High-antimony tin-based babbitt metal material and preparation method thereof

A kind of alloy material, based babbitt technology, applied in the field of high antimony tin-based babbitt alloy material and its preparation, can solve the problems of cumbersome operation, low alloy quality, high labor intensity, etc., and achieve complex equipment, improved flexibility, The effect of improving slagging ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

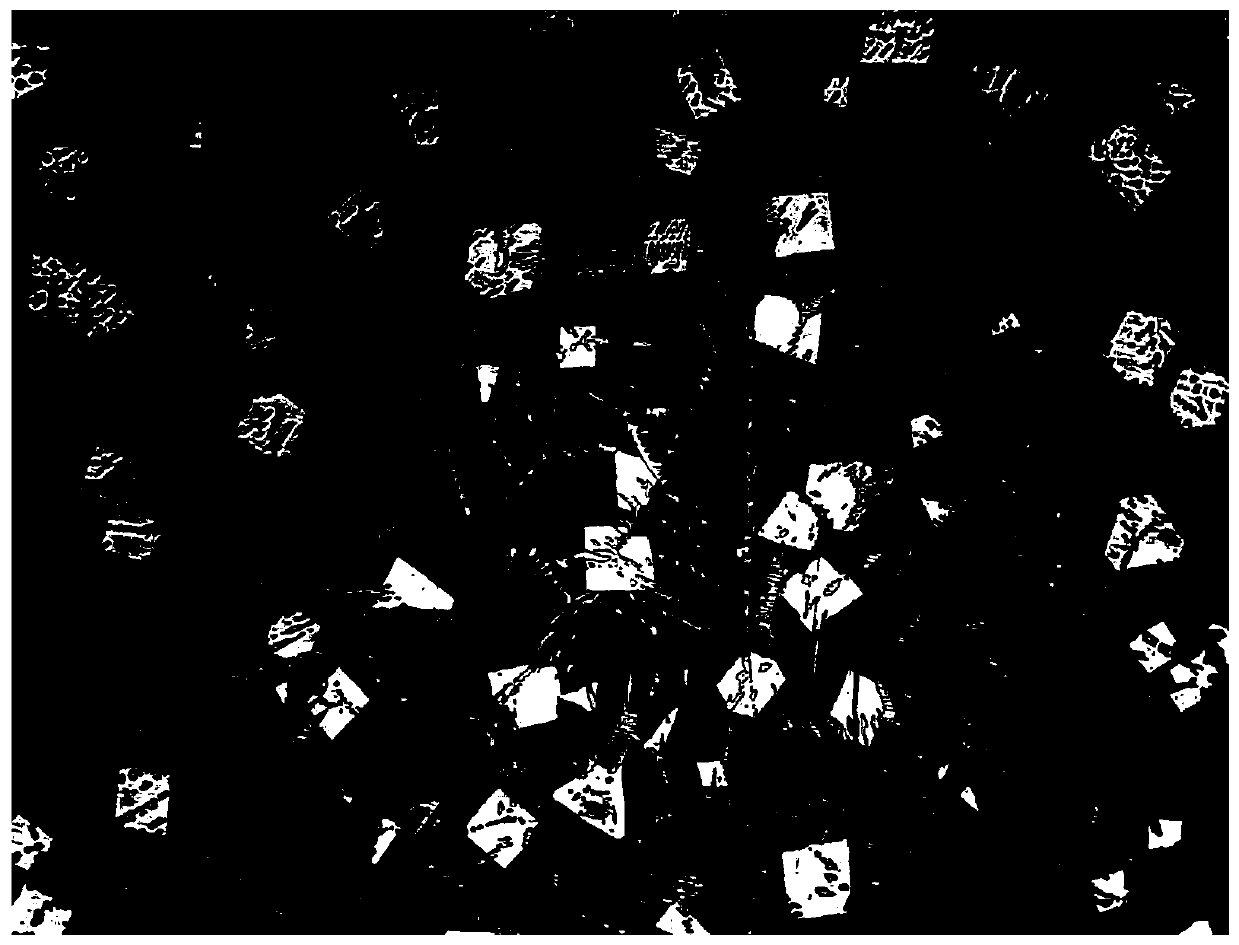

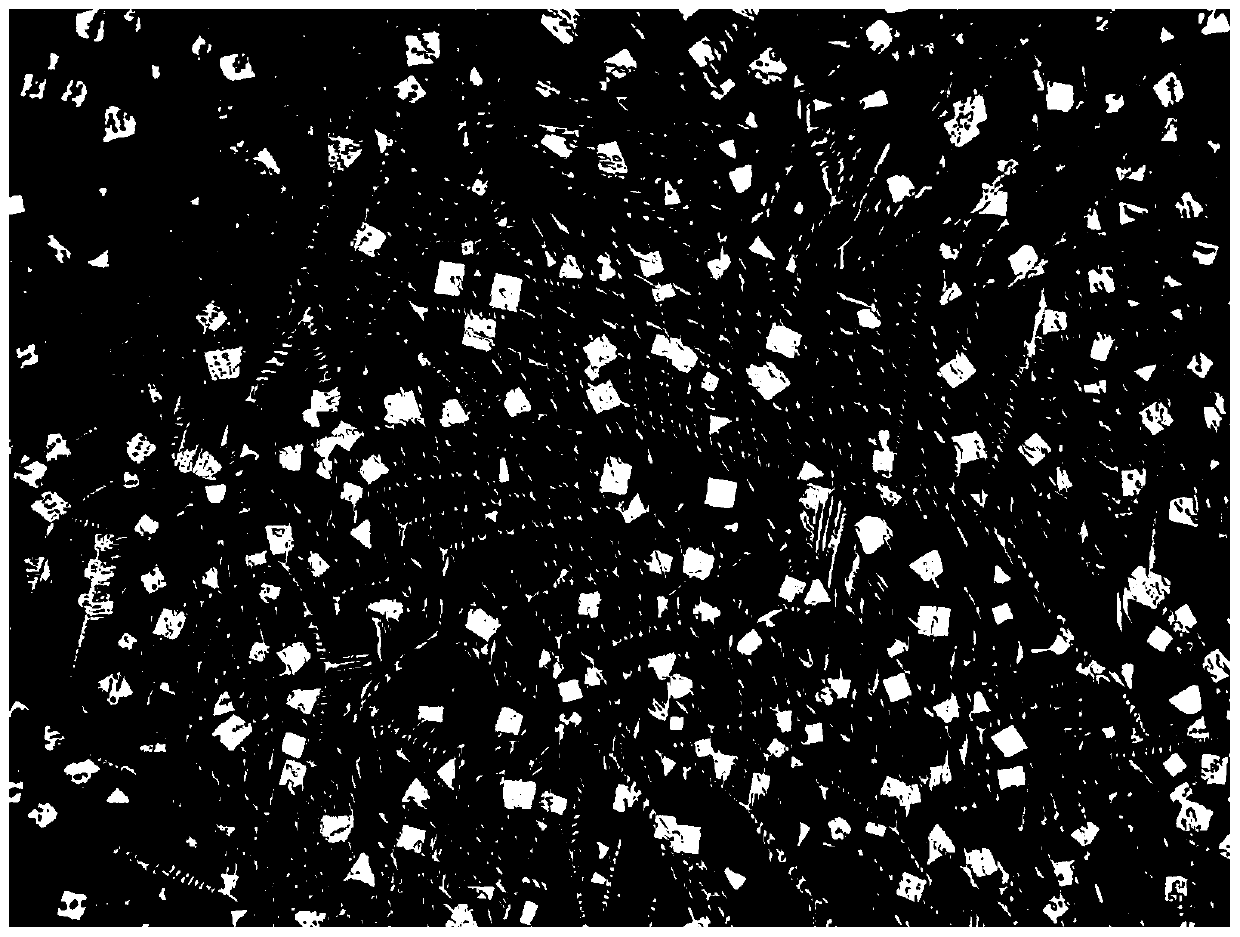

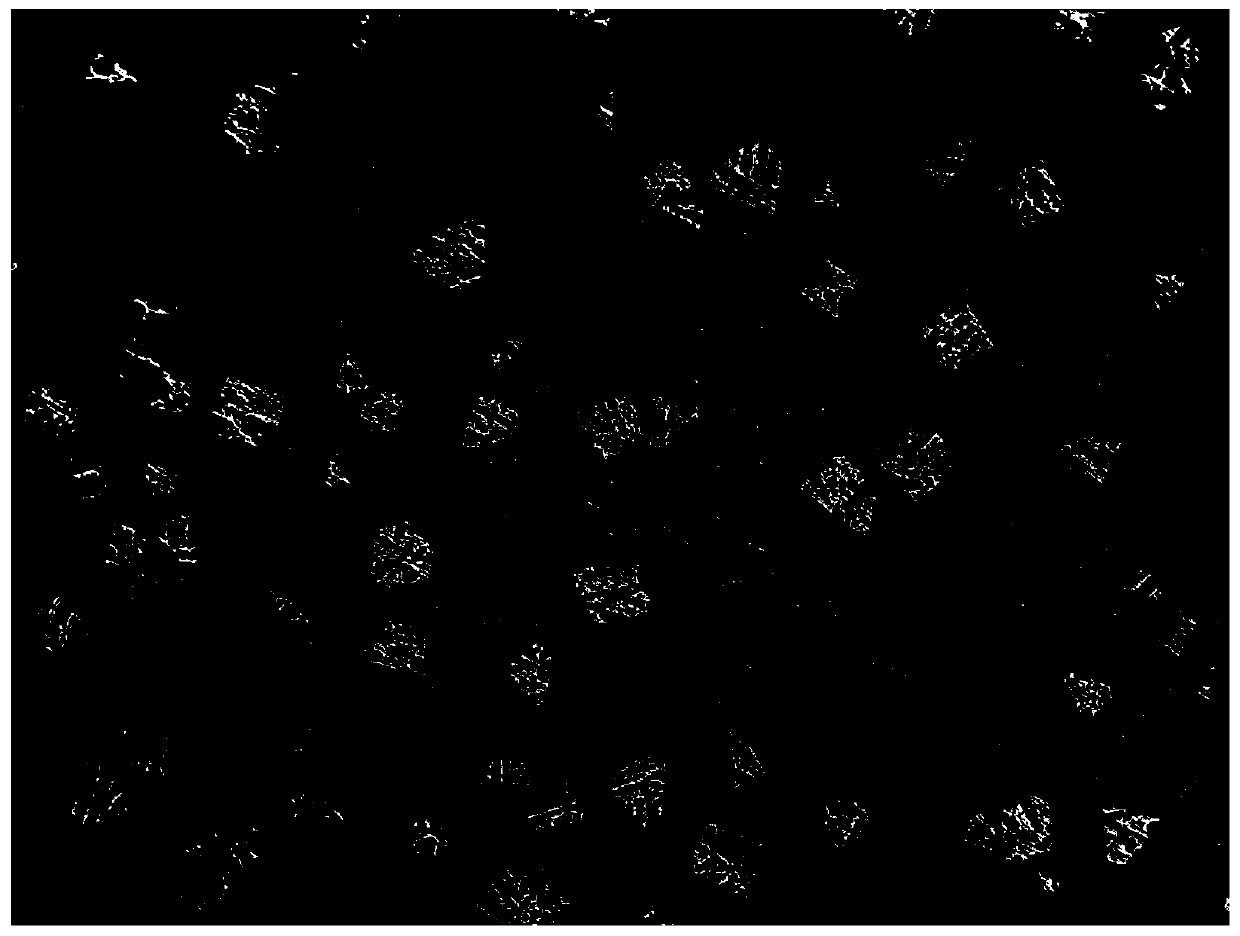

Image

Examples

Embodiment 1

[0026] A high-antimony tin-based babbitt alloy material comprises the following components in weight percent: antimony 11%, copper 6%, tellurium 0.003%, germanium 0.011%, and tin as the balance.

[0027] The preparation method of above-mentioned high-antimony tin-based babbitt alloy material, comprises the following steps:

[0028] (1) Weigh tin-germanium alloy, antimony-tellurium alloy, copper, antimony and 1 / 2~1 / 3 weight of tin, and the weight ratio of antimony, tin-germanium alloy and antimony-tellurium alloy is 11:0.1~0.15:0.02~0.07, Heat up to 800-850°C to melt, stir, then keep warm for 1 hour, then cool naturally to 680-700°C to obtain molten metal 1;

