A method for rapid preparation of three-dimensional porous gold-silver alloy nanomaterials

A technology of three-dimensional porous and nanomaterials, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of high reaction temperature, difficulty in achieving uniform element ratio, and numerous steps to achieve preparation The process is simple and easy to operate, the preparation time is shortened, and the effect of monodispersity is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

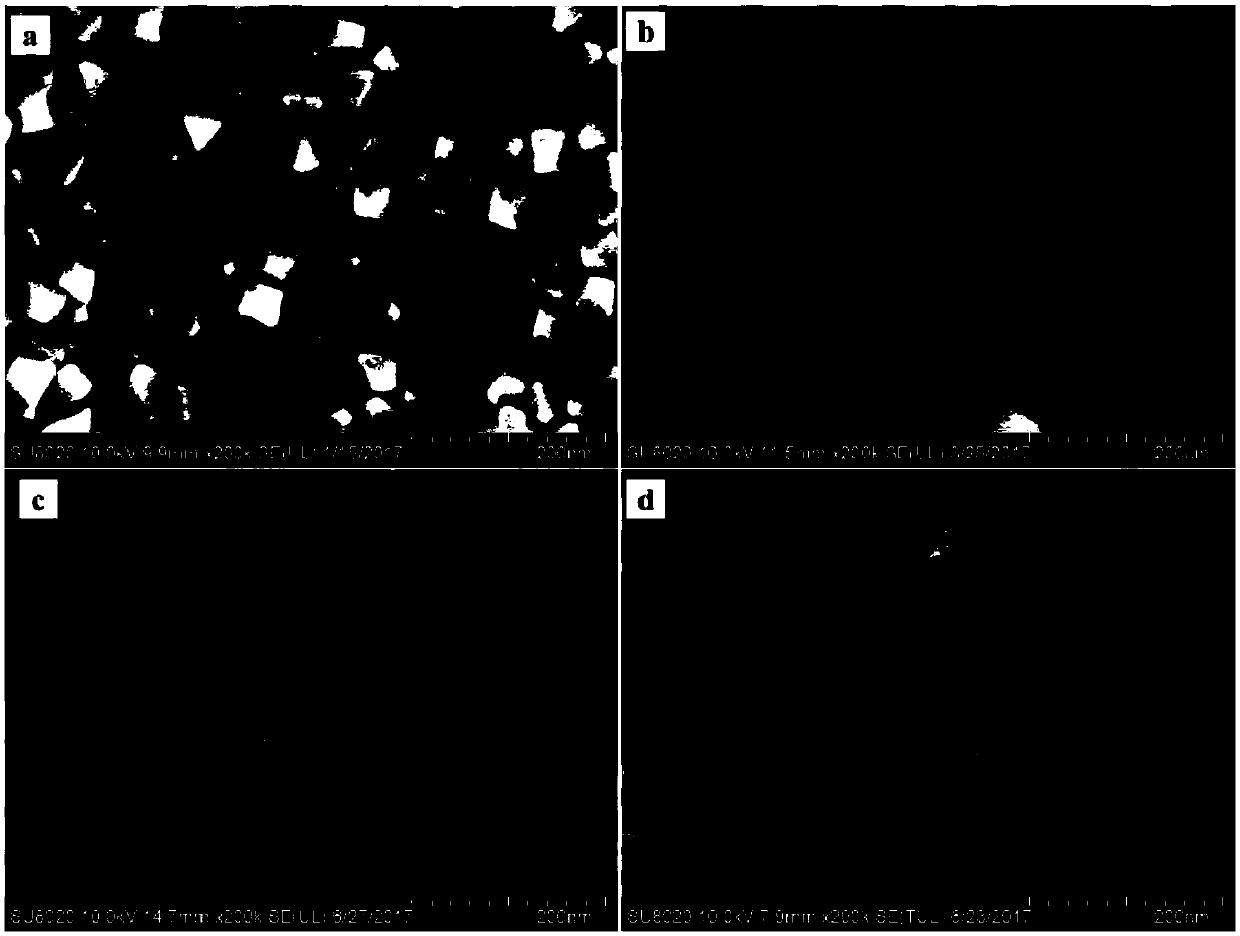

[0024] Step A, add silver nitrate and ascorbic acid to the gold nanometer octahedral colloidal solution, make the concentration of silver nitrate in the liquid after mixing be 0.002~0.005mol / L, the concentration of ascorbic acid be 0.005~0.02mol / L, and in 50~80 °C for 30 minutes to prepare a colloidal solution of gold@silver nanocubes. Wherein, the gold nano-octahedral colloidal solution is a gold nano-octahedral colloidal solution prepared in an ethylene glycol system. In practical application, the preparation method of the described gold nano-octahedral colloidal solution includes: adding chloroauric acid and polydiallyldimethylammonium chloride with a molecular weight of 100,000 to 200,000 to the ethylene glycol solution, mixing The concentration of chloroauric acid in the final liquid is 0.0001-0.005 mol / liter, the concentration of polydiallyl dimethyl ammonium chloride is 0.005-0.2 mol / liter, and then react at 180-220°C for 1-5 hour, thereby making gold nano-octahedral c...

