Medium-strength nitric acid corrosion-resistant titanium alloy

A titanium alloy and strength technology, applied in the field of titanium alloys, can solve the problem of not meeting the strength requirements of transmission components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

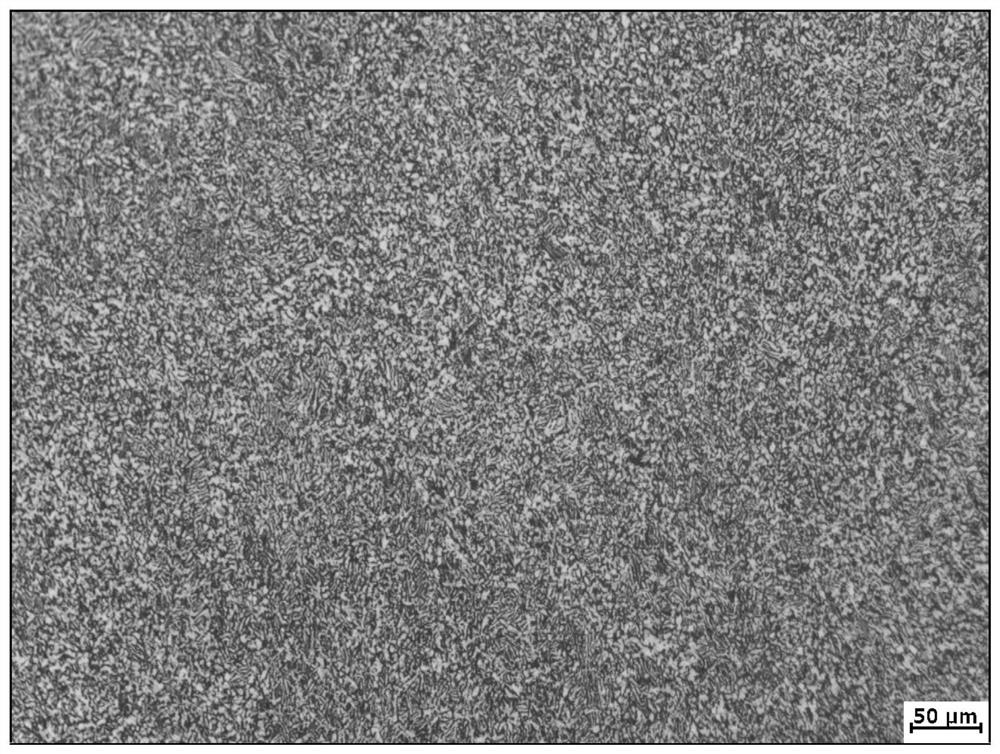

Image

Examples

Embodiment 1

[0021] The medium-strength nitric acid corrosion-resistant titanium alloy of this embodiment is composed of the following components in mass percentage: Ta5.5%, Al 0.7%, Zr 1.0%, Mo 0.8%, Nb 1.1%, and the balance is Ti and unavoidable impurities.

[0022] This embodiment includes the following steps:

[0023] Step 1, mixing Ti-50% Ta master alloy, Ti-30% Mo master alloy, Al-70% Nb master alloy, aluminum beans, sponge zirconium and sponge titanium, and then pressing to obtain an electrode;

[0024] Step 2, melting the electrode obtained in Step 1 three times in a vacuum consumable electric arc furnace to obtain an ingot;

[0025] Step 3. Carrying out billet forging three times at 1150° C., 1050° C. and 950° C. respectively on the ingot obtained in step 2 to obtain the forged ingot;

[0026] Step 4. Convert the forged ingot obtained in Step 3 into a rolled billet at 850° C., and then perform finished rolling at 870° C. to obtain a medium-strength nitric acid corrosion-resistant...

Embodiment 2

[0052] The medium-strength nitric acid corrosion-resistant titanium alloy in this embodiment is composed of the following components in mass percentage: Ta 5.0%, Al 0.9%, Zr 2.0%, Mo 1.0%, Nb 0.7%, and the balance is Ti and unavoidable impurities.

[0053] This embodiment includes the following steps:

[0054] Step 1, mixing Ti-50% Ta master alloy, Ti-30% Mo master alloy, Al-70% Nb master alloy, aluminum beans, sponge zirconium and sponge titanium, and then pressing to obtain an electrode;

[0055] Step 2, melting the electrode obtained in Step 1 three times in a vacuum consumable electric arc furnace to obtain an ingot;

[0056] Step 3. Carrying out billet forging three times at 1150° C., 1050° C. and 950° C. respectively on the ingot obtained in step 2 to obtain the forged ingot;

[0057] Step 4. The forged ingot obtained in Step 3 is converted into a rolled billet at 900°C, and then rolled at 830°C to obtain a medium-strength nitric acid corrosion-resistant titanium alloy ...

Embodiment 3

[0061] The medium-strength nitric acid corrosion-resistant titanium alloy in this embodiment is composed of the following components in mass percentage: Ta 6.0%, Al 1.1%, Zr 1.5%, Mo 0.6%, Nb 2.0%, and the balance is Ti and unavoidable impurities.

[0062] This embodiment includes the following steps:

[0063] Step 1, mixing Ti-50% Ta master alloy, Ti-30% Mo master alloy, Al-70% Nb master alloy, aluminum beans, sponge zirconium and sponge titanium, and then pressing to obtain an electrode;

[0064] Step 2, melting the electrode obtained in Step 1 three times in a vacuum consumable electric arc furnace to obtain an ingot;

[0065] Step 3. Carrying out billet forging three times at 1150° C., 1050° C. and 950° C. respectively on the ingot obtained in step 2 to obtain the forged ingot;

[0066] Step 4. Convert the forged ingot obtained in Step 3 into a rolled billet at 870° C., and then perform finished rolling at 850° C. to obtain a medium-strength nitric acid corrosion-resistan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cross section diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com