High-performance cold patch asphalt, cold patch material based on waste asphalt pavement material and preparation methods of cold patch asphalt and cold patch material

A technology for cold patching asphalt and pavement materials, which is applied to building thermal insulation materials, building components, buildings, etc., can solve the problems of the stacking cost of milling materials, the great influence of temperature conditions, and the high price of cold patching materials, so as to reduce pavement diseases. , good durability, high overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Preparation of high performance cold patch asphalt:

[0042] Heat 90# road petroleum A-grade asphalt to 150°C, and mix it with the active regeneration additive at room temperature in a ratio of 1:1 by weight. The mixing of the two is required to be completed within 10 minutes. For the production of large-tonnage cold-mix asphalt, it can be Finished in asphalt storage tanks with agitators. In the absence of heating, start the stirrer and stir in this state for 1-2 hours. For small-volume cold-mix asphalt, it can be produced by mixing in iron drums, and the mixture can be stirred evenly by hand.

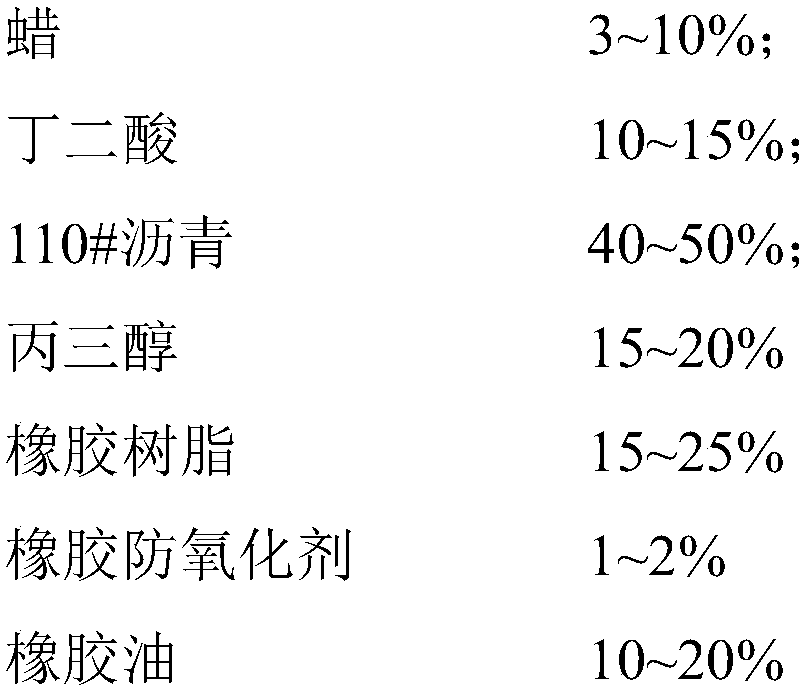

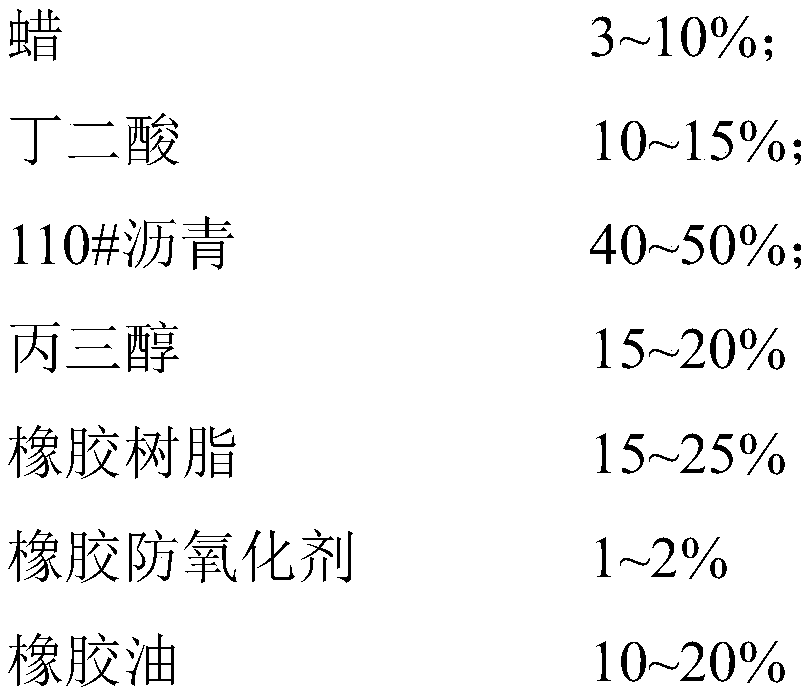

[0043] The active regenerative additive is uniformly mixed from the following materials:

[0044]

Embodiment 2

[0046] Preparation of Cold Feed:

[0047] [Binder] The high-performance cold-patch asphalt obtained in Example 1.

[0048] 【Aggregate】Waste asphalt pavement materials

[0049] Use 5mm*5mm, 10mm*10mm, and 15*15mm sieves to sieve waste asphalt pavement materials into three grades, and the gradation range of each grade is as follows:

[0050]

[0051]

[0052] The cold feed material adopts medium-grain gradation, and the synthetic gradation is shown in the following table:

[0053] mesh size

19

13.2

9.5

4.75

2.36

1.18

0.6

0.3

0.15

0.075

synthetic grading

100.0

96.0

83.5

56.5

35.2

23.5

13.9

6.6

3.3

1.9

Grading requirements

100.0

90-100

-

50-75

30-55

-

-

-

-

2-7

[0054] 【Preparation】

[0055] Add the cold-patch aggregate with a weight ratio of 99:1 and the high-performance cold-patch asphalt to the mixing equipment for mixing, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| stability | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com