Small stone cutting machine

A cutting machine, stone technology, applied in the direction of stone processing tools, stone processing equipment, manufacturing tools, etc., can solve problems such as safety accidents, saw blade breakage, inability to cut stone, and achieve the effect of prolonging the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

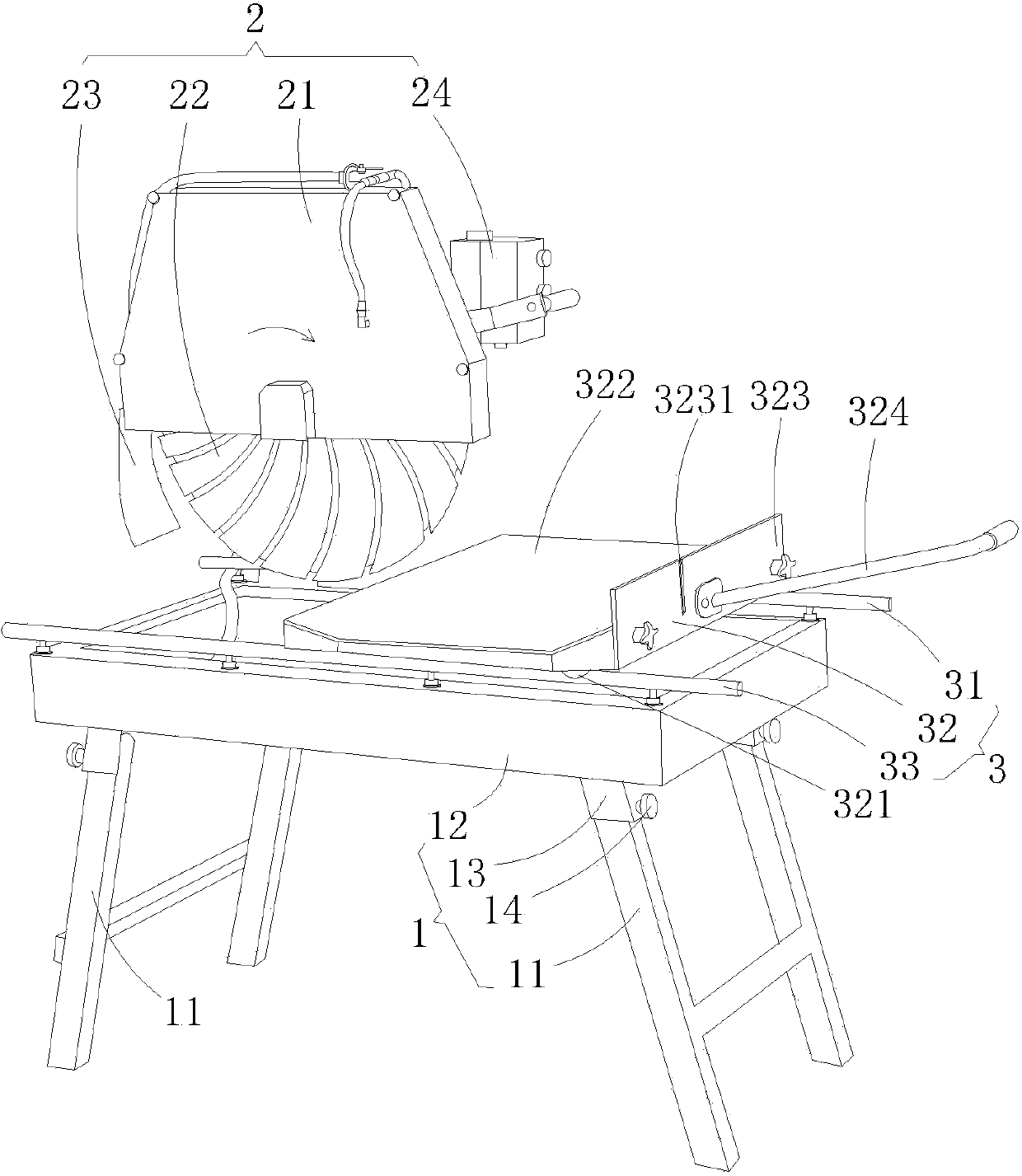

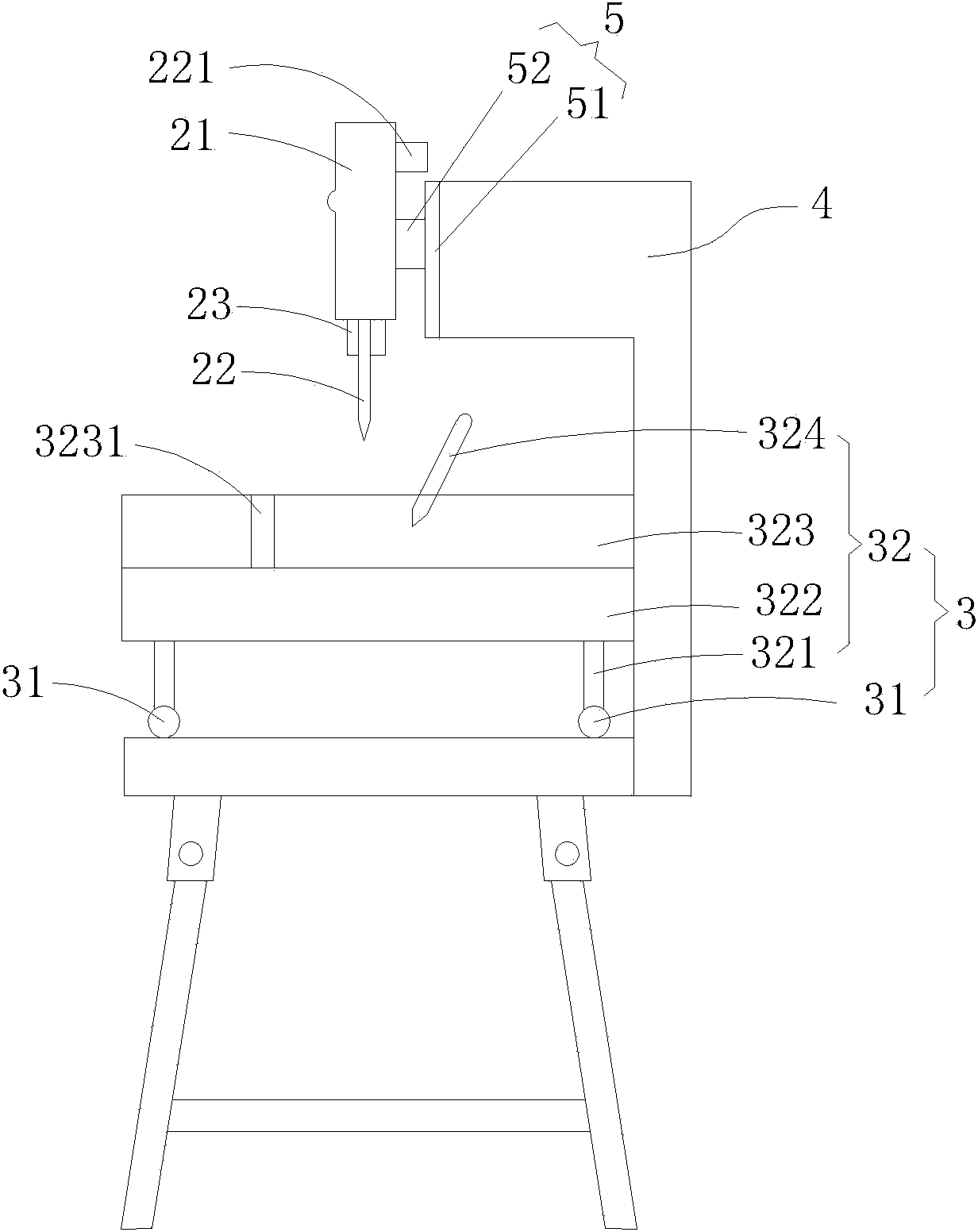

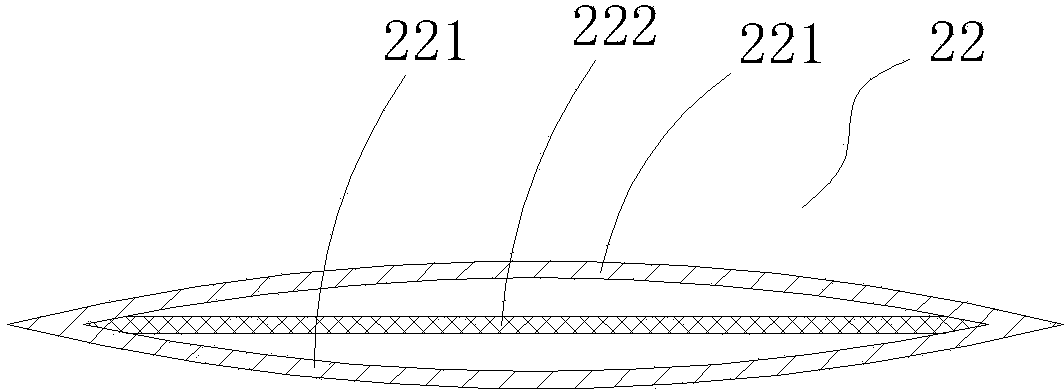

[0025] Example: see Figure 1 to Figure 4 Shown, a kind of small-sized stone cutting machine, this small-sized stone cutting machine comprises frame 1, cutting device 2 and movable workbench 3; One side of the workbench 3 extends upwards to form an L-shaped tool holder 4. The inner side of the tool holder 4 has a lifting mechanism 5. The cutting device 2 is fixed on the lifting mechanism 5 and can be realized by the lifting mechanism 4. Lifting of the cutting device.

[0026] see Figure 1 to Figure 4 As shown, the frame 1 includes two support legs 11 and a support plate 12, the bottom surface of the support plate 11 has a connection groove 13, and the two support legs 12 are hinged in the corresponding connection groove 13 by bolts 14 to form a foldable frame structure.

[0027] see Figure 1 to Figure 4 As shown, the mobile workbench 3 includes two slide rails 31 and a workbench 32, the two slide rails 31 are respectively fixed on both sides of the frame, and the pulley ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com