[0029] (2) Add the remaining amount of tin to the metal liquid 1 obtained in step (1), then lower the temperature to 450-460°C and stir, and then carry out refining and deslagging in the order of 2 times of pine wood chips, 1 time of rosin, and 2 times of ammonium chloride, After refining, the molten metal II is obtained...

Embodiment 2

[0040] A high-antimony tin-based babbitt alloy material comprises the following components in weight percent: antimony 11%, copper 6%, tellurium 0.005%, germanium 0.013%, and tin as the balance.

[0041] The preparation method of above-mentioned high-antimony tin-based babbitt alloy material, comprises the following steps:

[0042] (1) Weigh tin-germanium alloy, antimony-tellurium alloy, copper, antimony and 1 / 2~1 / 3 weight of tin, and the weight ratio of antimony, tin-germanium alloy and antimony-tellurium alloy is 11:0.1~0.15:0.02~0.07, Heat up to 800-850°C to melt, stir, then keep warm for 1 hour, then cool naturally to 680-700°C to obtain molten metal 1;

[0043] (2) Add the remaining amount of tin to the metal liquid 1 obtained in step (1), then lower the temperature to 450-460°C and stir, and then carry out refining and deslagging in the order of 2 times of pine wood chips, 1 time of rosin, and 2 times of ammonium chloride, After refining, the molten metal II is obtained...

Embodiment 3

[0055] A high-antimony tin-based babbitt alloy material comprises the following components in weight percent: antimony 11%, copper 6%, tellurium 0.008%, germanium 0.015%, and tin as the balance.

[0056] The preparation method of above-mentioned high-antimony tin-based babbitt alloy material, comprises the following steps:

[0057] (1) Weigh tin-germanium alloy, antimony-tellurium alloy, copper, antimony and 1 / 2~1 / 3 weight of tin, and the weight ratio of antimony, tin-germanium alloy and antimony-tellurium alloy is 11:0.1~0.15:0.02~0.07, Heat up to 800-850°C to melt, stir, then keep warm for 1 hour, then cool naturally to 680-700°C to obtain molten metal 1;

[0058] (2) Add the remaining amount of tin to the metal liquid 1 obtained in step (1), then lower the temperature to 450-460°C and stir, and then carry out refining and deslagging in the order of 2 times of pine wood chips, 1 time of rosin, and 2 times of ammonium chloride, After refining, the molten metal II is obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com