A kind of preparation method of uniform gold-tin eutectic alloy foil

A technology of eutectic alloy and uniform structure, which is applied in the field of metal material preparation to achieve the effect of reducing production cost, uniform deformation and stress of welding piece, and good welding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Precisely configure the gold-tin eutectic alloy whose composition is 20% by mass of tin and 80% by mass of gold. Air in the body, and then evacuate until the vacuum degree reaches 10 -3 After Pa, under the working current of 900A, the arc is smelted, the smelting peak temperature is 1300 ℃, and the gold-tin alloy melt is obtained, and the melt is electromagnetically stirred, and the electromagnetic stirring speed is 1100r / min, and the stirring time is 1-2 minutes. Then, use Cool the water-cooled copper crucible to room temperature, and control the cooling rate to 1.0-1.1*10 3 K / min; repeat the process of smelting, stirring, and cooling 4 times; take out the ingot and hold it at 240°C for 2 hours. After homogenizing annealing, the ingot is then thermally compressed at 240°C. The pressure is 0.02mm / s, the holding time is 2 minutes, the deformation of each pass is controlled at 17-19%, annealing is performed at 240-260°C between passes, the annealing holding time is 10 mi...

Embodiment 2

[0035] Precisely configure the gold-tin eutectic alloy whose composition is 20% by mass of tin and 80% by mass of gold. Air in the body, and then evacuate until the vacuum degree reaches 10 -3After Pa, under the working current of 950A, the arc is smelted, the smelting peak temperature is 1300 ℃, and the gold-tin alloy melt is obtained, and the melt is electromagnetically stirred, and the electromagnetic stirring speed is 1300r / min, and the stirring time is 1-2 minutes. Then, use The water-cooled copper crucible is cooled to room temperature, and the cooling rate is controlled to be 1.2-1.3*10 3 K / min; repeat the process of smelting, stirring, and cooling 5 times; take out the ingot and hold it at 250°C for 3 hours. After homogenizing annealing, the ingot is then thermally compressed at 250°C. The pressure is 0.01mm / s, the holding time is 2 minutes, the deformation of each pass is controlled at 16-18%, annealing is performed at 240-260°C between passes, the annealing holding ...

