, the vane lock cylinder is capable of effectively prolonging the service life of the number slices.

Owner:黄志佳

All-inner plastic composite steel pipe and flange assembly and its forming process

ActiveCN106678455BEliminate the possibility of contactEliminate the hidden danger of penetrating corrosionFlanged jointsCoatingsManufacturing technologyButt joint

Owner:HANGZHOU JIETONG CABLE PROTECTION TUBE

A production process of anti-static wall cloth

ActiveCN113580615BPromote exchangeAvoid Thermal Fatigue LossLaminationLamination apparatusPolymer sciencePlasticulture

The invention discloses a production process of antistatic wall cloth, which comprises the following steps, step 3: put the mixed material and the added material into the internal mixer to obtain the block mixed material, and use the two-roller open mill to grind the block mixture The material is further mixed and plasticized to obtain a plasticized block mixture; step 4: use a filter to plasticize the block mixture to filter, remove impurity particles, and obtain a purified block mixture; step 5: use a four-roller calender Carry out calendering to the purified block mixture to obtain the bottom layer and the surface layer; step 6: use laminating equipment to bond the bottom layer, filament cloth and surface layer in order to obtain anti-static wall coverings. The present invention relates to the technical field of wall coverings . The finished product produced by this process has uniform holes and channels, which are connected to each other, so it has strong adsorption capacity, which makes the anti-static wall covering no peculiar smell, and the filament cloth is used to enhance the overall stability of the anti-static wall covering.

