A kind of pre-alloyed powder for diamond sawing tool

A technology of pre-alloyed powder and diamond sawing, which is applied in the field of pre-alloyed powder for diamond sawing tools, which can solve the problems of uneven diffusion connection between metal matrix and diamond, poor mechanical grip of diamond, and high oxygen content of pre-alloyed powder. , to achieve the effect of high hardness, low oxygen content and sufficient alloying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A pre-alloyed powder for diamond sawing tools, the weight percent composition of each component of the pre-alloyed powder is: Cu20%, Co5%, Ni1%, Cr3%, Fe71%.

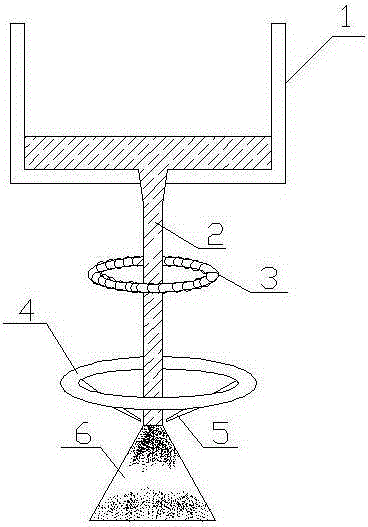

[0039] Such as figure 1 Shown, the preparation method of described pre-alloyed powder comprises the following steps:

[0040] (1) Put the raw materials into the electric furnace according to the ratio, heat up and melt, and keep the molten metal at 1600°C for 5 minutes.

[0041] (2) Then the molten metal flows down through the leakage hole at the bottom of the leakage bag 1 at a flow rate of 60kg / min. The molten metal flow 2 passes through the pulsed magnetic field 3 and the annular spray plate 4 from top to bottom in sequence, and the nozzle 5 of the annular spray plate 4 sprays The high-pressure water flow crushes the metal liquid flow 2 to form metal powder and enters the atomizing barrel 6, which is filled with nitrogen gas for gas protection.

[0042] The pulse generation voltage of the pulsed magnetic fie...

Embodiment 2

[0048] A pre-alloyed powder for diamond sawing tools, the weight percent composition of each component of the pre-alloyed powder is: Cu25%, Co10%, Ni3%, Cr6%, Fe56%.

[0049] Such as figure 1 Shown, the preparation method of described pre-alloyed powder comprises the following steps:

[0050] (1) Put the raw materials into the electric furnace according to the ratio, heat up and melt, and keep the molten metal at 1650°C for 1min.

[0051] (2) Then the molten metal flows down through the leakage hole at the bottom of the leakage bag 1 at a flow rate of 80kg / min. The molten metal flow 2 passes through the pulsed magnetic field 3 and the annular spray plate 4 from top to bottom in sequence, and the nozzle 5 of the annular spray plate 4 sprays The high-pressure water flow crushes the metal liquid flow 2 to form metal powder and enters the atomizing barrel 6, which is filled with nitrogen gas for gas protection.

[0052] The pulse generation voltage of the pulsed magnetic field i...

Embodiment 3

[0058] A pre-alloyed powder for diamond sawing tools, the weight percentage of each component of the pre-alloyed powder is composed of: Cu22%, Co8%, Ni2%, Cr4%, Fe64%.

[0059] Such as figure 1 Shown, the preparation method of described pre-alloyed powder comprises the following steps:

[0060] (1) Put the raw materials into the electric furnace according to the ratio, heat up and melt, and keep the molten metal at 1620°C for 3 minutes.

[0061] (2) Then the molten metal flows down through the leakage hole at the bottom of the leakage bag 1 at a flow rate of 70kg / min. The molten metal flow 2 passes through the pulsed magnetic field 3 and the annular spray plate 4 sequentially from top to bottom, and the nozzle 5 of the annular spray plate 4 sprays The high-pressure water flow crushes the metal liquid flow 2 to form metal powder and enters the atomizing barrel 6, which is filled with nitrogen gas for gas protection.

[0062] The pulse generation voltage of the pulsed magnetic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com