A high-efficiency die-casting preparation method of ultra-thin gold-tin eutectic material

A eutectic material and ultra-thin technology, which are used in the preparation of difficult-to-deform eutectic alloy materials and the high-efficiency die-casting preparation of ultra-thin gold-tin eutectic materials, which can solve the problem that the alloy solder cannot be completely alloyed and the gold-tin eutectic alloy is prone to cracking. , the quality of the welding piece cannot be accurately controlled, etc., to achieve the effect of reducing the plastic processing process, reducing the cracking of the material, and not easy to crack the foil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

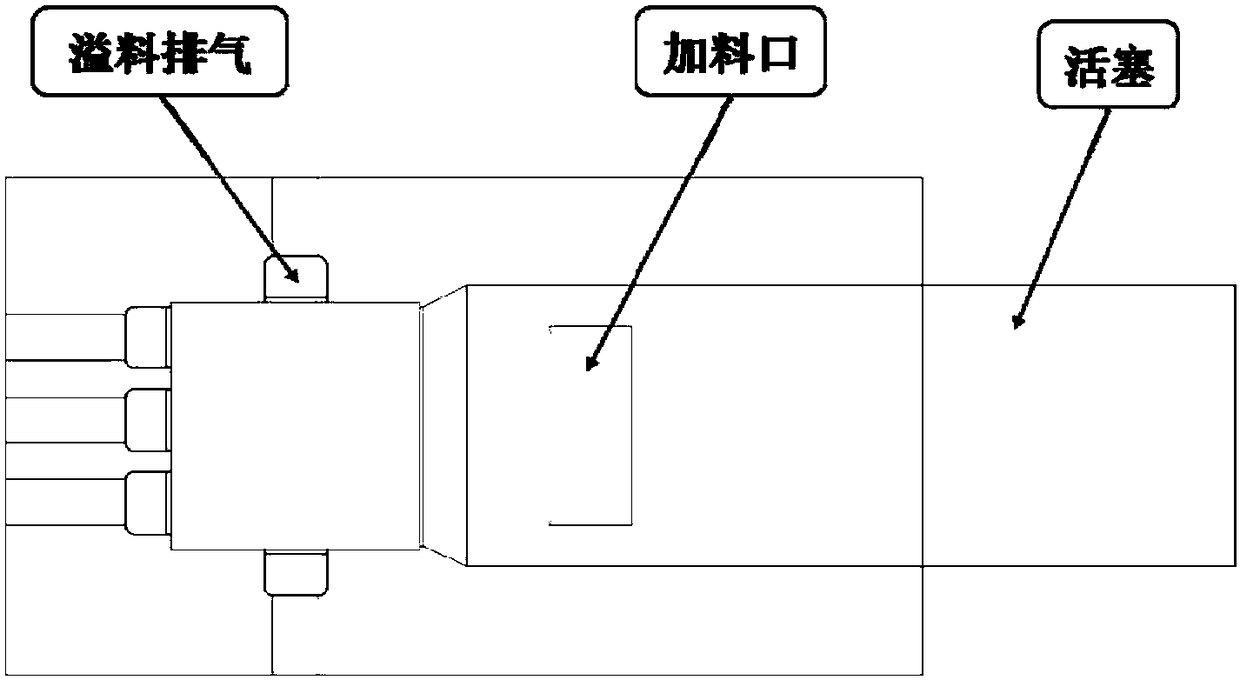

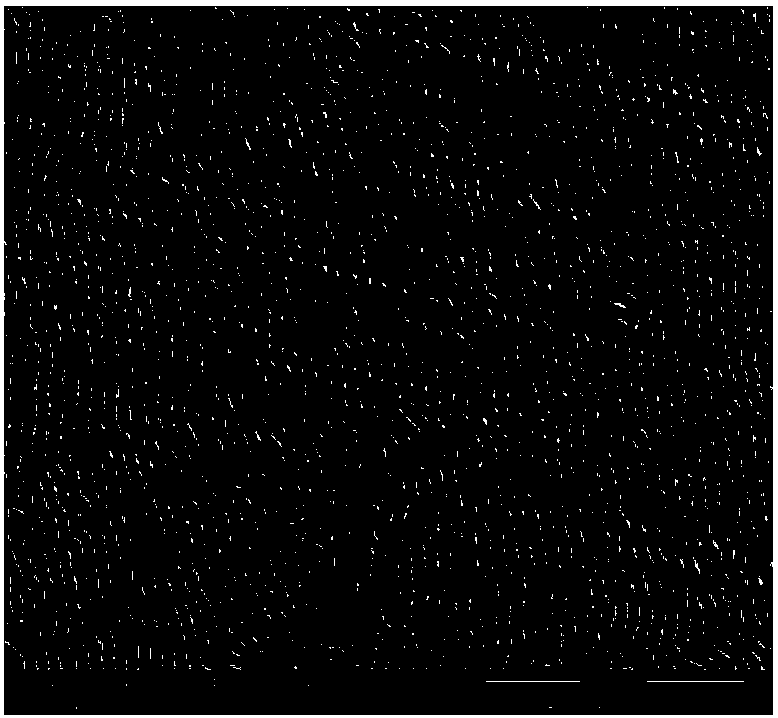

Embodiment 1

[0036] The precise configuration composition is a gold-tin eutectic alloy with a tin mass percentage of 20% and a gold mass percentage of 80%. The prepared raw materials are placed in a vacuum non-consumable arc melting furnace, and then vacuumed until the vacuum degree reaches 6× 10 -4 After Pa, start arc smelting under 400A working current to obtain a gold-tin alloy melt, electromagnetically stir the melt, the electromagnetic stirring speed is 1100r / min, the stirring time is 1 minute, and then the water-cooled copper crucible is cooled to room temperature; repeat; The process of smelting, stirring and cooling is 4 times to obtain a die-cast ingot; take out the die-cast ingot and put it into the metal pool of the hot chamber die-casting machine, heat the ingot in the metal pool to a molten state at 350℃, and die-casting punch stroke at a speed of 0.1m / s To 100mm, fill the molten liquid into a die-casting mold with a holding temperature of 300°C and a thickness of 0.1mm to obtai...

Embodiment 2

[0041] The precise configuration composition is a gold-tin eutectic alloy with a tin mass percentage of 20% and a gold mass percentage of 80%. The prepared raw materials are placed in a vacuum non-consumable arc melting furnace, and then vacuumed until the vacuum degree reaches 6× 10 -4 After Pa, start arc smelting under 500A working current to obtain a gold-tin alloy melt, electromagnetically stir the melt, the electromagnetic stirring speed is 1200r / min, the stirring time is 1 minute, and then the water-cooled copper crucible is cooled to room temperature; repeat; The process of smelting, stirring, and cooling 4 times to obtain the die-cast ingot; take out the die-cast ingot and put it into the metal pool of the hot chamber die-casting machine, heat the ingot in the metal pool to the molten state at 400℃, and die-cast the punch stroke at a speed of 0.3m / s To 200mm, fill the melt into a die-casting mold with a holding temperature of 250°C and a thickness of 0.3mm. The schematic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com