Preparation method of special soybean protein particles for liquid beverage

A soybean protein and beverage technology, applied in the field of food raw material processing, can solve the problems of fast dispersion, good stability, and low centrifugal precipitation rate of soybean protein, and achieve surface wetting prevention, enhanced stability, and low centrifugal precipitation rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

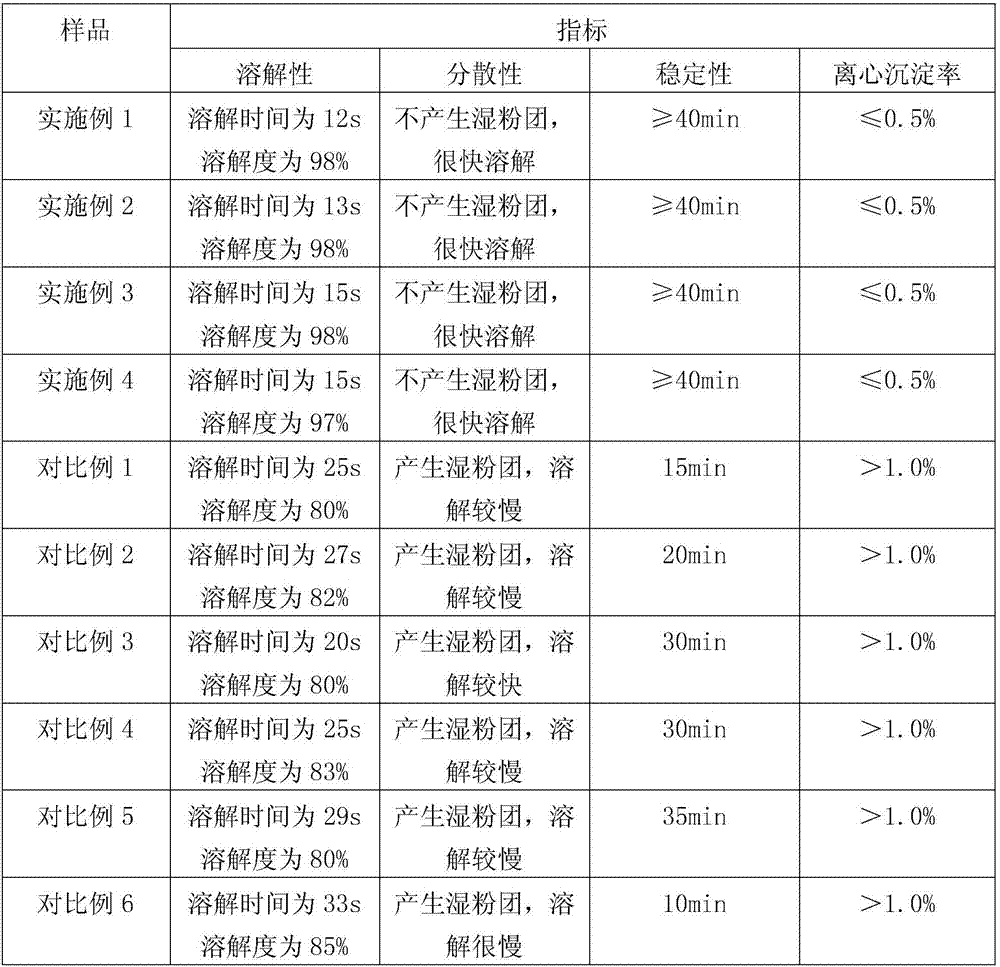

Examples

Embodiment 1

[0048] A preparation method of special soybean protein granules for liquid beverages, comprising the following steps:

[0049] (1) Preparation of soybean protein enzymatic hydrolyzate: 1.5kg soybean protein isolate is dissolved in 12kg deionized water, and the pH value is adjusted to 7.2 with a 30% NaOH aqueous solution with a mass concentration; add 1.2g compound flavor protease (enzyme activity is 20000U / g), at a stirring rate of 200r / min and a temperature of 45°C, perform enzymatic hydrolysis for 1 hour; heat in a water bath at 100°C to inactivate the enzyme for 20 minutes, and cool to room temperature to obtain a soybean protein enzymatic hydrolyzate;

[0050] (2) Homogenization and spray drying of soybean protein hydrolyzate: the soybean protein hydrolyzate obtained in step (1) was sheared and homogenized for 2 minutes at 10000 r / min, filtered through a 40-mesh sieve to obtain homogeneous soybean protease Hydrolyzate; the obtained homogeneous soybean protein enzymatic hy...

Embodiment 2

[0055] A preparation method of special soybean protein granules for liquid beverages, comprising the following steps:

[0056] (1) Preparation of soybean protein enzymatic hydrolyzate: 1.5kg soybean protein isolate is dissolved in the deionized water of 13.0kg, and be 30% NaOH aqueous solution adjustment pH value is 7.0 with mass concentration; Add 1.2g compound flavor protease (enzyme activity is 10000U / g), at a stirring rate of 100r / min and a temperature of 40°C, perform enzymatic hydrolysis for 3 hours; heat in a water bath at 100°C to inactivate the enzyme for 20 minutes, and cool to room temperature to obtain soybean protein enzymatic hydrolyzate;

[0057] (2) Homogenization and spray drying of soybean protein enzymatic hydrolyzate: the soybean protein enzymatic hydrolyzate obtained in step (1) was sheared and homogenized for 10 min at 8000 r / min, filtered through a 40-mesh sieve to obtain homogeneous soybean protease Hydrolyzate: The obtained homogeneous soybean protein ...

Embodiment 3

[0061] A preparation method of special soybean protein granules for liquid beverages, comprising the following steps:

[0062] (1) Preparation of soybean protein enzymatic hydrolyzate: 2.0kg soybean protein isolate is dissolved in the deionized water of 16.0kg, and be 30% NaOH aqueous solution adjustment pH value is 6.8 with mass concentration; Add 1.6g compound flavor protease (enzyme activity is 20000U / g), at a stirring rate of 300r / min and a temperature of 50°C, perform enzymatic hydrolysis for 0.5h; heat in a water bath at 100°C to inactivate the enzyme for 20min, and cool to room temperature to obtain soybean protein enzymatic hydrolyzate;

[0063] (2) Homogenization and spray drying of soybean protein enzymatic hydrolyzate: the soybean protein enzymatic hydrolyzate obtained in step (1) was sheared and homogenized at 15000 r / min for 1 min, filtered through a 40-mesh sieve to obtain homogeneous soybean protease Hydrolyzate: The obtained homogeneous soybean protein enzymati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com