Embodiment 1

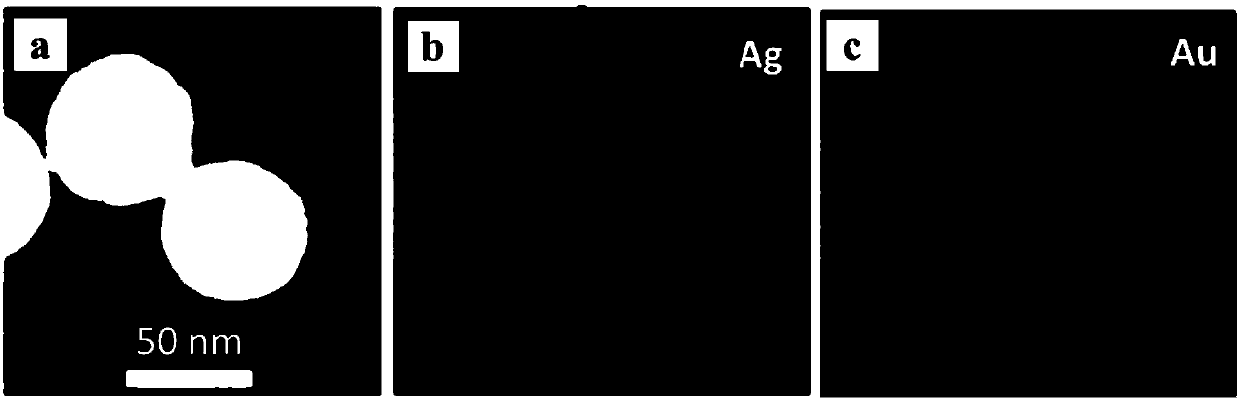

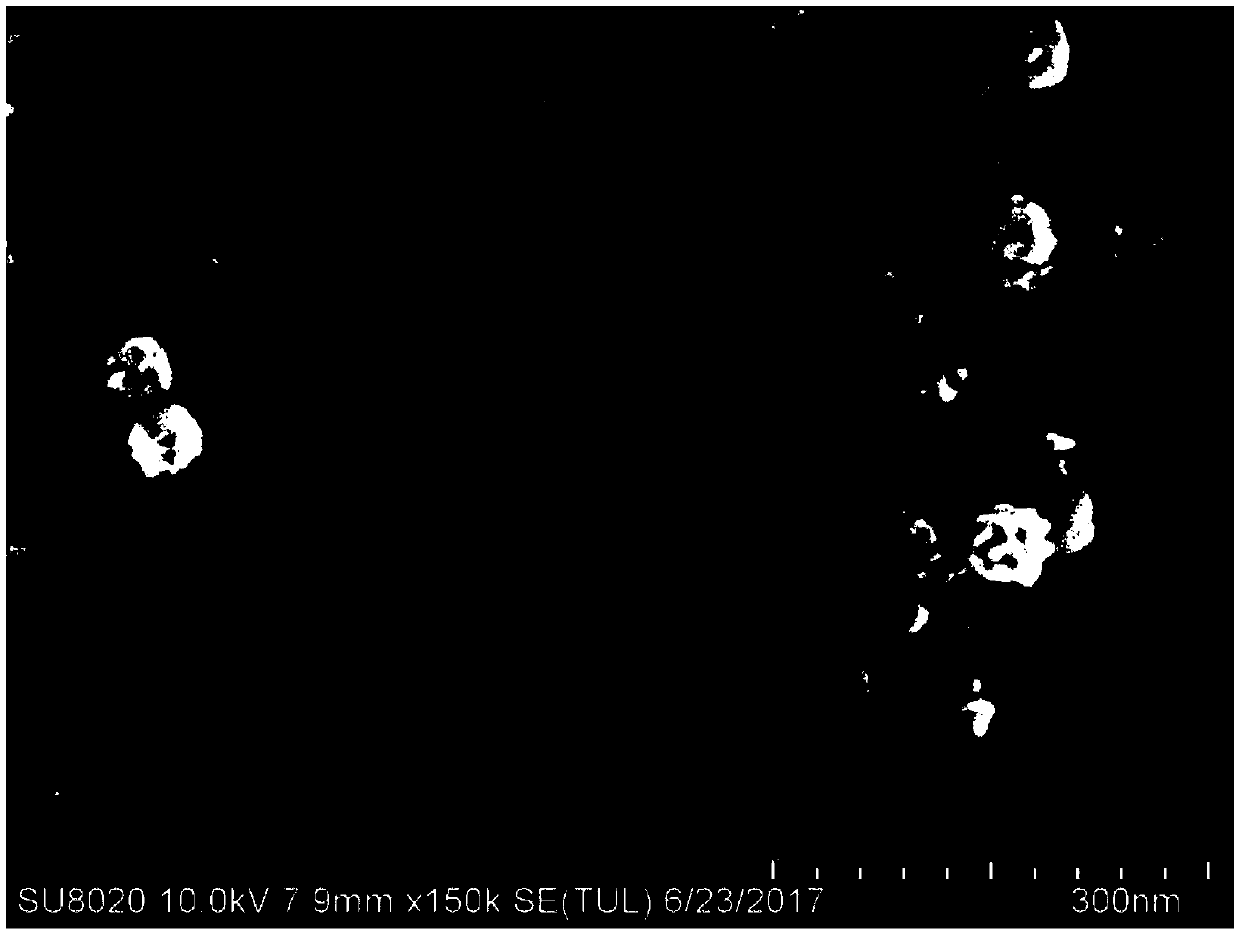

[0036] like Image 6 Shown, a kind of three-dimensional porous gold-silver alloy nano material, its preparation method comprises the following steps:

[0037] Step a1, adding chloroauric acid and molecular weight to 60 milliliters of ethylene glycol solutions is the polydiallyl dimethyl ammonium chloride (Mw=100000~200000, 20wt%) of 100000~200000, makes the chlorine in the liquid after mixing The concentration of gold acid is 0.0005 mol / liter, the concentration of polydiallyl dimethyl ammonium chloride is 0.025 mol / liter, then heated and reacted in an oil bath at 220°C for 1 hour, and naturally cooled to room temperature, thereby producing A gold nano-octahedral colloidal solution was obtained.

[0038] Step b1, under the condition of stirring at room temperature, add silver nitrate and ascorbic acid to the gold nano octahedral colloidal solution, so that the concentration of silver nitrate in the mixed liquid is 0.002~0.005mol / L, and the concentration of ascorbic acid is 0.0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com