Special intermediate alloy for iron base amorphous nanocrystalline alloy and smelting method thereof

An iron-based amorphous and intermediate alloy technology, applied in the field of metallurgy, can solve problems such as numerous processes and high power consumption, and achieve the effects of optimizing alloy melting point, improving production efficiency, and reducing smelting temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

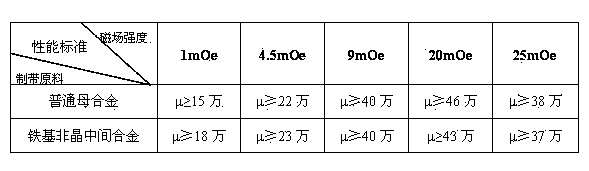

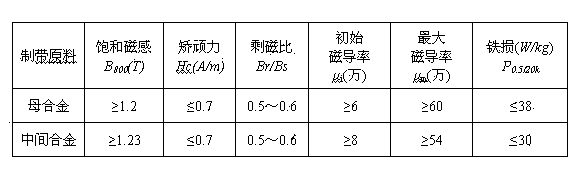

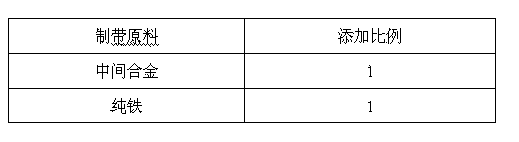

[0033] The embodiment is carried out in a 150kg intermediate frequency induction furnace. The iron material is industrial pure iron, and the rest of the added raw materials include industrial silicon, ferroboron, ferroniobium and pure copper. The chemical composition and addition ratio of each raw material are shown in Table 1. Prepare materials according to the data calculated in Table 1, smelt 5 furnaces of 150 kg iron-based amorphous nano-special master alloy, prepare 10 furnaces of iron-based amorphous nano-crystalline strips, and add iron-based amorphous master alloy ingots required for strip production The ratio with pure iron is shown in Table 2.

[0034] When feeding into the intermediate frequency furnace, first lay the base with industrial pure iron of the given quality in Table 1, then add ferroniobium, industrial silicon, pure copper, and ferroboron in sequence, and the feeding is completed at one time. When smelting, preheat with a power of 10-20KW for 15 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com