Owner:绍兴寿春针纺织有限公司

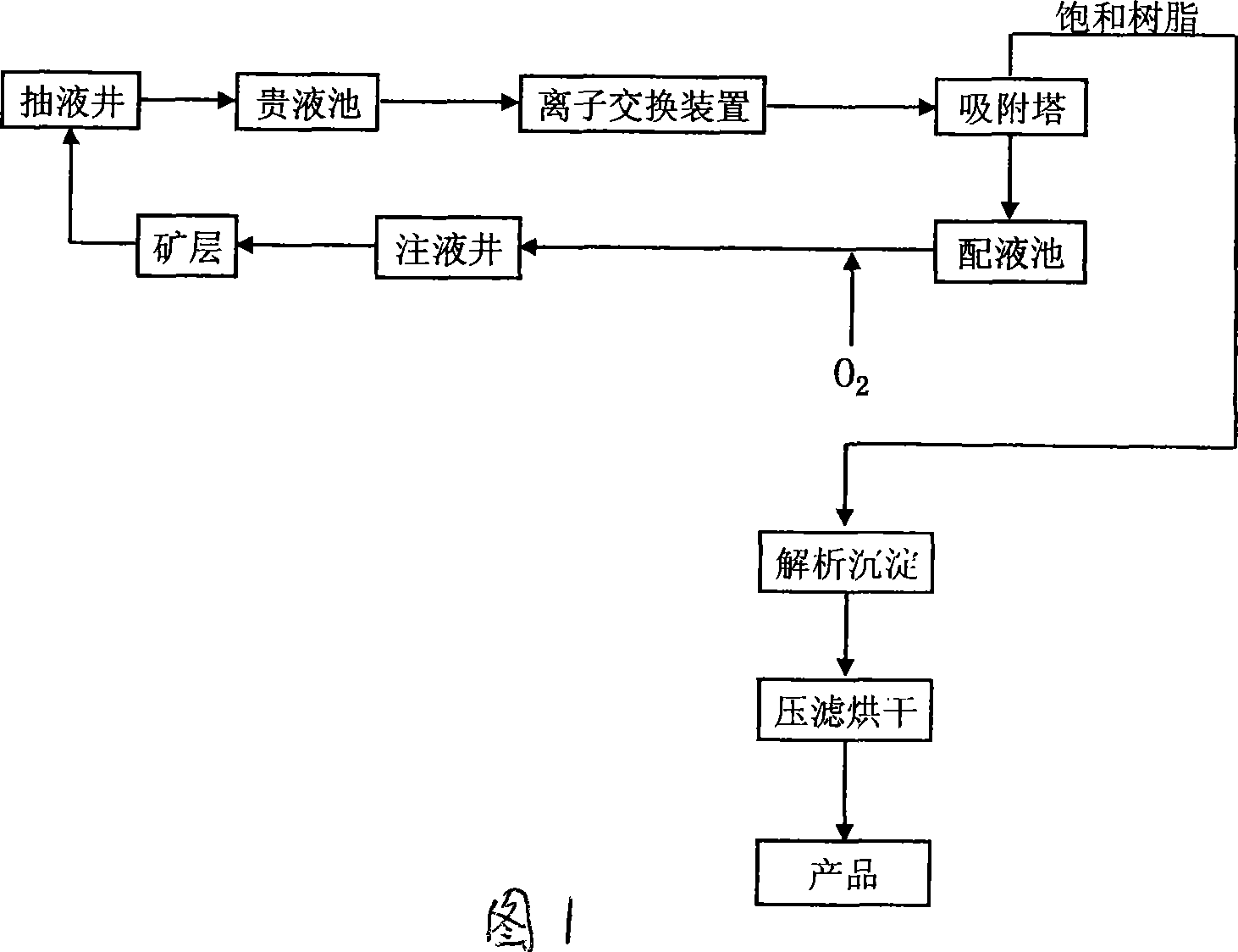

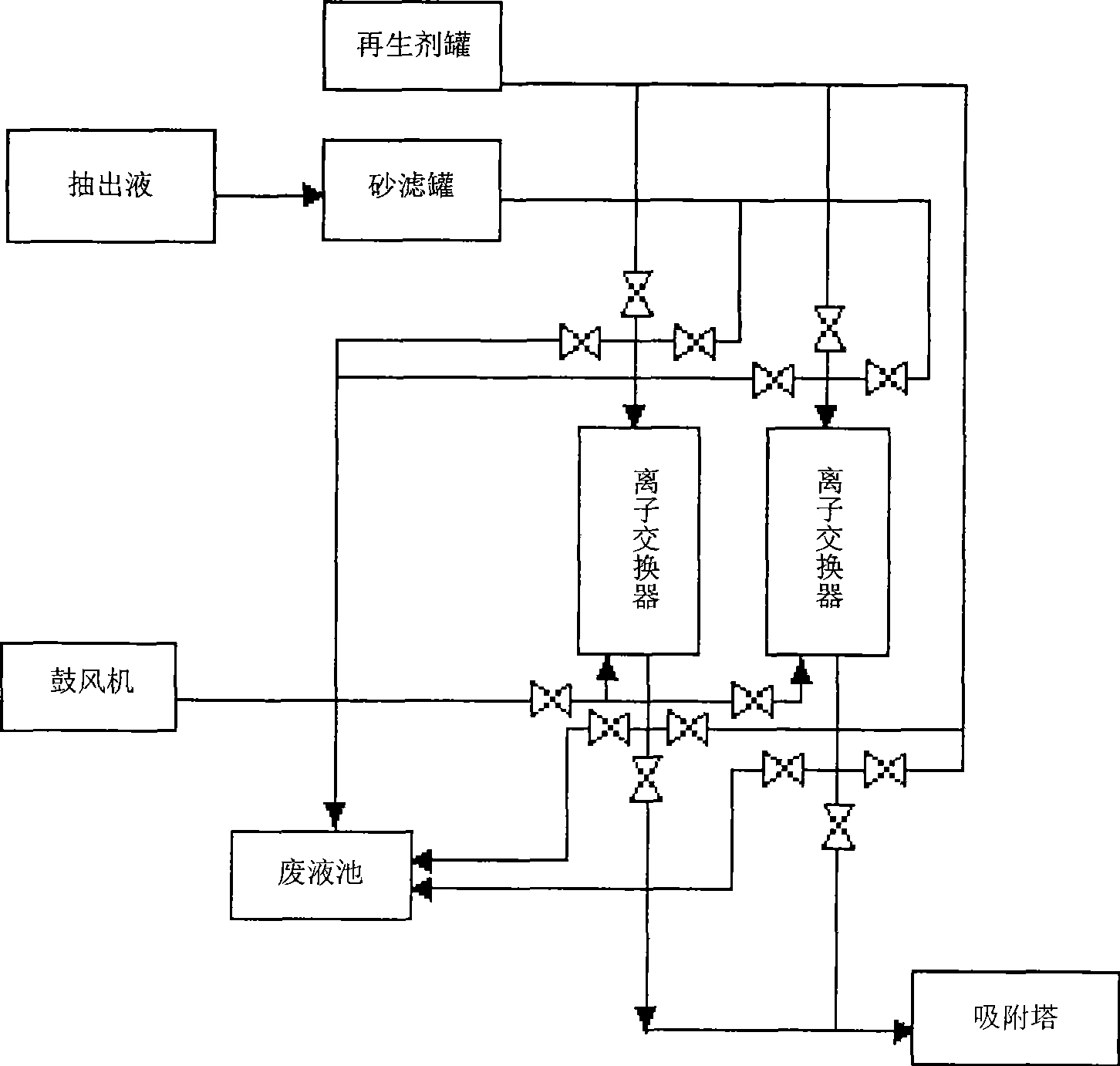

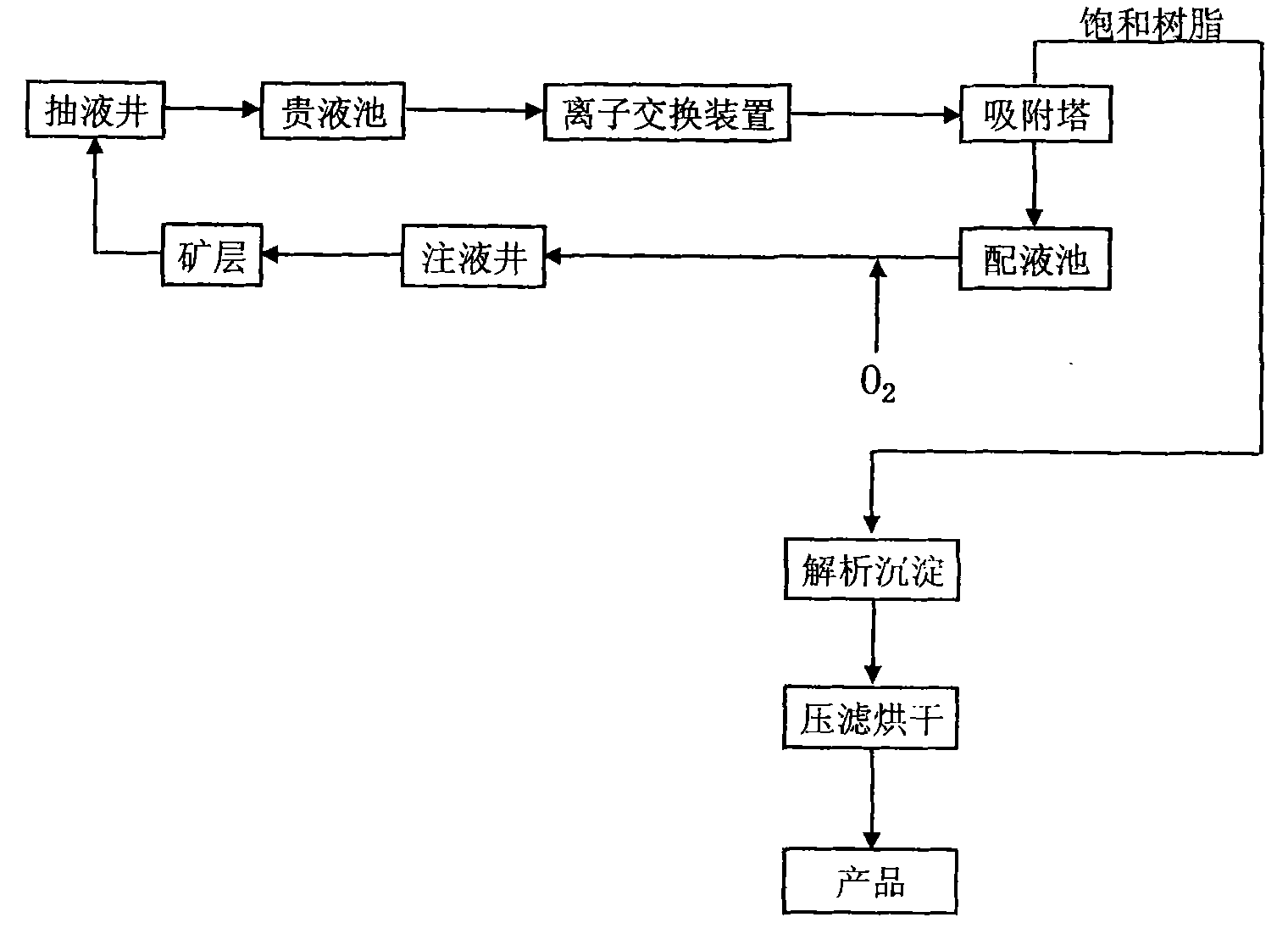

Non-reagent ground dipping uranium extracting process flow

InactiveCN101435320BGuarantee continuous and stable operationReduce supplementationFluid removalIon exchangeMaterials science

The invention relates to a reagent-free in-situ leaching uranium mining technological process which is additionally provided with a set of ion interchange unit consisting of an ion exchanger, a blast blower, a sand filtering tank, a regenerant tank and a waste liquid pool before a medium entering an absorption tower on the basis of the conventional reagent-free in-situ leaching uranium mining technological process. Leaching solution containing an oxidizing agent is injected into an ore bed through an injection hole so that the uranium in the ore bed is changed into the form of uranyl ions or other complex icons which are dissolved in leaching solution groundwater, then leaching solution containing uranium components is extracted to ground through an extracting hole, the leaching solution is injected back