Vane lock cylinder

A blade lock cylinder and lock pin technology, applied in the field of locks, can solve problems such as mutual opening and technical opening, and achieve the effect of prolonging the service life, prolonging the service life and avoiding collision damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to facilitate those skilled in the art to better understand the essence of the present invention, the specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

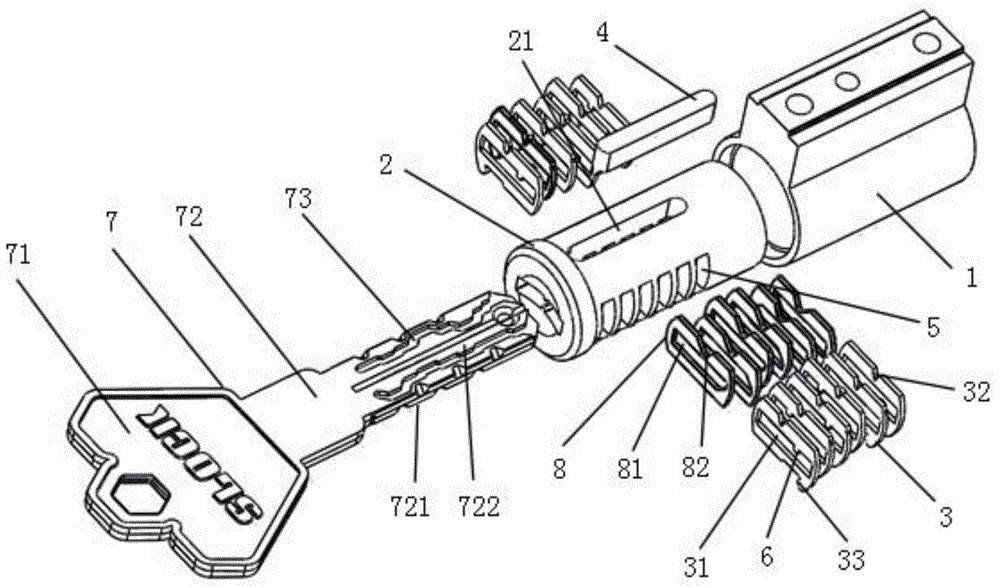

[0024] Such as figure 1 As shown, a blade lock cylinder includes: a lock outer tank 1, a lock inner tank 2, a number plate 3 and a lock pin 4.

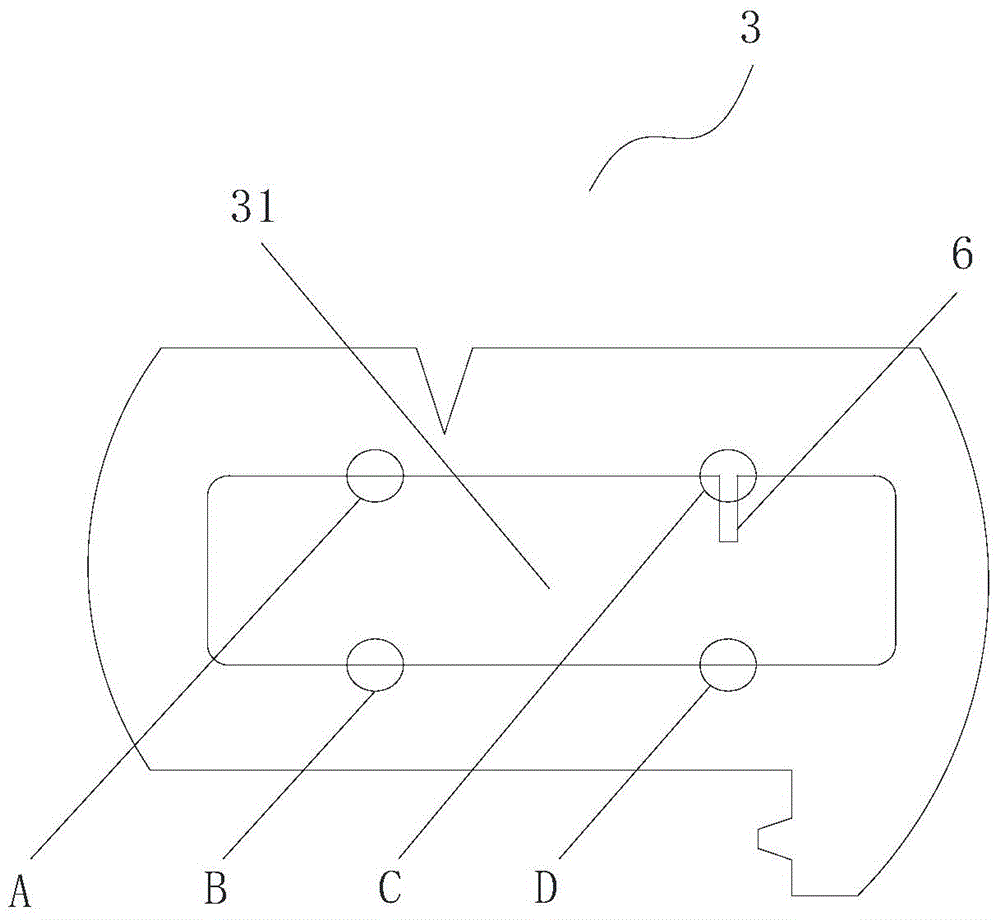

[0025] Wherein, the lock inner container 2 is rotatably arranged in the lock outer container 1 . On the lock liner 2, six slots 5 are arranged parallel to the axial direction and perpendicular to the axis, and a pair of number plates 3 are arranged in each slot 5, and a keyhole 31 and a key hole 31 are arranged on each number plate 3. The return spring that makes the serial number 3 move outside the slot hole is provided with a projection 33 on the serial number 3 , and the return spring is connected between the projection 33 and the lock inner container 2 . One side of the numbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com