A kind of anti-oxidation iron-based superalloy and preparation method thereof

A superalloy and iron oxide-based technology, applied in the field of anti-oxidation iron-based superalloy and its preparation, can solve problems such as unsatisfactory anti-oxidation performance, and achieve the effects of low cost, increased working temperature, and improved anti-oxidation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with specific examples.

[0017] A group of preparation method embodiments, including:

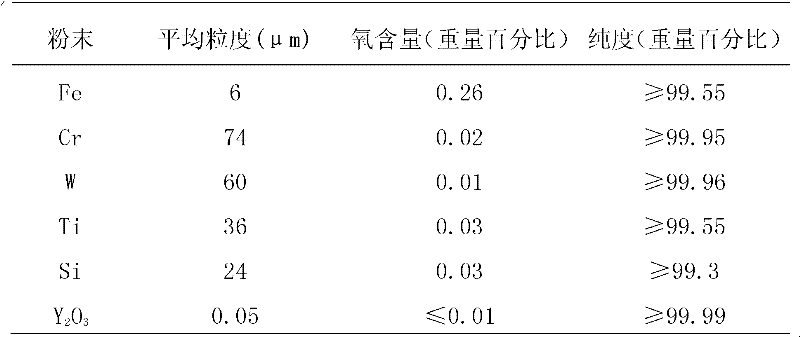

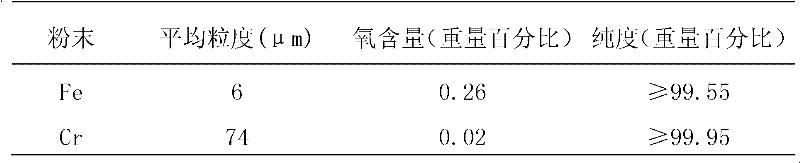

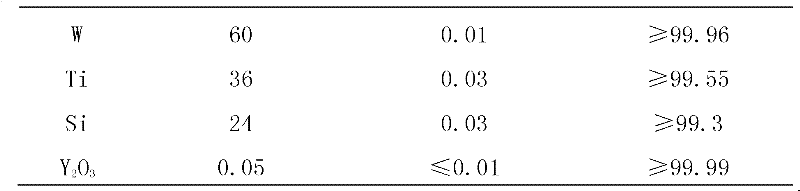

[0018] (1) Mechanical alloying step: Cr, W, Ti, Si, Y 2 o 3 And Fe powder according to mass percentage: 12%Cr, 2.5%W, 0.4%Ti, 0.5%Si, 0.3%Y 2 o 3 , the balance is Fe, mixed, and the average particle size, oxygen content and purity of the powder used are as shown in Table 1:

[0019] Table 1 Raw material powder average particle size, oxygen content and purity

[0020]

[0021]

[0022] Divide the mixed powder into 5 groups of A1~A5, and use planetary ball mill to carry out ball milling twice, the first ball milling is dry ball milling, ball milling time is 48h~60h; Water ethanol was used as a process control agent, and ball milling was continued for 2 to 4 hours, and argon protection was used during the two ball milling processes, and alloy powder with uniform composition was finally obtained; the ball mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com