to the ore bed for recycling after carrying out sedimentation, icon exchange treatment and adsorption, and a uranate product is obtained after carrying out the procedures of analyzing, sedimentation, filter pressing and the like to saturated resin containing uranium. The method has the advantages of little investment, mature operative technique, obvious anti-blocking effect and the like. The utilizing of the process method can guarantee the continuous and stable running of uranium mining wells and a production system, and improve the production time efficiency and the product output.

Owner:LIAOHE GASOLINEEUM EXPLORATION BUREAU

Device and method for controlling cascaded SVG (static var generator) cooling system

ActiveCN104953491AReduce the number of startsImprove work efficiencySemiconductor/solid-state device detailsSubstation/switching arrangement cooling/ventilationStart timeAir volume

The invention discloses a device and a method for controlling a cascaded SVG (static var generator) cooling system. The device comprises a temperature detection module, a temperature signal converting module and a control module, wherein the temperature detection module is mounted on an IGBT (insulated gate bipolar transistor) kernel of each cascaded unit of a cascaded SVG and used for detecting the temperature of the IGBT kernel in real time and generating temperature signals; the temperature signal converting module is used for determining the temperature of the IGBT kernels according to the temperature signals generated by the temperature detection module; the control module is used for controlling the air volume of a cooling fan according to the current temperature of the IGBT kernels. According to the device and the method, the temperature of the IGBT kernels can be tracked in real time, the cascaded units of the cascaded SVG work at the optimal temperature, and the working efficiency is improved to the maximum; the starting times of the fan can be reduced effectively, the service life can be prolonged, the working efficiency of the fan can be improved, energy loss can be reduced, the rotating speed of the fan can be controlled, and noise caused by fan operation can be reduced.

Owner:SHANDONG HADA ELECTRIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com