Embodiment 3

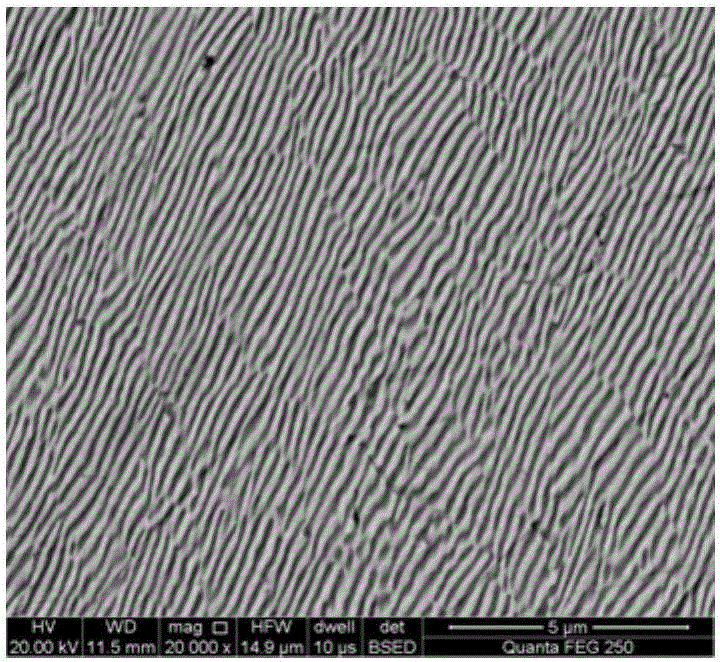

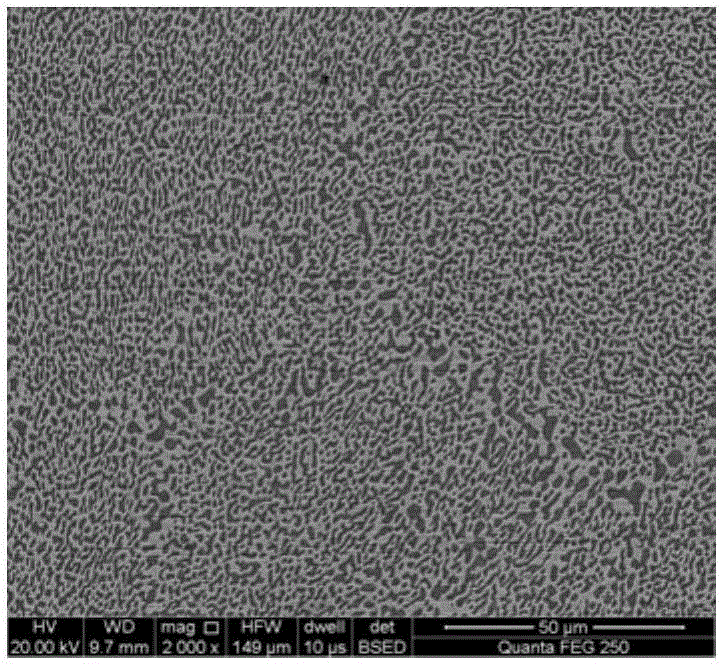

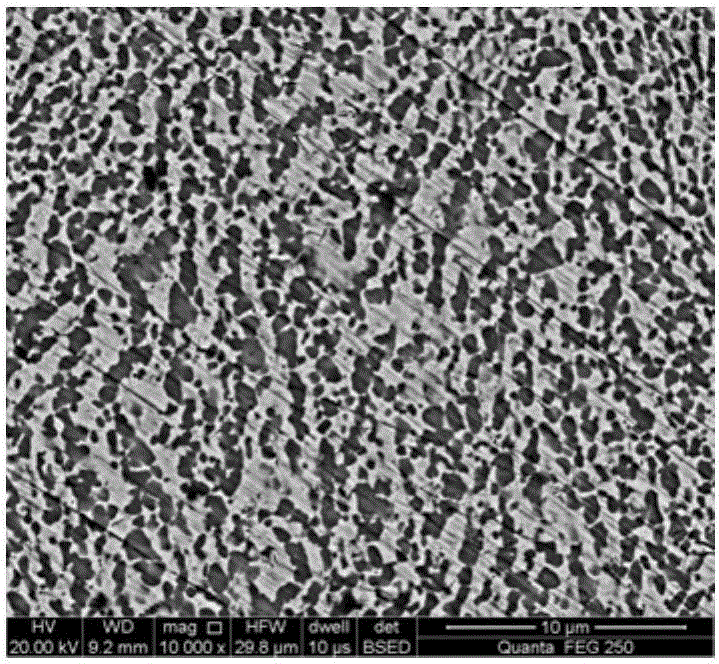

[0038] Precisely configure the gold-tin eutectic alloy whose composition is 20% by mass of tin and 80% by mass of gold. Air in the body, and then evacuate until the vacuum degree reaches 10 -3 After Pa, arc melting under the working current of 1000A, the melting peak temperature is 1300 ℃, and the gold-tin alloy melt is obtained, and the melt is electromagnetically stirred, and the electromagnetic stirring speed is 1500r / min, and the stirring time is 1-2 minutes. Then, use Cool the water-cooled copper crucible to room temperature, and control the cooling rate to 1.4-1.5*10 3 K / min; repeat the process of smelting, stirring and cooling 6 times; the solidified structure after smelting is as follows figure 1 As shown, it is a full-sheet lamellar eutectic structure without primary phase; the ingot is taken out and kept at 260°C for 5 hours for homogenization annealing. The microstructure of the ingot after homogenization heat treatment is as follows: figure 2 As shown, it is an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com