A spiral wire rotation wrench and design solution

A spiral wire and wrench technology, applied in the field of tightening tools, can solve the problems of high air pressure requirements, complex structure, large loss, etc., and achieve the effects of saving high-pressure air consumption, overcoming technical prejudice, and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

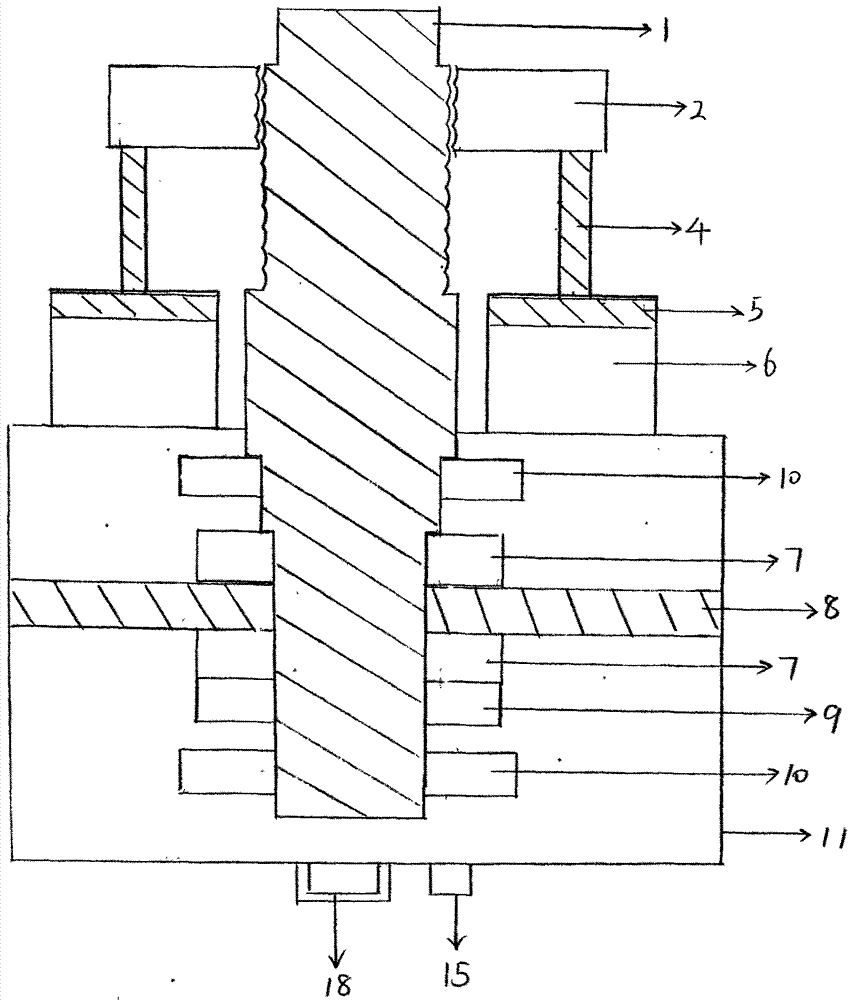

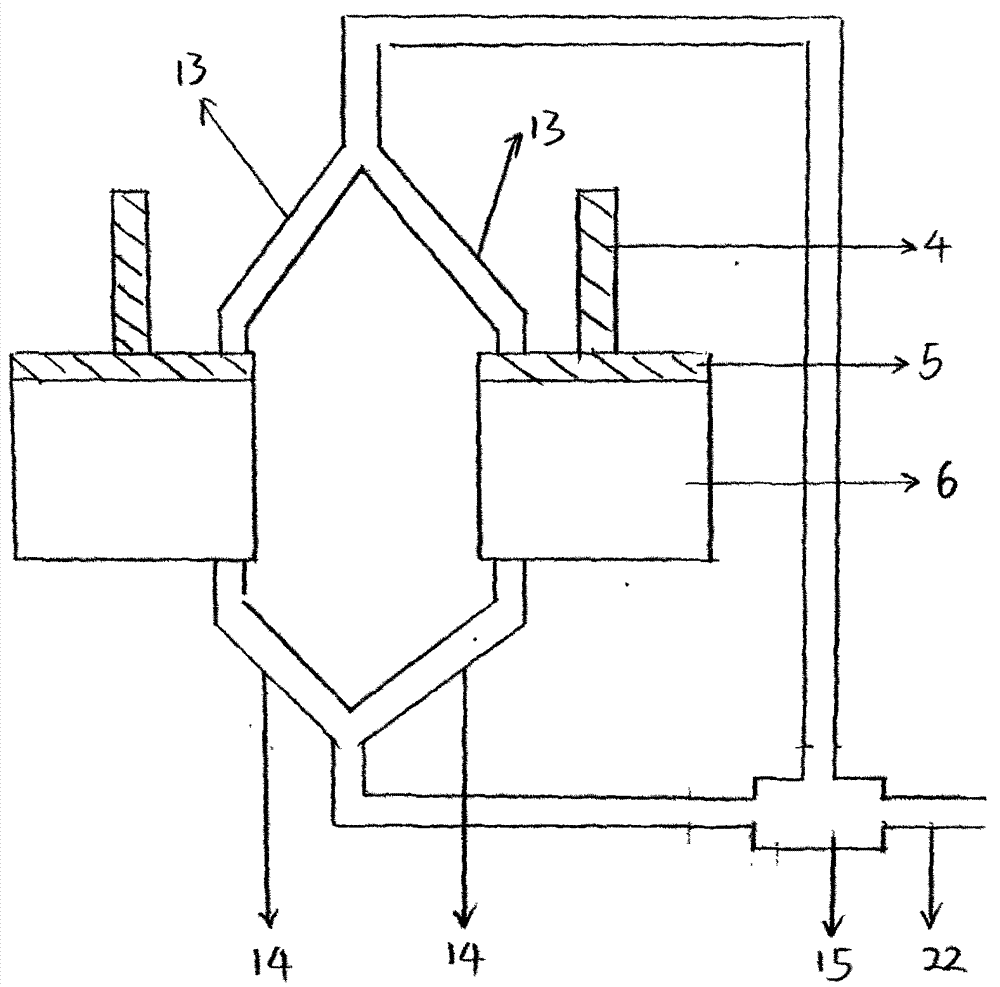

[0013] When the screw wrench completes the previous rotation and stops, the two pull rods (4) of the cylinder are in the extended state, install the required casing head on the upper end of the wrench pull rod (1), press the switch of the solenoid valve (15), and the cylinder ( 6) The pull rod (4) recovers quickly. Since the screw nut (2) is connected by the two pull rods, it cannot rotate. The screw nut moves down rapidly with the pull rod. At the same time as the screw nut moves down, the pull rod rotates accordingly, and the solenoid valve is pressed again. , the pull rod will be stretched out quickly, and the pull rod will rotate again. The two rotation directions of the pull rod are always opposite. When using it, select the direction to be rotated according to the needs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com